Shear Strength Prediction of Steel-Fiber-Reinforced Concrete Beams Using the M5P Model

Abstract

:1. Introduction

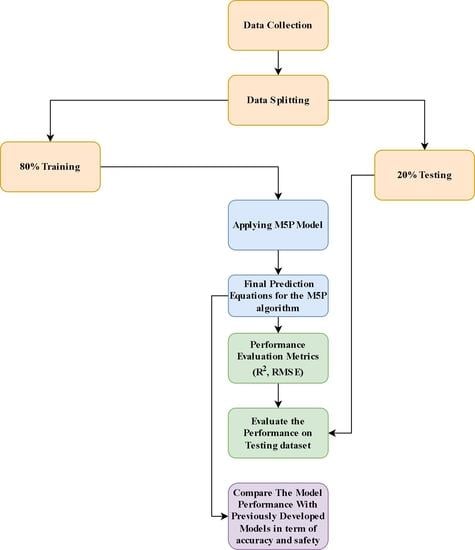

2. Research Methodology

2.1. Selection of the Input Parameters

2.1.1. Shear Span to Effective Depth Ratio (a/d)

2.1.2. Longitudinal Reinforcement Ratio (ρ)

2.1.3. Concrete Compressive Strength (fc)

2.1.4. Fiber Factor (Fsf)

2.2. Data Collection and Pre-Processing

2.3. M5P Model Tree Techniques

3. Model Result

3.1. M5P Derived Models

3.2. Performance Analysis

3.3. K-Fold Cross Validation Results

- Divide the data into five equal parts (or “folds”).

- Choose one fold as the test set and the other four folds as the training set.

- Train the model on the training set and use it to predict the target values on the test set.

- Calculate the RMSE between the predicted values and the actual values in the test set.

- Repeat steps 2–4 for each of the five folds, using a different fold as the test set each time.

- Calculate the average RMSE across all five folds. This is the overall measure of the model’s performance.

3.4. Comparision with Previouly Developed Models

3.5. Model Safety Analysis

3.6. Safety Factor Inclusion

4. Conclusions

- The M5P model demonstrated high accuracy in predicting the shear strength of SFRC beams, outperforming existing models in terms of performance metrics. The simplicity and ease of use of the M5P tree algorithm highlight its effectiveness in handling complex relationships and its potential applicability to other civil engineering problems.

- The safety analysis conducted using the Collins scale revealed that the M5P model had the lowest demerit penalty and was the safest among the different prediction models. Approximately 70% of the predictions made by the M5P algorithm fell within the safe and acceptable range, emphasizing its reliability and effectiveness in practical applications.

- By developing a more accurate, reliable, and user-friendly prediction tool, this research provides a significant contribution to the design and optimization of SFRC beams. It ensures that the desired level of shear strength is achieved while optimizing resource utilization and improving safety in SFRC structure design and construction.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rahman, J.; Ahmed, K.S.; Khan, N.I.; Islam, K.; Mangalathu, S. Data-driven shear strength prediction of steel fiber reinforced concrete beams using machine learning approach. Eng. Struct. 2021, 233, 111743. [Google Scholar] [CrossRef]

- Yang, J.; Doh, J.-H.; Yan, K.; Zhang, X. Experimental investigation and prediction of shear capacity for UHPC beams. Case Stud. Constr. Mater. 2022, 16, e01097. [Google Scholar] [CrossRef]

- Soltanabadi, R.; Behfarnia, K. Shear strength of reinforced concrete deep beams containing recycled concrete aggregate and recycled asphalt pavement. Constr. Build. Mater. 2022, 314, 125597. [Google Scholar] [CrossRef]

- Li, W.; Huang, W.; Fang, Y.; Zhang, K.; Liu, Z.; Kong, Z. Experimental and theoretical analysis on shear behavior of RC beams reinforced with GFRP stirrups. Structures 2022, 46, 1753–1763. [Google Scholar] [CrossRef]

