Design and Evaluation of a Mechanical Floor-Standing Jujube Picker

Abstract

:1. Introduction

2. Materials and Methods

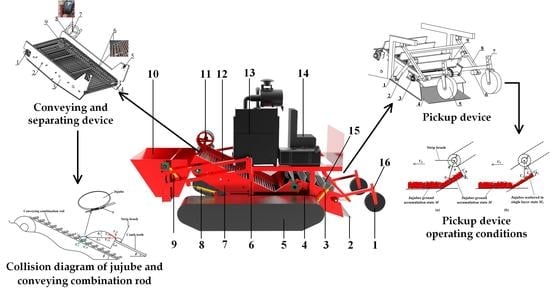

2.1. Machine Structure

2.2. Operating Principle of the Entire Machine

2.3. Design of the Pickup Device

2.3.1. Structural Design of Pickup Device

2.3.2. Determination of Structural Parameters of the Pickup Device

2.3.3. Analysis of Conditions Meeting the Requirements of the Jujube Picking Operation

2.4. Conveying and Separating Device

2.4.1. Structural Design of the Conveying and Separating Device

2.4.2. Analysis of the Contact Process between the Jujubes and Conveying Combination Rod

2.5. Test Materials

2.6. Test Methods

2.7. Test Results

3. Result and Discussion

- (1)

- Establishment of the regression equation and significance analysis of the pickup rate

- (2)

- Establishment of the regression equation and significance analysis of the breakage rate

- (3)

- Establishment and significance analysis of the impurity rate regression equation

3.1. Response Surface Analysis

- (1)

- Influence analysis of the pickup rate.

- (2)

- Analysis of the influence of the breakage rate

- (3)

- Analysis of the influence of the impurity rate.

3.2. Parameter Optimization and Test Verification

3.3. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fan, X.; Zhang, H.; Li, C.; Meng, W. Present situation and development suggestions of jujube harvester in Xinjiang. Xinjiang Agric. Mech. 2013, 6, 40–41. [Google Scholar]

- Liang, H. On the Actuality, Existing Problems and Solutions to the Industry of the Chinese Jujube; Shaanxi Normal University: Xi’an, China, 2006. [Google Scholar]

- Ma, X.P. Xinjiang Characteristic Product Marketing Strategy Research; Sichuan Normal University: Chengdu, China, 2016. [Google Scholar]

- Wang, Y.K. Study on the Changes of Xinjiang Jujube Production Layout and Its Influencing Factors; Xinjiang Normal University: Kashi, China, 2020. [Google Scholar]

- Zheng, W. Study on current situation and countermeasures about mechanization of the fruit industry in Xinjiang. Xinjiang Agric. Mech. 2019, 3, 7–9+13. [Google Scholar]

- Lu, B. Design and Experimental Study of Electric Self-Propelled Ground Jujube Harvester by Cleaning and Collecting; Tarim University: Alar, China, 2017. [Google Scholar]

- Zhou, Y.; Kan, Z.; Li, C.; Zhang, H.; Fu, W.; Cui, J. The research and development of the falling tree fruits and nuts collect and pick-up technology. Agric. Mech. Res. 2017, 39, 256–263. [Google Scholar]

- Sumner, H.R.; Hedden, S.L. Design and performance of a citrus rake-pickup machine. Trans. ASAE 1974, 17, 209–211. [Google Scholar] [CrossRef]

- Oxbo International Corp. Article Pickup Apparatus. U.S. Patent US20070137162A, 21 June 2007. [Google Scholar]

- Zhang, X.; Bai, S.; Jin, W.; Yuan, P.; Yu, M.; Yan, J.; Zhang, C. Development of pneumatic collecting machine of jujube in dwarfing and closer cultivation. Trans. Chin. Soc. Agric. Eng. 2019, 35, 1–9. [Google Scholar]

- Pan, J.B. The Design and Experimental Research of Air Blow Type Ground Jujube Picking Device; Shihezi University: Shihezi, China, 2018. [Google Scholar]

- Lu, B.; Wang, X.; Zhang, P.; Hu, C. Design of new type landing-jujube harvest machine. Agric. Mech. Res. 2017, 39, 68–72. [Google Scholar]

- Wang, C.; Ding, L.; Dou, F.; Kan, Z.; Li, F.; Li, J. Design and experiment of comb type picking device of ground jujube. Shihezi Univ. Nat. Sci. 2021, 39, 409–414. [Google Scholar]

