Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification

Abstract

:1. Introduction

2. Multiple Fault Classification and Fault Severity Determination

2.1. Brief Introduction of Multi-Label Classification Methods

2.2. The Scheme of the Proposed Method

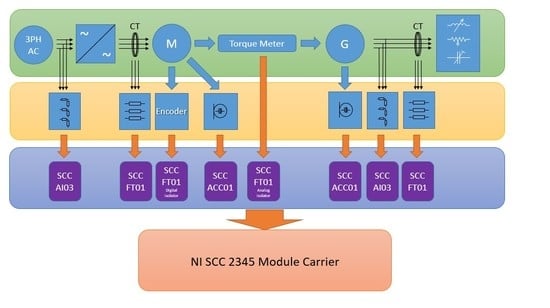

3. System Description and Experiment

3.1. System Description

3.2. Feature Extraction and Dataset Preparation for Training

4. Results

5. Discussion

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

Nomenclature

| FDD | Fault detection and diagnosis |

| ML | Machine learning |

| MCSA | Motor current signature analysis |

| ESA | Electrical signature analysis |

| FDI | Detection and isolation |

| ANFIS | Adaptive neuro-fuzzy inference system |

| CART | Classification and regression Tree |

| CNN | Random forest classifier convolutional neural network |

| SVM | Support vector machine |

| KNN | k-nearest neighbors |

| PMSM | Permanent magnet synchronous machine |

| RF | Random Forest |

| ISO | International Organization for Standardization |

References

- Dineva, A.; Mosavi, A.; Ardabili, S.; Vajda, I.; Shamshirband, S.; Rabczuk, T.; Chau, K.W. Review of soft computing models in design and control of rotating electrical machines. Energies 2019, 12, 1049. [Google Scholar] [CrossRef]

- Jokanović, B.; Bebić, M.; Kartalović, N. The influence of combined strain and constructive solutions for stator insulation of rotating electrical machines on duration of their reliable exploitation. Int. J. Electr. Power Energy Syst. 2019, 110, 36–47. [Google Scholar] [CrossRef]

- Roubache, L.; Boughrara, K.; Dubas, F.; Ibtiouen, R. Elementary subdomain technique for magnetic field calculation in rotating electrical machines with local saturation effect. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2019, 38, 24–45. [Google Scholar] [CrossRef]

- Boughrara, K.; Dubas, F.; Ibtiouen, R. 2-D exact analytical method for steady-state heat transfer prediction in rotating electrical machines. IEEE Trans. Magn. 2018, 54. [Google Scholar] [CrossRef]

- Caruso, M.; Di Tommaso, A.O.; Miceli, R.; Rizzo, R. The use of slightly asymmetrical windings for rotating electrical machines. Int. Trans. Elecr. Energy Syst. 2018, 28. [Google Scholar] [CrossRef]

- Kande, M.; Isaksson, A.J.; Thottappillil, R.; Taylor, N. Rotating electrical machine condition monitoring automation-A review. Machines 2017, 5, 24. [Google Scholar] [CrossRef]

- Byerly, K.; Ohodnicki, P.R.; Moon, S.R.; Leary, A.M.; Keylin, V.; McHenry, M.E.; Simizu, S.; Beddingfield, R.; Yu, Y.; Feichter, G.; et al. Metal Amorphous Nanocomposite (MANC) Alloy Cores with Spatially Tuned Permeability for Advanced Power Magnetics Applications. JOM 2018, 70, 879–891. [Google Scholar] [CrossRef]

- Fu, Y.; Huang, X.; Xu, Y.; Bai, C. Controllable inertial control strategy of rotating motor in DC distribution network. Dianli Zidonghua Shebei Electr. Power Autom. Equip. 2018, 38, 32–38. [Google Scholar] [CrossRef]

- Guerroudj, C.; Saou, R.; Boulayoune, A.; El-hadi Zaïm, M.; Moreau, L. Performance analysis of Vernier slotted doubly salient permanent magnet generator for wind power. Int. J. Hydrogen Energy 2017, 42, 8744–8755. [Google Scholar] [CrossRef]

- Song, Z.; Li, Y.; Zhang, C.; Liu, Y. Rotating core loss model for motor considering skin effect and dynamic hysteresis effect. Nongye Gongcheng Xuebao 2019, 35, 74–80. [Google Scholar] [CrossRef]

- Zhang, J.; Yu, H.; Chen, Q.; Hu, M. Dynamic characteristics and experiment analysis of a single phase permanent magnet linear generator for wave energy conversion. Diangong Jishu Xuebao 2013, 28, 110–116. [Google Scholar]

- Mosavi, A.; Faizollahzadeh Ardabili, S.; Shamshirband, S. Demand prediction with machine learning models: State of the art and a systematic review of advances. 2019. Available online: https://eprints.qut.edu.au/129249/ (accessed on 20 November 2019). [CrossRef]