- Xu, T.; Li, J. Experimental investigations of failure modes of reinforced concrete beams without web reinforcement. Eng. Struct. 2019, 185, 47–57. [Google Scholar] [CrossRef]

- ACI. Building Code Requirements for Structural Concrete (ACI 318-19) and Commentary (ACI 318R-19); Detroit, M., Ed.; American Concrete Institute: Farmington Hills, MI, USA, 2019. [Google Scholar]

- European Commission. Eurocode 2: Design of Concrete Structures-Part 1–1: General Rules and Rules for Buildings; CEN (European Committee for Standardization): Brussels, Belgium, 2010. [Google Scholar]

- Ma, Z.; Shen, J.; Wang, C.; Wu, H. Characterization of sustainable mortar containing high-quality recycled manufactured sand crushed from recycled coarse aggregate. Cem. Concr. Compos. 2022, 132, 104629. [Google Scholar] [CrossRef]

- Tran, T.T.; Pham, T.M.; Hao, H. Effect of hybrid fibers on shear behaviour of geopolymer concrete beams reinforced by basalt fiber reinforced polymer (BFRP) bars without stirrups. Compos. Struct. 2020, 243, 112236. [Google Scholar] [CrossRef]

- Said, A.; Elsayed, M.; Abd El-Azim, A.; Althoey, F.; Tayeh, B.A. Using ultra-high performance fiber reinforced concrete in improvement shear strength of reinforced concrete beams. Case Stud. Constr. Mater. 2022, 16, e01009. [Google Scholar] [CrossRef]

- Mansour, W.; Tayeh, B.A. Shear behaviour of RC beams strengthened by various ultrahigh performance fibre-reinforced concrete systems. Adv. Civ. Eng. 2020, 2020, 2139054. [Google Scholar] [CrossRef]

- D’Antino, T.; Focacci, F.; Sneed, L.H.; Pellegrino, C. Shear strength model for RC beams with U-wrapped FRCM composites. J. Compos. Constr. 2020, 24, 04019057. [Google Scholar] [CrossRef]

- Abadel, A.; Abbas, H.; Almusallam, T.; Alshaikh, I.M.; Khawaji, M.; Alghamdi, H.; Salah, A.A. Experimental study of shear behavior of CFRP strengthened ultra-high-performance fiber-reinforced concrete deep beams. Case Stud. Constr. Mater. 2022, 16, e01103. [Google Scholar] [CrossRef]

- Nana, W.; Tran, H.; Goubin, T.; Kubisztal, G.; Bennani, A.; Bui, T.; Cardia, G.; Limam, A. Behaviour of macro-synthetic fibers reinforced concrete: Experimental, numerical and design code investigations. Structures 2021, 32, 1271–1286. [Google Scholar] [CrossRef]

- Hui, L.; López-Almansa, F. New modifying truss model and numerical simulation of steel fiber reinforced concrete under pure torsion. Structures 2018, 14, 32–42. [Google Scholar] [CrossRef]

- Gümüş, M.; Arslan, A. Effect of fiber type and content on the flexural behavior of high strength concrete beams with low reinforcement ratios. Structures 2019, 20, 1–10. [Google Scholar] [CrossRef]

- Furlan, S., Jr.; de Hanai, J.B. Shear behaviour of fiber reinforced concrete beams. Cem. Concr. Compos. 1997, 19, 359–366. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Karimi, A.; Gholampour, A. Pre-and post-heating behavior of concrete-filled steel tube stub columns containing steel fiber and tire rubber. Structures 2020, 27, 2346–2364. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Hasan-Nattaj, F.; Gholampour, A.; Sabetifar, H.; Ngo, T.D. Strengthening of heat-damaged steel fiber-reinforced concrete using CFRP composites: Experimental study and analytical modeling. Structures 2021, 32, 1856–1870. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Baradaran-Nasiri, A. Mechanical performance of fiber-reinforced recycled refractory brick concrete exposed to elevated temperatures. Comput. Concr. Int. J. 2019, 24, 19–35. [Google Scholar]