- Yamin, M.; Hamid, S.; Ali, M.A.; Bashir, S.; Iqbal, M.; Ashraf, M. Performance optimization and knife dynamics of power tiller operated reaper during wheat harvesting. Pak. J. Agric. Sci. 2022, 59, 261–268. [Google Scholar]

- Yamin, M.; Ismail, W.I.b.W.; Aziz, S.A.; Kassim, M.S.b.M.; Akbar, F.N.; Ibrahim, M. Design considerations of variable rate liquid fertilizer applicator for mature oil palm trees. Precis. Agric. 2022, 23, 1413–1448. [Google Scholar] [CrossRef]

- Wang, C.X. Experimental Study and Parameter Optimization of Comb-Brush Roller Type Picking Device of Ground Jujube; Shihezi University: Shihezi, China, 2021. [Google Scholar]

- Li, F.N. Design and Experiment of Disc Brush Type Ground Jujube Picking Device; Shihezi University: Shihezi, China, 2021. [Google Scholar]

- Rao, H.; Wang, Y.; Li, Q.; Wang, B.; Yang, J.; Liu, M. Design and experiment of camellia fruit layered harvesting device. Trans. Chin. Soc. Agric. Mach. 2021, 52, 203–212. [Google Scholar]

- Liu, H. Mechanics of Materials; Higher Education Press: Beijing, China, 2011. [Google Scholar]

- Shi, G.; Li, J.; Ding, L.; Kan, Z. Design and Experiment of Inertia Pneumatic Type Cleaner System of Jujube Fruit. Trans. Chin. Soc. Agric. Mach. 2022, 53, 167–176. [Google Scholar]

- Zhang, F.; Yu, F.; Li, Z.; Zhang, H.; Lan, H.; Li, P.; Zhang, C. Design and field testing of the air-suction machine for picking up Chinese jujube fruits. Fruit Sci. 2020, 37, 278–285. [Google Scholar]

- Yu, F.; Li, P.; Zhang, F.; Li, Z.; Zhang, H.; Fan, X. Experiment determination and analysis of suspension velocity characteristics for red jujube. Chin. Agric. Mech. 2020, 41, 99–105. [Google Scholar]

- Fu, W.; Zhang, Z.; Ding, K.; Cao, W.; Kan, Z.; Pan, J.; Liu, Y. Design and test of 4ZZ-4A2 full-hydraulic self-propelled jujube harvester. Int. J. Agric. Biol. Eng. 2018, 11, 98–104. [Google Scholar] [CrossRef]

- Bao, Y.; Yang, C.; Zhao, Y.; Liu, X.; Guo, Y. Collision injury assessment of mechanical harvesting blueberry fruit based on collision deformation energy. Trans. Chin. Soc. Agric. Eng. 2017, 33, 283–292. [Google Scholar]

- Li, Z.; Liu, J.; Li, P. Relationship between mechanical property and damage of tomato during robot harvesting. Trans. Chin. Soc. Agric. Eng. 2010, 26, 112–116. [Google Scholar]

- Ma, X.; Chen, X.; Yan, Y.; Jiang, X. Mechanical damage test and biomechanical characteristics of red bayberry fruit. Trans. Chin. Soc. Agric. Eng. 2012, 28, 282–287. [Google Scholar]

- Yang, Z.; Sun, J.; Guo, Y. Effect of moisture content on compression mechanical properties and frictional characteristics of millet grain. Trans. Chin. Soc. Agric. Eng. 2015, 31, 253–260. [Google Scholar]

- Valentin, L. Contact Mechanics and Friction Physical Principles and Applications, 2nd ed.; Tsinghua University Press: Beijing, China, 2011. [Google Scholar]

- Lü, J.; Yang, X.; Lü, Y.; Li, Z.; Li, J.; Du, C. Analysis and experiment of potato damage in process of lifting and separating potato excavator. Trans. Chin. Soc. Agric. Mach. 2020, 51, 103–113. [Google Scholar]

- Fu, W.; He, R.; Kan, Z.; Zhang, H.; Wang, L.; Yang, H.; Sun, Y. Experimental study on mechanical properties of jujube. Shihezi Univ. Nat. Sci. 2013, 31, 518–522. [Google Scholar]

- Shen, H.; Wang, B.; Hu, L.; Wang, G.; Ji, L.; Shen, G.; Wu, T. Design of potato connecting and conveying mechanism for 4UZL-1 type sweet potato combine harvester. Trans. Chin. Soc. Agric. Eng. 2020, 36, 9–17. [Google Scholar]

- Chinese Academy of Agricultural Mechanization Sciences. Agricultural Machinery Design Manual; Agricultural Science and Technology Press: Beijing, China, 2007; Volume 2. [Google Scholar]

