Composite Films of Nanofibrillated Cellulose with Sepiolite: Effect of Preparation Strategy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Cellulose Nanofibril Preparation

2.2. Cellulose Nanofibril Characterization

2.3. CNF-Based Film Preparation

2.4. CNF-Based Film Characterization

2.5. Statistical Analysis

3. Results and Discussion

3.1. CNF Preparation and Characterization

3.2. CNF-Based Composite Film Characterization

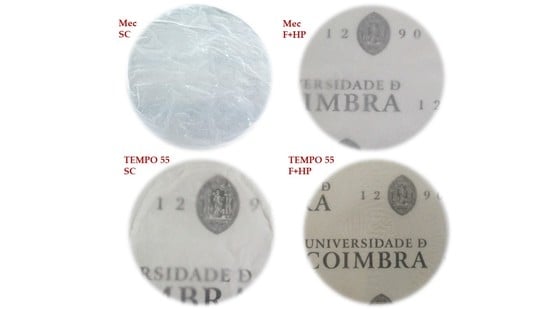

3.2.1. Optical Properties

3.2.2. Mechanical Properties

3.2.3. Morphological Properties

3.2.4. Barrier Properties

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Sample | Solvent Casting | Filtration + Hot Pressing | ||

|---|---|---|---|---|

| Force Max. (N) | Elongation at Break (%) | Force Max. (N) | Elongation at Break (%) | |

| Mec | 32.7 | 5.6 | 71.5 | 10.5 |

| Mec + 10% Sep | 38.7 | 6.7 | 53.2 | 7.2 |

| Mec + 50% Sep | 14.2 | 3.5 | 24.4 | 2.8 |

| Enz | 24.5 | 2.5 | 51.9 | 5.0 |

| Enz + 10% Sep | 24.7 | 2.8 | 44.4 | 3.8 |

| Enz + 50% Sep | 8.7 | 1.7 | 19.0 | 1.3 |

| TEMPO | 15.1 | 1.5 | 25.6 | 2.3 |

| TEMPO + 10% Sep | 13.5 | 1.7 | 43.9 | 1.2 |

| TEMPO + 50% Sep | 14.2 | 3.5 | 19.3 | 1.5 |

References

- Ayuso, C.F.; Agüero, A.A.; Hernández, J.A.P.; Santoyo, A.B.; Gómez, E.G. High oxygen barrier polyethylene films. Polym. Polym. Compos. 2017, 25, 571–582. [Google Scholar] [CrossRef]

- Alves, L.; Ferraz, E.; Gamelas, J.A.F. Composites of nanofibrillated cellulose with clay minerals: A review. Adv. Colloid Interface Sci. 2019, 272, 101994. [Google Scholar] [CrossRef] [PubMed]

- Gamelas, J.A.F.; Ferraz, E. Composite films based on nanocellulose and nanoclay minerals as high strength materials with gas barrier capabilities: Key points and challenges. BioResources 2015, 10, 6310–6313. [Google Scholar] [CrossRef] [Green Version]

- Magalhães, S.; Alves, L.; Medronho, B.; Romano, A.; Rasteiro, M.d.G. Microplastics in ecosystems: From current trends to bio-based removal strategies. Molecules 2020, 25, 3954. [Google Scholar] [CrossRef]

- Mahalik, N.P.; Nambiar, A.N. Trends in food packaging and manufacturing systems and technology. Trends Food Sci. Technol. 2010, 21, 117–128. [Google Scholar] [CrossRef]

- Zeng, J.; Zeng, Z.; Cheng, Z.; Wang, Y.; Wang, X.; Wang, B.; Gao, W. Cellulose nanofibrils manufactured by various methods with application as paper strength additives. Sci. Rep. 2021, 11, 11918. [Google Scholar] [CrossRef]

- González del Campo, M.M.; Darder, M.; Aranda, P.; Akkari, M.; Huttel, Y.; Mayoral, A.; Bettini, J.; Ruiz-Hitzky, E. Functional hybrid nanopaper by assembling nanofibers of cellulose and sepiolite. Adv. Funct. Mater. 2018, 28, 1703048. [Google Scholar] [CrossRef]

