Life Cycle Assessment of Sustainable Broiler Production Systems: Effects of Low-Protein Diet and Litter Incineration

Abstract

:1. Introduction

2. Materials and Methods

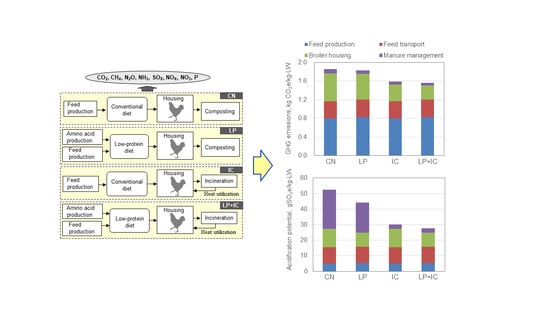

2.1. System Description

2.2. Life Cycle Inventory

2.3. Impact Assessment

2.4. Sensitivity Analysis

3. Results

4. Discussion

4.1. Comparison of the Four Broiler Production Systems

4.2. Environmental Impacts of Broiler Production Systems

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- FAO. FAOSTAT. Production–Livestock Primary; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020. [Google Scholar]

- OECD-FAO. OECD-FAO Agricultural Outlook 2020–2029; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020; Available online: http://www.fao.org/publications/oecd-fao-agricultural-outlook/2020-2029/en/ (accessed on 14 August 2021).

- FAO. Poultry Development Review; Food and Agriculture Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- De Vries, M.; de Boer, I.J.M. Comparing environmental impacts for livestock products: A review of life cycle assessments. Livest. Sci. 2010, 128, 1–11. [Google Scholar] [CrossRef]

- Poore, J.; Nemecek, T. Reducing food’s environmental impacts through producers and consumers. Science 2018, 360, 987–992. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Misselbrook, T.H.; Van der Weerden, T.J.; Pain, B.F.; Jarvis, S.C.; Chambers, B.J.; Smith, K.A.; Phillips, V.R.; Demmers, T.G.M. Ammonia emission factors for UK agriculture. Atmos. Environ. 2000, 34, 871–880. [Google Scholar] [CrossRef]

- Hojito, M.; Ikeguchi, A.; Kohyama, K.; Shimada, K.; Ogino, A.; Mishima, S.; Kaku, K. Estimation of nitrogen loading in Japanese prefectures and scenario testing of abatement strategies. Jpn. J. Soil Sci. Plant. Nutr. 2003, 74, 467–474. [Google Scholar]

- Kidd, M.T.; Maynard, C.W.; Mullenix, G.J. Progress of amino acid nutrition for diet protein reduction in poultry. J. Anim. Sci. Biotechnol. 2021, 12, 45. [Google Scholar] [CrossRef] [PubMed]

- Selle, P.H.; de Paula Dorigam, J.C.; Lemme, A.; Chrystal, P.V.; Liu, S.Y. Synthetic and crystalline amino acids: Alternatives to soybean meal in chicken-meat production. Animals 2020, 10, 729. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dagnall, S.; Hill, J.; Pegg, D. Resource mapping and analysis of farm livestock manures — Assessing the opportunities for biomass-to-energy schemes. Bioresour. Technol. 2000, 71, 225–234. [Google Scholar] [CrossRef]

- Kelleher, B.P.; Leahy, J.J.; Henihan, A.M.; O’Dwyer, T.F.; Sutton, D.; Leahy, M.J. Advances in poultry litter disposal technology—A review. Bioresour. Technol. 2002, 83, 27–36. [Google Scholar] [CrossRef]

- Santos Dalólio, F.; da Silva, J.N.; de Oliveira, A.C.C.; de Fátima Ferreira Tinôco, I.; Barbosa, R.C.; de Oliveira Resende, M.; Albino, L.F.T.; Coelho, S.T. Poultry litter as biomass energy: A review and future perspectives. Renew. Sustain. Energy Rev. 2017, 76, 941–949. [Google Scholar] [CrossRef]

- ISO. Environmental Management—Life Cycle Assessment—Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006; Available online: https://www.iso.org/standard/37456.html (accessed on 14 August 2021).