- Jafarzadeh, H.; Nematzadeh, M. Evaluation of post-heating flexural behavior of steel fiber-reinforced high-strength concrete beams reinforced with FRP bars: Experimental and analytical results. Eng. Struct. 2020, 225, 111292. [Google Scholar] [CrossRef]

- Gao, D.; Gu, Z.; Zhu, H.; Huang, Y. Fatigue behavior assessment for steel fiber reinforced concrete beams through experiment and fatigue prediction model. Structures 2020, 27, 1105–1117. [Google Scholar] [CrossRef]

- Bi, J.; Wang, Z.; Zhao, Y.; Huo, L.; Xie, Y. A mechanical model for shear design of steel fiber reinforced concrete beams without shear reinforcements. Structures 2021, 31, 216–229. [Google Scholar] [CrossRef]

- Nematzadeh, M.; Hasan-Nattaj, F. Compressive stress-strain model for high-strength concrete reinforced with forta-ferro and steel fibers. J. Mater. Civ. Eng. 2017, 29, 04017152. [Google Scholar] [CrossRef]

- Yu, Y.; Zhao, X.-Y.; Xu, J.-J.; Wang, S.-C.; Xie, T.-Y. Evaluation of shear capacity of steel fiber reinforced concrete beams without stirrups using artificial intelligence models. Materials 2022, 15, 2407. [Google Scholar] [CrossRef]

- Shatnawi, A.; Alkassar, H.M.; Al-Abdaly, N.M.; Al-Hamdany, E.A.; Bernardo, L.F.A.; Imran, H. Shear Strength Prediction of Slender Steel Fiber Reinforced Concrete Beams Using a Gradient Boosting Regression Tree Method. Buildings 2022, 12, 550. [Google Scholar] [CrossRef]

- Olalusi, O.B.; Awoyera, P.O. Shear capacity prediction of slender reinforced concrete structures with steel fibers using machine learning. Eng. Struct. 2021, 227, 111470. [Google Scholar] [CrossRef]

- Momani, Y.; Tarawneh, A.; Alawadi, R.; Momani, Z. Shear strength prediction of steel fiber-reinforced concrete beams without stirrups. Innov. Infrastruct. Solut. 2022, 7, 107. [Google Scholar] [CrossRef]

- Keshtegar, B.; Bagheri, M.; Yaseen, Z.M. Shear strength of steel fiber-unconfined reinforced concrete beam simulation: Application of novel intelligent model. Compos. Struct. 2019, 212, 230–242. [Google Scholar] [CrossRef]

- Chaabene, W.B.; Nehdi, M.L. Novel soft computing hybrid model for predicting shear strength and failure mode of SFRC beams with superior accuracy. Compos. Part C Open Access 2020, 3, 100070. [Google Scholar] [CrossRef]

- Al-Abdaly, N.M.; Al-Taai, S.R.; Imran, H.; Ibrahim, M. Development of prediction model of steel fiber-reinforced concrete compressive strength using random forest algorithm combined with hyperparameter tuning and k-fold cross-validation. East.-Eur. J. Enterp. Technol. 2021, 5, 113. [Google Scholar] [CrossRef]

- Tariq, M.; Khan, A.; Ullah, A.; Shayanfar, J.; Niaz, M. Improved shear strength prediction model of steel fiber reinforced concrete beams by adopting gene expression programming. Materials 2022, 15, 3758. [Google Scholar] [CrossRef]

- Tarawneh, A.; Almasabha, G.; Alawadi, R.; Tarawneh, M. Innovative and reliable model for shear strength of steel fibers reinforced concrete beams. Structures 2021, 32, 1015–1025. [Google Scholar] [CrossRef]