- Bardet, R.; Reverdy, C.; Belgacem, N.; Leirset, I.; Syverud, K.; Bardet, M.; Bras, J. Substitution of nanoclay in high gas barrier films of cellulose nanofibrils with cellulose nanocrystals and thermal treatment. Cellulose 2015, 22, 1227–1241. [Google Scholar] [CrossRef]

- Liu, A.; Berglund, L.A. Fire-retardant and ductile clay nanopaper biocomposites based on montmorrilonite in matrix of cellulose nanofibers and carboxymethyl cellulose. Eur. Polym. J. 2013, 49, 940–949. [Google Scholar] [CrossRef]

- Qin, S.; Pour, M.G.; Lazar, S.; Köklükaya, O.; Gerringer, J.; Song, Y.; Wågberg, L.; Grunlan, J.C. Super gas barrier and fire resistance of nanoplatelet/nanofibril multilayer thin films. Adv. Mater. Interfaces 2019, 6, 1801424. [Google Scholar] [CrossRef]

- Castro, D.O.; Karim, Z.; Medina, L.; Häggström, J.O.; Carosio, F.; Svedberg, A.; Wågberg, L.; Söderberg, D.; Berglund, L.A. The use of a pilot-scale continuous paper process for fire retardant cellulose-kaolinite nanocomposites. Compos. Sci. Technol. 2018, 162, 215–224. [Google Scholar] [CrossRef]

- Ghanadpour, M.; Carosio, F.; Ruda, M.C.; Wågberg, L. Tuning the nanoscale properties of phosphorylated cellulose nanofibril-based thin films to achieve highly fire-protecting coatings for flammable solid materials. ACS Appl. Mater. Interfaces 2018, 10, 32543–32555. [Google Scholar] [CrossRef]

- Guggenheim, S.; Krekeler, M.P.S. Chapter 1—The structures and microtextures of the palygorskite–sepiolite group minerals. In Developments in Clay Science; Galàn, E., Singer, A., Eds.; Elsevier: Amsterdam, The Netherlands, 2011; Volume 3, pp. 3–32. [Google Scholar] [CrossRef]

- Pinto, L.; Bonifacio, M.A.; De Giglio, E.; Santovito, E.; Cometa, S.; Bevilacqua, A.; Baruzzi, F. Biopolymer hybrid materials: Development, characterization, and food packaging applications. Food Packag. Shelf Life 2021, 28, 100676. [Google Scholar] [CrossRef]

- Lourenço, A.F.; Gamelas, J.A.F.; Nunes, T.; Amaral, J.; Mutjé, P.; Ferreira, P.J. Influence of TEMPO-oxidised cellulose nanofibrils on the properties of filler-containing papers. Cellulose 2017, 24, 349–362. [Google Scholar] [CrossRef]

- Lourenço, A.F.; Gamelas, J.A.F.; Sarmento, P.; Ferreira, P.J.T. Enzymatic nanocellulose in papermaking—The key role as filler flocculant and strengthening agent. Carbohydr. Polym. 2019, 224, 115200. [Google Scholar] [CrossRef]

- Saito, T.; Kimura, S.; Nishiyama, Y.; Isogai, A. Cellulose nanofibers prepared by TEMPO-mediated oxidation of native cellulose. Biomacromolecules 2007, 8, 2485–2491. [Google Scholar] [CrossRef]

- Henriksson, M.; Berglund, L.A.; Isaksson, P.; Lindström, T.; Nishino, T. Cellulose nanopaper structures of high toughness. Biomacromolecules 2008, 9, 1579–1585. [Google Scholar] [CrossRef]

- Almeida, R.O.; Ramos, A.; Alves, L.; Potsi, E.; Ferreira, P.J.T.; Carvalho, M.G.V.S.; Rasteiro, M.G.; Gamelas, J.A.F. Production of nanocellulose gels and films from invasive tree species. Int. J. Biol. Macromol. 2021, 188, 1003–1011. [Google Scholar] [CrossRef]