- Akhtar, M.J.; Behera, R.K. Optimal design of stator and rotor slot of induction motor for electric vehicle applications. IET Electr. Syst. Transp. 2019, 9, 35–43. [Google Scholar] [CrossRef]

- Deng, W.; Zuo, S. Electromagnetic vibration and noise of the permanent-magnet synchronous motors for electric vehicles: An overview. IEEE Trans. Transp. Electrif. 2019, 5, 59–70. [Google Scholar] [CrossRef]

- Fan, Y.; Qu, G.; Tan, C.; Zhang, Q.; Wang, W. Design and analysis of a new five-phase dual-stator consequent-pole brushless hybrid excitation machine. IEEE Trans. Magn. 2019, 55. [Google Scholar] [CrossRef]

- Ulu, C.; Korman, O.; Kömürgöz, G. Electromagnetic and thermal design/analysis of an induction motor for electric vehicles. Int. J. Mech. Eng. Robot. Res. 2019, 8, 239–245. [Google Scholar] [CrossRef]

- Mosavi, A.; Salimi, M.; Faizollahzadeh Ardabili, S.; Rabczuk, T.; Shamshirband, S.; Varkonyi-Koczy, A.R. State of the art of machine learning models in energy systems, a systematic review. Energies 2019, 12, 1301. [Google Scholar] [CrossRef]

- Baranyai, M.; Mosavi, A.; Vajda, I.; Varkonyi-Koczy, A.R. Optimal Design of Electrical Machines: State of the Art Survey. In Proceedings of the International Conference on Global Research and Education, Iasi, Romania, 25–28 September 2017; pp. 209–216. [Google Scholar]

- Aljehaimi, A.M.; Pillay, P. Operating Envelopes of the Variable-Flux Machine with Positive Reluctance Torque. IEEE Trans. Transp. Electrif. 2018, 4, 707–719. [Google Scholar] [CrossRef]

- Catuogno, G.R.; Garcia, G.O. Conversion of Three-phase Commercial Machines into Six- phase Machines for Didactic and Research Purposes. IEEE. Lat. Am. Trans. 2018, 16, 467–475. [Google Scholar] [CrossRef]

- Morozov, A.; Humphries, K.; Zou, T.; Rahman, T.; Angeles, J. Design, Analysis, and Optimization of a Multi-Speed Powertrain for Class-7 Electric Trucks. SAE Int. J. Altern. Powertrains 2018, 7. [Google Scholar] [CrossRef]

- Palanivel, A.; Padmanabhan, S. Software-based performance estimation and real-time thermal analysis of brushless direct current motor with corroded permanent magnets. Comput. Electr. Eng. 2018, 71, 938–952. [Google Scholar] [CrossRef]

- Praveenkumar, T.; Saimurugan, M.; Ramachandran, K.I. Comparison of vibration, sound and motor current signature analysis for detection of gear box faults. Int. J. Progn. Health Manag. 2017, 8, 132–151. [Google Scholar]

- Bessous, N.; Sbaa, S.; Megherbi, A.C. Mechanical fault detection in rotating electrical machines using MCSA-FFT and MCSA-DWT techniques. Bull. Pol. Acad. Sci. Tech. Sci. 2019, 67, 571–582. [Google Scholar] [CrossRef]

- Corne, B.; Vervisch, B.; Derammelaere, S.; Knockaert, J.; Desmet, J. Emulating single point bearing faults with the use of an active magnetic bearing. IET Sci. Meas. Technol. 2018, 12, 39–48. [Google Scholar] [CrossRef]

- Glowacz, A.; Glowacz, W.; Glowacz, Z.; Kozik, J.; Gutten, M.; Korenciak, D.; Khan, Z.F.; Irfan, M.; Carletti, E. Fault diagnosis of three phase induction motor using current signal, MSAF-Ratio15 and selected classifiers. Arch. Metall. Mater. 2017, 62, 2413–2419. [Google Scholar] [CrossRef]

- Martín-Díaz, I.; Duque-Perez, O.; Romero-Troncoso, R.; Morinigo-Sotelo, D. Supervised diagnosis of induction motor faults: A proposed methodology for an improved performance evaluation. In Proceedings of the IEEE 10th International Symposium on Diagnostics for Electrical Machines, Power Electronics and Drives, Guarda, Portugal, 1–4 September 2015; pp. 359–365. [Google Scholar]

- Irhoumah, M.; Pusca, R.; Lefevre, E.; Mercier, D.; Romary, R.; Demian, C. Information Fusion with Belief Functions for Detection of Interturn Short-Circuit Faults in Electrical Machines Using External Flux Sensors. IEEE Trans. Ind. Electron. 2018, 65, 2642–2652. [Google Scholar] [CrossRef]

- Lopez-Perez, D.; Antonino-Daviu, J. Application of Infrared Thermography to Failure Detection in Industrial Induction Motors: Case Stories. IEEE Trans. Ind. Appl. 2017, 53, 1901–1908. [Google Scholar] [CrossRef]

