Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates?

Abstract

:1. Introduction

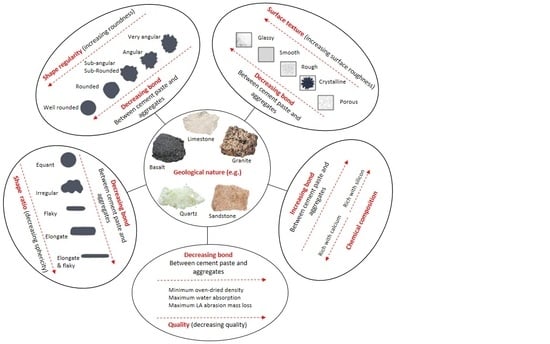

1.1. General Facts on Compressive Strength Estimation

1.2. Background of the Compressive Strength Estimation Models

2. Methodology

3. Results

3.1. Effect of the Geological Nature of Natural Aggregates on the Compressive Strength of Concrete

3.2. Effect of the Quality of Natural Aggregates on the Compressive Strength of Concrete

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Feret, R. On the compactness of hydraulic mortars (in French–Sur la compacité des mortiers hydrauliques). Ann. Ponts Chaussées Sér. 1892, 7, 5–164. [Google Scholar]

- Abrams, L.D. Properties of Concrete, 3rd ed.; Pitman Publishing Ltd.: London, UK, 1919. [Google Scholar]

- Powers, T.; Brownyard, T. Studies of the Physical Properties of Hardened Portland Cement Paste; American Concrete Institute (ACI): Farmington Hills, MI, USA, 1946; Volume 18, pp. 669–712. [Google Scholar]

- Silva, R. Use of Recycled Aggregates from Construction and Demolition Wastes in the Production of Structural Concrete. Ph.D. Thesis, Universidade de Lisboa, Instituto Superior Técnico, Lisbon, Portugal, 2015. [Google Scholar]

- Mechling, J.; Lecomte, A.; Diliberto, C. Relation between cement composition and compressive strength of pure pastes. Cem. Concr. Compos. 2009, 31, 255–262. [Google Scholar] [CrossRef]

- Maruyama, I.; Igarashi, G. Cement reaction and resultant physical properties of cement paste. J. Adv. Concr. Technol. 2014, 12, 200–213. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J.; Dhir, R.K. Properties and composition of recycled aggregates from construction and demolition waste suitable for concrete production. Constr. Build. Mater. 2014, 65, 201–217. [Google Scholar] [CrossRef]

- Struble, L.; Skalny, J.; Mindess, S. A review of the cement-aggregate bond. Cem. Concr. Res. 1980, 10, 277–286. [Google Scholar] [CrossRef]

- Brandt, M. Optimization Methods for Material Design of Cement-Based Composites; CRC Press: Boca Raton, FL, USA, 2014; 328p. [Google Scholar]

- Bolomey, J. Granulation et prevision de la resistance probable des betons. Travoux 1935, 19, 228–232. [Google Scholar]

- Lijuan, K.; Yuanbo, D. Interfacial interaction of aggregate-cement paste in concrete. J. Wuhan Univ. Technol.-Mater. Sci. Ed. 2015, 30, 117–121. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Influence of recycled aggregates and high contents of fly ash on concrete fresh properties. Cem. Concr. Compos. 2017, 84, 198–213. [Google Scholar] [CrossRef]

- De Larrard, F. Concrete Mixture Proportioning: A Scientific Approach; CRC Press: London, UK, 1999; p. 448. [Google Scholar]

- Ollivier, J.P.; Maso, J.C.; Bourdette, B. Interfacial transition zone in concrete. Adv. Cem. Based Mater. 1995, 2, 30–38. [Google Scholar] [CrossRef]

- Behnood, A.; Behnood, V.; Gharehveran, M.M.; Alyamac, K.E. Prediction of the compressive strength of normal and high-performance concretes using M5P model tree algorithm. Constr. Build. Mater. 2017, 142, 199–207. [Google Scholar] [CrossRef]

- Chidiac, S.E.; Moutassem, F.; Mahmoodzadeh, F. Compressive strength model for concrete. Mag. Concr. Res. 2013, 65, 557–572. [Google Scholar] [CrossRef] [Green Version]

- Hicks, T. Civil Engineering Formulas, 2nd ed.; McGraw-Hill Education-Europe: New York, NY, USA, 2009; 416p. [Google Scholar]

- Slater, W.A. Relation of 7-day to 28-day compressive strength of mortar and concrete. J. Proc. 1926, 22, 437–449. [Google Scholar]

