Investigation of the Tendency of Carbon Fibers to Disintegrate into Respirable Fiber-Shaped Fragments

Abstract

:1. Introduction

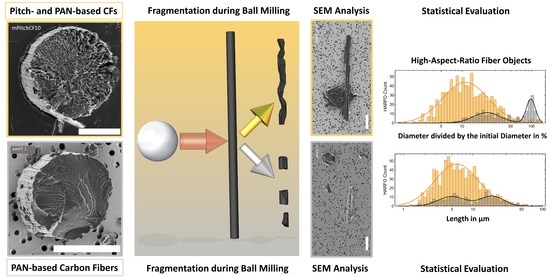

2. Materials and Methods

2.1. Materials

2.2. Measurements of Material Properties

2.3. Fragmentation Characterization

2.3.1. Structural Disintegration by Milling

2.3.2. Suspension and Filtration

2.3.3. SEM Analysis and Morphological Characterization

2.3.4. Direction of Fragmentation

2.3.5. Wedge-Shaped Fragments

2.3.6. Fragment Analysis and Compilation of Morphological Statistics

- Number and diameter of low aspect ratio fragments, i.e., LARPOs

- Number, length and diameter of high aspect ratio fragments, i.e., HARFOs.

- HARFCs: HARFOs with diameters of the initial CF

- HARFSs: HARFOs with diameters below that of the initial CF

- Respirable HARFOs: HARFOs thinner than 3 µm

- WHOFOs: respirable HARFOs longer than 5 µm

- Respirable HARFOs too short to be WHOFOs, i.e., shorter than 5 µm

- Wedge-shaped HARFOs with opening-angle above 10°.

3. Results

3.1. Material Properties

3.2. Fracture Behavior during Ball Milling

3.2.1. Fragment Yield in Different Metrices

3.2.2. Wedge-Shaped Fragments

3.3. Visualization of Material Parameters and Fragment Characteristics

4. Discussion

4.1. Material Grouping Based on the Mean Diameter of High-Aspect Ratio Fragments

- “LDH” (Lower mean Diameter HARFO) materials, including panCF 1 and mPitchCFs 10, 11, 14 which formed HARFOs with mean diameters below 2.0 µm

- “HDH” (Higher mean Diameter HARFO) materials, including panCFs 4, 5, 8, 15 and iPitchCF 12 which formed HARFOs with mean diameters greater than 2.0 µm.

- With respect to diameter

- ○

- Compared to the HDH materials, the LDH materials formed fewer HARFCs per HARFOs ((3 ± 1)% vs. (26 ± 4)%), i.e., “chunk” HARFOs of approximately the initial CF diameter.

- ○

- Therefore, not only the HARFOs but also the HARFSs, i.e., “splinter” HARFOs with diameters below the initial diameter, tended to be thinner for LDH than for HDH materials ((1.3 ± 0.5) µm vs. (2.0 ± 0.7) µm).

- ○

- This resulted in a significantly lower percentage of HARFOs thicker than 3 µm and HARFCs for the LDH materials than for the HDH materials ((9 ± 2)% vs. (44 ± 6)%).

- ○

- Naturally, the mean HARFO diameter of the LDH materials was lower than that of the HDH materials ((1.5 ± 0.8) µm vs. (3.0 ± 1.0) µm), as this observable was used to define the two groups of materials.

- In terms of length

- ○

- The HARFOs formed from the LDH materials were on average not only thinner than the HDH materials but also showed a tendency to be shorter ((7 ± 4) µm vs. (13 ± 5) µm), except for mPitchCF 10, see Section 4.4.

4.2. Material- and Group-Specific Findings

- The panCF 1, being a very commonly-used fiber with standard material properties, disintegrated into—on average—thinner HARFOs than the other panCFs. In this respect its fragmentation characteristics were more similar to mPitchCFs than to the other panCFs, which motivated to the formation of the LDH group of materials. As the mean diameter of the HARFSs formed was not significantly thinner than that of the other panCFs, the smaller mean HARFO diameter of panCF 1 was due to the lower percentage of HARFCs formed.

- PanCF 1 was the highest-ranking panCF in terms of HARFOs and WHOFOs per milled length. In terms of this metric, it differed significantly from panCF 8, which has the same initial diameter and quite similar material properties. PanCF 5, 4 and 15 are materials with a smaller initial diameter and require a greater length to be milled for the same volume. As a result, the distance of panCF 1 to 4, 5 and 15 is smaller when normalized to volume.

- Although panCF 8 is very similar to panCF 1 in terms of material properties, their fragmentation characteristics were significantly different, particularly in terms of the mean length and diameter of the HARFOs and the percentage of HARFOs that were too short or too thick to form WHOFOs.

- However, when compared to mPitchCF, the propensity of panCF 1 to form HARFOs and WHOFOs was only (11 ± 2)%/(44 ± 3)% = (24 ± 4)% and (1.9 ± 0.6)%/(16.3 ± 1.2)% = (12 ± 4)%, respectively, indicating that pan CF 1 formed far more LARPOs.

- The isotropic pitchCF 12, with material properties similar to those of panCFs, showed a disintegration behavior similar to panCFs in all aspects.

4.3. Correlations between Fragmentation Characteristics and Material Properties

4.3.1. Testing of Normality, Linear Indepence and Goodness-of-Fit

- Green cells: Data with high χ2-probability Pndf(χ2), small δb-error and small pPC-value

- Cyan to blue cells: Data with Pndf(χ2) ≥ 5%, δb-error < 100% but a pPC-value > 0.05

- Yellow to orange cells: Data with reduced Pndf(χ2) or large δb > 100% but small pPC-value < 0.05

- Red to purple cells: Data with low Pndf(χ2) < 5% or large δb > 100% and high pPC-value > 0.05.

4.3.2. Correlations among Material Properties

- (P1)

- Microporosity Pµ and specific density ϱ

- (P2)

- Partial orientation OP

- (P3)

- Interlayer spacing d002, thermal volume conductivity qT, tensile

- Modulus EM, crystallite domain size parallel and perpendicular to fiber axis , Raman area ratio and elongation at break . The linear correlation between the characteristic domain size and was practically perfect, so was omitted for the subsequent discussion.

- (P4)

- Tensile Strength σT

- (P5)

- Initial CF diameter di.