- Saito, T.; Nishiyama, Y.; Putaux, J.-L.; Vignon, M.; Isogai, A. homogeneous suspensions of individualized microfibrils from tempo-catalyzed oxidation of native cellulose. Biomacromolecules 2006, 7, 1687–1691. [Google Scholar] [CrossRef]

- Serra, A.; González, I.; Oliver-Ortega, H.; Tarrès, Q.; Delgado-Aguilar, M.; Mutjé, P. Reducing the amount of catalyst in tempo-oxidized cellulose nanofibers: Effect on properties and cost. Polymers 2017, 9, 557. [Google Scholar] [CrossRef] [Green Version]

- Ruiz-Hitzky, E.; Darder, M.; Alcântara, A.C.S.; Wicklein, B.; Aranda, P. Chapter 1—Functional nanocomposites based on fibrous clays. In Functional Polymer Composites with Nanoclays; Lvov, Y., Guo, B., Fakhrullin, R.F., Eds.; The Royal Society of Chemistry: Cambridge, UK, 2017; pp. 1–53. [Google Scholar] [CrossRef]

- Xu, D.; Wang, S.; Berglund, L.A.; Zhou, Q. Surface charges control the structure and properties of layered nanocomposite of cellulose nanofibrils and clay platelets. ACS Appl. Mater. Interfaces 2021, 13, 4463–4472. [Google Scholar] [CrossRef] [PubMed]

- González del Campo, M.M.; Caja-Munoz, B.; Darder, M.; Aranda, P.; Vázquez, L.; Ruiz-Hitzky, E. Ultrasound-assisted preparation of nanocomposites based on fibrous clay minerals and nanocellulose from microcrystalline cellulose. Appl. Clay Sci. 2020, 189, 105538. [Google Scholar] [CrossRef]

- Honorato, C.; Kumar, V.; Liu, J.; Koivula, H.; Xu, C.; Toivakka, M. Transparent nanocellulose-pigment composite films. J. Mater. Sci. 2015, 50, 7343–7352. [Google Scholar] [CrossRef]

- Yun, X.; Dong, T. 5—Fabrication of high-barrier plastics and its application in food packaging. In Food Packaging; Grumezescu, A.M., Ed.; Academic Press: Cambridge, MA, USA, 2017; pp. 147–184. [Google Scholar] [CrossRef]

- Carosio, F.; Colonna, S.; Fina, A.; Rydzek, G.; Hemmerlé, J.; Jierry, L.; Schaaf, P.; Boulmedais, F. Efficient gas and water vapor barrier properties of thin poly(lactic acid) packaging films: Functionalization with moisture resistant nafion and clay multilayers. Chem. Mater. 2014, 26, 5459–5466. [Google Scholar] [CrossRef]

| Sample | Yield of Fibrillation (%) | Degree of Polymerization | CCOOH (mmol/g) | Transmittance, 600 nm (%) | Particle Size, D0.5 (nm) | Zeta Potential (mV) |

|---|---|---|---|---|---|---|

| Mec | 6.5 | 2287 | 0.12 | 4 | 861 ± 151 | −14 ± 4 |

| Enz | 16.6 | 960 | 0.14 | 8 | 436 ± 49 | −18 ± 2 |

| TEMPO | 49.3 | 381 | 0.74 | 29 | 381 ± 19 | −42 ± 10 |

| Film | Basis Weight (g/m2) | Thickness (µm) | Transparency (%) | |||

|---|---|---|---|---|---|---|

| SC | F + HP | SC | F + HP | SC | F + HP | |

| Mec | 25.7 ± 1.3 | 40.5 ± 0.5 | 39.0 ± 4.3 (a) | 33.8 ± 4.1 (d) | 68.5 ± 5.8 (a’) | 59.3 ± 0.8 (f’) |