- Pelletier, N. Environmental performance in the US broiler poultry sector: Life cycle energy use and greenhouse gas, ozone depleting, acidifying and eutrophying emissions. Agric. Syst. 2008, 98, 67–73. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G.; Wiseman, J.; Guy, J.; Kyriazakis, I. Predicting the environmental impacts of chicken systems in the United Kingdom through a life cycle assessment: Broiler production systems. Poult. Sci. 2012, 91, 8–25. [Google Scholar] [CrossRef]

- Da Silva, V.P.; van der Werf, H.M.G.; Soares, S.R.; Corson, M.S. Environmental impacts of French and Brazilian broiler chicken production scenarios: An LCA approach. J. Environ. Manag. 2014, 133, 222–231. [Google Scholar] [CrossRef]

- Costantini, M.; Ferrante, V.; Guarino, M.; Bacenetti, J. Environmental sustainability assessment of poultry productions through life cycle approaches: A critical review. Trends Food Sci. Technol. 2021, 110, 201–212. [Google Scholar] [CrossRef]

- De Boer, I.J.M. Environmental impact assessment of conventional and organic milk production. Livest. Prod. Sci. 2003, 80, 69–77. [Google Scholar] [CrossRef]

- Lorenz, H.; Reinsch, T.; Hess, S.; Taube, F. Is low-input dairy farming more climate friendly? A meta-analysis of the carbon footprints of different production systems. J. Clean. Prod. 2019, 211, 161–170. [Google Scholar] [CrossRef]

- Ogino, A.; Kaku, K.; Osada, T.; Shimada, K. Environmental impacts of the Japanese beef-fattening system with different feeding lengths as evaluated by a life-cycle assessment method. J. Anim. Sci. 2004, 82, 2115–2122. [Google Scholar] [CrossRef]

- Cusack, D.F.; Kazanski, C.E.; Hedgpeth, A.; Chow, K.; Cordeiro, A.L.; Karpman, J.; Ryals, R. Reducing climate impacts of beef production: A synthesis of life cycle assessments across management systems and global regions. Glob. Chang. Biol. 2021, 27, 1721–1736. [Google Scholar] [CrossRef] [PubMed]

- Basset-Mens, C.; van der Werf, H.M.G. Scenario-based environmental assessment of farming systems: The case of pig production in France. Agric. Ecosyst. Environ. 2005, 105, 127–144. [Google Scholar] [CrossRef]

- McAuliffe, G.A.; Chapman, D.V.; Sage, C.L. A thematic review of life cycle assessment (LCA) applied to pig production. Environ. Impact Assess. Rev. 2016, 56, 12–22. [Google Scholar] [CrossRef]

- Costa, M.P.; Schoeneboom, J.C.; Oliveira, S.A.; Viñas, R.S.; de Medeiros, G.A. A socio-eco-efficiency analysis of integrated and non-integrated crop-livestock-forestry systems in the Brazilian Cerrado based on LCA. J. Clean. Prod. 2018, 171, 1460–1471. [Google Scholar] [CrossRef] [Green Version]

- Ogino, A.; Van Thu, N.; Hosen, Y.; Izumi, T.; Suzuki, T.; Sakai, T.; Ando, S.; Osada, T.; Kawashima, T. Environmental impacts of a rice-beef-biogas integrated system in the Mekong Delta, Vietnam evaluated by life cycle assessment. J. Environ. Manag. 2021, 294, 112900. [Google Scholar] [CrossRef]

- Ogino, A.; Murakami, H.; Yamashita, T.; Furuya, M.; Kawahara, H.; Ohkubo, T.; Osada, T. Estimation of nutrient excretion factors of broiler and layer chickens in Japan. Anim. Sci. J. 2017, 88, 659–668. [Google Scholar] [CrossRef] [PubMed]

- Aviagen, I. Ross Broiler Nutrition Specifications 2019; Aviagen: Huntsville, AL, USA, 2019. [Google Scholar]

- JEMAI. LCA Software MiLCA. Available online: http://www.milca-milca.net/english/index.php (accessed on 13 March 2014).

