1. Introduction

A thermal protection system (TPS) is required to be lightweight, provide high strength under dynamic and acoustic pressures, and withstand aerodynamic heating during hypersonic flight. During its service lifetime, a hypersonic vehicle will operate in harsh conditions, such as high aerodynamic heating on the surface, which results in a thermal gradient across the thickness direction of the TPS panel [

1,

2,

3,

4,

5]. In addition, thermal stress will increase, which causes the TPS panel to deflect outwardly and may damage the vehicle [

6,

7]. The outward deflection of the TPS panel may cause a transition from laminar to turbulent boundary conditions, which may increase local aerodynamic heating [

8,

9]. Thus, the design of the TPS panel must ensure a safe temperature for the vehicle structure at below the allowable temperature of the internal structure’s material [

10,

11]. It must also provide an acceptable surface deflection to prevent flow transition during flight [

12].

Several studies have focused on the thermomechanical performance of the TPS panel to determine the deflection limit. Daryabeigi et al. [

12] theoretically calculated the deflection of a honeycomb panel for a TPS panel and evaluated the maximum deflections in terms of the boundary layer transition. Guo et al. [

13] investigated the thermomechanical performance of a TPS panel with a honeycomb panel at the top surface. They also presented an application of the finite element method for TPS panel optimization. Their TPS model followed the design of NASA’s TPS panel [

1,

12]. Most of the research focused on the goal of the temperature limit in the internal structure of the vehicle, and they determined the proper thickness and material for the TPS panel [

11,

14,

15,

16]. Moreover, they also investigated whether the residual stress in the TPS panel remained at high levels [

17]. Nevertheless, deformation due to thermal gradient has not received much attention. Thus, there remained a need for research on the deflection limit and permanent deformation of the TPS panel. In our previous design of the TPS panel [

6], we employed a dense Inconel superalloy plate for the outer plate of the TPS panel, which was directly exposed to high aerodynamic heating, as shown in

Figure 1. Note that the outer plate of the TPS panel is formed in the shape of the vehicle and its deformation can create roughness of the outer mold line of the vehicle. However, the dense plate used in our previous work [

6], which was made of an Inconel superalloy, was heavy even though it guaranteed high strength for the TPS panel. Therefore, in this study, we developed lightweight structures that can be used as the exterior part of the TPS panel and ensure the high strength at a high temperature.

One candidate for a lightweight structure is a sandwich structure, which has been widely used in the hypersonic vehicles as a thermal protection structure. Recently, sandwich structures consisting of two solid face sheets and a low-density core were inspired from biological structures [

18,

19,

20]. Over the course of the long evolution of nature, biological structures have been optimized for survival and have adapted themselves to various environmental conditions. Thus, they were considered for a lightweight and high-strength structure for modern engineering applications. Many researchers have designed sandwich structures and investigated their thermal and mechanical performance under various conditions, such as crushing testing [

18,

21], aerodynamic heating [

10,

22], and thermal-acoustic analysis [

23]. Ha et al. [

24] reviewed the most recent research on bio-inspired materials for energy absorption structure. Fatemi et al. [

25] computationally investigated the thermomechanical performance of honeycomb core panels for hot structure applications. Marshall et al. [

26] introduced integral textile structures that were able to function in high-temperature working conditions with high specific strength. Although the conceptual design and structural efficiency can be improved by using the above approaches, these concepts also lead to manufacturing and testing problems. In particular, Blosser et al. [

27] presented the use of the honeycomb sandwich structure in the metallic TPS panel, which could be used under a high temperature of 1073 K. However, welding of a honeycomb core to the face sheets is a big challenge. Hence, what remains to be developed is a novel lightweight sandwich structure with a corrugated core that takes advantage of easy manufacturing.