- ACI 2000-I. ACI Manual of Concrete Practice 2000, Part 1: Materials and General Properties of Concrete; American Concrete Institute (ACI): Farmington Hills, MI, USA, 2000. [Google Scholar]

- Karni, J. Prediction of compressive strength of concrete. Mater. Struct. 1974, 7, 197–200. [Google Scholar] [CrossRef]

- Popovics, S. New formulas for the prediction of the effect of porosity on concrete strength. ACI Mater. J. 1985, 82, 136–146. [Google Scholar]

- Popovics, S. History of a mathematical model for strength development of Portland cement concrete. ACI Mater. J. 1998, 95, 593–600. [Google Scholar]

- Popovics, S.; Ujhelyi, J. Contribution to the concrete strength versus water-cement ratio relationship. J. Mater. Civ. Eng. 2008, 20, 459–463. [Google Scholar] [CrossRef]

- Adewole, K.; Olutoge, F.; Habib, H. Effect of Nigerian Portland limestone cement grades on concrete compressive strength. Int. J. Civ. Environ. Struct. Constr. Archit. Eng. 2014, 8, 1199–1202. [Google Scholar]

- Faury, J. Le Béton; Dunod: Paris, France, 1958. (In French) [Google Scholar]

- Ajdukiewicz, A.B.; Kliszczewicz, A.T. Comparative tests of beams and columns made of recycled aggregate concrete and natural aggregate concrete. J. Adv. Concr. Technol. 2007, 5, 259–273. [Google Scholar] [CrossRef]

- Al-Swaidani, A.; Baddoura, M.; Aliyan, S.; Choeb, W. Assesment of alkali resistance of basalt used as concrete aggregates. SSP-J. Civ. Eng. 2015, 10, 17–27. [Google Scholar] [CrossRef]

- Bairagi, N.K.; Ravande, K.; Pareek, V.K. Behaviour of concrete with different proportions of natural and recycled aggregates. Resour. Conserv. Recyc. 1993, 9, 109–126. [Google Scholar] [CrossRef]

- Collins, F.; Sanjayan, J.G. Strength and shrinkage properties of alkali-activated slag concrete containing porous coarse aggregate. Cem. Concr. Res. 1999, 29, 607–610. [Google Scholar] [CrossRef]

- Dilbas, H.; Şimşek, M.; Çakır, Ö. An investigation on mechanical and physical properties of recycled aggregate concrete (RAC) with and without silica fume. Constr. Build. Mater. 2014, 61, 50–59. [Google Scholar] [CrossRef]

- Kishore, I.; Mounika, L.; Prasad, C.; Krishna, B. Experimental study on the use of basalt aggregate in concrete mixes. SSRG Int. J. Civ. Eng. 2015, 2, 39–42. [Google Scholar]

- Mittal, A.; Kaisare, M.; Shetti, R. Experimental study on use of fly ash in concrete. Use of SCC in a pump house at TAPP 3 & 4, Tarapur. Indian Concr. J. 2004, 78, 30–34. [Google Scholar]

- Özturan, T.; Çeçen, C. Effect of coarse aggregate type on mechanical properties of concretes with different strengths. Cem. Concr. Res. 1997, 27, 165–170. [Google Scholar] [CrossRef]

- Paine, K.; Collery, D.; Dhir, R. Strength and deformation characteristics of concrete containing coarse recycled and manufactured aggregates. In Proceedings of the 11th International Conference on Non-Conventional Materials and Technologies (NOCMAT 2009), Bath, UK, 6–9 September 2009; p. 9. [Google Scholar]

- Rahal, K. Mechanical properties of concrete with recycled coarse aggregate. Build. Environ. 2007, 42, 407–415. [Google Scholar] [CrossRef]

- Akbarnezhad, A.; Ong, K.C.G.; Zhang, M.H.; Tam, C.T.; Foo, T.W.J. Microwave-assisted beneficiation of recycled concrete aggregates. Constr. Build. Mater. 2011, 25, 3469–3479. [Google Scholar] [CrossRef]

- Barra, M.; Vázquez, E. Properties of concretes with recycled aggregates: Influence of properties of the aggregates and their interpretation. In Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; pp. 19–30. [Google Scholar]

- Berndt, M.L. Properties of sustainable concrete containing fly ash, slag and recycled concrete aggregate. Constr. Build. Mater. 2009, 23, 2606–2613. [Google Scholar] [CrossRef]

