Enhanced Tensile Plasticity in Ultrafine Lamellar Eutectic Al-CuBased Composites with α-Al Dendrites Prepared by Progressive Solidification

Abstract

:Featured Application

Abstract

1. Introduction

2. Experimental Procedures

3. Results and Discussion

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Gleiter, H. Nanocrystalline materials. Prog. Mater. Sci. 1989, 33, 223–315. [Google Scholar] [CrossRef] [Green Version]

- Koch, C. The synthesis and structure of nanocrystalline materials produced by mechanical attrition: A review. Nanostruct. Mater. 1993, 2, 109–129. [Google Scholar] [CrossRef]

- Lu, K. Nanocrystalline metals crystallized from amorphous solids: Nanocrystallization, structure, and properties. Mater. Sci. Eng. R Rep. 1996, 16, 161–221. [Google Scholar] [CrossRef]

- Valiev, R.; Islamgaliev, R.; Alexandrov, I. Bulk nanostructured materials from severe plastic deformation. Prog. Mater. Sci. 2000, 45, 103–189. [Google Scholar] [CrossRef]

- Erb, U.; El-Sherik, A.; Palumbo, G.; Aust, K. Synthesis, structure and properties of electroplated nanocrystalline materials. Nanostruct. Mater. 1993, 2, 383–390. [Google Scholar] [CrossRef]

- Hughes, G.; Smith, S.; Pande, C.; Johnson, H.; Armstrong, R. Hall-petch strengthening for the microhardness of twelve nanometer grain diameter electrodeposited nickel. Scr. Met. 1986, 20, 93–97. [Google Scholar] [CrossRef]

- Lu, L.; Sui, M.L. Superplastic Extensibility of Nanocrystalline Copper at Room Temperature. Science 2000, 287, 1463–1466. [Google Scholar] [CrossRef]

- Nagarajan, R.; Chattopadhyay, K. Intermetallic Ti2Ni/TiNi nanocomposite by rapid solidification. Acta Met. Mater. 1994, 42, 947–958. [Google Scholar] [CrossRef]

- He, G.; Eckert, J.; Löser, W.; Schultz, L. Novel Ti-base nanostructure-dendrite composite with enhanced plasticity. Nat. Mater. 2003, 2, 33–37. [Google Scholar] [CrossRef]

- Louzguine, D.V.; Kato, H.; Inoue, A. High strength and ductile binary Ti–Fe composite alloy. J. Alloys Compd. 2004, 384, L1–L3. [Google Scholar] [CrossRef]

- Park, J.; Kim, K.; Kim, D.; Mattern, N.; Li, R.; Liu, G.; Eckert, J. Multi-phase Al-based ultrafine composite with multi-scale microstructure. Intermet. 2010, 18, 1829–1833. [Google Scholar] [CrossRef]

- Cao, G.; Peng, Y.; Liu, N.; Li, X.; Lei, Z.; Ren, Z.; Gerthsen, D.; Russell, A. Formation of a bimodal structure in ultrafine Ti–Fe–Nb alloys with high-strength and enhanced ductility. Mater. Sci. Eng. A 2014, 609, 60–64. [Google Scholar] [CrossRef]

- Maity, T.; Das, J. High strength Ni–Zr–(Al) nanoeutectic composites with large plasticity. Intermet. 2015, 63, 51–58. [Google Scholar] [CrossRef]

- Kim, J.; Hong, S.; Park, H.; Park, G.; Suh, J.-Y.; Park, J.; Kim, K. Influence of microstructural evolution on mechanical behavior of Fe–Nb–B ultrafine composites with a correlation to elastic modulus and hardness. J. Alloys Compd. 2015, 647, 886–891. [Google Scholar] [CrossRef]

- Lei, Q.; Ramakrishnan, B.P.; Wang, S.; Wang, Y.; Mazumder, J.; Misra, A. Structural refinement and nanomechanical response of laser remelted Al-Al2Cu lamellar eutectic. Mater. Sci. Eng. A 2017, 706, 115–125. [Google Scholar] [CrossRef]

- Ramakrishnan, B.P.; Lei, Q.; Misra, A.; Mazumder, J. Effect of laser surface remelting on the microstructure and properties of Al-Al2Cu-Si ternary eutectic alloy. Sci. Rep. 2017, 7, 13468. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.; Hong, S.; Park, J.; Eckert, J.; Kim, K. Microstructure and mechanical properties of hierarchical multi-phase composites based on Al-Ni-type intermetallic compounds in the Al-Ni-Cu-Si alloy system. J. Alloys Compd. 2018, 749, 205–210. [Google Scholar] [CrossRef]

- Kim, J.; Hong, S.; Kim, Y.; Park, H.; Maity, T.; Chawake, N.; Bian, X.; Sarac, B.; Park, J.; Prashanth, K.; et al. Cooperative deformation behavior between the shear band and boundary sliding of an Al-based nanostructure-dendrite composite. Mater. Sci. Eng. A 2018, 735, 81–88. [Google Scholar] [CrossRef]

- Yang, C.; Kang, L.; Li, X.; Zhang, W.; Zhang, D.; Fu, Z.; Li, Y.; Zhang, L.; Lavernia, E. Bimodal titanium alloys with ultrafine lamellar eutectic structure fabricated by semi-solid sintering. Acta Mater. 2017, 132, 491–502. [Google Scholar] [CrossRef]

- Hays, C.C.; Kim, C.P.; Johnson, W.L. Microstructure Controlled Shear Band Pattern Formation and Enhanced Plasticity of Bulk Metallic Glasses Containing in situ Formed Ductile Phase Dendrite Dispersions. Phys. Rev. Lett. 2000, 84, 2901–2904. [Google Scholar] [CrossRef]