- Sharifi, Y.; Moghbeli, A. New predictive models via gene expression programming and multiple nonlinear regression for SFRC beams. J. Mater. Res. Technol. 2020, 9, 14294–14306. [Google Scholar] [CrossRef]

- Sabetifar, H.; Nematzadeh, M. An evolutionary approach for formulation of ultimate shear strength of steel fiber-reinforced concrete beams using gene expression programming. Structures 2021, 34, 4965–4976. [Google Scholar] [CrossRef]

- Ahmadi, M.; Kheyroddin, A.; Dalvand, A.; Kioumarsi, M. New empirical approach for determining nominal shear capacity of steel fiber reinforced concrete beams. Constr. Build. Mater. 2020, 234, 117293. [Google Scholar] [CrossRef]

- Shahnewaz, M.; Tannert, M. Shear strength prediction of steel fiber reinforced concrete beams from genetic programming and its sensitivity analysis. In Proceedings of the FRC: The Modern Landscape BEFIB 2016 9th Rilem International Symposium on Fiber Reinforced Concrete, Vancouver, BC, Canada, 19–21 September 2016; pp. 19–21. [Google Scholar]

- Ismail, M.K.; Yosri, A.; El-Dakhakhni, W. A multi-gene genetic programming model for predicting shear strength of steel fiber concrete beams. ACI Struct. J. 2022, 119, 317–328. [Google Scholar]

- Gandomi, A.H.; Yun, G.J.; Alavi, A.H. An evolutionary approach for modeling of shear strength of RC deep beams. Mater. Struct. 2013, 46, 2109–2119. [Google Scholar] [CrossRef]

- Gandomi, A.; Alavi, A.; Yun, G. Nonlinear modeling of shear strength of SFRC beams using linear genetic programming. Struct. Eng. Mech. 2011, 38, 1–25. [Google Scholar] [CrossRef]

- Arslan, G. Shear strength of steel fiber reinforced concrete (SFRC) slender beams. KSCE J. Civ. Eng. 2014, 18, 587–594. [Google Scholar] [CrossRef]

- Singh, B.; Sihag, P.; Tomar, A.; SEHGAL, A. Estimation of compressive strength of high-strength concrete by random forest and M5P model tree approaches. J. Mater. Eng. Struct. 2019, 6, 583–592. [Google Scholar]

- Shah, H.A.; Nehdi, M.L.; Khan, M.I.; Akmal, U.; Alabduljabbar, H.; Mohamed, A.; Sheraz, M. Predicting Compressive and Splitting Tensile Strengths of Silica Fume Concrete Using M5P Model Tree Algorithm. Materials 2022, 15, 5436. [Google Scholar] [CrossRef]

- Kocamaz, A.F.; Ayaz, Y.; Karakoç, M.B.; Türkmen, İ.; Demirboğa, R. Prediction of compressive strength and ultrasonic pulse velocity of admixtured concrete using tree model M5P. Struct. Concr. 2021, 22, E800–E814. [Google Scholar] [CrossRef]

- Henedy, S.N.; Naser, A.H.; Imran, H.; Bernardo, L.F.; Teixeira, M.M.; Al-Khafaji, Z. Development of Prediction Models for the Torsion Capacity of Reinforced Concrete Beams Using M5P and Nonlinear Regression Models. J. Compos. Sci. 2022, 6, 366. [Google Scholar] [CrossRef]

- Ahmed, H.U.; Mohammed, A.S.; Mohammed, A.A. Multivariable models including artificial neural network and M5P-tree to forecast the stress at the failure of alkali-activated concrete at ambient curing condition and various mixture proportions. Neural Comput. Appl. 2022, 34, 17853–17876. [Google Scholar] [CrossRef]

- Spinella, N.; Colajanni, P.; Recupero, A. Simple plastic model for shear critical SFRC beams. J. Struct. Eng. 2010, 136, 390–400. [Google Scholar] [CrossRef]