- Bordelon, A.; Cervantes, V.; Roesler, J.R. Fracture properties of concrete containing recycled concrete aggregates. Mag. Concr. Res. 2009, 61, 665–670. [Google Scholar] [CrossRef]

- Bravo, M.; de Brito, J.; Pontes, J.; Evangelista, L. Performance of concrete made with recycled aggregates from Portuguese CDW recycling plants. Key Eng. Mater. 2015, 634, 193–205. [Google Scholar] [CrossRef]

- Butler, L.; West, J.S.; Tighe, S.L. The effect of recycled concrete aggregate properties on the bond strength between RCA concrete and steel reinforcement. Cem. Concr. Res. 2011, 41, 1037–1049. [Google Scholar] [CrossRef]

- Buyle-Bodin, F.; Hadjieva-Zaharieva, R. Influence of industrially produced recycled aggregates on flow properties of concrete. Mater. Struct. 2002, 35, 504–509. [Google Scholar] [CrossRef]

- Carro-López, D.; González-Fonteboa, B.; de Brito, J.; Martínez-Abella, F.; González-Taboada, I.; Silva, P. Study of the rheology of self-compacting concrete with fine recycled concrete aggregates. Constr. Build. Mater. 2015, 96, 491–501. [Google Scholar] [CrossRef]

- Cartuxo, F.; de Brito, J.; Evangelista, L.; Jiménez, J.R.; Ledesma, E.F. Rheological behaviour of concrete made with fine recycled concrete aggregates—Influence of the superplasticizer. Constr. Build. Mater. 2015, 89, 36–47. [Google Scholar] [CrossRef]

- Casuccio, M.; Torrijos, M.C.; Giaccio, G.; Zerbino, R. Failure mechanism of recycled aggregate concrete. Constr. Build. Mater. 2008, 22, 1500–1506. [Google Scholar] [CrossRef]

- Correia, J.; de Brito, J.; Pereira, A. Effects on concrete durability of using recycled ceramic aggregates. Mater. Struct. 2006, 39, 169–177. [Google Scholar] [CrossRef]

- Dapena, E.; Alaejos, P.; Lobet, A.; Pérez, D. Effect of recycled sand content on characteristics of mortars and concretes. J. Mater. Civ. Eng. 2011, 23, 414–422. [Google Scholar] [CrossRef]

- Debieb, F.; Kenai, S. The use of coarse and fine crushed bricks as aggregate in concrete. Constr. Build. Mater. 2008, 22, 886–893. [Google Scholar] [CrossRef]

- Abd Elhakam, A.; Mohamed, A.E.; Awad, E. Influence of self-healing, mixing method and adding silica fume on mechanical properties of recycled aggregates concrete. Constr. Build. Mater. 2012, 35, 421–427. [Google Scholar] [CrossRef]

- Etxeberria, M.; Vázquez, E.; Marí, A.; Barra, M. Influence of amount of recycled coarse aggregates and production process on properties of recycled aggregate concrete. Cem. Concr. Res. 2007, 37, 735–742. [Google Scholar] [CrossRef]

- Evangelista, L.; de Brito, J. Mechanical behaviour of concrete made with fine recycled concrete aggregates. Cem. Concr. Compos. 2007, 29, 397–401. [Google Scholar] [CrossRef]

- García-González, J.; Barroqueiro, T.; Evangelista, L.; de Brito, J.; de Belie, N.; Pozo, J.M.; Juan-Valdés, A. Fracture energy of coarse recycled aggregate concrete using the wedge splitting test method: Influence of water-reducing admixtures. Mater. Struct. 2017, 50, 120. [Google Scholar] [CrossRef]

- Gómez-Soberón, J.M.V. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Gonçalves, A.; Esteves, A.; Vieira, M. Influence of recycled concrete aggregates on concrete durability. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8–11 November 2004; pp. 554–562. [Google Scholar]

- Gonzalez-Corominas, A.; Etxeberria, M. Properties of high performance concrete made with recycled fine ceramic and coarse mixed aggregates. Constr. Build. Mater. 2014, 68, 618–626. [Google Scholar] [CrossRef]

- Knights, J. Relative performance of high quality concretes containing recycled aggregates and their use in construction. In Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; pp. 275–286. [Google Scholar]

- Kou, S.C.; Poon, C.S.; Chan, D. Influence of fly ash as cement replacement on the properties of recycled aggregate concrete. J. Mater. Civ. Eng. 2007, 19, 709–717. [Google Scholar] [CrossRef]

- Kumar, P.; Dhinakaran, G. Effect of admixed recycled aggregate concrete on properties of fresh and hardened concrete. J. Mater. Civ. Eng. 2012, 24, 494–498. [Google Scholar] [CrossRef]

