Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators

Abstract

:1. Introduction

2. Experimental Section

3. Results and Discussion

3.1. Thermoelectric and Structual Properties of n-Type Bi2Te3 and p-Type Sb2Te3 Thin Films

3.2. Fabrication of Flexible Thin-Film Thermoelectric Generators

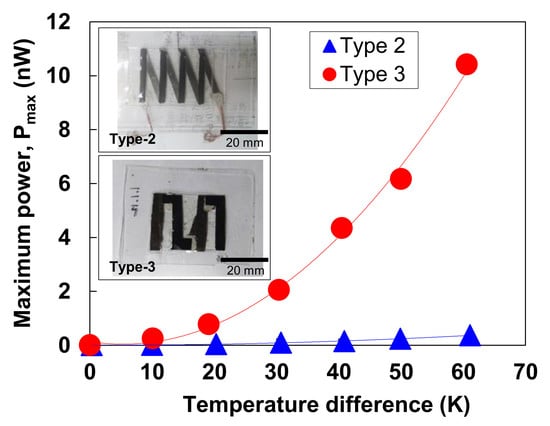

3.3. Performance of Flexible Thin-Film Thermoelectric Generators

4. Conclusions

Acknowledgements

Author Contributions

Conflicts of Interest

References

- Beeby, S.P.; Tudor, M.J.; White, N.M. Energy harvesting vibration sources for microsystems applications. Meas. Sci. Technol. 2006, 17, R175–R195. [Google Scholar] [CrossRef]

- Paradiso, J.A.; Starner, T. Energy scavenging for mobile and wireless electronics. IEEE Pervasive Comput. 2005, 4, 18–27. [Google Scholar] [CrossRef]

- Kulah, H.; Najafi, K. Energy Scavenging from low-frequency vibrations by using frequency up-conversion for wireless sensor applications. IEEE Sens. J. 2008, 8, 261–268. [Google Scholar] [CrossRef]

- Takayama, K.; Takashiri, M. Multi-layered-stack thermoelectric generators using p-type Sb2Te3 and n-type Bi2Te3 thin films by radio-frequency magnetron sputtering. Vacuum 2017, 144, 164–171. [Google Scholar] [CrossRef]

- Kurosaki, J.; Yamamoto, A.; Tanaka, S.; Cannon, J.; Miyazaki, K.; Tsukamoto, H. Fabrication and evaluation of a thermoelectric microdevice on a free-standing substrate. J. Electron. Mater. 2009, 38, 1326–1330. [Google Scholar] [CrossRef]

- Mizoshiri, M.; Mikami, M.; Ozaki, K. p-Type Sb2Te3 and n-Type Bi2Te3 films for thermoelectric modules deposited by thermally assisted sputtering method. Jpn. J. Appl. Phys. 2013, 52, 06GL07. [Google Scholar] [CrossRef]

- Chen, X.; Xu, S.; Yao, N.; Shi, Y. 1.6 V nanogenerator for mechanical energy harvesting using PZT nanofibers. Nano Lett. 2010, 10, 2133–2137. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yang, Y.; Hou, T.C.; Su, Y.; Hu, C.; Wang, Z.L. Triboelectric nanogenerator built inside clothes for self-powered glucose biosensors. Nano Energy 2013, 2, 1019–1024. [Google Scholar] [CrossRef]

- Francioso, L.; Pascali, C.D.; Farella, I.; Martucci, C.; Cretì, P.; Siciliano, P.; Perrone, A. Flexible thermoelectric generator for ambient assisted living wearable biometric sensors. J. Power Sources 2011, 196, 3239–3243. [Google Scholar] [CrossRef]

- Fan, P.; Zheng, Z.; Li, Y.; Lin, Q.; Luo, J.; Liang, G.; Cai, X.; Zhang, D.; Ye, F. Low-cost flexible thin-film thermoelectric generator on zinc based thermoelectric materials. Appl. Phys. Lett. 2015, 106, 073901. [Google Scholar] [CrossRef]