Yang et al. [

18] reviewed the high performance of the energy absorption capacity of the bio-inspired sinusoidal corrugated core sandwich structure under quasi-static loads. Ha et al. [

28] presented a bio-inspired conical corrugated wall for high energy absorption. Sareh et al. [

29] studied the design of a developable double corrugation surface that could be employed for transformable structures. Fischer et al. [

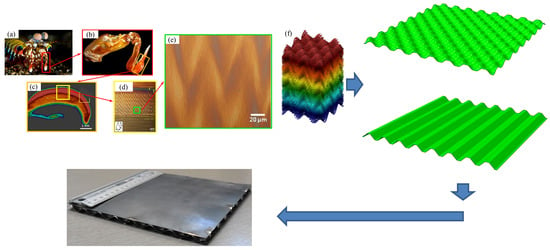

30] presented the influences on mechanical properties of a zigzag-like foldcore sandwich structure in a compression test. However, the use of the bio-inspired corrugated core sandwich structure under extreme thermal loads is very rare and thermomechanical characteristics have not been identified yet. To address these challenges, we proposed a modified design of a bio-inspired sinusoidal corrugated core sandwich structures and investigated their thermomechanical performance under high-temperature conditions. Here, we present the bio-inspired sandwich structure as a lightweight, high-strength structure for the outer structure of the TPS panel. The corrugated core of the sandwich panel was inspired and modified from the microstructural shape of the

Odontodactylus scyllarus shrimp’s dactyl club, which is shown in

Figure 2a,b. Photos are reproduced from the work of [

31]. The sagittal section of the impact region of the dactyl club was observed by computerized tomography scan, as shown in

Figure 2c. Higher magnifications of the sinusoidal shape are shown in

Figure 2d,e. A schematic of the geometry for the sinusoidal shape is shown in

Figure 2f. This paper aims to propose the corrugated core sandwich structure panel to reduce the weight and guarantee the strength for the TPS panel under high-temperature conditions. We developed two types of corrugated core for the sandwich structures: the unidirectionally corrugated core sandwich structure (UCS) and the bidirectionally corrugated core sandwich structure (BCS). The study investigates the deflection of the two sandwich structures for typical operating trajectories of the hypersonic vehicle and determines whether the resulting deflection was acceptable for the TPS panel. In addition, we compared the two sandwich structures in terms of the thermal stress and the thermal deflection limits. Furthermore, we investigated the parameter effects of the sandwich structures on the thermomechanical performance.

2. Bio-Inspired Corrugated Core Sandwich Structure

A lightweight structure was our main goal in designing the skin structure for the TPS panel that would satisfy the thermal stress and thermal deflection limits. The density of each part in the whole sandwich structure needed to be decreased. Thus, in this study, we employed the corrugated core sandwich structure inspired from natural material that had a lower density compared with the dense structure used in our previous TPS panel-solid plate, Inconel 625 [

5,

6]. The unit cell consisted of three parts: the outer face sheet, corrugated cores (unidirectional and bidirectional cores), and the inner face sheet. The face sheets are used as the impact surface layer and the bio-inspired corrugated core take the function of impact protection like the ordered herringbone or wrinkle pattern. For fabrication of the corrugated core sandwich structure, the main shape of the core was modified from the original sinusoidal wave and the bi-sinusoidal wave, which are mathematically expressed in Equation (1).

where

x and

y represent the longitudinal and transverse direction of the plane,

z is the thickness direction (perpendicular to the plane),

nx and

ny are the number of waves along the two directions in the plane,

L is the length of the unit cell (21.2 mm), and

f is the amplitude of cosine wave (3.78).

The upper peak and the lower peak of the sinusoidal and bi-sinusoidal shapes were flattened with the cutting planes so that the corrugated cores could be successfully welded to the outer and inner face sheets, as shown in

Figure 3a,b.