- Since tensile strength (P4) results from plastic deformation behavior in the non-linear part of the stress-strain relationship, no linear correlation with the other properties was found here, except perhaps with initial diameter (P5), although this relationship was supported only by PC-statistics only by the -test, see Figure 9

- The initial fiber diameter (P5) shows an apparent correlation with microporosity and density only for Group P1, as the higher graphitized mPitchCFs were produced with generally larger diameters

- The properties microporosity and density of Group P1 are mutually correlated as is proportional to the product of the interlayer distance and ∙ These Group P1 properties and are also well correlated with the properties of Group P2 and P3

- Within property Group P3 only the interlayer distance is correlated with all others

- A too large Raman area ratio of iPitchCF 12 is responsible for the non-correlation in Group P3, although the other materials show linear trends, see Figure 10.

- The logarithm of the domain size and seems to correlate well with the elongation at break , see Figure 11.

4.3.3. Correlations between Observed Fragmentation Characteristics and Material Properties

- Diameter of WHOFOs and HARFOs: According to PC- and χ2-tests, the mean diameters of the WHOFOs and HARFOs were linearly correlated with the property Groups P1 (high and low ), P2 (low ) and, partially, P3 (large , low , small , and , low and high ). However, due to the large statistical error in the diameters of the WHOFO and HARFO ensembles of about 33%, a large relative error resulted, limiting the information on the slope of the linear function obtained from the fit.

- Length of WHOFOs and HARFOs: The statistical errors on the lengths of the WHOFO and HARFO ensembles were also large (about 30%), especially for panCF 8, and resulted in a relative error in the fitted slope of more than 200%. In addition, PC-testing showed high significance for linear independence (red to purple cells). Therefore, there was no convincing evidence of a correlation between the mean WHOFO lengths and the tested property Groups P1–P5. Also the slightly smaller relative error for the mean HARFO lengths and P1–P2 did not result in a convincing relationship.

- Aspect ratio of WHOFOs and HARFOs: As the relative error in aspect ratio is the sum of the relative errors in length and diameter, the power of the -test is also weak for these observables. All properties are compatible with error-weighted linear fits to the aspect ratio, but the large errors do not significantly constrain the slope . However, the trends that the aspect ratio of fragments increases with the material quality are also supported by the PC-tests, except for P2 and P4.

- Ratio of WHOFOs to HARFOs: The formation of WHOFOs relative to HARFOs was favored by the two characteristics of Group P1 (low and high ) and partially by P3 (small , high , large , and high ). As a general trend, the ratio of WHOFO to HARFO fragments increased with material quality. The apparent correlation with the initial diameter , on closer inspection, actually looks like random scatter, biased by the larger synthesis diameters of mPitchCFs 10 and 11.

- Number of WHOFOs formed: Most important for the subsequent discussion of risk assessment is the number of WHO fibers formed per volume of CF milled. The WHOFO count appears to be linearly dependent on the two properties low and high of Group P1. Figure 12 shows that, due to the clustering of the PAN and iPitch CF data points, the leverage of the mPitchCF 11 and 14 data points determines the outcome of the fit. However, plotting the WHOFO counts against the important material property longitudinal tensile modulus in Figure 13 shows the following trend, which is also found for the other properties of Group P3: All data points of the PAN and iPitch materials are aligned in the direction of the mPitchCF 10 data point. This could be interpreted as a linear relationship between the material properties of Group P3 and the propensities to form WHO fiber fragments. However, this linearity does not include the mPitchCFs 11 and 14 materials! These released drastically higher numbers of WHOFOs than their material parameters would imply for a linear relationship. If we consider the WHOFO concentrations observed for iPitchCF, panCFs and mPitchCF 10 to be reliable and the linear correlation with the P3 properties to be significant, we can determine the either unweighted or weighted linear correlation by fitting with the WHOFO data of mPitchCFs 11 and 14, which were either omitted or reduced in weight, respectively, cf. Figure 13 and Figure 14. The fit weight reduction was technically achieved by setting the relative errors in the WHOFO counts to 100%. The revised linear model marks mPitchCFs 11 and 14 as materials with excessive WHOFO formation.

- The WHOFO and HARFO counts of the most graphitic mPitch CF material 10 were systematically underestimated due to non-brittle transformation of fragments to unquantifiable graphitic smear by ball impact.

- Not yet understood and not-quantitatively described microstructural properties of the highly lamellar mPitch CF materials 11 and 14 determined their excessive disintegration characteristics into fibrous fragments, cf. Figure 2.

4.3.4. Correlations among Observed Fragmentation Characteristics

- The concentrations of formed WHO and HAR fiber objects per milled CF volume were correlated.

- The observation that the ratio of formed WHOFOs to HARFOs increased with mean aspect ratio and decreased with mean WHOFO diameter is plausible, but the estimated errors of the WHOFO and HARFO length, diameter and aspect ratio are rather large, so the power of the χ2-test is limited here, cf. Figure 15.

- For the same milled CF volume, materials that produced WHOFO and HARFO fragments with small mean diameters, cf. Figure 16, and HARFOs with small mean lengths, cf. Figure 17, tended to produce more WHOFO and HARFO objects. However, this trend only holds when the mPitchCFs 11 and 14 are included in the correlation analysis.

4.4. Material- and Microstructure-Related Fragmentation Differences

4.4.1. Material Property Effects

4.4.2. Microstructural Effects

4.4.3. Direction of Filament Fragmentation

4.5. Carbon Fiber Diameter Paradox

4.6. Identification of Critical CF Materials

- CF materials of higher graphitization, density, microstructural order, and mechanical and thermal performance, as characterized by the material parameter Groups P1–P4, tended to form

- ○

- WHOFOs of smaller diameter, see Figure 28

- as well as

- ○

- higher ratios of WHOFOs to HARFOs; the highest correlation was found to the crystallite domain size perpendicular to the fiber axis, see Figure 29.

- Among these parameters (P1)–(P4), those that characterize higher microstructural order (P2), namely density , microporosity Pµ and crystalline order in fiber direction , also correlated to the number of WHOFOs formed, see Figure 24, and to a decrease in the number of HARFOs thicker than the WHO-fiber diameter threshold of 3 µm, see Figure 30.

