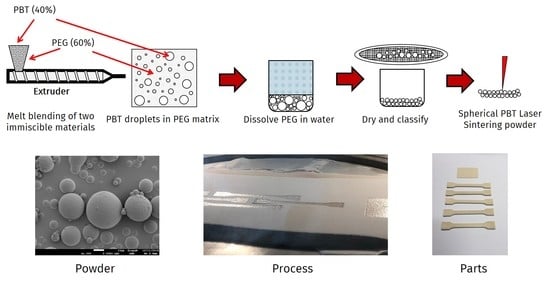

Production and Processing of a Spherical Polybutylene Terephthalate Powder for Laser Sintering

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Extrusion

3.2. Powder classification

3.3. Particle Morphology and Shape

3.4. Powder Flowability

3.5. Thermal Properties

3.6. Rheological Properties

3.7. Laser Sintering

3.8. Tensile Tests

3.9. Part Morphology and Microstructure

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Thomas, D.S.; Gilbert, S.W. Costs and Cost Effectiveness of Additive Manufacturing; NIST: Gaithersburg, MD, USA, 2014.

- Ruffo, M.; Tuck, C.; Hague, R. Cost estimation for rapid manufacturing—Laser sintering production for low to medium volumes. Proc. Proc. Imeche Part B 2006, 220, 1417–1427. [Google Scholar] [CrossRef]

- Hopkinson, N.; Dickens, P. Analysis of rapid manufacturing—Using layer manufacturing processes for production. Proc. Proc. Imeche Part C 2003, 217, 31–39. [Google Scholar]

- Schmid, M. Laser Sintering with Plastics; Hanser Verlag: Rastatt, Germany, 2018. [Google Scholar]

- Schmid, M.; Amado, A.; Wegener, K. Materials perspective of polymers for additive manufacturing with selective laser sintering. J. Mater. Res. 2014, 29, 1824–1832. [Google Scholar] [CrossRef]

- Wohlers Associates Inc. Wohlers Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2017. [Google Scholar]

- Wegner, A.; Oehler, M.; Ünlü, T. Development of a new polybutylene terephthalate material for laser sintering process. Procedia Cirp 2018, 74, 254–258. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Blümel, C.; Fanselow, S.; Winzer, B.; Wirth, K.; Peukert, W. A Novel Process Route for the Production of Polymer Powders of Small Size and Good Flowability for Selective Laser Sintering of Polymers. In Proceedings of the Fraunhofer Direct Digital Manufacturing Conference, Berlin, Germany, 12–13 March 2014; pp. 1–6. [Google Scholar]

- Schmidt, J.; Sachs, M.; Blümel, C.; Winzer, B.; Toni, F.; Wirth, K.-E.; Peukert, W. A Novel Process Route for the Production of Spherical SLS Polymer Powders. Procedia Eng. 2015, 102, 550–556. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Fanselow, S.; Zhao, M.; Romeis, S.; Drummer, D.; Wirth, K.; Peukert, W. Optimized polybutylene terephthalate powders for selective laser beam melting. Chem. Eng. Sci. 2016, 156, 1–10. [Google Scholar] [CrossRef]

- Schmidt, J.; Sachs, M.; Zhao, M.; Fanselow, S.; Wudy, K.; Drexler, M.; Wirth, K.; Peukert, W.; Schmidt, J.; Sachs, M.; et al. A Novel Process For Production Of Spherical PBT Powders And Their Processing Behavior During Laser Beam Melting. Aip Conf. Proc. 2016, 1713, 140008. [Google Scholar]

- Salmoria, G.V.; Lauth, V.R.; Cardenuto, M.R.; Magnago, R.F. Characterization of PA12/PBT specimens prepared by selective laser sintering. Opt. Laser Technol. 2018, 98, 92–96. [Google Scholar] [CrossRef]

- Arai, S.; Tsunoda, S.; Kawamura, R.; Kuboyama, K.; Ougizawa, T. Comparison of crystallization characteristics and mechanical properties of poly (butylene terephthalate) processed by laser sintering and injection molding. Mater. Des. 2017, 113, 214–222. [Google Scholar] [CrossRef]

- Arai, S.; Tsunoda, S.; Yamaguchi, A.; Ougizawa, T. Effects of short-glass-fiber content on material and part properties of poly(butylene terephthalate) processed by selective laser sintering. Addit. Manuf. 2018, 21, 683–693. [Google Scholar] [CrossRef]

- Berretta, S.; Ghita, O.; Evans, K.; Anderson, A.; Newman, C. Size, shape and flow of powders for use in Selective Laser Sintering (SLS). In Proceedings of the 6th International Conference on Advanced Research and Rapid Prototyping, VRAP, Leiria, Portugal, 1–5 October 2013; pp. 49–54. [Google Scholar]

