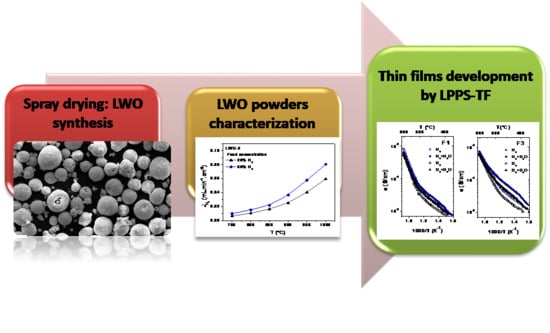

Towards Upscaling of La5.5WO11.25−δ Manufacture for Plasma Spraying-Thin Film Coated Hydrogen Permeable Membranes

Abstract

:1. Introduction

2. Materials and Methods

2.1. Synthesis

2.2. Powder Characterization

2.3. Hydrogen Permeation in Bulk Membranes

2.4. Development and Electrochemical Characterization of Thin Films

3. Results

3.1. Powder Characterization

3.2. Hydrogen Permeation Test

3.3. LWO Thin Films Characterization

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bausá, N.; Escolástico, S.; Serra, J.M. Direct CO2 conversion to syngas in a BaCe0.2Zr0.7Y0.1O3-δ-based proton-conducting electrolysis cell. J. CO2 Util. 2019, 34, 231–238. [Google Scholar] [CrossRef]

- Morejudo, S.H.; Zanón, R.; Escolástico, S.; Yuste-Tirados, I.; Malerød-Fjeld, H.; Vestre, P.K.; Coors, W.G.; Martínez, A.; Norby, T.; Serra, J.M.; et al. Direct conversion of methane to aromatics in a catalytic co-ionic membrane reactor. Science 2016, 353, 563–566. [Google Scholar] [CrossRef] [PubMed]

- Vøllestad, E.; Strandbakke, R.; Tarach, M.; Catalán-Martínez, D.; Fontaine, M.-L.; Beeaff, D.; Clark, D.R.; Serra, J.M.; Norby, T. Mixed proton and electron conducting double perovskite anodes for stable and efficient tubular proton ceramic electrolysers. Nat. Mater. 2019, 18, 752–759. [Google Scholar] [CrossRef] [PubMed]

- Malerød-Fjeld, H.; Clark, D.; Yuste-Tirados, I.; Zanón, R.; Catalán-Martinez, D.; Beeaff, D.; Morejudo, S.H.; Vestre, P.K.; Norby, T.; Haugsrud, R.; et al. Thermo-electrochemical production of compressed hydrogen from methane with near-zero energy loss. Nat. Energy 2017, 2, 923–931. [Google Scholar] [CrossRef]

- Escolástico, S.; Schroeder, M.; Serra, J.M. Optimization of the mixed protonic-electronic conducting materials based on (Nd5/6Ln1/6)5.5WO11.25−δ. J. Mater. Chem. A 2014, 2, 6616–6630. [Google Scholar] [CrossRef]

- Escolastico, S.; Seeger, J.; Roitsch, S.; Ivanova, M.; Meulenberg, W.A.; Serra, J.M. Enhanced H2 separation through mixed proton-electron conducting membranes based on La5.5W0.8M0.2O11.25-δ. ChemSusChem 2013, 6, 1523–1532. [Google Scholar] [CrossRef] [PubMed]

- Escolástico, S.; Somacescu, S.; Serra, J.M. Solid state transport and hydrogen permeation in the system Nd5.5W1-xRexO11.25-δ. Chem. Mater. 2014, 26, 982–992. [Google Scholar] [CrossRef]

- Escolástico, S.; Solís, C.; Scherb, T.; Schumacher, G.; Serra, J.M. Hydrogen separation in La5.5WO11.25-δ membranes. J. Membr. Sci. 2013, 444, 276–284. [Google Scholar] [CrossRef]

- Escolástico, S.; Somacescu, S.; Serra, J.M. Tailoring mixed ionic-electronic conduction in H2 permeable membranes based on the system Nd5.5W1-xMoxO11.25-δ. J. Mater. Chem. A 2015, 3, 719–731. [Google Scholar] [CrossRef]

- Escolástico, S.; Stournari, V.; Malzbender, J.; Haas-Santo, K.; Dittmeyer, R.; Serra, J.M. Chemical stability in H2S and creep characterization of the mixed protonic conductor Nd5.5WO11.25-Δ. Int. J. Hydrog. Energy 2018, 43, 8342–8354. [Google Scholar] [CrossRef]

- Magrasó, A.; Frontera, C.; Marrero-López, D.; Núñez, P. New crystal structure and characterization of lanthanum tungstate “La6WO12” prepared by freeze-drying synthesis. Dalt. Trans. 2009, 10273–10283. [Google Scholar] [CrossRef] [PubMed]