Figure 3b,c show the unit cells of the unidirectionally and bidirectionally corrugated core sandwich structure, respectively. The geometrical sizes of the unit cells are given in

Table 1. The full sandwich structure models are presented in

Figure 4. Each sandwich structure consists of 8 × 8-unit cells with a length of 170 mm. The sandwich structure must bear the maximum temperature of about 1100 K at the outer face sheet. Therefore, we needed to choose materials with high strength that could endure high-temperature loads. Furthermore, fracture toughness is essential to the sandwich structure to prevent possible impact from orbital debris in space. We chose two metallic materials to design the corrugated core sandwich structures: Inconel 625 superalloy and stainless steel 304.

Owing to the complex sinusoidal perturbation of the corrugated cores, the bending characteristics of the two corrugated cores and flattened corrugated cores were difficult to obtain; therefore, the three-dimensional unit cell model of the two corrugated cores was built in a CAD software using the expression in Equation (1), as shown in

Figure 3a,b. The area moment of inertia of each corrugated core about the axes on the midplane of the structure was calculated. The results of the area moment of inertia are shown in

Table 2. Obviously, the area moment of inertia of the unidirectional core was larger than that of the bidirectional core. Therefore, the unidirectional core structure would bend less than the bidirectional core structure.

In the literature, several kinds of the UCS structure were investigated by experiment and simulation [

11,

15,

32,

33]. Yang et al. [

18] reported that the BCS structure greatly reduced the risk of damage in the crushing test. The results from this numerical simulation revealed that the UCS structure deflected unsymmetrically, which could increase the localized boundary layer transition, as presented in

Section 4. The UCS structure should be considered carefully for the skin structure of the metallic TPS panel. Therefore, the use of a bidirectional core structure is preferred over the unidirectional core structure for such a skin structure of a metallic TPS panel.

Hence, we decided to fabricate and test the BCS structure in a thermomechanical experiment before it was employed in the TPS panel. In this study, the BCS structure was first fabricated by Doowon Heavy Industrial Company, Republic of Korea, using the design already explained. However, because of cost and usage constraints, the use of Inconel 625 material is limited. Thus, in this study, we fabricated a prototype of the BCS structure in which the corrugated core was made by bending the 0.2 mm thick stainless steel sheet in a mold. Then, the sandwich structure was assembled by brazing the corrugated core with the 0.3 mm thick stainless steel face sheets. A picture of the bidirectionally corrugated core sandwich structure is shown in

Figure 5. The weights for the as-fabricated structures are listed in

Table 3.

4. Thermomechanical Performance

Here, we present the results of a typical corrugated core sandwich structure. The resulting surface temperatures of the stainless steel unidirectionally corrugated core sandwich structures and the temperature differences across the stainless steel sandwich structures for the two heating rates are shown in

Figure 14. There was a rapid surface temperature rise from 0 s to 500 s, after which the surface temperature rose slowly to peaks of 1113 K and 1015 K at 1800 s for the high heating rate and low heating rate, respectively. This was followed by rapid surface cooling between 1800 and 2200 s. The maximum temperature difference across the sandwich structures was 138 K at 260 s and 119 K at 350 s for the high heating rate and low heating rate, respectively. The temperature differences were close to zero as the temperature of the sandwich structures approached the steady-state and then became negative values, implying that the outer face sheet of the sandwich structures was cooler than the inner face sheet. The minimum temperature differences reached −137 K and −120 K at 2400 s for the high heating rate and low heating rate, respectively. It was clear that the temperature difference was largest when the sandwich structures were experiencing rapid heating and cooling. The results of the other sandwich structures are summarized in

Table 4. As discussed earlier, the surface temperature of the sandwich structures only depends on the incident heating rate and the emissivity.

Table 5 confirms that the surface temperatures of the sandwich structures with the same applied heating rate and emissivity had similar values. The maximum temperature difference between the outer and inner face sheets was very slight among the types of corrugated core. The results also demonstrated that the two sandwich structures had similar effective thermal conductivities.