- Kurda, R. Sustainable Development of Cement-Based Materials: Application to Recycled Aggregates Concrete. Ph.D. Thesis, Universidade de Lisboa, Instituto Superior Técnico, Lisbon, Portugal, 2017. [Google Scholar]

- Kwan, W.H.; Ramli, M.; Kam, K.J.; Sulieman, M.Z. Influence of the amount of recycled coarse aggregate in concrete design and durability properties. Constr. Build. Mater. 2012, 26, 565–573. [Google Scholar] [CrossRef]

- Lotfy, A.; Al-Fayez, M. Performance evaluation of structural concrete using controlled quality coarse and fine recycled concrete aggregate. Cem. Concr. Compos. 2015, 61, 36–43. [Google Scholar] [CrossRef]

- Lima, C.; Caggiano, A.; Faella, C.; Martinelli, E.; Pepe, M.; Realfonzo, R. Physical properties and mechanical behaviour of concrete made with recycled aggregates and fly ash. Constr. Build. Mater. 2013, 47, 547–559. [Google Scholar] [CrossRef]

- Muhammad, M.; Abdullah, W.; Abdul-Kadir, M. Post-fire mechanical properties of concrete made with recycled tire rubber as fine aggregate replacement. Sulaimani J. Eng. Sci. 2017, 4, 74–85. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Influence of the crushing process of recycled aggregates on concrete properties. Key Eng. Mater. 2015, 634, 151–162. [Google Scholar] [CrossRef]

- Pepe, M. A Conceptual Model for Designing Recycled Aggregate Concrete for Structural Applications. Ph.D. Thesis, University of Salerno, Fisciano, Italy, 2015. [Google Scholar]

- Poon, C.; Kou, S. Effects of fly ash on mechanical properties of 10-year-old concrete prepared with recycled concrete aggregates. In Proceedings of the 2nd International Conference on Waste Engineering Management (ICWEM 2010), Shanghai, China, 13–15 October 2010; pp. 46–59. [Google Scholar]

- Poon, C.; Shui, Z.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L.; Fok, H.; Kou, S.C. Influence of moisture states of natural and recycled aggregates on the slump and compressive strength of concrete. Cem. Concr. Res. 2004, 34, 31–36. [Google Scholar] [CrossRef]

- Ravindrarajah, R.; Loo, Y.H.; Tam, C.T. Recycled concrete as fine and coarse aggregates in concrete. Mag. Concr. Res. 1987, 39, 214–220. [Google Scholar] [CrossRef]

- Razaqpur, A.G.; Fathifazl, G.; Isgor, B.; Abbas, A.; Fournier, B.; Foo, S. How to produce high quality concrete mixes with recycled concrete aggregate. In Proceedings of the 2nd International Conference on Waste Engineering Management (ICWEM 2010), Shanghai, China, 13–15 October 2010; pp. 11–35. [Google Scholar]

- Ridzuan, A.; Ibrahim, A.; Ismail, A.; Diah, A. Durability performance of recycled aggregate concrete. In Proceedings of the International Conference on Global construction: Ultimate Concrete Opportunities: Achieving Sustainability in Construction, London, UK, 5–6 July 2005; pp. 193–202. [Google Scholar]

- Safiuddin, M.; Alengaram, U.; Salam, M.; Jumaat, M.; Jaafar, F.; Saad, H. Properties of high-workability concrete with recycled concrete aggregate. Mater. Res. 2011, 14, 248–255. [Google Scholar] [CrossRef] [Green Version]

- Sarhat, S. An experimental investigation on the viability of using fine concrete recycled aggregate in concrete production. In Proceedings of the International Conference on Sustainable Construction Materials and Technologies, Coventry, UK, 1–13 June 2007; pp. 53–57. [Google Scholar]

- Soares, D.; de Brito, J.; Ferreira, J.; Pacheco, J. Use of coarse recycled aggregates from precast concrete rejects: Mechanical and durability performance. Constr. Build. Mater. 2014, 71, 263–272. [Google Scholar] [CrossRef]

- Surya, M.; Rao, V.; Parameswaran, L. Mechanical, durability, and time-dependent properties of recycled aggregate concrete with fly ash. ACI Mater. J. 2015, 112, 653–662. [Google Scholar] [CrossRef]

- Thomas, C.; Setién, J.; Polanco, J.A.; Alaejos, P.; de Juan, M.S. Durability of recycled aggregate concrete. Constr. Build. Mater. 2013, 40, 1054–1065. [Google Scholar] [CrossRef]