- Minelli, F. Plain and Fiber Reinforced Concrete Beams under Shear Loading: Structural Behavior and Design Aspects; Università di Brescia: Brescia, Italy, 2005. [Google Scholar]

- Lantsoght, E.O. Database of shear experiments on steel fiber reinforced concrete beams without stirrups. Materials 2019, 12, 917. [Google Scholar] [CrossRef]

- Choi, K.-K.; Hong-Gun, P.; Wight, J.K. Shear strength of steel fiber-reinforced concrete beams without web reinforcement. ACI Struct. J. 2007, 104, 12. [Google Scholar]

- Narayanan, R.; Darwish, I. Use of steel fibers as shear reinforcement. Struct. J. 1987, 84, 216–227. [Google Scholar]

- Swamy, R.; Bahia, H. Influence of fiber reinforcement on the dowel resistance to shear. J. Proc. 1979, 76, 327–356. [Google Scholar]

- Li, V.C.; Ward, R.J.; Hamza, A.M. Steel and Synthetic Fibers as Shear Reinforcement. Am. Concr. Instiute 1992, 89, 499–508. [Google Scholar]

- Khuntia, M.; Stojadinovic, B.; Goel, S.C. Shear strength of normal and high-strength fiber reinforced concrete beams without stirrups. Struct. J. 1999, 96, 282–289. [Google Scholar]

- Greenough, T.; Nehdi, M. Shear behavior of fiber-reinforced self-consolidating concrete slender beams. ACI Mater. J. 2008, 105, 468. [Google Scholar]

- Quinlan, J.R. Learning with continuous classes. In Proceedings of the 5th Australian Joint Conference on Artificial Intelligence, Hobart, Tasmania, 16–18 November 1992; pp. 343–348. [Google Scholar]

- Wang, Y.; Witten, I.H. Induction of Model Trees for Predicting Continuous Classes; The University of Waikato: Hamilton, New Zealand, 1996. [Google Scholar]

- Witten, I.H.; Frank, E. Data Mining: Practical Machine Learning Tools and Techniques, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Kumar, S.A.; Vijayalakshmi, M. A naive based approach of model pruned trees on learner’s response. Int. J. Mod. Educ. Comput. Sci. 2012, 4, 52. [Google Scholar] [CrossRef]

- Ayaz, Y.; Kocamaz, A.F.; Karakoç, M.B. Modeling of compressive strength and UPV of high-volume mineral-admixtured concrete using rule-based M5 rule and tree model M5P classifiers. Constr. Build. Mater. 2015, 94, 235–240. [Google Scholar] [CrossRef]

- Ashour, S.A.; Hasanain, G.S.; Wafa, F.F. Shear behavior of high-strength fiber reinforced concrete beams. Struct. J. 1992, 89, 176–184. [Google Scholar]

- Zsutty, T.C. Beam shear strength prediction by analysis of existing data. J. Proc. 1968, 65, 943–951. [Google Scholar]

- Sarveghadi, M.; Gandomi, A.H.; Bolandi, H.; Alavi, A.H. Development of prediction models for shear strength of SFRCB using a machine learning approach. Neural Comput. Appl. 2019, 31, 2085–2094. [Google Scholar] [CrossRef]

- Chaabene, W.B.; Nehdi, M.L. Genetic programming based symbolic regression for shear capacity prediction of SFRC beams. Constr. Build. Mater. 2021, 280, 122523. [Google Scholar] [CrossRef]

- Koza, J.R. Genetic Programming: On the Programming of Computers by Means of Natural Selection (Complex Adaptive Systems). A Bradf. Book 1993, 1, 18. [Google Scholar]

- Sarıdemir, M. Empirical modeling of splitting tensile strength from cylinder compressive strength of concrete by genetic programming. Expert Syst. Appl. 2011, 38, 14257–14268. [Google Scholar] [CrossRef]