- Ma, Y.; Wu, X. Discriminant sparse and collaborative preserving embedding for bearing fault diagnosis. Neurocomputing 2018, 313, 259–270. [Google Scholar] [CrossRef]

- Sapena-Bano, A.; Martinez-Roman, J.; Puche-Panadero, R.; Pineda-Sanchez, M.; Perez-Cruz, J.; Riera-Guasp, M. Induction machine model with space harmonics for fault diagnosis based on the convolution theorem. Int. J. Electr. Power Energy Syst. 2018, 100, 463–481. [Google Scholar] [CrossRef]

- Antonino-Daviu, J.; Popaleny, P. Detection of Induction Motor Coupling Unbalanced and Misalignment Via Advanced Transient Current Signature Analysis. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 2359–2364. [Google Scholar]

- Bessous, N.; Chemsa, A.; Sbaa, S. New Vision about the Mixed Eccentricity Fault Causes in Induction Motors and its relationship with the Rolling Element Bearing Faults: Analytical model dedicated to the REB faults. In Proceedings of the 2018 International Conference on Communications and Electrical Engineering (ICCEE), El Oued, Algeria, 17–18 December 2018. [Google Scholar]

- Brandt, M.; Gutten, M.; Koltunowicz, T.; Zukowski, P. Analysis of winding fault in electric machines by frequency method. In Proceedings of the 2018 ELEKTRO, Mikulov, Czech Republic, 21–23 May 2018; pp. 1–4. [Google Scholar]

- Nikita, T.; Manickavasagam, K.; Sachin, S. Magnetostriction analysis on doubly fed induction generator under normal and low voltage ride through (LVRT) condition. In Proceedings of the 2017 International Conference on Technological Advancements in Power and Energy (TAP Energy), Kollam, India, 21–23 December 2017; pp. 1–5. [Google Scholar]

- Ugale, R.T.; Gore, S.N.; Chaudhari, B.N. Web based remote and locally operated all in one electrical machine laboratory with data acquisition, fault diagnosis and protection. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1979–1985. [Google Scholar]

- Ullah, S.; McDonald, S.P.; Martin, R.; Benarous, M.; Atkinson, G.J. A permanent magnet assist, segmented rotor, switched reluctance drive for fault tolerant aerospace applications. IEEE Trans. Ind. Appl. 2019, 55, 298–305. [Google Scholar] [CrossRef]

- Wang, X.B.; Zhang, X.; Li, Z.; Wu, J. Ensemble extreme learning machines for compound-fault diagnosis of rotating machinery. Knowl. Syst. 2019. [Google Scholar] [CrossRef]

- Kankar, P.K.; Sharma, S.C.; Harsha, S.P. Fault diagnosis of ball bearings using machine learning methods. Expert Syst. Appl. 2011, 38, 1876–1886. [Google Scholar] [CrossRef]

- Pöyhönen, S.; Negrea, M.; Jover, P.; Arkkio, A.; Hyötyniemi, H. Numerical magnetic field analysis and signal processing for fault diagnostics of electrical machines. COMPEL Int. J. Comput. Math. Electr. Electron. Eng. 2003, 22, 969–981. [Google Scholar] [CrossRef] [Green Version]

- Ijadi Maghsoodi, A.; Ijadi Maghsoodi, A.; Mosavi, A.; Rabczuk, T.; Zavadskas, E. Renewable energy technology selection problem using integrated h-swara-multimoora approach. Sustainability 2018, 10, 4481. [Google Scholar] [CrossRef] [Green Version]

- Papoutsidakis, M.; Kalovrektis, K.; Drosos, C.; Stamoulis, G. Design of an Autonomous Robotic Vehicle for Area Mapping and Remote Monitoring. Int. J. Comput. Appl. 2017, 167, 36–41. [Google Scholar] [CrossRef]

- Zekveld, M.; Hancke, G.P. Vibration Condition Monitoring Using Machine Learning. In Proceedings of the IECON 2018-44th Annual Conference of the IEEE Industrial Electronics Society, Washington, DC, USA, 21–23 October 2018; pp. 4742–4747. [Google Scholar]

- Aydemir, G. Deep learning based spectrum compression algorithm for rotating machinery condition monitoring. In Proceedings of the ASME 2018 Conference on Smart Materials, Adaptive Structures and Intelligent Systems, San Antonio, TX, USA, 10–12 September 2018. [Google Scholar]

- Dos Santos, T.; Ferreira, F.J.T.E.; Pires, J.M.; Damasio, C. Stator winding short-circuit fault diagnosis in induction motors using random forest. In Proceedings of the 2017 IEEE International Electric Machines and Drives Conference (IEMDC), Miami, FL, USA, 21–24 May 2017. [Google Scholar]