- Yang, K.; Chung, H.; Ashour, A. Influence of type and replacement level of recycled aggregates on concrete properties. ACI Mater. J. 2008, 105, 289–296. [Google Scholar]

- Yang, J.; Du, Q.; Bao, Y. Concrete with recycled concrete aggregate and crushed clay bricks. Constr. Build. Mater. 2011, 25, 1935–1945. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, L.; Cui, Z.; Zhou, M. Effect of recycled coarse aggregate on concrete compressive strength. Trans. Tianjin Univ. 2011, 17, 229–234. [Google Scholar] [CrossRef]

- Kurad, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Effect of incorporation of high volume of recycled concrete aggregates and fly ash on the strength and global warming potential of concrete. J. Clean. Prod. 2017, 166, 485–502. [Google Scholar] [CrossRef]

- Kenai, S.; Debieb, F.; Azzouz, L. Mechanical properties and durability of concrete made with coarse and fine recycled aggregates. In Proceedings of the International Symposium on Sustainable Concrete Construction, Dundee, Scotland, UK, 9–11 September 2002; pp. 383–392. [Google Scholar]

- Akça, K.R.; Çakır, Ö.; İpek, M. Properties of polypropylene fiber reinforced concrete using recycled aggregates. Constr. Build. Mater. 2015, 98, 620–630. [Google Scholar] [CrossRef]

- González, B.; Martínez, F. Shear strength of concrete with recycled aggregates. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8–11 November 2004; pp. 619–628. [Google Scholar]

- Medina, C.; de Rojas, M.I.S.; Frías, M. Properties of recycled ceramic aggregate concretes: Water resistance. Cem. Concr. Compos. 2013, 40, 21–29. [Google Scholar] [CrossRef] [Green Version]

- Park, S. Recycled Concrete Construction Rubble as Aggregate for New Concrete; Study Report No 86; BRANZ: Wellington, New Zealand, 1999; p. 20. [Google Scholar]

- Nagataki, S.; Gokce, A.; Saeki, T.; Hisada, M. Assessment of recycling process induced damage sensitivity of recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 965–971. [Google Scholar] [CrossRef]

- Teranishi, K.; Dosho, Y.; Narikawa, M.; Kikuchi, M. Application of recycled aggregate concrete for structural concrete: Part 3-Production of recycled aggregate by real-scale plant and quality of recycled aggregate concrete. In Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; pp. 143–156. [Google Scholar]

- Beltrán, M.G.; Barbudo, A.; Agrela, F.; Galvín, A.P.; Jiménez, J.R. Effect of cement addition on the properties of recycled concretes to reach control concretes strengths. J. Clean. Prod. 2014, 79, 124–133. [Google Scholar] [CrossRef]

- Chen, H.J.; Yen, T.; Chen, K.H. The use of building rubbles in concrete and mortar. J. Chin. Inst. Eng. 2003, 26, 227–236. [Google Scholar] [CrossRef]

- Choi, W.-C.; Yun, H.-D. Compressive behavior of reinforced concrete columns with recycled aggregate under uniaxial loading. Eng. Struct. 2012, 41, 285–293. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Recycling of concrete in precast concrete production. In Proceedings of the Sustainable Construction Materials and Technologies, London, UK, 11–13 June 2007; pp. 69–75. [Google Scholar]

- Corinaldesi, V.; Moriconi, G. Concrete and mortar performance by using recycled aggregates. In Proceedings of the International Conference on Sustainable Waste Management and Recycling: Construction Demolition Waste, London, UK, 14–15 September 2004; pp. 157–164. [Google Scholar]

- Dhir, R.K.; Paine, K.A. Performance Related Approach to the Use of Recycled Aggregates; Waste and Resources Action Programme (WRAP) Aggregates Research Programme: Banbury, Oxon, UK, 2007; p. 77. [Google Scholar]

- Dhir, R.K.; MLimbachiya, C.; Leelawat, T. Suitability of recycled concrete aggregate for use in bs 5328 designated mixes. Proc. Inst. Civ. Eng.-Struct. Build. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Dhir, R.K.; Paine, K.A.; O’Leary, S. Use of recycled concrete aggregate in concrete pavement construction: A case study. In Proceedings of the International Symposium on Sustainable Waste Management, Dundee, Scotland, UK, 9–11 September 2003; pp. 373–382. [Google Scholar]