- Surprisingly, the lengths and aspect ratios of WHOFOs formed correlated to the initial fiber diameter di, see Figure 22. A possible physical origin of this correlation is unclear. It may be a side effect of the fact that the CFs of the LD-HARFO group that generally formed more WHOFOs were of higher initial diameter and exhibited higher microstructural order, see Figure 26.

4.7. Safe and Sustainable by Design

4.8. Occupational Hygiene Aspects

4.9. Practical Relevance of CF Disintegration Testing by Ball Mill Grinding

5. Conclusions

- Not only mesophase pitch-based but also PAN-based carbon fibers can form WHO-fiber fragments in situations of mechanical overload. Such fibers are to be considered as potentially carcinogenic and require toxicological testing.

- The observed differences in the propensity of the PAN- and mesophase pitch-based CFs to form WHO-fibers, in terms of the volume of fiber milled, were smaller than previously reported in the literature; in most cases they were less than one order of magnitude.

- Based on fragment surface analysis, the present work supports the assumption that the studied mesophase pitch-based CFs form fragments preferentially in the direction of the CF axis. However, such a disintegration pattern however did not systematically result in longer fragments, as mesophase pitch-based CF fragments tended to be thinner: Their higher tensile modulus values had only a small and insignificant effect on the aspect ratio of their fragments.

- For product designers unfamiliar with precursor-related material properties, the specific density data provided in the technical data sheet of a carbon fiber, could help to raise awareness of a potentially excessive propensity to form WHO-fiber fragments during mechanical disintegration. Densities above 1.95 g/cm3 are considered critical.

- A smaller initial carbon fiber diameter was observed to reduce the propensity to form fragments of WHO-fiber morphology: More fragments had the initial diameter as a result of fracturing transverse to the fiber axis. However, carbon fibers with a smaller initial diameter are likely to cause problems during recycling of polymer composite, as diameter thinning during pyrolysis processes brings such fibers closer to the respirable threshold. Such thinning can occur during the final pyrolysis stage where an oxygen-containing hot atmosphere is used to remove of polyaromatic hydrocarbon residues and soot.

- The mean diameter of the high-aspect-ratio-fragments formed is also an important characteristic as it can directly influence the number of fiber fragments formed: The thinner the mean fragment diameter, the more fragments can be formed from the same volume of disintegrated material. Two groups of materials have been proposed: The Low-Diameter (LDH) and High-Diameter (HDH) materials, containing carbon fiber types that formed mean fragment diameters below and above 2 µm, respectively. However, this criterion requires laborious microscopic evaluation of fragment morphologies.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| CF | Carbon Fiber |

| HARFC | High Aspect Ratio Fiber Chunk: HARFO of initial CF diameter |

| HARFO | High Aspect Ratio Fiber Object: Aspect ratio |

| HARFS | High Aspect Ratio Fiber Splinter: HARFO with diameter below initial CF diameter |

| HDH | Higher mean Diameter HARFO-forming material. Here: iPitchCF 12 and panCFs 4, 5, 8, 15 |

| iPitchCF | CF made from Isotropic Pitch |

| LDH | Lower mean Diameter HARFO-forming material. Here: panCF 1 and mPitchCFs 10, 11, 14 |

| LARPC | Low Aspect Ratio Particle Chunk: LARPO with a size of the initial CF diameter in one dimension |

| LARPO | Low Aspect Ratio Particle Object: Aspect ratio |

| mPitchCF | CF made from Mesophase Pitch |

| pitchCF | CF made from Mesophase or Isotropic Pitch |

| panCF | CF made from Polyacrylonitrile |

| SEM | Scanning Electron Microscope |

| WHO | World Health Organization |

| WHOFO | HARFO of WHO dimensions: Length: , width: , aspect ratio: . |

References

- Industry Experts Inc. Carbon Fibers & Carbon Fiber Reinforced Plastics (CFRP): A Global Market Overview; Industry Experts Inc.: San Dimas, CA, USA, 2018. [Google Scholar]

- Kadla, J.; Kubo, S.; Venditti, R.; Gilbert, R.; Compere, A.; Griffith, W. Lignin-based carbon fibers for composite fiber applications. Carbon 2002, 40, 2913–2920. [Google Scholar] [CrossRef]

- Frank, E.L.M.; Steudle, D.; Ingildeev, J.M.; Sporl, M.R.; Buchmeiser, M.R. Carbon fibers: Precursor systems, processing, structure, and properties. Angew. Chem. Int. Ed. Engl. 2014, 53, 5262–5298. [Google Scholar] [CrossRef]

- Spörl, J.M.; Ota, A.; Son, S.; Massonne, K.; Hermanutz, F.; Buchmeiser, M.R. Carbon fibers prepared from ionic liquid-derived cellulose precursors. Mater. Today Commun. 2016, 7, 1–10. [Google Scholar] [CrossRef]

- Huang, X. Fabrication and Properties of Carbon Fibers. Materials 2009, 2, 2369–2403. [Google Scholar] [CrossRef]

- Naito, K.; Tanaka, Y.; Yang, J.-M. Transverse compressive properties of polyacrylonitrile (PAN)-based and pitch-based single carbon fibers. Carbon 2017, 118, 168–183. [Google Scholar] [CrossRef]

- Kehren, D.; Simonow, B.; Bäger, D.; Dziurowitz, N.; Wenzlaff, D.; Thim, C.; Neuhoff, J.; Meyer-Plath, A.; Plitzko, S. Release of respirable fibrous dust from carbon fibers due to splitting along the fiber axis. Aerosol. Air Qual. Res. 2019, 19, 2185–2195. [Google Scholar] [CrossRef]

- Kumoi, J.; Ikegami, A.; Fujitani, Y.; Morikawa, K.; Ichihara, G.; Yano, T.; Ichihara, S. Factory site analysis of respirable fibers generated during the process of cutting and grinding of carbon fibers-reinforced plastics. Int. Arch. Occup. Environ. Health 2022, 95, 1557–1565. [Google Scholar] [CrossRef] [PubMed]

- World Health Organization. Determination of Airborne Fibre Number Concentrations: A Recommended Method, By Phase-Contrast Optical Microscopy (Membrane Filter Method); World Health Organization: Geneva, Switzerland, 1997; Available online: https://apps.who.int/iris/handle/10665/41904 (accessed on 30 May 2023).