- Ferreira, J.G.; Warzecha, A. An application of machine learning approach to fault detection of a synchronous machine. In Proceedings of the 2017 International Symposium on Electrical Machines (SME), Naleczow, Poland, 18–21 June 2017. [Google Scholar]

- Senanayaka, J.S.L.; Kandukuri, S.T.; Khang, H.V.; Robbersmyr, K.G. Early detection and classification of bearing faults using support vector machine algorithm. In Proceedings of the 2017 IEEE Workshop on Electrical Machines Design, Control and Diagnosis (WEMDCD), Nottingham, UK, 20–21 April 2017; pp. 250–255. [Google Scholar]

- Senanayaka, J.S.L.; Van Khang, H.; Robbersmyr, K.G. Towards online bearing fault detection using envelope analysis of vibration signal and decision tree classification algorithm. In Proceedings of the 2017 20th International Conference on Electrical Machines and Systems (ICEMS), Sydney, NSW, Australia, 11–14 August 2017. [Google Scholar]

- Zhang, J.; Zhan, W.; Ehsani, M. On-line fault diagnosis of electric machine based on the Hidden Markov Model. In Proceedings of the 2016 IEEE Transportation Electrification Conference and Expo (ITEC), Dearborn, MI, USA, 27–29 June 2016. [Google Scholar]

- Abid, F.B.; Zgarni, S.; Braham, A. Distinct bearing faults detection in induction motor by a hybrid optimized SWPT and aiNet-DAG SVM. IEEE Trans. Energy Convers. 2018, 33, 1692–1699. [Google Scholar] [CrossRef]

- Giantomassi, A.; Ferracuti, F.; Iarlori, S.; Ippoliti, G.; Longhi, S. Signal Based Fault Detection and Diagnosis for Rotating Electrical Machines: Issues and Solutions. In Studies in Fuzziness and Soft Computing; Springer: Berlin/Heidelberg, Germany, 2015; Volume 319, pp. 275–309. [Google Scholar]

- Afrasiabi, S.; Afrasiabi, M.; Parang, B.; Mohammadi, M. Real-Time Bearing Fault Diagnosis of Induction Motors with Accelerated Deep Learning Approach. In Proceedings of the 2019 10th International Power Electronics, Drive Systems and Technologies Conference (PEDSTC), Shiraz, Iran, 12–14 February 2019; pp. 155–159. [Google Scholar]

- He, D.; Fahimi, B. Power management of a self-powered multi-parameter wireless sensor for IoT application. In Proceedings of the 2018 IEEE Applied Power Electronics Conference and Exposition (APEC), San Antonio, TX, USA, 4–8 March 2018; pp. 1380–1385. [Google Scholar]

- Martin-Diaz, I.; Morinigo-Sotelo, D.; Duque-Perez, O.; Romero-Troncoso, R.J. An Experimental Comparative Evaluation of Machine Learning Techniques for Motor Fault Diagnosis under Various Operating Conditions. IEEE Trans. Ind. Appl. 2018, 54, 2215–2224. [Google Scholar] [CrossRef]

- Shamshirband, S.; Rabczuk, T.; Chau, K.W. A Survey of Deep Learning Techniques: Application in Wind and Solar Energy Resources. IEEE Access 2019, 7, 164650–164666. [Google Scholar] [CrossRef]

- Senanayaka, J.S.L.; Van Khang, H.; Robbersmyr, K.G. Online Fault Diagnosis System for Electric Powertrains Using Advanced Signal Processing and Machine Learning. In Proceedings of the 2018 XIII International Conference on Electrical Machines (ICEM), Alexandroupoli, Greece, 3–6 September 2018; pp. 1932–1938. [Google Scholar]

- Chahine, K. Rotor fault diagnosis in induction motors by the matrix pencil method and support vector machine. Int. Trans. Elecr. Energy Syst. 2018, 28. [Google Scholar] [CrossRef]

- Kao, I.H.; Wang, W.J.; Lai, Y.H.; Perng, J.W. Analysis of Permanent Magnet Synchronous Motor Fault Diagnosis Based on Learning. IEEE Trans. Instrum. Meas. 2019, 68, 310–324. [Google Scholar] [CrossRef]

- Mendonça, P.L.; Bonaldi, E.L.; de Oliveira, L.E.L.; Lambert-Torres, G.; Borges da Silva, J.G.; Borges da Silva, L.E.; Salomon, C.P.; Santana, W.C.; Shinohara, A.H. Detection and modelling of incipient failures in internal combustion engine driven generators using Electrical Signature Analysis. Electr. Power Syst. Res. 2017, 149, 30–45. [Google Scholar] [CrossRef]

- Cabal-Yepez, E.; Romero-Troncoso, R.; Garcia-Perez, A.; Osornio-Rios, R. Single-parameter fault identification through information entropy analysis at the startup-transient current in induction motors. Electr. Power Syst. Res. 2012, 89, 64–69. [Google Scholar] [CrossRef]