- Dolara, E.; Di Niro, G.; Cairns, R. Recycled aggregate concrete prestressed beams. In Proceedings of the International Symposium on Sustainable Construction: Use of Recycled Concrete Aggregate, London, UK, 11–12 November 1998; pp. 255–261. [Google Scholar]

- Domingo-Cabo, A.; Lázaro, C.; López-Gayarre, F.; Serrano-López, M.A.; Serna, P.; Castaño-Tabares, J.O. Creep and shrinkage of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2545–2553. [Google Scholar] [CrossRef]

- Dosho, Y. Development of a sustainable concrete waste recycling system—Application of recycled aggregate concrete produced by aggregate replacing method. J. Adv. Concr. Technol. 2007, 5, 27–42. [Google Scholar] [CrossRef]

- Fan, C.-C.; Huang, R.; Hwang, H.; Chao, S.-J. Properties of concrete incorporating fine recycled aggregates from crushed concrete wastes. Constr. Build. Mater. 2016, 112, 708–715. [Google Scholar] [CrossRef]

- Juan, M.S.; Gutiérrez, P.A. Influence of recycled aggregate quality on concrete properties. In Proceedings of the International RILEM Conference on the Use of Recycled Materials in Buildings and Structures, Barcelona, Spain, 8–11 November 2004; pp. 545–553. [Google Scholar]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- Kim, S.-W.; Yun, H.-D. Influence of recycled coarse aggregates on the bond behavior of deformed bars in concrete. Eng. Struct. 2013, 48, 133–143. [Google Scholar] [CrossRef]

- Kim, K.; Shin, M.; Cha, S. Combined effects of recycled aggregate and fly ash towards concrete sustainability. Constr. Build. Mater. 2013, 48, 499–507. [Google Scholar] [CrossRef]

- Koulouris, A.; Limbachiya, M.C.; Fried, A.N.; Roberts, J.J. Use of recycled aggregate in concrete application: Case studies. In Proceedings of the International Conference on Sustainable Waste Management and Recycling: Challenges and Opportunities, London, UK, 14–15 September 2004; pp. 245–257. [Google Scholar]

- Limbachiya, M.; Meddah, M.S.; Ouchagour, Y. Use of recycled concrete aggregate in fly-ash concrete. Constr. Build. Mater. 2012, 27, 439–449. [Google Scholar] [CrossRef]

- Otsuki, N.; Miyazato, S.-I.; Yodsudjai, W. Influence of recycled aggregate on interfacial transition zone, strength, chloride penetration and carbonation of concrete. J. Mater. Civ. Eng. 2003, 15, 443–451. [Google Scholar] [CrossRef]

- Rao, M.; Bhattacharyya, S.; Barai, S. Influence of recycled aggregate on mechanical properties of concrete. In Proceedings of the 5th Civil Engineering Conference in the Asian Region and Australasian Structural Engineering Conference, Sydney, Australia, 8–12 August 2010; pp. 749–754. [Google Scholar]

- Waleed, N.; Canisius, T. Engineering Properties of Concrete Containing Recycled Aggregates; Waste and Resources Action Programme: Banbury, UK, 2007; p. 104. [Google Scholar]

- Zhou, C.; Chen, Z. Mechanical properties of recycled concrete made with different types of coarse aggregate. Constr. Build. Mater. 2017, 134, 497–506. [Google Scholar] [CrossRef]

- Corinaldesi, V.; Moriconi, G. Influence of mineral additions on the performance of 100% recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 2869–2876. [Google Scholar] [CrossRef]

- Padmini, A.K.; Ramamurthy, K.; Mathews, M.S. Influence of parent concrete on the properties of recycled aggregate concrete. Constr. Build. Mater. 2009, 23, 829–836. [Google Scholar] [CrossRef]

- Yanagi, K.; Kasai, Y.; Kaga, S.; Abe, M. Experimental study on the applicability of recycled aggregate concrete to cast-in-place concrete pile. In Sustainable Construction: Use of Recycled Concrete Aggregate; Thomas Telford: London, UK, 2015; pp. 359–370. [Google Scholar]

- Kou, S.; Poon, C. Properties of self-compacting concrete prepared with coarse and fine recycled concrete aggregates. Cem. Concr. Compos. 2009, 31, 622–627. [Google Scholar] [CrossRef]

- Lin, Y.-H.; Tyan, Y.-Y.; Chang, T.-P.; Chang, C.-Y. An assessment of optimal mixture for concrete made with recycled concrete aggregates. Cem. Concr. Res. 2004, 34, 1373–1380. [Google Scholar] [CrossRef]