- Cox, R.G. The motion of long slender bodies in a viscous fluid Part 1. General theory. J. Fluid Mech. 1970, 44, 791. [Google Scholar] [CrossRef]

- Donaldson, K.; Murphy, F.A.; Duffin, R.; Poland, C.A. Asbestos, carbon nanotubes and the pleural mesothelium: A review of the hypothesis regarding the role of long fibre retention in the parietal pleura, inflammation and mesothelioma. Part. Fibre Toxicol. 2010, 7, 1–17. [Google Scholar] [CrossRef] [PubMed]

- Cooke, W.E. Fibrosis of the lungs due to the inhalation of asbestos dust. BMJ 1924, 2, 147. [Google Scholar] [CrossRef]

- Borow, M.; Conston, A.; Livornese, L.; Schalet, N. Mesothelioma following exposure to asbestos: A review of 72 cases. Chest 1973, 64, 641–646. [Google Scholar] [CrossRef]

- Selikoff, I.J.; Lee, D.H.K. Asbestos and Disease; Academic Press, Inc.: New York, NY, USA, 1978. [Google Scholar] [CrossRef]

- Selikoff, I.J.; Greenberg, M. A landmark case in asbestosis. JAMA 1991, 265, 898–901. [Google Scholar] [CrossRef] [PubMed]

- Furuya, S.; Chimed-Ochir, O.; Takahashi, K.; David, A.; Takala, J. Global asbestos disaster. Int. J. Environ. Res. Public Health 2018, 15, 1000. [Google Scholar] [CrossRef] [PubMed]

- Holt, P.; Horne, M. Dust from carbon fibre. Environ. Res. 1978, 17, 276–283. [Google Scholar] [CrossRef]

- Martin, T.R.; Meyer, S.W.; Luchtel, D.R. An evaluation of the toxicity of carbon fiber composites for lung cells in vitro and in vivo. Environ. Res. 1989, 49, 246–261. [Google Scholar] [CrossRef] [PubMed]

- Warheit, D.B.; Hansen, J.F.; Carakostas, M.C.; Hartsky, M.A. Acute inhalation toxicity studies in rats with a respirable-sized experimental carbon fibre: Pulmonary biochemical and cellular effects. Ann. Work. Expo. Health 1994, 38, 769–776. [Google Scholar] [CrossRef]

- Waritz, R.S.; Ballantyne, B.; Clary, J.J. Subchronic inhalation toxicity of 3.5-micron diameter carbon fibers in rats. J. Appl. Toxicol. 1998, 18, 215–23. J. Appl. Toxicol. 1998, 18, 215–223. [Google Scholar] [CrossRef]

- Warheit, D.; Hart, G.; Hesterberg, T.; Collins, J.; Dyer, W.; Swaen, G.; Castranova, V.; Soiefer, A.; Kennedy, G. Potential pulmonary effects of man-made organic fiber (MMOF) dusts. Crit. Rev. Toxicol. 2001, 31, 697–736. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, X.; Lin, L.; Xing, S.; Wu, Y.; Li, Y.; Wu, L.; Gang, B. The effects of carbon fibre and carbon fibre composite dusts on bronchoalveolar lavage component of rats. J. Occup. Health 2001, 43, 75–79. [Google Scholar] [CrossRef]

- Wang, J.; Schlagenhauf, L.; Setyan, A. Transformation of the released asbestos, carbon fibers and carbon nanotubes from composite materials and the changes of their potential health impacts. J. Nanobiotechnology 2017, 15, 15. [Google Scholar] [CrossRef] [PubMed]

- Tölle, L.; Monsé, C.; Rosenkranz, N.; Haibel, N.; Walter, D.; Bünger, J.; Hopp, M.; Westphal, G.A. Characterization of fiber dust resulting from recycling of carbon fiber-reinforced thermoplastics (CFRP) and their cell toxicity. J. Mater. Sci. Chem. Eng. 2022, 10, 1–16. [Google Scholar] [CrossRef]

- Friesen, A.; Fritsch-Decker, S.; Mülhopt, S.; Quarz, C.; Mahl, J.; Baumann, W.; Hauser, M.; Wexler, M.; Schlager, C.; Gutmann, B.; et al. Comparing the toxicological responses of pulmonary air–liquid interface models upon exposure to differentially treated carbon fibers. Int. J. Mol. Sci. 2023, 24, 1927. [Google Scholar] [CrossRef] [PubMed]

- Gandhi, S.; Lyon, R.; Speitel, L. Potential health hazards from burning aircraft composites. J. Fire Sci. 1999, 17, 20–41. [Google Scholar] [CrossRef]

- Rödelsperger, K. Extrapolation of the carcinogenic potency of fibers from rats to humans. Inhal. Toxicol. 2004, 16, 801–807. [Google Scholar] [CrossRef]

- Maxim, L.D.; Galvin, J.B.; Niebo, R.; Segrave, A.M.; Kampa, O.A.; Utell, M.J. Occupational exposure to carbon/coke fibers in plants that produce green or calcined petroleum coke and potential health effects: 1. Fiber Characteristics. Inhal. Toxicol. 2006, 18, 1–16. [Google Scholar] [CrossRef]

- Thomson, S.A.; Hilaski, R.J.; Wright, R.; Mattie, D. Nonrespirability of Carbon Fibers in Rats from Repeated Inhalation Exposure; Chemical Research, Development & Engineering Center, Aberdeen Proving Ground: Harford County, MD, USA, 1990. [Google Scholar]

- Owen, P.E.; Glaister, J.R.; Ballantyne, B.; Clary, J.J. Subchronic inhalation toxicology of carbon fibers. J. Occup. Med. Off. Publ. Ind. Med. Assoc. 1986, 28, 373–376. [Google Scholar]

- Henry, W.M.; Melton, C.M.; Schmidt, E.W. Method for Measuring Carbon Fiber Emissions from Stationery Sources; US Environmental Protection Agency: Washington, DC, USA, 1982. [Google Scholar]

- Jones, H.D.; Jones, T.R.; Lyle, W.H. Carbon fibre: Results of a survey of process workers and their environment in a factory producing continous filament. Ann. Occup. Hyg. 1982, 26, 861–867. [Google Scholar] [CrossRef]

- Gieseke, J.A.; Reif, R.B.; Schmidt, E.W. Characterization of Carbon Fiber Emissions from Current and Projected Activities for the Manufacture and Disposal of Carbon Fiber Products; US Environmental Protection Agency: Washington, DC, USA, 1984. [Google Scholar]