- Dehghani, M.; Riahi-Madvar, H.; Hooshyaripor, F.; Mosavi, A.; Shamshirband, S.; Zavadskas, E.K.; Chau, K.W. Prediction of hydropower generation using grey wolf optimization adaptive neuro-fuzzy inference system. Energies 2019, 12, 289. [Google Scholar] [CrossRef] [Green Version]

- Delpha, C.; Diallo, D.; Al Samrout, H.; Moubayed, N. Multiple incipient fault diagnosis in three-phase electrical systems using multivariate statistical signal processing. Eng. Appl. Artif. Intell. 2018, 73, 68–79. [Google Scholar] [CrossRef]

- Vas, P. Parameter Estimation, Condition Monitoring, and Diagnosis of Electrical Machines; Oxford University Press: Oxford, UK, 1993; Volume 27. [Google Scholar]

- Tidriri, K.; Tiplica, T.; Chatti, N.; Verron, S. A generic framework for decision fusion in fault detection and diagnosis. Eng. Appl. Artif. Intell. 2018, 71, 73–86. [Google Scholar] [CrossRef]

- Delgado-Arredondo, P.A.; Morinigo-Sotelo, D.; Osornio-Rios, R.A.; Avina-Cervantes, J.G.; Rostro-Gonzalez, H.; de Jesus Romero-Troncoso, R. Methodology for fault detection in induction motors via sound and vibration signals. Mech. Syst. Signal Process. 2017, 83, 568–589. [Google Scholar] [CrossRef]

- Serdio, F.; Lughofer, E.; Pichler, K.; Pichler, M.; Buchegger, T.; Efendic, H. Fuzzy fault isolation using gradient information and quality criteria from system identification models. Inf. Sci. 2015, 316, 18–39. [Google Scholar] [CrossRef]

- Serdio, F.; Lughofer, E.; Zavoianu, A.-C.; Pichler, K.; Pichler, M.; Buchegger, T.; Efendic, H. Improved fault detection employing hybrid memetic fuzzy modeling and adaptive filters. Appl. Soft Comput. 2017, 51, 60–82. [Google Scholar] [CrossRef]

- Jafari, H.; Poshtan, J. Fault detection and isolation based on fuzzy-integral fusion approach. IET Sci. Meas. Technol. 2019, 13, 296–302. [Google Scholar] [CrossRef]

- Chen, Z.; Li, X.; Yang, C.; Peng, T.; Yang, C.; Karimi, H.R.; Gui, W. A data-driven ground fault detection and isolation method for main circuit in railway electrical traction system. ISA Trans. 2019, 87, 264–271. [Google Scholar] [CrossRef]

- Jung, D.; Frisk, E. Residual selection for fault detection and isolation using convex optimization. Automatica 2018, 97, 143–149. [Google Scholar] [CrossRef]

- Jung, D.; Sundstrom, C. A Combined Data-Driven and Model-Based Residual Selection Algorithm for Fault Detection and Isolation. IEEE Trans. Control. Syst. Technol 2019, 27, 616–630. [Google Scholar] [CrossRef] [Green Version]

- Kannan, R.; Solai Manohar, S.; Senthil Kumaran, M. Nominal features-based class specific learning model for fault diagnosis in industrial applications. Comput. Ind. Eng. 2018, 116, 163–177. [Google Scholar] [CrossRef]

- Na, W.; Park, C.; Lee, S.; Yu, S.; Lee, H. Sensitivity-based fault detection and isolation algorithm for road vehicle chassis sensors. Sensors 2018, 18, 2720. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- El Bakri, A.; Koumir, M.; Boumhidi, I. Extreme learning machine-based non-linear observer for fault detection and isolation of wind turbine. Aust. J. Electr. Electron. Eng. 2019, 16, 12–20. [Google Scholar] [CrossRef]

- Sarwar, M.; Mehmood, F.; Abid, M.; Khan, A.Q.; Gul, S.T.; Khan, A.S. High impedance fault detection and isolation in power distribution networks using support vector machines. J. King Saud Univ. Eng. Sci. 2019. [Google Scholar] [CrossRef]

- Shahnazari, H.; Mhaskar, P.; House, J.M.; Salsbury, T.I. Modeling and fault diagnosis design for HVAC systems using recurrent neural networks. Comput. Chem. Eng. 2019, 189–203. [Google Scholar] [CrossRef]

- Yang, J.; Guo, Y.; Zhao, W. Long short-term memory neural network based fault detection and isolation for electro-mechanical actuators. Neurocomputing 2019. [Google Scholar] [CrossRef]

- Abderrahmane, M.; Mohammed, B. Fault diagnosis of a wind turbine benchmark via statistical and support vector machine. Int. J. Eng. Res. Afr. 2018, 37, 29–42. [Google Scholar] [CrossRef]

- Ait-Izem, T.; Harkat, M.F.; Djeghaba, M.; Kratz, F. On the application of interval PCA to process monitoring: A robust strategy for sensor FDI with new efficient control statistics. J. Process. Control. 2018, 63, 29–46. [Google Scholar] [CrossRef]