- Azamathulla, H.M.; Guven, A.; Demir, Y.K. Linear genetic programming to scour below submerged pipeline. Ocean Eng. 2011, 38, 995–1000. [Google Scholar] [CrossRef]

- Alavi, A.H.; Gandomi, A.H. A robust data mining approach for formulation of geotechnical engineering systems. Eng. Comput. 2011, 28, 242–274. [Google Scholar] [CrossRef]

- Collins, M.P. Evaluation of Shear Design Procedures for Concrete Structures; A CSA Technical Committee Reinforced Concrete Design Report; Canadian Standards Association: Toronto, ON, Canada, 2001. [Google Scholar]

- AbdelAleem, B.H.; Ismail, M.K.; Haggag, M.; El-Dakhakhni, W.; Hassan, A.A. Interpretable soft computing predictions of elastic shear buckling in tapered steel plate girders. Thin-Walled Struct. 2022, 176, 109313. [Google Scholar] [CrossRef]

| Data Category | Statistics | bw (mm) * | d (mm) * | ρ * | a/d * | fc (MPa) * | Fst * | Vu (kN) * |

|---|---|---|---|---|---|---|---|---|

| Training data | Standard deviation | 64.104 | 176.606 | 0.010 | 0.639 | 25.993 | 0.336 | 154.425 |

| Mean | 157.429 | 283.045 | 0.026 | 3.367 | 49.390 | 0.552 | 152.166 | |

| Median | 150.000 | 251.000 | 0.027 | 3.440 | 41.000 | 0.503 | 110.000 | |

| Maximum | 610.000 | 1118.000 | 0.057 | 6.000 | 215.000 | 2.865 | 1081.000 | |

| Minimum | 55.000 | 85.250 | 0.004 | 2.500 | 9.770 | 0.102 | 13.000 | |

| Testing data | Standard deviation | 77.563 | 181.879 | 0.008 | 0.638 | 26.216 | 0.322 | 199.085 |

| Mean | 161.291 | 284.693 | 0.024 | 3.338 | 48.005 | 0.513 | 157.588 | |

| Median | 150.000 | 251.000 | 0.024 | 3.400 | 40.210 | 0.450 | 108.500 | |

| Maximum | 600.000 | 920.000 | 0.048 | 6.000 | 215.000 | 2.000 | 1481.000 | |

| Minimum | 55.000 | 85.250 | 0.010 | 2.500 | 19.600 | 0.102 | 16.000 |

| Linear Model | Coefficient | ||||||

|---|---|---|---|---|---|---|---|

| LM1 | 0.0594 | 0.8624 | 0.9484 | 0.5095 | −0.7424 | 0.1799 | 0.1105 |

| LM2 | 0.0903 | 1.1591 | 0.4655 | 0.6299 | −0.6499 | 0.4844 | 0.117 |

| LM3 | 0.0566 | 1.0062 | 0.3897 | 0.2336 | −0.2345 | 0.4727 | 0.3405 |

| LM4 | 0.0301 | 0.5163 | 1.1544 | 0.4401 | −0.360 | 0.3881 | 0.2199 |

| Vu(exp) (kN) | bw (mm) | d (mm) | ρ | a/d | fc (MPa) | Fst |

|---|---|---|---|---|---|---|

| 220 | 152 | 381 | 0.0271 | 3.4 | 49.2 | 0.8 |

| Statistics | RMSE (kN) | R | R2 |

|---|---|---|---|

| Training | 33.924 | 0.976 | 0.952 |

| Testing | 37.307 | 0.984 | 0.969 |

| Total | 38.563 | 0.977 | 0.955 |

| Predicted Model | RMSE | R2 | Statistical Properties of Vactual/VM5P | ||||

|---|---|---|---|---|---|---|---|

| SD | COV% | Min | Max | ||||

| Khuntia et al. [54] | 42.7104 | 0.8917 | 1.4963 | 0.4536 | 30.32 | 0.1735 | 4.0345 |