- Ajinomoto. CO2 Emission Factor Database for Food-Related Materials; Ajinomoto Co., Inc.: Tokyo, Japan, 2010. [Google Scholar]

- Wathes, C.M.; Holden, M.R.; Sneath, R.W.; White, R.P.; Phillips, V.R. Concentrations and emission rates of aerial ammonia, nitrous oxide, methane, carbon dioxide, dust and endotoxin in UK broiler and layer houses. Br. Poult. Sci. 1997, 38, 14–28. [Google Scholar] [CrossRef] [PubMed]

- GIO (Greenhouse Gas Inventory Office of Japan); MOE (Ministry of the Environment, Japan). National Greenhouse Gas. Inventory Report of JAPAN 2020; Center for Global Environmental Research, National Institute for Environmental Studies: Tsukuba, Japan, 2020.

- Morand, P.; Peres, G.; Robin, P.; Yulipriyanto, H.; Baron, S. Gaseous emissions from composting bark/manure mixtures. Compost Sci. Util. 2005, 13, 14–26. [Google Scholar] [CrossRef]

- Billen, P.; Costa, J.; Van der Aa, L.; Van Caneghem, J.; Vandecasteele, C. Electricity from poultry manure: A cleaner alternative to direct land application. J. Clean. Prod. 2015, 96, 467–475. [Google Scholar] [CrossRef]

- EEA (European Environment Agency). EMEP/EEA Air Pollutant Emission Inventory Guidebook 2019; European Environment Agency: Copenhagen, Denmark, 2019; Available online: https://www.eea.europa.eu/publications/emep-eea-guidebook-2019 (accessed on 14 August 2021).

- Demmers, T.G.M.; Burgess, L.R.; Short, J.L.; Philips, V.R.; Clark, J.A.; Wathes, C.M. Ammonia emissions from two mechanically ventilated UK livestock buildings. Atmos. Environ. 1999, 33, 217–227. [Google Scholar] [CrossRef]

- Koerkamp, P.W.G.G.; Metz, J.H.M.; Uenk, G.H.; Phillips, V.R.; Holden, M.R.; Sneath, R.W.; Short, J.L.; White, R.P.; Hartung, J.; Seedorf, J.; et al. Concentrations and emissions of ammonia in livestock buildings in Northern Europe. J. Agric. Eng. Res. 1998, 70, 79–95. [Google Scholar] [CrossRef]

- Hayes, E.T.; Curran, T.P.; Dodd, V.A. Odour and ammonia emissions from intensive poultry units in Ireland. Bioresour. Technol. 2006, 97, 933–939. [Google Scholar] [CrossRef] [Green Version]

- Wheeler, E.F.; Casey, K.D.; Gates, R.S.; Xin, H.; Zajaczkowski, J.L.; Topper, P.A.; Liang, Y.; Pescatore, A.J. Ammonia emissions from twelve US broiler chicken houses. Trans. ASABE 2006, 49, 1495–1512. Available online: https://www.nal.usda.gov/exhibits/ipd/frostonchickens/exhibits/show/henhouses/item/290 (accessed on 14 August 2021).

- USDA-ERS. Farm. Business and Household Survey Data: Customized Data Summaries From Agricultural Resources and Management Survey (ARMS); United States Department of Agriculture, Economic Research Service: Washington, DC, USA, 2009.

- Wang, M. GREET 1.8b; Argonne National Laboratory: Argonne, IL, USA, 2008. [Google Scholar]

- Mosnier, E.; van der Werf, H.M.G.; Boissy, J.; Dourmad, J.-Y. Evaluation of the environmental implications of the incorporation of feed-use amino acids in the manufacturing of pig and broiler feeds using Life Cycle Assessment. Animal 2011, 5, 1972–1983. [Google Scholar] [CrossRef] [Green Version]

- IPCC. 2006 IPCC Guidelines for National Greenhouse Gas. Inventories; Institute for Global Environmental Strategies (IGES): Hayama, Japan, 2006. [Google Scholar]

- Bouwman, A.F.; Boumans, L.J.M.; Batjes, N.H. Estimation of global NH3 volatilization loss from synthetic fertilizers and animal manure applied to arable lands and grasslands. Glob. Biogeochem. Cycles 2002, 16, 1024. [Google Scholar] [CrossRef]

- MOF (Ministry of Finance). Trade Statistics of Japan; Ministry of Finance: Tokyo, Japan, 2019.