- Fazai, R.; Ben Abdellafou, K.; Said, M.; Taouali, O. Online fault detection and isolation of an AIR quality monitoring network based on machine learning and metaheuristic methods. Int. J. Adv. Manuf. Technol. 2018, 99, 2789–2802. [Google Scholar] [CrossRef]

- Khorasgani, H.; Biswas, G. A methodology for monitoring smart buildings with incomplete models. Appl. Soft Comput. J. 2018, 71, 396–406. [Google Scholar] [CrossRef]

- Lindahl, P.A.; Green, D.H.; Bredariol, G.; Aboulian, A.; Donnal, J.S.; Leeb, S.B. Shipboard Fault Detection Through Nonintrusive Load Monitoring: A Case Study. IEEE Sens. J. 2018, 18, 8986–8995. [Google Scholar] [CrossRef]

- Mohamed Syed Ali, A. Helmet deduction using image processing. Indones. J. Electr. Eng. Comput. Sci. 2018, 9, 342–344. [Google Scholar] [CrossRef]

- Zhang, D.; Qian, L.; Mao, B.; Huang, C.; Huang, B.; Si, Y. A Data-Driven Design for Fault Detection of Wind Turbines Using Random Forests and XGboost. IEEE Access 2018, 6, 21020–21031. [Google Scholar] [CrossRef]

- Cheng, F.; Wang, J.; Qu, L.; Qiao, W. Rotor current-based fault diagnosis for DFIG wind turbine drivetrain gearboxes using frequency analysis and a deep classifier. IEEE Trans. Ind. Appl. 2018, 54, 1062–1071. [Google Scholar] [CrossRef]

- Mosavi, A.; Faizollahzadeh ardabili, S.; Várkonyi-Kóczy, A.R. List of Deep Learning Models. Preprints 2019, 2019080152. [Google Scholar] [CrossRef]

- Gao, Z.; Sheng, S. Real-time monitoring, prognosis, and resilient control for wind turbine systems. Renew. Energy 2018, 116, 1–4. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhu, C.; Song, C.; Li, Y.; Chen, X.; Yong, B. Improvement of reliability and wind power generation based on wind turbine real-time condition assessment. Int. J. Electr. Power Energy Syst. 2019, 113, 344–354. [Google Scholar] [CrossRef]

- Vigneshkumar, S.; Shankar, V.K.; Krishna, P.N.; Supriya, P. Fault Detection in Gearbox Using Motor Electrical Signature Analysis. In Proceedings of the 2018 9th International Conference on Computing, Communication and Networking Technologies (ICCCNT), Bangalore, India, 10–12 July 2018; pp. 1–6. [Google Scholar]

- Yang, B.-S.; Oh, M.-S.; Tan, A.C.C. Fault diagnosis of induction motor based on decision trees and adaptive neuro-fuzzy inference. Expert Syst. Appl. 2009, 36, 1840–1849. [Google Scholar]

- Patel, R.K.; Giri, V. Feature selection and classification of mechanical fault of an induction motor using random forest classifier. Perspect. Sci. 2016, 8, 334–337. [Google Scholar] [CrossRef] [Green Version]

- Wardle, F.P. Vibration forces produced by waviness of the rolling surfaces of thrust loaded ball bearings Part 1: Theory. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1988, 202, 305–312. [Google Scholar] [CrossRef]

- Lynagh, N.; Rahnejat, H.; Ebrahimi, M.; Aini, R. Bearing induced vibration in precision high speed routing spindles. Int. J. Mach. Tools Manuf. 2000, 40, 561–577. [Google Scholar] [CrossRef]

- Zimroz, R.; Bartelmus, W.; Barszcz, T.; Urbanek, J. Diagnostics of bearings in presence of strong operating conditions non-stationarity—A procedure of load-dependent features processing with application to wind turbine bearings. Mech. Syst. Signal Process. 2014, 46, 16–27. [Google Scholar] [CrossRef]

- Chen, J.; Pan, J.; Li, Z.; Zi, Y.; Chen, X. Generator bearing fault diagnosis for wind turbine via empirical wavelet transform using measured vibration signals. Renew. Energy 2016, 89, 80–92. [Google Scholar] [CrossRef]

- Teng, W.; Ding, X.; Zhang, X.; Liu, Y.; Ma, Z. Multi-fault detection and failure analysis of wind turbine gearbox using complex wavelet transform. Renew. Energy 2016, 93, 591–598. [Google Scholar] [CrossRef]

- Muralidharan, V.; Sugumaran, V. Feature extraction using wavelets and classification through decision tree algorithm for fault diagnosis of mono-block centrifugal pump. Measurement 2013, 46, 353–359. [Google Scholar] [CrossRef]