- Berretta, S.; Ghita, O.; Evans, K. Morphology of polymeric powders in Laser Sintering (LS): From Polyamide to new PEEK powders. Eur. Polym. J. 2014, 59, 218–229. [Google Scholar] [CrossRef] [Green Version]

- Verbelen, L. Towards Scientifically Based Screening Criteria for Polymer Laser Sintering. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2016. [Google Scholar]

- van den Eynde, M. Expanding the Polymer Material Palette for Laser Sintering—The Importance of Powder Flowability. Ph.D. Thesis, KU Leuven, Leuven, Belgium, 2018. [Google Scholar]

- Schmid, M.; Kleijnen, R.; Vetterli, M.; Wegener, K. Influence of the origin of polyamide 12 powder on the laser sintering process and laser sintered parts. Appl. Sci. 2017, 7, 462. [Google Scholar] [CrossRef]

- Amado, F. Characterization and Prediction of SLS Processability of Polymer Powders with Respect to Powder Flow and Part Warpage. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2016. [Google Scholar]

- Vetterli, M.; Kleijnen, R.; Schmid, M.; Wegener, K. Process impact of elliptic smoothness and powder shape factors on additive manufacturing wiht laser sintering. In Proceedings of the ANTEC 2018, Orlando, FL, USA, 7–10 May 2018. [Google Scholar]

- Lang, B.; McGinity, J.W.; Williams, R.O. Hot-melt extrusion--basic principles and pharmaceutical applications. Drug Dev. Ind. Pharm. 2014, 40, 1133–1155. [Google Scholar] [CrossRef]

- Drummer, D.; Medina-Hernández, M.; Drexler, M.; Wudy, K. Polymer powder production for laser melting through immiscible blends. Procedia Eng. 2015, 102, 1918–1925. [Google Scholar] [CrossRef]

- Fanselow, S.; Emamjomeh, S.E.; Wirth, K.E.; Schmidt, J.; Peukert, W. Production of spherical wax and polyolefin microparticles by melt emulsification for additive manufacturing. Chem. Eng. Sci. 2016, 141, 282–292. [Google Scholar] [CrossRef]

- Fanselow, S.; Schmidt, J.; Laumer, T.; Schmidt, M.; Wirth, K.; Fanselow, S.; Schmidt, J.; Laumer, T.; Schmidt, M.; Wirth, K. Production of polyolefin powder for additive manufacturing by melt emulsification. In Proceedings of the Rapid.Tech Fachforum “Wissenschaft”, Erfurt, Germany, 10–11 June 2015. [Google Scholar]

- Van Puyvelde, P.; Moldenaers, P. Rheology and morphology development in immiscible polymer blends. Rheol. Rev. 2005, 101–145. [Google Scholar]

- Meijer, H.E.H.; Janssen, J.M.H.; Anderson, P.D. Mixing of Immiscible Liquids. Mix. Compd. Polym. 2012, 41–182. [Google Scholar]

- Vetterli, M. Powder Optimization for Laser Sintering—An Insight in Powder Intrinsic and Extrinsic Properties. Ph.D. Thesis, ETH Zurich, Zurich, Switzerland, 2019. [Google Scholar]

- Ziegelmeier, S.; Christou, P.; Wöllecke, F.; Tuck, C.; Goodridge, R.; Hague, R.; Krampe, E.; Wintermantel, E. An experimental study into the effects of bulk and flow behaviour of laser sintering polymer powders on resulting part properties. J. Mater. Process. Technol. 2015, 215, 239–250. [Google Scholar] [CrossRef]

- Huber, M.L.; Perkins, R.A.; Laesecke, A.; Friend, D.G.; Sengers, J.V.; Assael, M.J.; Metaxa, I.N.; Vogel, E.; Mareš, R.; Miyagawa, K. New international formulation for the viscosity of H2O. J. Phys. Chem. Ref. Data 2009, 38, 101–125. [Google Scholar] [CrossRef]

- Schmid, M.; Amado, F.; Levy, G. iCoPP—A new polyolefin for additive manufacturing (SLS). In Proceedings of the International Conference on Additive Manufacturing AM, Loughborough, UK, 29 June–2 July 2011. [Google Scholar]

- Ziegelmeier, S.; Wöllecke, F.; Tuck, C.; Goodridge, R.; Hague, R. Characterizing the Bulk & Flow Behaviour of LS Polymer Powders. In Proceedings of the 24th International SFF Symposium—An Additive Manufacturing Conference, Austin, TX, USA, 12–14 August 2013; pp. 354–367. [Google Scholar]