- Zhu, W.; Deng, Y.; Cao, L. Light-concentrated solar generator and sensor based on flexible thin-film thermoelectric device. Nano Energy 2017, 34, 463–471. [Google Scholar] [CrossRef]

- Zhao, D.; Min, Z. Enhanced thermoelectric performance of Ga-added Bi0.5Sb1.5Te3 films by flash evaporation. Intermetallics 2012, 31, 321–324. [Google Scholar] [CrossRef]

- Takashiri, M.; Tanaka, S.; Miyazaki, K. Determination of the origin of crystal orientation for nanocrystalline bismuth telluride-based thin films prepared by use of the flash evaporation method. J. Electron. Mater. 2014, 43, 1881–1889. [Google Scholar] [CrossRef]

- Takashiri, M.; Imai, K.; Uyama, M.; Hagino, H.; Tanaka, S.; Miyazaki, K.; Nishi, Y. Comparison of crystal growth and thermoelectric properties of n-type Bi-Se-Te and p-type Bi-Sb-Te nanocrystalline thin films: Effects of homogeneous irradiation with an electron beam. J. Appl. Phys. 2014, 115, 214311. [Google Scholar] [CrossRef]

- Böttner, H.; Nurnus, J.; Gavrikov, A.; Kühner, G.; Jägle, M.; Kunzel, C.; Eberhard, D.; Plescher, G.; Schubert, A.; Schlereth, K.H. New thermoelectric components using microsystem technologies. J. Microelectromech. Syst. 2004, 13, 414–420. [Google Scholar] [CrossRef]

- Kusagaya, K.; Takashiri, M. Investigation of the effects of compressive and tensile strain on n-type bismuth telluride and p-type antimony telluride nanocrystalline thin films for use in flexible thermoelectric generators. J. Alloy. Compd. 2015, 653, 480–485. [Google Scholar] [CrossRef]

- Kusagaya, K.; Hagino, H.; Tanaka, S.; Miyazaki, K.; Takashiri, M. Structural and thermoelectric properties of nanocrystalline bismuth telluride thin films under compressive and tensile strain. J. Electron. Mater. 2015, 44, 1632–1636. [Google Scholar] [CrossRef]

- Snyder, G.J.; Lim, J.R.; Huang, C.; Fleurial, J. Thermoelectric microdevice fabricated by a MEMS-like electrochemical process. Nat. Mater. 2003, 2, 528–531. [Google Scholar] [CrossRef] [PubMed]

- Matsuoka, K.; Okuhata, M.; Takashiri, M. Dual-bath electrodeposition of n-type Bi-Te/Bi-Se multilayer thin films. J. Alloy. Compd. 2015, 649, 721–725. [Google Scholar] [CrossRef]

- Venkatasubramanian, R.; Siivola, E.; Colpitts, T.; O’Quinn, B. Thin-film thermoelectric devices with high room-temperature figures of merit. Nature 2001, 413, 597–602. [Google Scholar] [CrossRef] [PubMed]

- Harman, T.C.; Taylor, P.J.; Walsh, M.P.; LaForge, B.E. Quantum dot superlattice thermoelectric materials and devices. Science 2002, 297, 2229–2232. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Chen, Y.; Gong, C.; Yang, J.; Qian, R.; Wang, Y. Optimization of superlattice thermoelectric materials and microcoolers. J. Microelectromech. Syst. 2007, 16, 1113–1119. [Google Scholar] [CrossRef]

- Poudel, B.; Hao, Q.; Ma, Y.; Lan, Y.; Minnich, A.; Yu, B.; Yan, X.; Wang, D.; Muto, A.; Vashaee, D.; et al. High-thermoelectric performance of nanostructured bismuth antimony telluride bulk alloys. Science 2008, 320, 634–638. [Google Scholar] [CrossRef] [PubMed]

- Yamauchi, K.; Takashiri, M. Highly oriented crystal growth of nanocrystalline bismuth telluride thin films with anisotropic thermoelectric properties using two-step treatment. J. Alloy. Compd. 2017, 698, 977–983. [Google Scholar] [CrossRef]