- Hofmann, D.C.; Suh, J.Y.; Wiest, A.; Duan, G.; Lind, M.L.; Demetriou, M.D.; Johnson, W.L. Designing metallic glass matrix composites with high toughness and tensile ductility. Nature 2008, 451, 1085–1089. [Google Scholar] [CrossRef] [PubMed]

- Liu, D.M.; Lin, S.F.; Ge, S.F.; Zhu, Z.W.; Fu, H.M.; Zhang, H.F. A Ti-based bulk metallic glass composite with excellent tensile properties and significant work-hardening capacity. Mater. Lett. 2018, 233, 107–110. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, G.; Zhao, W.; Wang, Z.; Zhang, Z. Enhancement of tensile properties by the solid solution strengthening of nitrogen in Zr-based metallic glass composites. Mater. Sci. Eng. A 2017, 696, 461–465. [Google Scholar] [CrossRef]

- Cheng, J.; Wang, J.; Yun, Y.; Rui, J.; Zhao, W.; Li, F. A novel core-shell structure reinforced Zr-based metallic glass composite with combined high strength and good tensile ductility. J. Alloys Compd. 2019, 803, 413–416. [Google Scholar] [CrossRef]

- Wu, Y.; Xiao, Y.; Chen, G.; Liu, C.T.; Lu, Z. Bulk Metallic Glass Composites with Transformation-Mediated Work-Hardening and Ductility. Adv. Mater. 2010, 22, 2770–2773. [Google Scholar] [CrossRef]

- Song, W.; Wu, Y.; Wang, H.; Liu, X.; Chen, H.; Guo, Z.; Lu, Z. Microstructural Control via Copious Nucleation Manipulated by In Situ Formed Nucleants: Large-Sized and Ductile Metallic Glass Composites. Adv. Mater. 2016, 28, 8156–8161. [Google Scholar] [CrossRef] [PubMed]

- Park, J.M.; Mattern, N.; Kühn, U.; Eckert, J.; Kim, K.B.; Kim, W.T.; Chattopadhyay, K.; Kim, D.H. High-strength bulk Al-based bimodal ultrafine eutectic composite with enhanced plasticity. J. Mater. Res. 2009, 24, 2605–2609. [Google Scholar] [CrossRef] [Green Version]

- Lee, M.L.; Li, Y.; Schuh, C.A. Effect of a controlled volume fraction of dendritic phases on tensile and compressive ductility in La-based metallic glassmatrix composites. Acta Mater. 2004, 52, 4121–4131. [Google Scholar] [CrossRef]

- Xia, S.H.; Wang, J.T. A micromechanical model of toughening behavior in the dual-phase composite. Int. J. Plast. 2010, 26, 1442–1460. [Google Scholar] [CrossRef]

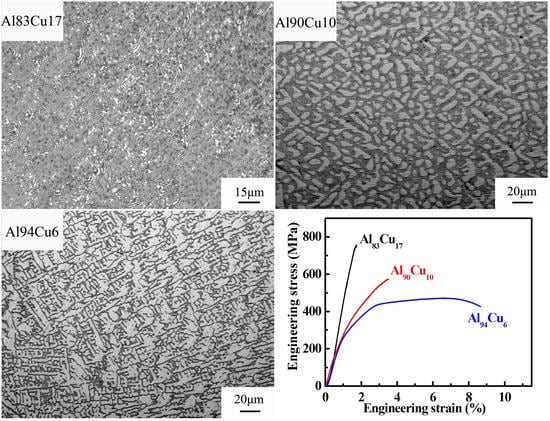

| Composition | σy (MPa) | σb (MPa) | εp (%) |

|---|---|---|---|

| Al83Cu17 | - | 758 | - |

| Al90Cu10 | 392 | 571 | 2.0 |

| Al94Cu6 | 306 | 472 | 7.4 |

| Structure | H (GPa) | E (GPa) |

|---|---|---|

| Eutectic (α-Al + θ-Al2Cu) | 2.5 ± 0.2 | 86 ± 2 |

| α-Al in Al90Cu10 alloy | 1.8 ± 0.2 | 64 ± 3 |

| α-Al in Al94Cu6 alloy | 1.3 ± 0.2 | 40 ± 1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, J.; Yun, Y.; Rui, J. Enhanced Tensile Plasticity in Ultrafine Lamellar Eutectic Al-CuBased Composites with α-Al Dendrites Prepared by Progressive Solidification. Appl. Sci. 2019, 9, 3922. https://doi.org/10.3390/app9183922

Cheng J, Yun Y, Rui J. Enhanced Tensile Plasticity in Ultrafine Lamellar Eutectic Al-CuBased Composites with α-Al Dendrites Prepared by Progressive Solidification. Applied Sciences. 2019; 9(18):3922. https://doi.org/10.3390/app9183922

Chicago/Turabian StyleCheng, Jialin, Yeling Yun, and Jiaxin Rui. 2019. "Enhanced Tensile Plasticity in Ultrafine Lamellar Eutectic Al-CuBased Composites with α-Al Dendrites Prepared by Progressive Solidification" Applied Sciences 9, no. 18: 3922. https://doi.org/10.3390/app9183922

APA StyleCheng, J., Yun, Y., & Rui, J. (2019). Enhanced Tensile Plasticity in Ultrafine Lamellar Eutectic Al-CuBased Composites with α-Al Dendrites Prepared by Progressive Solidification. Applied Sciences, 9(18), 3922. https://doi.org/10.3390/app9183922