- Sato, K. Life cycle CO2 emissions from soy oil and soymeal production. In Life Cycle Assessment of Foods and Development of a Sustainability Indicator for Agro-Food Consumption and Production; Food Study Group, Inst. LCA Jpn: Tokyo, Japan, 2006. [Google Scholar]

- AFFTIS. Investigation of Energy-Managing Agricultural Production System Development [In Japanese]; Agriculture, Forestry and Fisheries Technology Information Society: Tokyo, Japan, 2000. [Google Scholar]

- LEIO. A Guide to Treatment and Utilization of Livestock Manure; Livestock Environment Improvement Organization: Tokyo, Japan, 1998. [Google Scholar]

- NARO. Japanese Feeding Standard for Poultry, 2011; Japan Livestock Industry Association: Tokyo, Japan, 2012.

- NARO. Standard Tables of Feed Composition in Japan, 2009; Japan Livestock Industry Association: Tokyo, Japan, 2010.

- IPCC. Climate Change 2007: The Physical Science Basis; Intergovernmental Panel on Climate Change: Geneva, Switzerland, 2007. [Google Scholar]

- Heijungs, R.; Guinee, J.; Huppes, G.; Lankreijer, R.M.; de Haes, H.A.U.; Sleeswijk, A.W.; Ansems, A.M.M.; Eggels, P.G.; Van Duin, R.; De, G.P. Environmental Life Cycle Assessment of Products–Guide; Center of Environmental Science (CML) Leiden University: Leiden, The Netherlands, 1992. [Google Scholar]

- Garcia-Launay, F.; van der Werf, H.M.G.; Nguyen, T.T.H.; Tutour, L.L.; Dourmad, J.Y. Evaluation of the environmental implications of the incorporation of feed-use amino acids in pig production using Life Cycle Assessment. Livest. Sci. 2014, 161, 158–175. [Google Scholar] [CrossRef]

- Panichelli, L.; Dauriat, A.; Gnansounou, E. Life cycle assessment of soybean-based biodiesel in Argentina for export. Int. J. Life Cycle Assess. 2009, 14, 144–159. [Google Scholar] [CrossRef] [Green Version]

- Ogino, A.; Osada, T.; Takada, R.; Takagi, T.; Tsujimoto, S.; Tonoue, T.; Matsui, D.; Katsumata, M.; Yamashita, T.; Tanaka, Y. Life cycle assessment of Japanese pig farming using low-protein diet supplemented with amino acids. Soil Sci. Plant. Nutr. 2013, 59, 107–118. [Google Scholar] [CrossRef]

- Leinonen, I.; Williams, A.G. Effects of dietary protease on nitrogen emissions from broiler production: A holistic comparison using Life Cycle Assessment. J. Sci. Food Agric. 2015, 95, 3041–3046. [Google Scholar] [CrossRef] [Green Version]

- Ogino, A.; Ishida, M.; Ohmori, H.; Tanaka, Y.; Yamashita, T.; Yokoyama, H.; Tatsugawa, K.; Ijiri, S.; Kawashima, T. Life cycle assessment of animal feeds prepared from liquid food residues: A case study of rice-washing water. J. Environ. Qual. 2012, 41, 1982–1988. [Google Scholar] [CrossRef] [PubMed]

- Oshita, K.; Sun, X.C.; Taniguchi, M.; Takaoka, M.; Matsukawa, K.; Fujiwara, T. Emission of greenhouse gases from controlled incineration of cattle manure. Environ. Technol. 2012, 33, 1539–1544. [Google Scholar] [CrossRef]

- Monteiro, A.N.; Garcia-Launay, F.; Brossard, L.; Wilfart, A.; Dourmad, J.Y. Effect of feeding strategy on environmental impacts of pig fattening in different contexts of production: Evaluation through life cycle assessment. J. Anim. Sci. 2016, 94, 4832–4847. [Google Scholar] [CrossRef]

- González-García, S.; Gomez-Fernández, Z.; Dias, A.C.; Feijoo, G.; Moreira, M.T.; Arroja, L. Life Cycle Assessment of broiler chicken production: A Portuguese case study. J. Clean. Prod. 2014, 74, 125–134. [Google Scholar] [CrossRef]