- Shi, G.; Li, J.; Kan, Z.; Ding, L.; Ding, H.; Zhou, L.; Wang, L. Design and Parameters Optimization of a Provoke-Suction Type Harvester for Ground Jujube Fruit. Agriculture 2022, 12, 409. [Google Scholar] [CrossRef]

- Chen, K. Design and Analysis of Experiments, 2nd ed.; Tsinghua University Press: Beijing, China, 2005. [Google Scholar]

- Wen, B.; Wang, K.; Kan, Z.; Li, J.; Li, L.; Liu, S. Design and experiments of segmented helical kneading and cutting device for licorice straw. Trans. Chin. Soc. Agric. Eng. 2020, 36, 1–11. [Google Scholar]

| Parameters | Values |

|---|---|

| Structure form | Self-propelled |

| Fuselage steering mode | Hydraulic type |

| Overall dimension (length × width × height)/mm | 4270 × 2200 × 2017 |

| Engine rated power/kW | 38 |

| Engine rated speed/(r·min−1) | 2400 |

| The whole machine quality/kg | 1600 |

| Effective working width/mm | 1150 |

| Parameters | Values |

|---|---|

| Length of conveying side plate/mm | 1900 |

| Conveying width/mm | 1280 |

| Driving shaft speed of conveying/r·min−1 | 11~185 |

| clearance of conveying combination rod/mm | 18 |

| Fan air volume/m3·h−1 | 3300 |

| Levels | Forward Speed of the Machine X1/(m·s−1) | Speed of the Strip Brush Roller Shaft X2/(rpm) | The Hole Pitch Height of the Profiling Rod X3/mm |

|---|---|---|---|

| −1 | 0.2 | 45 | 21 |

| 0 | 0.3 | 55 | 48 |

| 1 | 0.4 | 65 | 75 |

| No. | X1 | X2 | X3 | Pick Up Rate Y1/% | Breakage Rate Y2/% | Impurity Rate Y3/% |

|---|---|---|---|---|---|---|

| 1 | −1 | −1 | 0 | 92.1 | 1.61 | 4.45 |

| 2 | 1 | 0 | 1 | 92.27 | 1.83 | 3.35 |

| 3 | 0 | 1 | 1 | 96.52 | 3.65 | 3.42 |

| 4 | 0 | 0 | 0 | 95.27 | 2.16 | 4.93 |

| 5 | −1 | 0 | −1 | 93.68 | 2.4 | 7.89 |

| 6 | 0 | 1 | −1 | 96.9 | 3.61 | 9.75 |

| 7 | −1 | 1 | 0 | 94.43 | 3.8 | 6.21 |

| 8 | 1 | 0 | −1 | 91.26 | 1.98 | 8.34 |

| 9 | 0 | −1 | −1 | 93.51 | 1.44 | 7.21 |

| 10 | 0 | 0 | 0 | 95.44 | 2.01 | 5.02 |

| 11 | 1 | −1 | 0 | 89.55 | 1.56 | 4.76 |

| 12 | 0 | −1 | 1 | 91.33 | 1.96 | 3.13 |

| 13 | −1 | 0 | 1 | 90.3 | 2.63 | 3.26 |

| 14 | 0 | 0 | 0 | 95.39 | 2.09 | 4.86 |

| 15 | 0 | 0 | 0 | 96.15 | 1.97 | 5.17 |

| 16 | 1 | 1 | 0 | 95.86 | 3.17 | 6.37 |

| 17 | 0 | 0 | 0 | 95.92 | 1.92 | 4.91 |

| Simulated Item | Sum of Squares | Degree of Freedom | Mean Square | F-Value | p-Value | Significance | |