- Kudo, S.; Hagino, H.; Tanaka, S.; Miyazaki, K.; Takashiri, M. Determining the thermal conductivities of nanocrystalline bismuth telluride thin films using the differential 3ω method while accounting for thermal contact resistance. J. Electron. Mater. 2015, 44, 2021–2025. [Google Scholar] [CrossRef]

- Lee, J.; Galli, G.A.; Grossman, J.C. Nanoporous Si as an efficient thermoelectric material. Nano Lett. 2008, 8, 3750–3754. [Google Scholar] [CrossRef] [PubMed]

- Kashiwagi, M.; Hirata, S.; Harada, K.; Zheng, Y.; Miyazaki, K.; Yahiro, M.; Adachi, C. Enhanced figure of merit of a porous thin film of bismuth antimony telluride. Appl. Phys. Lett. 2011, 98, 023114. [Google Scholar] [CrossRef]

- Takashiri, M.; Tanaka, S.; Hagino, H.; Miyazaki, K. Combined effect of nanoscale grain size and porosity on lattice thermal conductivity of bismuth-telluride-based bulk alloys. J. Appl. Phys. 2012, 112, 084315. [Google Scholar] [CrossRef]

- Biswas, K.; He, J.; Zhang, Q.; Wang, G.; Uher, C.; Dravid, V.P.; Kanatzidis, M.G. Strained endotaxial nanostructures with high thermoelectric figure of merit. Nat. Chem. 2011, 3, 160–166. [Google Scholar] [CrossRef] [PubMed]

- Inamoto, T.; Takashiri, M. Experimental and first-principles study of the electronic transport properties of strained Bi2Te3 thin films on a flexible substrate. J. Appl. Phys. 2016, 120, 125105. [Google Scholar] [CrossRef]

- Inamoto, T.; Morikawa, S.; Takashiri, M. Combined infrared spectroscopy and first-principles calculation analysis of electronic transport properties in nanocrystalline Bi2Te3 thin films with controlled strain. J. Alloys Compd. 2017, 702, 229–235. [Google Scholar] [CrossRef]

- Frantz, C.; Stein, N.; Zhang, Y.; Bouzy, E.; Picht, O.; Toimil-Molares, M.E.; Boulanger, C. Electrodeposition of bismuth telluride nanowires with controlled composition in polycarbonate membranes. Electrochim. Acta 2012, 69, 30–37. [Google Scholar] [CrossRef]

- Xiao, F.; Hangarter, C.; Yoo, B.; Rheem, Y.; Lee, K.H.; Myung, N.V. Recent progress in electrodeposition of thermoelectric thin films and nanostructures. Electrochim. Acta 2008, 53, 8103–8117. [Google Scholar] [CrossRef]

- Manzano, C.V.; Abad, B.; Rojo, M.M.; Borca-Tasciuc, T.; Gonzalez, M.M. Anisotropic effects on the thermoelectric properties of highly oriented electrodeposited Bi2Te3 films. Sci. Rep. 2016, 6, 19129. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ye, Y.; Mao, Y.; Wang, F.; Lu, H.; Qu, L.; Dai, L. Solvent-free functionalization and transfer of aligned carbon nanotubes with vapor-deposited polymer nanocoatings. J. Mater. Chem. 2011, 21, 837–842. [Google Scholar] [CrossRef]

- Bell, L.E. Cooling, heating, generating power, and recovering waste heat with thermoelectric systems. Science 2008, 321, 1457–1461. [Google Scholar] [CrossRef] [PubMed]

- Matsuoka, K.; Okuhata, M.; Hatsuta, N.; Takashiri, M. Effect of composition on the properties of bismuth telluride thin films produced by galvanostatic electrodeposition. Trans. Mater. Res. Soc. Jpn. 2015, 40, 383–387. [Google Scholar] [CrossRef]