- Maxim, L.D.; Galvin, J.B.; Niebo, R.; Segrave, A.M.; Kampa, O.A.; Utell, M.J. Occupational exposure to carbon/coke fibers in plants that produce green or calcined petroleum coke and potential health effects: 2. Fiber concentrations. Inhal. Toxicol. 2006, 18, 17–32. [Google Scholar] [CrossRef]

- Bello, D.; Wardle, B.L.; Yamamoto, N.; de Villoria, R.G.; Garcia, E.J.; Hart, A.J.; Ahn, K.; Ellenbecker, M.J.; Hallock, M. Exposure to nanoscale particles and fibers during machining of hybrid advanced composites containing carbon nanotubes. J. Nanoparticle Res. 2009, 11, 231–249. [Google Scholar] [CrossRef]

- Bello, D.; Wardle, B.L.; Zhang, J.; Yamamoto, N.; Santeufemio, C.; Hallock, M.; Virji, M.A. Characterization of exposures to nanoscale particles and fibers during solid core drilling of hybrid carbon nanotube advanced composites. Int. J. Occup. Environ. Health 2010, 16, 434–450. [Google Scholar] [CrossRef]

- Eibl, S.; Reiner, D.; Lehnert, M. Gefährdung durch lungengängige Faserfragmente nach dem Abbrand Kohlenstofffaser verstärkter Kunststoffe. Gefahrst. Reinhalt. Luft 2014, 74, 285–286. [Google Scholar]

- Schlagenhauf, L.; Kuo, Y.-Y.; Michel, S.; Terrasi, G.; Wang, J. Exposure assessment of a high-energy tensile test with large carbon fiber reinforced polymer cables. J. Occup. Environ. Hyg. 2015, 12, D178–D183. [Google Scholar] [CrossRef] [PubMed]

- Jensen, A.C.; Levin, M.; Koivisto, A.J.; Kling, K.I.; Saber, A.T.; Koponen, I.K. Exposure assessment of particulate matter from abrasive treatment of carbon and glass fibre-reinforced epoxy-composites—Two case studies. Aerosol Air Qual. Res. 2015, 15, 1906–1916. [Google Scholar] [CrossRef]

- Mattenklott, M.; Van Gelder, R. Carbonfasern und carbonfaserverstärkte Kunststoffe (CFK). Gefahrst. Reinhalt. Luft 2019, 79, 317–322. [Google Scholar] [CrossRef]

- Lovreglio, P.; Stufano, A.; Mele, D.; Acquafredda, P.; Cottica, D.; Gardinali, F.; Vimercati, L.; Soleo, L.; De Palma, G. Occupational exposure to carbon fibers impregnated with epoxy resins and evaluation of their respirability. Inhal. Toxicol. 2020, 32, 63–67. [Google Scholar] [CrossRef]

- Tölle, L.; Hopp, M. Influence of process parameters on the formation ofinhalable fiber dust during shredding for mechanicalrecycling of fiber-reinforced organo sheets. J. Appl. Polym. Sci. 2022, 139, e52646. [Google Scholar] [CrossRef]

- Mattenklott, M. Bewertung von Faserexpositionen in Arbeitsbereichen. Gefahrst. Reinhalt. Luft 2022, 82, 123–131. [Google Scholar] [CrossRef]

- European Commission. Recommendation from the Scientific Committee on Occupational Exposure Limits for Man Made-Mineral Fibres (MMMF) with no Indication for Carcinogenicity and not Specified Elsewhere; SCOEL/SUM/88. March 2012; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Bundesministerium für Arbeit und Soziales. TRGS 905: Verzeichnis Krebserzeugender, Keimzellmutagener Oder Reproduktionstoxischer Stoffe. Gem. Minist. 2016, 19, 378. [Google Scholar]

- European Union. Classification, labelling and packaging of substances and mixtures, in Regulation (EC) No 1272/2008. Off. J. Eur. Union 2008, L353. Available online: http://data.europa.eu/eli/reg/2008/1272/oj (accessed on 30 May 2023).

- Pott, F.; Friedrichs, K.H. Tumoren der Ratte nach i.p.-Injektion faserförmiger Stäube. Naturwissenschaften 1972, 59, 318. [Google Scholar] [CrossRef]

- Stanton, M.F.; Wrench, C. Mechanisms of mesothelioma induction with asbestos and fibrous glass. Gynecol. Oncol. 1972, 48, 797–821. [Google Scholar] [CrossRef]

- Eibl, S. Potential for the formation of respirable fibers in carbon fiber reinforced plastic materials after combustion. Fire Mater. 2017, 41, 808–816. [Google Scholar] [CrossRef]

- Simonato, L.; Baris, R.; Saracci, R.; Skidmore, J.; Winkelmann, R. Relation of environmental exposure to erionite fibres to risk of respiratory cancer. IARC Sci. Publ. 1989, 90, 398–405. [Google Scholar]

- Kern, D.G.; Crausman, R.S.; Durand, K.T.; Nayer, A.; Kuhn, C., III. Flock worker’s lung: Chronic interstitial lung disease in the nylon flocking industry. Ann. Intern. Med. 1998, 129, 261–272. [Google Scholar] [CrossRef] [PubMed]

- Burdett, G.; Bard, D. An Inventory of Fibres to Classify their Potential Hazard and Risk; Health Safety Laboratory: Buxton, UK, 2006; pp. 1–116. [Google Scholar]

- Donaldson, K. The inhalation toxicology of p-aramid fibrils. Crit. Rev. Toxicol. 2009, 39, 540. [Google Scholar] [CrossRef]

- Arai, Y. Pitch-Based Carbon Fiber with Low Modulus and High Heat Conduction; Nippon Steel Technical Report No. 84; Nippon Steel Corporation: Tokyo, Japan, 2001; pp. 12–17. [Google Scholar]

- DIN EN ISO 10618:2004-11; Carbon Fibre—Determination of Tensile Properties of Resin-Impregnated Yarn (ISO 10618:2004). ISO: Geneva, Switzerland, 2004. [CrossRef]

- Scherrer, P. Bestimmung der inneren Struktur und der Größe von Kolloidteilchen mittels Röntgenstrahlen. Nachr. von der Ges. der Wiss. zu Göttingen, Math. Phys. Kl. 1918, 1918, 98–100. Available online: http://eudml.org/doc/59018 (accessed on 30 May 2023).