- Seeger, J.; Ivanova, M.E.; Meulenberg, W.A.; Sebold, D.; Stöver, D.; Scherb, T.; Schumacher, G.; Escolástico, S.; Solís, C.; Serra, J.M. Synthesis and characterization of nonsubstituted and substituted proton-conducting La6-xWO12-y. Inorg. Chem. 2013, 52, 10375–10386. [Google Scholar] [CrossRef] [PubMed]

- Solís, C.; Navarrete, L.; Balaguer, M.; Serra, J.M. Development and understanding of La0.85Sr0.15Cr 1-xNixO3-δ anodes for La5.6WO11.4-δ-based proton conducting solid oxide fuel cells. J. Power Sources 2014, 258, 98–107. [Google Scholar] [CrossRef]

- Solís, C.; Balaguer, M.; Bozza, F.; Bonanos, N.; Serra, J.M. Catalytic surface promotion of highly active La0.85Sr0.15Cr0.8Ni0.2O3-δ anodes for La5.6WO11.4-δ based proton conducting fuel cells. Appl. Catal. B Environ. 2014, 147, 203–207. [Google Scholar] [CrossRef] [Green Version]

- Escolástico, S.; Solís, C.; Kjølseth, C.; Serra, J.M. Outstanding hydrogen permeation through CO2-stable dual-phase ceramic membranes. Energy Environ. Sci. 2014, 7, 3736–3746. [Google Scholar] [CrossRef]

- Escolástico, S.; Kjølseth, C.; Serra, J.M. Catalytic activation of ceramic H2 membranes for CMR processes. J. Membr. Sci. 2016, 517, 57–63. [Google Scholar] [CrossRef]

- Escolástico, S.; Solís, C.; Kjølseth, C.; Serra, J.M. Catalytic layer optimization for hydrogen permeation membranes based on La5.5WO11.25-δ/La0.87Sr0.13CrO3-δ composites. ACS Appl. Mater. Interfaces 2017, 9, 35749–35756. [Google Scholar] [CrossRef]

- Ivanova, M.E.; Deibert, W.; Marcano, D.; Escolástico, S.; Mauer, G.; Meulenberg, W.A.; Bram, M.; Serra, J.M.; Vaßen, R.; Guillon, O. Lanthanum tungstate membranes for H2 extraction and CO2 utilization: Fabrication strategies based on sequential tape casting and plasma-spray physical vapor deposition. Sep. Purif. Technol. 2019, 219, 100–112. [Google Scholar] [CrossRef]

- Deibert, W.; Ivanova, M.E.; Meulenberg, W.A.; Vaßen, R.; Guillon, O. Preparation and sintering behaviour of La5.4WO12-δ asymmetric membranes with optimised microstructure for hydrogen separation. J. Membr. Sci. 2015, 492, 439–451. [Google Scholar] [CrossRef] [Green Version]

- Bergum, K.; Magrasó, A.; Fjellvåg, H.; Nilsen, O. Thin film fabrication and characterization of proton conducting lanthanum tungstate. J. Mater. Chem. A 2014, 2, 18463–18471. [Google Scholar] [CrossRef] [Green Version]

- Pinacci, P.; Louradour, E.; Wimbert, L.; Gindrat, M.; Jarligo, M.O.; Vassen, R.; Comite, A.; Serra, J.M.; Jewulski, J.; Mancuso, L.; et al. Dense membranes for oxygen and hydrogen separation (DEMOYS): Project overview and first results. Energy Procedia 2013, 37, 1030–1038. [Google Scholar] [CrossRef] [Green Version]

- Noh, J.S.; Schwarz, J.A. Estimation of the point of zero charge of simple oxides by mass titration. J. Colloid Interface Sci. 1989, 130, 157–164. [Google Scholar] [CrossRef]

- Gindrat, M.; Damani, R. LPPS hybrid technologies for emerging energy applications—Recent developments. In Proceedings of the International Thermal Spray Conference, Hamburg, Germany, 27–29 September 2011. [Google Scholar]

- Zhang, C.; Liao, H.-L.; Li, W.-Y.; Zhang, G.; Coddet, C.; Li, C.-J.; Li, C.-X.; Ning, X.-J. Characterization of YSZ solid oxide fuel cells electrolyte deposited by atmospheric plasma spraying and low pressure plasma spraying. J. Spray Technol. 2006, 15, 598–603. [Google Scholar] [CrossRef]

- Zhang, N.; Yi, R.; Zhou, L.; Gao, G.; Shi, R.; Qiu, G.; Liu, X. Lanthanide hydroxide nanorods and their thermal decomposition to lanthanide oxide nanorods. Mater. Chem. Phys. 2009, 114, 160–167. [Google Scholar] [CrossRef]

- Naito, M.; Yokoyama, T.; Hosokawa, K.; Nogi, K. Nanoparticle Technology Handbook; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Haugsrud, R.; Kjølseth, C. Effects of protons and acceptor substitution on the electrical conductivity of La6WO12. J. Phys. Chem. Solids 2008, 69, 1758–1765. [Google Scholar] [CrossRef]