- Da Silva Lima, N.D.; de Alencar Nääs, I.; Garcia, R.G.; de Moura, D.J. Environmental impact of Brazilian broiler production process: Evaluation using life cycle assessment. J. Clean. Prod. 2019, 237, 117752. [Google Scholar] [CrossRef]

- Giannenas, I.; Bonos, E.; Anestis, V.; Filioussis, G.; Papanastasiou, D.K.; Bartzanas, T.; Papaioannou, N.; Tzora, A.; Skoufos, I. Effects of protease addition and replacement of soybean meal by corn gluten meal on the growth of broilers and on the environmental performances of a broiler production system in Greece. PLoS ONE 2017, 12, e0169511. [Google Scholar] [CrossRef] [PubMed]

- Cesari, V.; Zucali, M.; Sandrucci, A.; Tamburini, A.; Bava, L.; Toschi, I. Environmental impact assessment of an Italian vertically integrated broiler system through a Life Cycle approach. J. Clean. Prod. 2017, 143, 904–911. [Google Scholar] [CrossRef]

| First Stage | Second Stage | |||

|---|---|---|---|---|

| Conventional | Low-Protein | Conventional | Low-Protein | |

| Corn | 54.17 | 56.35 | 58.07 | 65.55 |

| Soybean meal | 30.70 | 30.00 | 32.90 | 25.00 |

| Vegetable oil | 5.50 | 5.50 | 5.50 | 5.50 |

| Corn gluten meal | 4.90 | 3.30 | 0.00 | 0.00 |

| DL-methionine | 0.33 | 0.37 | 0.27 | 0.34 |

| L-lysine, HCl | 0.40 | 0.44 | 0.08 | 0.32 |

| L-threonine | 0.15 | 0.19 | 0.04 | 0.15 |

| Calcium carbonate | 1.00 | 1.00 | 0.75 | 0.75 |

| Tricalcium phosphate | 1.90 | 1.90 | 1.45 | 1.45 |

| Salt | 0.37 | 0.37 | 0.31 | 0.31 |

| Vitamins and minerals | 0.58 | 0.58 | 0.63 | 0.63 |

| CP | 21.72 | 20.64 | 19.48 | 16.83 |

| Composting | Ref. | Incineration | Ref. | |

|---|---|---|---|---|

| Animal housing: | ||||

| CH4, mgCH4/kg BW/d | 12.0 | Wathes et al., 1997 [30] | 12.0 | Wathes et al., 1997 [30] |

| N2O, mgN2O-N/kg BW/d | 18.0 a | Wathes et al., 1997 [30] | 18.0 a | Wathes et al., 1997 [30] |

| NH3, mgNH3-N/animal/d | 299.0 a | See the footnote b | 299.0 a | See the footnote b |

| Manure management: | ||||

| CH4, % c | 0.02 | GIO 2020 [31] | 0.40 | GIO 2020 [31] |

| N2O, % (N2O-N) | 0.08 | GIO 2020 [31] | 0.10 | GIO 2020 [31] |

| NH3, % (NH3-N) | 42.0 | Morand et al., 2005 [32] | 0.06 | Billen et al., 2015 [33] |

| NOX, kg/Mg manure | 0 | – | 4.99 | EEA 2019 [34] |

| CNV | LP + IC Baseline | LP + IC High N2O b | LP + IC Warmer Region c | LP + IC LULUC d | |

|---|---|---|---|---|---|

| GHG emissions, kg CO2e a | 1.86 | 84% | 88% | 90% | 84% |

| Acidification potential, g SO2e | 52.6 | 52% | 52% | 52% | 52% |

| Eutrophication potential, g PO4e | 18.3 | 76% | 76% | 76% | 76% |

| Energy consumption, MJ | 18.8 | 85% | 85% | 92% | 85% |

| System | Country | GWP, kg CO2e | AP, g SO2e | EP, g PO4e | EC, MJ | LULUC a | Slaughter Age, d | Slaughter Weight, kg | Ref. (First Author) |

|---|---|---|---|---|---|---|---|---|---|

| Per kg Liveweight | |||||||||

| Conventional | Japan | 1.86 | 52.6 | 18.3 | 18.8 | N | 52 | 3.06 | This study |