- Okuhata, M.; Takemori, D.; Takashiri, M. Effect of pulse frequency on structural and thermoelectric properties of bismuth telluride thin films by electrodeposition. ECS Trans. 2017, 75, 133–141. [Google Scholar] [CrossRef]

- Takemori, D.; Okuhata, M.; Takashiri, M. Thermoelectric properties of electrodeposited bismuth telluride thin films by thermal annealing and homogeneous electron beam irradiation. ECS Trans. 2017, 75, 123–131. [Google Scholar] [CrossRef]

- Hatsuta, N.; Takemori, D.; Takashiri, M. Effect of thermal annealing on the structural and thermoelectric properties of electrodeposited antimony telluride thin films. J. Alloy. Compd. 2016, 685, 147–152. [Google Scholar] [CrossRef]

- Scherrer, H.; Scherrer, S. Thermoelectric Materials. In CRC Handbook of Thermoelectrics; Rowe, D.M., Ed.; CRC Press: New York, NY, USA, 1995; pp. 211–237. [Google Scholar]

- Takashiri, M.; Kurita, K.; Hagino, H.; Tanaka, S.; Miyazaki, K. Enhanced thermoelectric properties of phase-separating bismuth selenium telluride thin films via a two-step method. J. Appl. Phys. 2015, 118, 065301. [Google Scholar] [CrossRef]

- Takashiri, M.; Asai, Y.; Yamauchi, K. Structural, optical, and transport properties of nanocrystalline bismuth telluride thin films treated with homogeneous electron beam irradiation and thermal annealing. Nanotechnology 2016, 27, 335703. [Google Scholar] [CrossRef] [PubMed]

- Kudo, S.; Tanaka, S.; Miyazaki, K.; Nishi, Y.; Takashiri, M. Anisotropic analysis of nanocrystalline bismuth telluride thin films treated by homogeneous electron beam irradiation. Mater. Trans. 2017, 58, 513–519. [Google Scholar] [CrossRef]

- Fan, P.; Zheng, Z.; Cai, Z.; Chen, T.; Liu, P.; Cai, X.; Zhang, D.; Liang, G.; Luo, J. The high performance of a thin-film thermoelectric generator with heat flow running parallel to film surface. Appl. Phys. Lett. 2013, 102, 033904. [Google Scholar] [CrossRef]

- Hanson, S.; Seok, M.; Lin, Y.S.; Foo, Z.Y.; Kim, D.; Lee, Y.; Liu, N.; Ylvester, S.D.; Blaauw, D. A Low-voltage processor for sensing applications with picowatt standby mode. IEEE J. Solid-State Circuits 2010, 45, 759–767. [Google Scholar] [CrossRef]

| Column Title | S (μV/K) | σ (S/cm) | Power Factor, S2σ (μW/(cm·K2)) |

|---|---|---|---|

| n-type film | −62.8 | 79 | 0.3 |

| p-type film | 172.3 | 3.2 | 0.1 |

| Type of Generator | Rtotal (kΩ) |

|---|---|

| Type 1 | N/A |

| Type 2 | 0 |

| Type 3 | 12 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yamamuro, H.; Hatsuta, N.; Wachi, M.; Takei, Y.; Takashiri, M. Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators. Coatings 2018, 8, 22. https://doi.org/10.3390/coatings8010022

Yamamuro H, Hatsuta N, Wachi M, Takei Y, Takashiri M. Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators. Coatings. 2018; 8(1):22. https://doi.org/10.3390/coatings8010022

Chicago/Turabian StyleYamamuro, Hiroki, Naoki Hatsuta, Makoto Wachi, Yoshihiro Takei, and Masayuki Takashiri. 2018. "Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators" Coatings 8, no. 1: 22. https://doi.org/10.3390/coatings8010022

APA StyleYamamuro, H., Hatsuta, N., Wachi, M., Takei, Y., & Takashiri, M. (2018). Combination of Electrodeposition and Transfer Processes for Flexible Thin-Film Thermoelectric Generators. Coatings, 8(1), 22. https://doi.org/10.3390/coatings8010022