- Ivanova, M.E.; Seeger, J.; Serra, J.M.; Solis, C.; Meulenberg, W.A.; Fischer, W.; Roitsch, S.; Buchkremer, H.P. Influence of the La6W2O15 phase on the properties and integrity of La6-xWO12-d–based membranes. Chem. Mater. Res. 2012, 2, 56–81. [Google Scholar]

| Sample ID | Mean Diameter (µm) |

|---|---|

| LWO-1 | <30 |

| LWO-2 | >30 |

| LWO-3 | >45 |

| Lwo Films | Plasma Parameter | Powder | Other | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Run | Thickness (µm) | Ar Flow (L/min) | He Flow (L/min) | H2 Flow (L/min) | Current (A) | Power (kW) | Feed Rate (g/min) | Carrier Gas (L/min) | Standoff (mm) | O2 Flow (L/min) | Coating Time (s) |

| F1 | 77 | 100 | 20 | 0 | 2600 | 118 | 2 × 20 | 2 × 6 | 1000 | 2 | 45 |

| F2 | 120 | 120 | 20 | 0 | 2600 | 123 | 2 × 20 | 2 × 6 | 1000 | 2 | 60 |

| F3 | 71 | 120 | 20 | 0 | 2600 | 123 | 2 × 20 | 2 × 6 | 1300 | 2 | 60 |

| At % Element | LWO-1 | LWO-2 | LWO-3 |

|---|---|---|---|

| La | 30.8 | 30.5 | 31.4 |

| W | 5.7 | 5.9 | 5.4 |

| O | 63.5 | 63.6 | 63.2 |

| Formula | La5.3WO11 | La5.1WO10.8 | La5.8WO11.7 |

| Atmosphere | F1 | F3 | ||||||

|---|---|---|---|---|---|---|---|---|

| 350–600 °C | 600–800 °C | 350–600 °C | 600–800 °C | |||||

| A | Ea | A | Ea | A | Ea | A | Ea | |

| (S·K/cm) | (eV) | (S·K/cm) | (eV) | (S·K/cm) | (eV) | (S·K/cm) | (eV) | |

| He | 190 | 0.66 | 183,000 | 1.19 | 21,800 | 1.03 | 71,000 | 1.12 |

| He + H2O | 91 | 0.56 | 22,000 | 0.98 | 79 | 0.50 | 1700 | 0.74 |

| He + D2O | 43.8 | 0.52 | 92,000 | 1.12 | 53 | 0.51 | 5400 | 0.86 |

| H2 | 21 | 0.47 | 680,000 | 1.26 | 26.8 | 0.43 | 15,000 | 0.89 |

| H2 + H2O | 17 | 0.44 | 48,000 | 1.05 | 44.5 | 0.45 | 2100 | 0.75 |

| D2 | 16 | 0.48 | 1.4 × 106 | 1.36 | 25 | 0.45 | 74,000 | 1.05 |

| D2 + D2O | 15 | 0.45 | 4.2 × 105 | 1.25 | 42 | 0.45 | 8400 | 0.86 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Escolástico, S.; Solís, C.; Comite, A.; Azzurri, F.; Gindrat, M.; Moser, S.; Rauch, J.; Szyndelman, G.; Damani, R.; Serra, J.M. Towards Upscaling of La5.5WO11.25−δ Manufacture for Plasma Spraying-Thin Film Coated Hydrogen Permeable Membranes. Membranes 2020, 10, 192. https://doi.org/10.3390/membranes10090192

Escolástico S, Solís C, Comite A, Azzurri F, Gindrat M, Moser S, Rauch J, Szyndelman G, Damani R, Serra JM. Towards Upscaling of La5.5WO11.25−δ Manufacture for Plasma Spraying-Thin Film Coated Hydrogen Permeable Membranes. Membranes. 2020; 10(9):192. https://doi.org/10.3390/membranes10090192

Chicago/Turabian StyleEscolástico, Sonia, Cecilia Solís, Antonio Comite, Fiorenza Azzurri, Malko Gindrat, Stefan Moser, Johannes Rauch, Gregory Szyndelman, Rajiv Damani, and Jose M. Serra. 2020. "Towards Upscaling of La5.5WO11.25−δ Manufacture for Plasma Spraying-Thin Film Coated Hydrogen Permeable Membranes" Membranes 10, no. 9: 192. https://doi.org/10.3390/membranes10090192

APA StyleEscolástico, S., Solís, C., Comite, A., Azzurri, F., Gindrat, M., Moser, S., Rauch, J., Szyndelman, G., Damani, R., & Serra, J. M. (2020). Towards Upscaling of La5.5WO11.25−δ Manufacture for Plasma Spraying-Thin Film Coated Hydrogen Permeable Membranes. Membranes, 10(9), 192. https://doi.org/10.3390/membranes10090192