- Li, D.; Wang, H.; Wang, X. Effect of microstructure on the modulus of PAN-based carbon fibers during high temperature treatment and hot stretching graphitization. J. Mater. Sci. 2007, 42, 4642–4649. [Google Scholar] [CrossRef]

- Shirasu, K.; Nagai, C.; Naito, K. Mechanical anisotropy of PAN-based and pitch-based carbon fibers. Mech. Eng. J. 2020, 7, 19-00599. [Google Scholar] [CrossRef]

- Brown, S.D.M.; Jorio, A.; Corio, P.; Dresselhaus, M.S.; Dresselhaus, G.; Saito, R.; Kneipp, K. Origin of the Breit-Wigner-Fano lineshape of the tangential G-band feature of metallic carbon nanotubes. Phys. Rev. B 2001, 63, 155414. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Dresselhaus, G.; Sugihara, K.; Spain, I.L.; Goldberg, H.A. Graphite Fibers and Filaments; Springer: Berlin/Heidelberg, Germany, 1988. [Google Scholar]

- Nippon Steel Corporation. Feature Story: The Genesis of Product Making—Raising the added value of carbon materials derived from coal tar—Pitch-based carbon fiber. In Nippon Steel News; No. 383; Nippon Steel Corporation: Tokyo, Japan, 2011. [Google Scholar]

- Arai, Y. Structure and Properties of Pitch-Based Carbon Fibers; Nippon Steel Technical Report No. 59; Nippon Steel Corporation: Tokyo, Japan, 1993; pp. 65–70. [Google Scholar]

- York, D.; Evensen, N.M.; Martínez, M.L.; Delgado, J.D.B. Unified equations for the slope, intercept, and standard errors of the best straight line. Am. J. Phys. 2004, 72, 367–375. [Google Scholar] [CrossRef]

- Mazumder, M.K.; Chang, R.J.; Bond, R.L. Aerodynamic and morphological properties of carbon-fiber aerosols. Aerosol Sci. Technol. 1982, 1, 427–440. [Google Scholar] [CrossRef]

- Boatman, E.; Covert, D.; Kalman, D.; Luchtel, D.; Omenn, G. Physical, morphological, and chemical studies of dusts derived from the machining of composite-epoxy materials. Environ. Res. 1988, 45, 242–255. [Google Scholar] [CrossRef] [PubMed]

- Seibert, J.F. Composite Fiber Hazards; AF Occupational and Environmental Health Laboratory: Texas, TX, USA, 1990. [Google Scholar]

- Audoly, B.; Neukirch, S. Fragmentation of rods by cascading cracks: Why spaghetti does not break in half. Phys. Rev. Lett. 2005, 95, 095505. [Google Scholar] [CrossRef] [PubMed]

- Heisser, R.H.; Patil, V.P.; Stoop, N.; Villermaux, E.; Dunkel, J. Controlling fracture cascades through twisting and quenching. Proc. Natl. Acad. Sci. USA 2018, 115, 8665–8670. [Google Scholar] [CrossRef] [PubMed]

- Broßell, D.; Meyer-Plath, A.; Kämpf, K.; Plitzko, S.; Wohlleben, W.; Stahlmecke, B.; Wiemann, A.; Haase, A. A Human risk banding scheme for high aspect-ratio materials. In Synthetic Nano- and Microfibers; Wagterveld, R.M., Ed.; WETSUS: Leeuwarden, The Netherlands, 2020; pp. 55–80. [Google Scholar]

| Fiber ID | 12 iPitch | 1 PAN | 8 PAN | 5 PAN | 4 PAN | 15 PAN | 14 mPitch | 11 mPitch | 10 mPitch | Mean |

|---|---|---|---|---|---|---|---|---|---|---|

| Mass on Filter [mg] | 0.055 | 0.050 | 0.050 | 0.050 | 0.050 | 0.050 | 0.050 | 0.040 | 0.100 | 0.055 ± 0.017 |

| Evaluated Filter Area [mm2] | 0.283 | 0.151 | 0.718 | 0.265 | 0.189 | 0.359 | 0.132 | 0.189 | 0.605 | 0.321 ± 0.207 |

| Count Correction Factor | 1.133 | 2.338 | 0.492 | 1.336 | 1.870 | 0.984 | 2.671 | 2.338 | 0.292 |

| Fiber ID | Product | Tensile Modulus [GPa] | Specific Density * [g/cm3] | Thermal Conductivity * [W/m/K] | Transverse Modulus [GPa] | Electrical Resistivity [µΩ m] | Elongation at Break [%] | Tensile Strength [MPa] | Initial Diameter [µm] |

|---|---|---|---|---|---|---|---|---|---|

| 12 iPitch | Mitsui GRANOC XN-05-30S | 54  | 1.65  | 5.0  | 40.9  | 28.0  | 2.0  | 1100  | 10.0  |

| 1 PAN | Teijin Carbon Tenax HTS40 F13 | 240  | 1.77  | 17.0  | 22.3  | 16.4  | 1.8  | 4400  | 7.0  |

| 8 PAN | SGL Carbon SIGRAFIL CT50-4.0/240 | 240  | 1.77  | 26.0  | 22.3  | 15.3  | 1.7  | 4000  | 7.0  |

| 5 PAN | Teijin Carbon Tenax IMS65 E23 | 290  | 1.77  | 35.0  | 20.0  | 13.8  | 2.1  | 6000  | 5.0  |

| 4 PAN | Teijin Carbon Tenax UMS40 F23 | 390  | 1.79  | 46.6  | 16.3  | 10.8  | 1.1  | 4500  | 4.9  |

| 15 PAN | Teijin Carbon Tenax UMS55 | 550  | 1.91  | 107.0  | 12.0  | 7.8  | 0.7  | 4000  | 4.4  |

| 14 mPitch | Mitsui YSH-50A-60S | 520  | 2.10  | 120.0  | 12.7  | 7.0  | 0.7  | 3830  | 7.0  |

| 11 mPitch | Mitsubishi Chemical Dialead K63712 | 640  | 2.12  | 140.0  | 10.2  | 6.6  | 0.4  | 2600  | 11.0  |