Figure 15 shows the displacement contour results of unidirectionally and bidirectionally corrugated core sandwich structures. The displacement contour of the unidirectional core had an ellipse shape owing to its asymmetrical geometry, while the bidirectional core had concentric circles owing to the symmetrical geometry. The displacement of the center point and the corner point in the diagonal line of the outer face sheets, as shown in

Figure 15a,b, were used to calculate the deflection.

The results showed that the UCS structure had less deflection than the BCS structure. However, the UCS structure has a weaker strength in the line with the direction perpendicular to the core direction, and the deflection distribution could differ from each direction location of the structure; therefore, it could result in several local wrinkles on the surface structure of the unidirectional corrugated core sandwich structure. Specifically, the localized wrinkles were found at the locations near the corner of the unidirectional corrugated core sandwich structure, as marked with circles in

Figure 15a,c. While the bidirectional core structure provides a similar strength in the two directions, the deflection distribution could be similar for the two directions, as shown in

Figure 15b,d. Note that the present corrugated core sandwich structure was intended to be employed for the skin structure of a metallic TPS panel, which needed to be as smooth as possible to prevent the boundary layer transition [

53]. The localized wrinkles could result in the local boundary layer transition, which could increase local aerodynamic heating. Therefore, the use of a bidirectional core structure was preferred over the unidirectional core structure for such the skin structure of a metallic TPS panel.

On the basis of the discussion earlier about the advantage of the bidirectional core structure for the skin structure of spaceflight vehicle, we only fabricated the bidirectionally corrugated core sandwich structure for our thermomechanical test. However, for applications such as nuclear engineering, civil engineering, or automotive engineering, the unidirectional core sandwich structure could be an excellent candidate along with the bidirectional core sandwich structure. The investigation on the performance of these two structures for other applications should be associated with the types of load and possible constraints.

The corresponding deflections of the UCS and BCS, made of Inconel and stainless steel materials, with the two applied heating rates are shown in

Figure 16 and

Figure 17, respectively. Note that, if the temperature difference is positive, zero, or negative, the sandwich structures will bow out, stay flat, or bow in, respectively. The deflections follow the general tendency of the temperature differences shown in

Figure 14b. With the applied high heating rate, the maximum deflections were 1.32 mm for the Inconel UCS and 1.62 mm for the BCS. For the stainless steel, they were 1.74 mm for the UCS and 2.04 mm for the BCS. With the applied low heating rate, the maximum deflections were 1.11 mm for the Inconel UCS and 1.32 mm for the BCS. They were 1.49 mm for the stainless steel UCS and 1.71 mm for the BCS.

In general, the maximum deflection of the BCS was larger than that of the UCS, and the sandwich structures made of Inconel resulted in a smaller deflection than those made of stainless steel. The deflections decreased from the maximum values to 0 mm at 2000 s, after which they went to negative and achieved minimum values at 2400 s (after touchdown). We were concerned about the bow-out deflection in the heating stage because the vehicle was in the flight path of a mission, and this bowing out into the boundary layer of the external surface of the vehicle could cause flow disturbances and lead to a transition of the boundary layer from laminar to turbulent, thereby greatly increasing the incident heating [

7,

53]. While the bow-in deflection in the cooling stage had negative values after 2000 s, the vehicle was approaching the ground and the largest deflection was observed when the vehicle was on the ground; thus, the bowing in of the sandwich structures may not cause significant overheating issues related to boundary layer transition, as also reported by the authors of [

8,

12]. There was some inward permanent deflection of the sandwich structures after one mission. The permanent deflection for the sandwich structures made of stainless steel was bigger than that made of Inconel because of the lower material strength. However, the inward permanent deflection of the two sandwich structures was very small compared with the total thickness of the sandwich structures. This may be because the residual stress appeared locally near the corners and edges of the sandwich structures, as further discussed in the next paragraph.