| Low-protein + litter incineration | Japan | 1.57 | 27.6 | 13.8 | 15.9 | N | 52 | 3.06 | This study |

| Conventional | Japan | 2.03 | 52.6 | 18.3 | 18.8 | Y | 52 | 3.06 | This study |

| Low-protein + litter incineration | Japan | 1.71 | 27.6 | 13.8 | 15.9 | Y | 52 | 3.06 | This study |

| Contemporary | USA | 1.40 | 15.8 | 3.9 | 15.0 | N | 48 | 2.26 | Pelletier 2008 [14] |

| Standard | UK | 2.91 | 30.8 | 13.4 | 16.7 | Y | 39 | 1.95 | Leinonen 2012 [15] |

| Free range | UK | 3.39 | 39.4 | 16.0 | 16.9 | Y | 58 | 2.06 | Leinonen 2012 [15] |

| Organic | UK | 3.73 | 60.4 | 32.2 | 26.6 | Y | 73 | 2.17 | Leinonen 2012 [15] |

| Standard | France | 2.22 | 28.7 | 13.8 | 19.1 | Y | 40 | 1.92 | Prudêncio da Silva 2014 [16] |

| High-quality | France | 2.70 | 47.2 | 19.3 | 29.5 | Y | 89 | 2.26 | Prudêncio da Silva 2014 [16] |

| Brazilian Center-West | Brazil | 2.06 | 31.4 | 14.0 | 18.0 | Y | 42 | 2.40 | Prudêncio da Silva 2014 [16] |

| Brazilian South | Brazil | 1.45 | 34.5 | 14.4 | 19.1 | Y | 42 | 2.48 | Prudêncio da Silva 2014 [16] |

| Conventional | Portugal | 1.62 | 28.5 | 13.4 | 10.2 | N | 34 | 1.70 | González-García 2014 [59] |

| Brazilian Center-West | Brazil | 2.70 | 40.0 | 26.0 | 15.0 | Y | 50 | 2.84 | Duarte da Silva Lima 2019 [60] |

| Soybean meal | Greece | 4.21 | 32.4 | 17.8 | 14.9 | Y | 42 | 2.42 | Giannenas 2017 [61] |

| Soybean meal + protease | Greece | 3.92 | 31.2 | 17.5 | 14.7 | Y | 42 | 2.39 | Giannenas 2017 [61] |

| Corn gluten meal | Greece | 1.63 | 28.7 | 17.5 | 15.4 | Y | 42 | 2.26 | Giannenas 2017 [61] |

| Light broilers | Italy | 3.03 | 14.3 | 10.0 | 10.2 | Y | 32 | 1.60 | Cesari 2017 [62] |

| Medium broilers | Italy | 3.25 | 15.8 | 10.6 | 10.7 | Y | 40 | 2.50 | Cesari 2017 [62] |

| Roasters (heavy) | Italy | 3.84 | 19.2 | 12.8 | 12.4 | Y | 53 | 3.80 | Cesari 2017 [62] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ogino, A.; Oishi, K.; Setoguchi, A.; Osada, T. Life Cycle Assessment of Sustainable Broiler Production Systems: Effects of Low-Protein Diet and Litter Incineration. Agriculture 2021, 11, 921. https://doi.org/10.3390/agriculture11100921

Ogino A, Oishi K, Setoguchi A, Osada T. Life Cycle Assessment of Sustainable Broiler Production Systems: Effects of Low-Protein Diet and Litter Incineration. Agriculture. 2021; 11(10):921. https://doi.org/10.3390/agriculture11100921

Chicago/Turabian StyleOgino, Akifumi, Kazato Oishi, Akira Setoguchi, and Takashi Osada. 2021. "Life Cycle Assessment of Sustainable Broiler Production Systems: Effects of Low-Protein Diet and Litter Incineration" Agriculture 11, no. 10: 921. https://doi.org/10.3390/agriculture11100921

APA StyleOgino, A., Oishi, K., Setoguchi, A., & Osada, T. (2021). Life Cycle Assessment of Sustainable Broiler Production Systems: Effects of Low-Protein Diet and Litter Incineration. Agriculture, 11(10), 921. https://doi.org/10.3390/agriculture11100921