- Pedro, D.; de Brito, J.; Evangelista, L. Mechanical characterization of high performance concrete prepared with recycled aggregates and silica fume from the precast industry. J. Clean. Prod. 2017, 164, 939–949. [Google Scholar] [CrossRef]

- Kurda, R.; Silvestre, J.D.; de Brito, J.; Ahmed, H. Optimizing recycled concrete containing high volume of fly ash in terms of the embodied energy and chloride ion resistance. J. Clean. Prod. 2018. [Google Scholar] [CrossRef]

- Kurda, R.; de Brito, J.; Silvestre, J.D. Indirect evaluation of the compressive strength of recycled aggregate concrete with high fly ash ratios. Mag. Concr. Res. 2018, 70, 204–216. [Google Scholar] [CrossRef]

- FIB Bullten 42. Constitutive Modelling of High Strength/High Performance Concrete; International Federation for Structural Concrete (FIB): Lausanne, Switzerland, 2008. [Google Scholar]

- Gul, M. Effect of cube size on the compressive strength of concrete. Int. J. Eng. Dev. Res. 2016, 4, 956–959. [Google Scholar]

- Neville, A.M. Properties of Concrete, 4th ed.; John Wiley & Sons: New York, NY, USA, 1997. [Google Scholar]

- Felekoğlu, B.; Türkel, S. Effects of specimen type and dimensions on compressive strength of concrete. GU J. Sci. 2005, 18, 639–645. [Google Scholar]

- Gonnerman, H. Effect of size and shape of test specimen on compressive strength of concrete. Proc. ASTM 1925, 25, 237–250. [Google Scholar]

- Nasser, K.; Al-Manaseer, A. It’s time for a change from 6_12 to 3_6 inch cylinders. ACI Mater. J. 1987, 84, 6–213. [Google Scholar]

- Malhotra, V. Are 4 × 8 Inch concrete cylinders as good as 6 × 12 Inch cylinder for quality control concrete? ACI J. 1976, 73, 33–36. [Google Scholar]

- Forstie, D.; Schnormeier, R. Development and Use of 4 × 8 in. Concrete Cylinders in Arizona. Concr. Int. 1981, 3, 41–45. [Google Scholar]

- Carrasquillo, R.; Nilson, A.; State, F. Propeties of high strength concrete subject to short-term loads. ACI J. 1981, 78, 42–45. [Google Scholar]

- Lessard, M.; Aitcin, P. Testing of High Performance Concrete, High Performance Concrete; E & FN Spon: London, UK, 1992; pp. 196–213. [Google Scholar]

- Halstead, P.E. The early history of Portland cement. Trans. Newcom. Soc. 1961, 34, 37–54. [Google Scholar] [CrossRef]

- Lea, F.; Mason, T. Cement; Encyclopædia Britannica, Inc.: Chicago, IL, USA, 2015. [Google Scholar]

- Bruhl, R. Understanding Statistical Analysis and Modeling; SAGE Publications: Thousand Oaks, CA, USA, 2017; p. 440. ISBN 9781506317373. [Google Scholar]

- Dahlquist, G.; Bjorck, A. Numerical Methods in Scientific Computing: Volume 1; SIAM: Philadelphia, PA, USA, 2008; p. 717. ISBN 9780898717785. [Google Scholar]

- Ingham, J.P. 4-Aggregates. In Geomaterials under the Microscope; Academic Press: Boston, MA, USA, 2013; pp. 61–74. [Google Scholar]

- Gill, R. Igneous Rocks and Processes: A Practical Guide; Wiley-Blackwell: Hoboken, NJ, USA, 2010; p. 438. [Google Scholar]

| Aggregate Class | A | B | C | D | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| I | II | III | I | II | III | I | II | III | ||

| Minimum oven-dried density (kg/m3) | 2600 | 2500 | 2400 | 2300 | 2200 | 2100 | 2000 | 1900 | 1800 | No limit |

| Maximum water absorption (%) | 1.5 | 2.5 | 3.5 | 5 | 6.5 | 8.5 | 10.5 | 13 | 15 | |

| Maximum LA abrasion mass loss (%) | 40 | 45 | 50 | |||||||

| Model | Formula a,b | Notes/Limitations |

|---|---|---|

| Abram | The constants A and B are 96 MPa and 7, respectively. The w/c ratio should be between 0.3 and 1.2 | |

| Slater | This formula can be used only for mixes without SP | |

| American Concrete Institute Manual of Concrete Practice (ACI2000-I) | The w/c ratio and cement content of the concrete mixes are limited to 0.41–0.82 and 300–360 kg/m3, respectively. The equation was adapted from the results of the table given in the specification with R2 = 0.996 | |