| 10 mPitch | Mitsubishi Chemical Dialead K13D2U | 935  | 2.20  | 800.0  | 5.4  | 1.5  | 0.4  | 3700  | 11.0  |

| Fiber ID | |||||||

|---|---|---|---|---|---|---|---|

| 12 iPitch | 1.36  | 2.9  | 1.6  | 25.3  | 57  | 0.353  | 23.1  |

| 1 PAN | 1.36  | 2.9  | 2.3  | 25.4  | 80  | 0.351  | 17.9  |

| 8 PAN | 1.61  | 3.5  | 2.4  | 25.5  | 81  | 0.349  | 18.4  |

| 5 PAN | 1.55  | 3.3  | 1.8  | 25.6  | 83  | 0.348  | 18.6  |

| 4 PAN | 2.87  | 6.2  | 6.6  | 25.8  | 88  | 0.345  | 18.4  |

| 15 PAN | 5.36  | 11.5  | 8.0  | 26.0  | 93  | 0.342  | 13.7  |

| 14 mPitch | 9.91  | 21.2  | 13.0  | 25.9  | 94  | 0.343  | 4.9  |

| 11 mPitch | 11.64  | 24.9  | 12.6  | 25.9  | 95  | 0.344  | 3.7  |

| 10 mPitch | 13.70  | 29.3  | 39.3  | 26.3  | 97  | 0.338  | 1.8  |

| Fiber ID | |||||||

|---|---|---|---|---|---|---|---|

| 12 iPitch | 1.36  | 2.9  | 1.6  | 25.3  | 57  | 0.353  | 23.1  |

| 1 PAN | 1.36  | 2.9  | 2.3  | 25.4  | 80  | 0.351  | 17.9  |

| 8 PAN | 1.61  | 3.5  | 2.4  | 25.5  | 81  | 0.349  | 18.4  |

| 5 PAN | 1.55  | 3.3  | 1.8  | 25.6  | 83  | 0.348  | 18.6  |

| 4 PAN | 2.87  | 6.2  | 6.6  | 25.8  | 88  | 0.345  | 18.4  |

| 15 PAN | 5.36  | 11.5  | 8.0  | 26.0  | 93  | 0.342  | 13.7  |

| 14 mPitch | 9.91  | 21.2  | 13.0  | 25.9  | 94  | 0.343  | 4.9  |

| 11 mPitch | 11.64  | 24.9  | 12.6  | 25.9  | 95  | 0.344  | 3.7  |

| 10 mPitch | 13.70  | 29.3  | 39.3  | 26.3  | 97  | 0.338  | 1.8  |

| Fiber ID | Mean Aspect Ratio 1 of WHOFOs [1] | Mean Aspect Ratio 1 of HARFOs [1] | Mean Length 2 of WHOFOs [µm] | Mean Length 2 of HARFOs [µm] | Mean Length 2 of HARFSs [µm] | Mean Diameter 3 of WHOFOs [µm] | Mean Diameter 3 of HARFOs [µm] | Mean Diameter 3 of HARFSs [µm] |

|---|---|---|---|---|---|---|---|---|

| 12 iPitch | 4.8 ± 1.5  | 4.2 ± 1.1  | 10.4 ± 4.9  | 17.7 ± 12.5  | 15.9 ± 12.3  | 2.2 ± 0.7  | 4.3 ± 3.0  | 3.6 ± 2.4  |

| 1 PAN | 4.6 ± 1.6  | 4.3 ± 1.0  | 8.8 ± 2.4  | 7.4 ± 8.6  | 5.6 ± 4.1  | 2.0 ± 0.4  | 1.7 ± 1.6  | 1.3 ± 1.0  |

| 8 PAN | 5.0 ± 2.2  | 4.8 ± 2.1  | 7.9 ± 2.2  | 19.3 ± 21.8  | 10.0 ± 7.5  | 1.7 ± 0.5  | 3.7 ± 2.7  | 2.4 ± 1.7  |

| 5 PAN | 4.4 ± 1.5  | 4.6 ± 2.3  | 7.5 ± 1.1  | 13.5 ± 15.9  | 6.1 ± 3.2  | 1.9 ± 0.7  | 2.7 ± 1.9  | 1.6 ± 1.0  |

| 4 PAN | 4.8 ± 1.4  | 4.5 ± 1.1  | 7.6 ± 2.4  | 9.9 ± 6.4  | 8.1 ± 5.4  | 1.7 ± 0.6  | 2.3 ± 1.6  | 1.8 ± 1.2  |

| 15 PAN | 4.3 ± 1.7  | 4.3 ± 1.2  | 7.1 ± 1.9  | 11.6 ± 7.6  | 5.0 ± 2.5  | 1.8 ± 0.6  | 2.8 ± 1.7  | 1.2 ± 0.8  |

| 14 mPitch | 5.3 ± 2.9  | 5.3 ± 2.5  | 8.0 ± 2.3  | 6.4 ± 5.9  | 5.5 ± 3.4  | 1.7 ± 0.6  | 1.4 ± 1.5  | 1.2 ± 0.9  |

| 11 mPitch | 6.9 ± 4.6  | 5.7 ± 3.2  | 8.0 ± 2.0  | 6.4 ± 5.3  | 6.1 ± 4.3  | 1.4 ± 0.6  | 1.3 ± 1.4  | 1.2 ± 1.1  |

| 10 mPitch | 8.2 ± 5.1  | 7.1 ± 4.3  | 10.9 ± 5.5  | 10.5 ± 7.4  | 10.3 ± 6.6  | 1.5 ± 0.7  | 1.8 ± 1.5  | 1.8 ± 1.3  |

| Fiber ID | LARPCs per Fragments [%] | HARFOs per Fragments [%] | WHOFOs per Fragments [%] | WHOFOs per HARFOs [%] | HARFOs shorter 5 µm per HARFOs [%] | HARFOs thicker 3 µm per HARFOs [%] | HARFSs per HARFOs [%] | HARFCs per HARFOs [%] |

|---|---|---|---|---|---|---|---|---|

| 12 iPitch | 5.5 ± 1.1  | 5 ± 1  | 1.0 ± 0.4  | 20 ± 10  | 20 ± 10  | 60 ± 20  | 88 ± 26  | 12 ± 7  |