Figure 18 shows the von Mises stress contours of the UCS and BCS at 5000 s. The maximum von Mises stresses in both thermal loads were approximately 510 MPa and 390 MPa for the sandwich structures made of Inconel and stainless steel, respectively, and did not exceed the ultimate strength of Inconel 625 (827 MPa), as shown in

Figure 18a–d, and stainless steel 304 (505 MPa), as shown in

Figure 18e–h.

For the sandwich structures made of Inconel material, the area of von Mises stress levels exceeding 420 MPa were very localized, as shown in the close-up view in

Figure 18a–d, whereas the highest von Mises stress levels elsewhere were less than 250 MPa, which was well within the material allowable strength (Inconel 625 yield strength: 420 MPa [

39,

40]). The high-stress areas occurred in several elements of the corrugated cores closest to the edges and the four corners of the sandwich structures. The high stress distribution may be because of the boundary conditions of the sandwich structures, which were the simply supported conditions applied on the four edges of the inner face sheet. For the sandwich structures made of stainless steel 304 under the low heating rate, there were several areas located near the four corners and the edges of the sandwich structures where the von Mises stress exceeded 210 MPa, while most areas of the sandwich structures resulted in low stress within the material allowable (stainless steel yield strength: 210 MPa [

41]), as shown in the close-up views in

Figure 18e,g. For the sandwich structures made of stainless steel 304 under a high heating rate, more areas located at the four corners and the edges of the sandwich structures had von Mises stress exceeding 210 MPa, as shown in the close-up view in

Figure 18f,h. Although the sandwich structures made of stainless steel under the high heating rate did not fail because the stress was below the ultimate strength of the material, the plastic deformation resulted in larger permanent deformation in more regions of the sandwich structures, as shown in

Figure 16. Therefore, the use of stainless steel for the sandwich structures under such a high heating rate needs to be considered in terms of stress failure and permanent deformation. Overall, we found that the high localized stress was acceptable for the sandwich structures, and the permanent deformation and maximum deflection should be considered along with the stress failure in designing sandwich structures. In the next paragraph, we present a discussion on the deflections of the sandwich structures in terms of deflection limits.

To discuss the effectiveness of the corrugated core sandwich structures compared with the dense structure used in our previous research [

6], we also performed a thermomechanical analysis of the dense structure made of Inconel material. The maximum deflection was just 0.14 mm, which satisfied the deflection limit for the outer surface of the vehicle; the weight of the solid structure was 0.62 kg, while that of the corrugated structure was 0.21 kg. To prevent boundary layer transition at high Mach numbers (M > 5), Blosser et al. [

1] and Dorsey et al. [

8] proposed a criterion for the deflection limit of the outer surface at the windward forebody and leeward forebody; that is, it should be less than 1% of the main diagonal span of the TPS panel at the windward forebody and 1.5% at the leeward forebody. Moreover, Poteet et al. [

4] added a deflection limit, which was imposed to prevent permanent compaction in the insulation layer; that is, the deflection limit should not exceed 10% of the total TPS panel thickness. As shown in

Figure 19, a typical TPS panel for the BCS with a 240 mm nominal diagonal length was fabricated with a total thickness of 33.6 mm. We calculated the ratios of the maximum deflections to the diagonal length and total thickness of the TPS panel and concluded that all maximum deflections from the UCS and BCS made of Inconel and stainless steel satisfied the deflection limits. Thus, our results confirmed that the two bio-inspired corrugated-core sandwich structures are suitable for the future TPS panel under the heating rates applied in this study. In addition, their weights are more compatible than that of the previous design of the dense structure. Therefore, in terms of weight and deflection limits, we concluded that the developed bio-inspired corrugated-core structure is an excellent candidate structure for the skin structure of the TPS panel.

For the optimal design of the TPS panel, we also examined the effect of emittance of the outer face sheet and the core thickness on the thermomechanical performance. We further investigated whether improving the surface coating of the outer face sheet and changing the weight of the corrugated core could affect the localized failures and deflection limits of the sandwich structures. The details of the investigation are presented in

Section 5.