| Ashour et al. [61] | 76.6893 | 0.8595 | 1.1195 | 0.3720 | 33.23 | 0.2327 | 3.1421 |

| Sabetifar and Nematzadeh [35] | 61.8467 | 0.9307 | 1.0146 | 0.2454 | 24.19 | 0.1974 | 2.0038 |

| Sarveghadi et al. [63] | 88.3206 | 0.9133 | 1.0007 | 0.2712 | 27.10 | 0.2267 | 2.2046 |

| Chaabene and Nehdi [64] | 38.2046 | 0.9294 | 1.1193 | 0.2492 | 22.27 | 0.4062 | 2.1188 |

| M5P in this study | 38.5633 | 0.9554 | 1.0160 | 0.1627 | 16.01 | 0.5407 | 1.7182 |

| Vactual/Vpredicted | Classification | Demerit Points |

|---|---|---|

| Extremely dangerous | 10 | |

| Dangerous | 5 | |

| Appropriate and safe | 0 | |

| Conservative | 2 | |

| Extremely conservative | 1 |

| Model | < 0.50 | < 0.85 | < 1.15 | < 2 | > 2 | Demerit Points |

|---|---|---|---|---|---|---|

| Khuntia et al. [54] | 4 | 15 | 42 | 247 | 24 | 410 |

| 4 × 10 | 15 × 5 | 42 × 0 | 247 × 1 | 24 × 2 | ||

| Ashour et al. [61] | 10 | 57 | 130 | 127 | 7 | 526 |

| 10 × 10 | 57 × 5 | 130 × 0 | 127 × 1 | 7 × 2 | ||

| Sabetifar and Nematzadeh [35] | 9 | 67 | 169 | 86 | 1 | 513 |

| 9 × 10 | 67 × 5 | 169 × 0 | 86 × 1 | 1 × 2 | ||

| Sarveghadi et al. [63] | 7 | 84 | 158 | 82 | 1 | 574 |

| 7 × 10 | 84 × 5 | 158 × 0 | 82 × 1 | 1 × 2 | ||

| Chaabene and Nehdi [64] | 1 | 41 | 150 | 138 | 2 | 357 |

| 1 × 10 | 41 × 5 | 150 × 0 | 138 × 1 | 2 × 2 | ||

| This study | - | 46 | 232 | 54 | 0 | 284 |

| 0 ×10 | 46 × 5 | 232 × 0 | 54 × 1 | 0 × 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Al-Abdaly, N.M.; Hussein, M.J.; Imran, H.; Henedy, S.N.; Bernardo, L.F.A.; Al-Khafaji, Z. Shear Strength Prediction of Steel-Fiber-Reinforced Concrete Beams Using the M5P Model. Fibers 2023, 11, 37. https://doi.org/10.3390/fib11050037

Al-Abdaly NM, Hussein MJ, Imran H, Henedy SN, Bernardo LFA, Al-Khafaji Z. Shear Strength Prediction of Steel-Fiber-Reinforced Concrete Beams Using the M5P Model. Fibers. 2023; 11(5):37. https://doi.org/10.3390/fib11050037

Chicago/Turabian StyleAl-Abdaly, Nadia Moneem, Mahdi J. Hussein, Hamza Imran, Sadiq N. Henedy, Luís Filipe Almeida Bernardo, and Zainab Al-Khafaji. 2023. "Shear Strength Prediction of Steel-Fiber-Reinforced Concrete Beams Using the M5P Model" Fibers 11, no. 5: 37. https://doi.org/10.3390/fib11050037

APA StyleAl-Abdaly, N. M., Hussein, M. J., Imran, H., Henedy, S. N., Bernardo, L. F. A., & Al-Khafaji, Z. (2023). Shear Strength Prediction of Steel-Fiber-Reinforced Concrete Beams Using the M5P Model. Fibers, 11(5), 37. https://doi.org/10.3390/fib11050037