- Amado, A.; Schmid, M.; Wegener, K. Simulation of warpage induced by non-isothermal crystallization of co-Polypropylene during the SLS process. AIP Conf. Proc. 2014, 1664, 160002. [Google Scholar]

- Pillin, I.; Pimbert, S.; Feller, J.F.; Levesque, G. Crystallization kinetics of poly(butylene terephthalate) (PBT): Influence of additives and free carboxylic acid chain ends. Polym. Eng. Sci. 2001, 41, 178–191. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Powder bed temperature | Tbed | 213–215 °C |

| Piston temperature | Tpiston | 160 °C |

| Cylinder temperature | Tcylinder | 200 °C |

| Powder feed temperature | Tfeed | 170 °C |

| Laser power | PL | 8 W |

| Laser scan speed | vs | 5 m/s |

| Hatch distance | ds | 0.30 mm |

| Layer thickness | tl | 0.12 mm |

| Energy density | ρE | 44.4 J/cm3 |

| Trial # | Speed [rpm] | Nozzle | PBT Content [wt. %] | PEG Content [wt. %] |

|---|---|---|---|---|

| 1 | 30 | ∅ = 1 mm; l = 20 mm | 40 | 60 |

| 2 | 60 | ∅ = 1 mm; l = 20 mm | 40 | 60 |

| 3 | 30 | ∅ = 3 mm; l = 20 mm | 40 | 60 |

| 4 | 60 | ∅ = 3 mm; l = 20 mm | 40 | 60 |

| 5 | 30 | ∅ = 3 mm; l = 10 mm | 40 | 60 |

| 6 | 60 | ∅ = 3 mm; l = 10 mm | 40 | 60 |

| 7 | 30 | Wide slit nozzle (WSN) | 40 | 60 |

| 8 | 60 | Wide slit nozzle (WSN) | 40 | 60 |

| Powder | D10 [µm] | D50 [µm] | D90 [µm] | Volume in 10–100 µm Range [%] |

|---|---|---|---|---|

| As-extruded (30 rpm, WSN) | 5.95 | 37.33 | 156.9 | 67.7 |

| After settling tank | 11.58 | 62.45 | 217.6 | 59.6 |

| After settling tank & sieving | 8.87 | 35.0 | 111.0 | 78.71 |

| Powder | σE [-] | A [-] | S [-] |

|---|---|---|---|

| PBT | 1.06 ± 0.04 | 1.22 ± 0.24 | 0.93 ± 0.02 |

| Duraform® PA | 1.06 ± 0.04 | 1.58 ± 0.39 | 0.87 ± 0.06 |

| iCoPP | 1.04 ± 0.02 | 1.10 ± 0.13 | 0.94 ± 0.03 |

| Powder | αA [°] | fA [-] | HR [-] |

|---|---|---|---|

| PBT | 42.05 ± 3.52 | 1.51 ± 0.16 | 1.097 |

| Duraform® PA | 43.76 ± 4.25 | 1.48 ± 0.20 | 1.221 |

| iCoPP | 45.01 ± 6.24 | 1.56 ± 0.26 | 1.236 |

| Material/Method | E [MPa] | σM [MPa] | EaB [%] |

|---|---|---|---|

| PBT Powder/SLS | 2211.4 ± 39 | 20.3 ± 2.30 | 0.98 ± 0.1 |

| PBT Granulate/IM | 2280 ± 199 | 52.7 ± 1.66 | 111.8 ± 23.2 |

| PBT Powder/CM | 1900 ± 378 | 23.9 ± 10.5 | 1.1 ± 0.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kleijnen, R.G.; Schmid, M.; Wegener, K. Production and Processing of a Spherical Polybutylene Terephthalate Powder for Laser Sintering. Appl. Sci. 2019, 9, 1308. https://doi.org/10.3390/app9071308

Kleijnen RG, Schmid M, Wegener K. Production and Processing of a Spherical Polybutylene Terephthalate Powder for Laser Sintering. Applied Sciences. 2019; 9(7):1308. https://doi.org/10.3390/app9071308

Chicago/Turabian StyleKleijnen, Rob G., Manfred Schmid, and Konrad Wegener. 2019. "Production and Processing of a Spherical Polybutylene Terephthalate Powder for Laser Sintering" Applied Sciences 9, no. 7: 1308. https://doi.org/10.3390/app9071308

APA StyleKleijnen, R. G., Schmid, M., & Wegener, K. (2019). Production and Processing of a Spherical Polybutylene Terephthalate Powder for Laser Sintering. Applied Sciences, 9(7), 1308. https://doi.org/10.3390/app9071308