- Wen, L.; Gao, L.; Li, X.; Wang, L.; Zhu, J. A Jointed Signal Analysis and Convolutional Neural Network Method for Fault Diagnosis. Procedia CIRP 2018, 72, 1084–1087. [Google Scholar] [CrossRef]

- Tsoumakas, G.; Katakis, I. Multi-label classification: An overview. Int. J. Data Warehous. Min. (IJDWM) 2007, 3, 1–13. [Google Scholar] [CrossRef]

- Herrera, F.; Charte, F.; Rivera, A.J.; Del Jesus, M.J. Multilabel classification. In Multilabel Classification; Springer: Berlin/Heidelberg, Germany, 2016; pp. 17–31. [Google Scholar]

- Read, J.; Pfahringer, B.; Holmes, G. Multi-label classification using ensembles of pruned sets. In Proceedings of the 8th IEEE International Conference on Data Mining, Pisa, Italy, 15–19 December 2008; pp. 995–1000. [Google Scholar]

- Read, J.; Pfahringer, B.; Holmes, G.; Frank, E. Classifier chains for multi-label classification. Mach. Learn. 2011, 85, 333. [Google Scholar] [CrossRef] [Green Version]

- Fu, H.; Cheng, J.; Xu, Y.; Wong, D.W.K.; Liu, J.; Cao, X. Joint optic disc and cup segmentation based on multi-label deep network and polar transformation. IEEE Trans. Med. Imaging 2018, 37, 1597–1605. [Google Scholar] [CrossRef] [PubMed]

- Rauber, T.W.; Mello, L.H.; Rocha, V.F.; Varejão, F.M. Multi-label fault classification experiments in a chemical process. In Proceedings of theIEEE Brazilian Conference on Intelligent Systems, Sao Paulo, Brazil, 18–22 October 2014; pp. 265–270. [Google Scholar]

- Cakir, E.; Heittola, T.; Huttunen, H.; Virtanen, T. Polyphonic sound event detection using multi label deep neural networks. In Proceedings of the 2015 International Joint Conference on Neural Networks (IJCNN), Killarney, Ireland, 12–17 July 2015; pp. 1–7. [Google Scholar]

- Yang, X.; Song, J.; Wu, X.; Xie, L.; Liu, X.; Li, G. Identification of unhealthy Panax notoginseng from different geographical origins by means of multi-label classification. Spectrochim. Acta Part A Mol. Biomol. Spectrosc. 2019, 222, 117243. [Google Scholar] [CrossRef] [PubMed]

- Hsu, C.-W.; Chang, C.-C.; Lin, C.-J. A Practical Guide to Support Vector Classification; National Taiwan University of Science and Technology (Taiwan Tech): Taipei City, Taiwan, 2003. [Google Scholar]

- Dudani, S.A. The distance-weighted k-nearest-neighbor rule. IEEE Trans. Syst. Man Cybern. 1976, SMC-6, 325–327. [Google Scholar] [CrossRef]

- Basu, K.; Debusschere, V.; Bacha, S.; Maulik, U.; Bondyopadhyay, S. Nonintrusive load monitoring: A temporal multilabel classification approach. IEEE Trans. Ind. Inf. 2014, 11, 262–270. [Google Scholar] [CrossRef]

- Domeniconi, C.; Gunopulos, D. Adaptive nearest neighbor classification using support vector machines. In Proceedings of the Advances in Neural Information Processing Systems, Vancouver, BC, Canada, 3–8 December 2001; pp. 665–672. [Google Scholar]

- Keskes, H.; Braham, A.; Lachiri, Z. Broken rotor bar diagnosis in induction machines through stationary wavelet packet transform and multiclass wavelet SVM. Electr. Power Syst. Res. 2013, 97, 151–157. [Google Scholar] [CrossRef]

- Imandoust, S.B.; Bolandraftar, M. Application of k-nearest neighbor (knn) approach for predicting economic events: Theoretical background. Int. J. Eng. Res. Appl. 2013, 3, 605–610. [Google Scholar]

- Hu, L.-Y.; Huang, M.-W.; Ke, S.-W.; Tsai, C.-F. The distance function effect on k-nearest neighbor classification for medical datasets. SpringerPlus 2016, 5, 1304. [Google Scholar] [CrossRef] [Green Version]

- Torabi, M.; Hashemi, S.; Saybani, M.R.; Shamshirband, S.; Mosavi, A. A Hybrid clustering and classification technique for forecasting short-term energy consumption. Environ. Prog. Sustain. Energy 2019, 38, 66–76. [Google Scholar] [CrossRef] [Green Version]

- Gómez, D.; Rojas, A. An empirical overview of the no free lunch theorem and its effect on real-world machine learning classification. Neural Comput. 2016, 28, 216–228. [Google Scholar] [CrossRef] [Green Version]

- Wolpert, D.H.; Macready, W.G. No free lunch theorems for optimization. IEEE Trans. Evolut. Comput. 1997, 1, 67–82. [Google Scholar] [CrossRef] [Green Version]