| Mec + 10% SEP | 23.9 ± 0.8 | 40.2 ± 1.4 | 39.2 ± 3.2 (a) | 47.6 ± 10.0 (a) (b) (c) (d) | 62.5 ± 0.7 (b’) | 43.4 ± 8.8 (c’) (d’) (g’) |

| Mec + 50% SEP | 25.1 ± 1.3 | 37.6 ± 1.1 | 46.7 ± 1.6 (b) | 44.5 ± 4.9 (b) | 41.6 ± 1.0 (c’) | 27.6 ± 1.2 |

| Enz | 24.7 ± 1.5 | 41.1 ± 0.6 | 37.9 ± 3.9 (a) | 33.2 ± 1.8 (d) | 67.2 ± 1.4 (a’) | 60.5 ± 0.3 (b’) |

| Enz + 10% SEP | 25.8 ± 1.5 | 43.3 ± 4.5 | 42.1 ± 1.3 (c) | 41.5 ± 2.9 (c) | 61.6 ± 1.9 (b’) | 49.5 ± 2.8 (g’) |

| Enz + 50% SEP | 25.1 ± 1.7 | 39.4 ± 0.6 | 47.7 ± 4.8 (b) | 44.8 ± 2.7 (b) | 43.7 ± 1.5 (d’) | 31.2 ± 0.2 (h’) |

| TEMPO | 23.8 ± 1.7 | 40.8 ± 0.8 | 33.0 ± 9.3 (a) (c) (d) (e) | 39.1 ± 4.8 (a) | 84.1 ± 0.9 | 82.9 ± 0.1 |

| TEMPO + 10% SEP | 23.9 ± 1.9 | 40.0 ± 0.7 | 25.4 ± 3.8 (e) | 36.4 ± 0.8 (a) | 78.5 ± 2.2 | 63.1 ± 8.8 (a’) (b’) (e’) (f’) |

| TEMPO + 50% SEP | 23.1 ± 1.8 | 39.7 ± 2.3 | 28.0 ± 3.9 (e) | 42.1 ± 2.1 (c) | 55.7 ± 2.8 (e’) | 31.8 ± 4.1 (h’) |

| Film | WVTR (g·m−2·d−1) | WVP × 106 (g·m·m−2·d−1·Pa−1) |

|---|---|---|

| Mec | 184 | 7.3 |

| Mec + 20% SEP | 233 | 8.3 |

| Enz | 104 | 3.4 |

| Enz + 20% SEP | 186 | 5.4 |

| TEMPO | 216 | 6.5 |

| TEMPO + 20% SEP | 176 | 5.4 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alves, L.; Ramos, A.; Rasteiro, M.G.; Vitorino, C.; Ferraz, E.; Ferreira, P.J.T.; Puertas, M.L.; Gamelas, J.A.F. Composite Films of Nanofibrillated Cellulose with Sepiolite: Effect of Preparation Strategy. Coatings 2022, 12, 303. https://doi.org/10.3390/coatings12030303

Alves L, Ramos A, Rasteiro MG, Vitorino C, Ferraz E, Ferreira PJT, Puertas ML, Gamelas JAF. Composite Films of Nanofibrillated Cellulose with Sepiolite: Effect of Preparation Strategy. Coatings. 2022; 12(3):303. https://doi.org/10.3390/coatings12030303

Chicago/Turabian StyleAlves, Luís, Ana Ramos, Maria G. Rasteiro, Carla Vitorino, Eduardo Ferraz, Paulo J. T. Ferreira, Maria L. Puertas, and José A. F. Gamelas. 2022. "Composite Films of Nanofibrillated Cellulose with Sepiolite: Effect of Preparation Strategy" Coatings 12, no. 3: 303. https://doi.org/10.3390/coatings12030303

APA StyleAlves, L., Ramos, A., Rasteiro, M. G., Vitorino, C., Ferraz, E., Ferreira, P. J. T., Puertas, M. L., & Gamelas, J. A. F. (2022). Composite Films of Nanofibrillated Cellulose with Sepiolite: Effect of Preparation Strategy. Coatings, 12(3), 303. https://doi.org/10.3390/coatings12030303