| Bolomey | if w/c > 0.4 if w/c ≤ 0.4 | The constants (A1 and A2) depend on the way aggregates are produced and on the strength class of cement (Table 3) |

| Feret | The constant, k, depends on the strength class of cement. It is 265–290 and 315–350 for cement class CEM I 32.5 and 42.5, respectively; v is the absolute volume of cement paste and I is the volume index (air and water contents) |

| Aggregate | w/c | Constants a | Strength Class of Cement (MPa) | |||||

|---|---|---|---|---|---|---|---|---|

| 25 | 35 | 40 | 45 | 52.5 | 55 | |||

| Natural (rolled) | >0.40 | A1 | 13.73 | 17.65 | 19.61 | 20.59 | 22.0675 | 22.56 |

| Natural (rolled) | ≤0.40 | A2 | 9.32 | 11.7 | 12.75 | 14.22 | 14.5875 | 14.71 |

| Natural (crushed) | >0.40 | A1 | 15.2 | 19.61 | 21.57 | 23.54 | 25.01 | 25.5 |

| Natural (crushed) | ≤0.40 | A2 | 10.3 | 13.24 | 14.22 | 15.69 | 16.7925 | 17.16 |

| References a | Aggregates | Cement | Mix Composition | Strength | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Geological Nature | Physical Properties | Oven-Dried Particle Density (kg/m3) | WA-24h (%) | Properties | Max. Aggregate Size (mm) | Los Angeles (LA) Abrasion (%) | Cement Type/Strength | Cement Content (kg/m3) | w/c | Water Content (L/m3) | fcm, cyl 150 × 300 (MPa) | |

| [26,27,28,29,30,31,32,33,34,35] | Basalt | AI | 2716–2915 | 0.68–1.60 | Crushed | 14–20 | 17–24 | CEM I 42.5–52.5 | 300–500 | 0.24–0.70 | 108–210 | 20–62 |

| [26,27,31,33,34,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62,63,64,65,66,67,68,69,70,71,72,73,74,75,76,77,78,79,80] | Limestone | AI-BI | 2277–2739 | 0.20–5.00 | Crushed/ rounded | 10–32 | 10–42 | CEM I 32.5–52.5 | 210–677 | 0.28–0.86 | 126–266 | 10–69 |

| [26,81,82,83,84] | Quartz | AI | 2624–2780 | 0.17–1.5 | Crushed/ rounded | 16–32 | 24–36 | CEM I 42.5 | 300–500 | 0.36–0.61 | 148–214 | 22–59 |

| [85,86,87] | Sandstone | AI | 2625–2660 | 0.50–0.94 | Crushed | 19–20 | - | CEM I 42.5 | 250–463 | 0.40–0.60 | 153–185 | 23–56 |

| [34,50,88,89,90,91,92,93,94,95,96,97,98,99,100,101,102,103,104,105,106,107,108,109] | Natural gravel (N.G.) b | AI-AII | 2511–2719 | 0.05–2.5 | Crushed/ rounded | 15–25 | 20–30 | CEM I 42.5 | 214–635 | 0.32–0.84 | 148–259 | 15–52 |

| Studies | fcm, cylinder 150 × 300 to fcm, cylinder 100 × 200 Ratio | Strength [MPa] |

|---|---|---|

| Malhotra [124] | 0.84 | ~46 |

| Forstie and Schnormeier [125] | 0.87 | ~48 |

| Carrasquillo et al. [126] | 0.93 | 48–80 |

| Lessaed and Aitcin [127] | 0.95 | 35–122 |

| Average over 33 MPa | 0.90 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

De Brito, J.; Kurda, R.; Raposeiro da Silva, P. Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates? Appl. Sci. 2018, 8, 1095. https://doi.org/10.3390/app8071095

De Brito J, Kurda R, Raposeiro da Silva P. Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates? Applied Sciences. 2018; 8(7):1095. https://doi.org/10.3390/app8071095

Chicago/Turabian StyleDe Brito, Jorge, Rawaz Kurda, and Pedro Raposeiro da Silva. 2018. "Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates?" Applied Sciences 8, no. 7: 1095. https://doi.org/10.3390/app8071095

APA StyleDe Brito, J., Kurda, R., & Raposeiro da Silva, P. (2018). Can We Truly Predict the Compressive Strength of Concrete without Knowing the Properties of Aggregates? Applied Sciences, 8(7), 1095. https://doi.org/10.3390/app8071095