|---|---|---|---|---|---|---|---|

| Y1 | Model | 86.50 | 9 | 9.61 | 105.32 | <0.0001 | *** |

| X1 | 0.3081 | 1 | 0.3081 | 3.38 | 0.1087 | ||

| X2 | 37.07 | 1 | 37.07 | 406.17 | <0.0001 | *** | |

| X3 | 3.04 | 1 | 3.04 | 33.29 | 0.0007 | *** | |

| X1X2 | 3.96 | 1 | 3.96 | 43.40 | 0.0003 | *** | |

| X1X3 | 4.82 | 1 | 4.82 | 52.80 | 0.0002 | *** | |

| X2X3 | 0.8100 | 1 | 0.8100 | 8.88 | 0.0205 | ** | |

| X12 | 29.98 | 1 | 29.98 | 328.49 | <0.0001 | *** | |

| X22 | 0.0016 | 1 | 0.0016 | 0.0171 | 0.8996 | ||

| X32 | 4.99 | 1 | 4.99 | 54.64 | 0.0002 | *** | |

| Residual | 0.6388 | 7 | 0.0913 | ||||

| Lack of fit | 0.0611 | 3 | 0.0204 | 0.1410 | 0.9303 | ||

| Pure error | 0.5777 | 4 | 0.1444 | ||||

| Cor total | 87.14 | 16 | |||||

| Y2 | Model | 9.14 | 9 | 1.02 | 69.47 | <0.0001 | *** |

| X1 | 0.4512 | 1 | 0.4512 | 30.88 | 0.0009 | *** | |

| X2 | 7.33 | 1 | 7.33 | 501.87 | <0.0001 | *** | |

| X3 | 0.0512 | 1 | 0.0512 | 3.50 | 0.1034 | ||

| X1X2 | 0.0841 | 1 | 0.0841 | 5.75 | 0.0475 | ** | |

| X1X3 | 0.0361 | 1 | 0.0361 | 2.47 | 0.1600 | ||

| X2X3 | 0.0576 | 1 | 0.0576 | 3.94 | 0.0875 | * | |

| X12 | 0.0026 | 1 | 0.0026 | 0.1801 | 0.6841 | ||

| X22 | 0.9701 | 1 | 0.9701 | 66.38 | <0.0001 | *** | |

| X32 | 0.1012 | 1 | 0.1012 | 6.92 | 0.0339 | ** | |

| Residual | 0.1023 | 7 | 0.0146 | ||||

| Lack of fit | 0.0657 | 3 | 0.0219 | 2.39 | 0.2091 | ||

| Pure error | 0.0366 | 4 | 0.0091 | ||||

| Cor total | 9.24 | 16 | |||||

| Y3 | Model | 58.49 | 9 | 6.50 | 260.63 | <0.0001 | *** |

| X1 | 0.1275 | 1 | 0.1275 | 5.11 | 0.0582 | * | |

| X2 | 4.80 | 1 | 4.80 | 192.69 | <0.0001 | *** | |

| X3 | 50.15 | 1 | 50.15 | 2011.12 | <0.0001 | *** | |

| X1X2 | 0.0056 | 1 | 0.0056 | 0.2256 | 0.6493 | ||

| X1X3 | 0.0324 | 1 | 0.0324 | 1.30 | 0.2918 | ||

| X2X3 | 1.27 | 1 | 1.27 | 50.75 | 0.0002 | *** | |

| X12 | 0.0960 | 1 | 0.0960 | 3.85 | 0.0905 | * | |

| X22 | 0.4271 | 1 | 0.4271 | 17.13 | 0.0044 | *** | |

| X32 | 1.42 | 1 | 1.42 | 57.00 | 0.0001 | *** | |

| Residual | 0.1746 | 7 | 0.0249 | ||||

| Lack of fit | 0.1151 | 3 | 0.0384 | 2.58 | 0.1911 | ||

| Pure error | 0.0595 | 4 | 0.0149 | ||||

| Cor total | 58.67 | 16 |

| Items | Y1/% | Y2/% | Y3/% |

|---|---|---|---|

| Model optimization value | 94.72 | 1.92 | 3.91 |

| Verification test value | 92.11 | 2.07 | 4.15 |

| Relative error/% | 2.83 | 7.25 | 5.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, L.; Li, J.; Ding, L.; Ding, H.; Shi, G.; Li, D. Design and Evaluation of a Mechanical Floor-Standing Jujube Picker. Agriculture 2022, 12, 1203. https://doi.org/10.3390/agriculture12081203

Zhou L, Li J, Ding L, Ding H, Shi G, Li D. Design and Evaluation of a Mechanical Floor-Standing Jujube Picker. Agriculture. 2022; 12(8):1203. https://doi.org/10.3390/agriculture12081203

Chicago/Turabian StyleZhou, Lun, Jingbin Li, Longpeng Ding, Huizhe Ding, Gaokun Shi, and Daolin Li. 2022. "Design and Evaluation of a Mechanical Floor-Standing Jujube Picker" Agriculture 12, no. 8: 1203. https://doi.org/10.3390/agriculture12081203

APA StyleZhou, L., Li, J., Ding, L., Ding, H., Shi, G., & Li, D. (2022). Design and Evaluation of a Mechanical Floor-Standing Jujube Picker. Agriculture, 12(8), 1203. https://doi.org/10.3390/agriculture12081203