- Galar, M.; Fernandez, A.; Barrenechea, E.; Bustince, H.; Herrera, F. A review on ensembles for the class imbalance problem: Bagging-, boosting-, and hybrid-based approaches. IEEE Trans. Syst. Man Cybern. Part C (Appl. Rev.) 2011, 42, 463–484. [Google Scholar] [CrossRef]

- Polikar, R. Ensemble based systems in decision making. IEEE Circuit. Syst. Mag. 2006, 6, 21–45. [Google Scholar] [CrossRef]

- Stack, J.R.; Habetler, T.G.; Harley, R.G. Effects of machine speed on the development and detection of rolling element bearing faults. IEEE Power Electr. Lett. 2003, 1, 19–21. [Google Scholar] [CrossRef]

- Skipp, B. Ground vibration—Codes and standards. In Ground Dynamics and Man-Made Processes; The Institution of Civil Engineers: Glasgow, UK, 1998; pp. 29–41. [Google Scholar]

- Liu, H.; Motoda, H. Feature Extraction, Construction and Selection: A Data Mining Perspective; Springer Science & Business Media: Berlin, Germany, 1998; Volume 453. [Google Scholar]

- Holcsik, P.; Pálfi, J.; Čonka, Z.; Avornicului, M. A Theoretical Approach to The Implementation of Low-Voltage Smart Switch Boards. Acta Polytech. Hung. 2019, 16, 123–149. [Google Scholar]

- Pálfi, J.; Takács, M.; Holcsik, P.; Mitrik, Z. Determination of the fault identification accuracy in LV networks using the Fuzzy method. In Proceedings of the 2016 IEEE International Conference on Systems, Man, and Cybernetics, Budapest, Hungary, 9–12 October 2016; pp. 2756–2761. [Google Scholar]

- Glowacz, A.; Głowacz, Z. Recognition of rotor damages in a DC motor using acoustic signals. Bull. Pol. Acad. Sci. Tech. Sci. 2017, 65, 187–194. [Google Scholar] [CrossRef] [Green Version]

- Glowacz, A.; Glowacz, W. Vibration-Based Fault Diagnosis of Commutator Motor. Shock Vib. 2018, 2018. [Google Scholar] [CrossRef]

- Glowacz, A. Acoustic fault analysis of three commutator motors. Mech. Syst. Signal Process. 2019, 133, 106226. [Google Scholar] [CrossRef]

| Vibration Velocity [mm/s] | Class I. Small Machines | Class II. Medium Machines | Class III. Large Rigid Foundation | Class IV. Large Soft Foundation |

|---|---|---|---|---|

| 0.28 | ||||

| 0.45 | GOOD | |||

| 0.71 | ||||

| 1.12 | ||||

| 1.80 | ||||

| 2.80 | SATISFACTORY | |||

| 4.50 | ||||

| 7.71 | UNSATISFACTORY | |||

| 11.20 | ||||

| 18.00 | ||||

| 28.00 | UNACCEPTABLE | |||

| 45.90 | ||||

| id | Ia_motor | Ib_motor | … | isUnbalance | isMisalignm | Severity |

|---|---|---|---|---|---|---|

| 0 | 0.687150 | 0.028560 | ... | 0 | 1 | ‘Good’ |

| 1 | 0.019699 | 0.388238 | … | 1 | 0 | ‘Good’ |

| Prediction Method and Label (0/1) | Precision | Recall | f1-Score | |

|---|---|---|---|---|

| Binarized Decision Tree | 0 | 0.79 | 0.88 | 0.83 |

| 1 | 0.85 | 0.94 | 0.89 | |

| Classifier Chain | 0 | 0.79 | 0.88 | 0.83 |

| 1 | 0.78 | 1.00 | 0.88 | |

| KNN | 0 | 0.76 | 0.76 | 0.76 |

| 1 | 0.82 | 1.00 | 0.90 | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dineva, A.; Mosavi, A.; Gyimesi, M.; Vajda, I.; Nabipour, N.; Rabczuk, T. Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification. Appl. Sci. 2019, 9, 5086. https://doi.org/10.3390/app9235086

Dineva A, Mosavi A, Gyimesi M, Vajda I, Nabipour N, Rabczuk T. Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification. Applied Sciences. 2019; 9(23):5086. https://doi.org/10.3390/app9235086

Chicago/Turabian StyleDineva, Adrienn, Amir Mosavi, Mate Gyimesi, Istvan Vajda, Narjes Nabipour, and Timon Rabczuk. 2019. "Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification" Applied Sciences 9, no. 23: 5086. https://doi.org/10.3390/app9235086

APA StyleDineva, A., Mosavi, A., Gyimesi, M., Vajda, I., Nabipour, N., & Rabczuk, T. (2019). Fault Diagnosis of Rotating Electrical Machines Using Multi-Label Classification. Applied Sciences, 9(23), 5086. https://doi.org/10.3390/app9235086