| 1 PAN | 2.9 ± 0.8  | 11 ± 2  | 1.9 ± 0.6  | 19 ± 6  | 69 ± 15  | 13 ± 5  | 94 ± 18  | 6 ± 3  |

| 8 PAN | 6.7 ± 1.2  | 14 ± 2  | 3.5 ± 0.9  | 25 ± 7  | 25 ± 7  | 51 ± 11  | 72 ± 13  | 30 ± 8  |

| 5 PAN | 5.5 ± 1.0  | 12 ± 2  | 2.8 ± 0.7  | 25 ± 7  | 39 ± 9  | 36 ± 9  | 70 ± 14  | 33 ± 8  |

| 4 PAN | 4.0 ± 0.9  | 5 ± 1  | 2.1 ± 0.6  | 41 ± 15  | 26 ± 11  | 33 ± 13  | 81 ± 23  | 26 ± 11  |

| 15 PAN | 10.5 ± 1.5  | 13 ± 2  | 2.6 ± 0.7  | 19 ± 6  | 30 ± 8  | 51 ± 11  | 51 ± 11  | 49 ± 10  |

| 14 mPitch | 1.0 ± 0.4  | 39 ± 3  | 13.7 ± 1.7  | 35 ± 5  | 58 ± 7  | 6 ± 2  | 97 ± 10  | 3 ± 1  |

| 11 mPitch | 0.9 ± 0.4  | 47 ± 4  | 16.3 ± 1.9  | 35 ± 4  | 58 ± 6  | 7 ± 2  | 99 ± 9  | 1 ± 1  |

| 10 mPitch | 0  | 72 ± 5  | 41.0 ± 3.4  | 57 ± 5  | 26 ± 3  | 18 ± 2  | 99 ± 7  | 1 ± 0  |

| Fiber ID | Milled Filament Length for 10k WHOFOs [mm/10k] | WHOFOs per Milled Filament Length [1/mm] | HARFOs per Milled Filament Length [1/mm] | WHOFOs per Milled CF Volume [1/pL] | HARFOs per Milled CF Volume [1/pL] | LARPOs per Milled CF Volume [1/pL] | LARPOs+HARFOs per Milled CF Volume [1/pL] |

|---|---|---|---|---|---|---|---|

| 12 iPitch | 490 ± 290  | 20 ± 12  | 102 ± 44  | 0.3 ± 0.1  | 1.3 ± 0.4  | 26.0 ± 6.5  | 27.3 ± 6.8  |

| 1 PAN | 226 ± 113  | 44 ± 22  | 239 ± 98  | 1.1 ± 0.5  | 6.2 ± 1.7  | 52.8 ± 13.0  | 59.0 ± 14.5  |

| 8 PAN | 632 ± 288  | 16 ± 7  | 64 ± 26  | 0.4 ± 0.1  | 1.7 ± 0.5  | 10.0 ± 2.5  | 11.6 ± 2.9  |

| 5 PAN | 517 ± 240  | 19 ± 9  | 79 ± 32  | 1.0 ± 0.3  | 4.0 ± 1.1  | 30.7 ± 7.6  | 34.8 ± 8.5  |

| 4 PAN | 518 ± 254  | 19 ± 9  | 47 ± 20  | 1.0 ± 0.4  | 2.5 ± 0.8  | 45.9 ± 11.3  | 48.4 ± 11.9  |

| 15 PAN | 969 ± 459  | 10 ± 5  | 53 ± 21  | 0.7 ± 0.2  | 3.5 ± 0.9  | 22.9 ± 5.6  | 26.4 ± 6.4  |

| 14 mPitch | 24 ± 10  | 420 ± 168  | 1200 ± 467  | 10.9 ± 2.9  | 31.2 ± 7.7  | 48.6 ± 11.9  | 79.8 ± 19.3  |

| 11 mPitch | 9 ± 3  | 1152 ± 457  | 3311 ± 1284  | 12.1 ± 3.2  | 34.8 ± 8.6  | 39.4 ± 9.6  | 74.2 ± 17.9  |

| 10 mPitch | 29 ± 11  | 348 ± 135  | 614 ± 237  | 3.7 ± 0.9  | 6.5 ± 1.6  | 2.5 ± 0.6  | 8.9 ± 2.2  |

| Fiber ID | WHOFOs ≤10° WOA [%] | WHOFOs ≤10° WOA [1] | Mean WOA [°] | Relative Error of Diameter [%] |

|---|---|---|---|---|

| 12 iPitch | 100 ± 76  | 7/7 | 1.2 ± 0.6  | 4.5 ± 1.8  |

| 1 PAN | 92 ± 52  | 12/13 | 3.3 ± 0.9  | 15.4 ± 2.9  |

| 8 PAN | 78 ± 39  | 14/18 | 5.9 ± 1.4  | 19.7 ± 2.6  |

| 5 PAN | 89 ± 42  | 17/19 | 4.5 ± 1.1  | 12.0 ± 2.6  |

| 4 PAN | 100 ± 63  | 10/10 | 1.7 ± 0.9  | 7.3 ± 3.3  |

| 15 PAN | 81 ± 43  | 13/16 | 5.6 ± 1.8  | 16.0 ± 4.4  |

| 14 mPitch | 92 ± 22  | 68/74 | 2.6 ± 0.5  | 8.9 ± 1.3  |

| 11 mPitch | 97 ± 19  | 104/107 | 1.4 ± 0.3  | 6.3 ± 1.0  |

| 10 mPitch | 95 ± 13  | 203/214 | 2.2 ± 0.2  | 8.6 ± 0.7  |

| panCF 8 Wedge-shaped |  |

| Arc length: 6.4 µm|Median width: 2.0 µm|Mean width: (1.8 ± 0.7) µm, δ = 39%|Opening angle: 20.2° | |

| panCF 8 Fiber-shaped |  |

| Arc length: 8.0 µm|Median width: 1.8 µm|Mean width: (1.7 ± 0.2) µm, δ = 13%|Opening angle: 3.5° | |

| panCF 5 Wedge-shaped |  |

| Arc length: 7.7 µm|Median width: 2.0 µm|Mean width: (1.9 ± 0.8) µm, δ = 44%|Opening angle: 16.1° | |

| panCF 5 Fiber-shaped |  |

| Arc length: 6.2 µm|Median width: 1.1 µm|Mean width: (1.0 ± 0.1) µm, δ = 14%|Opening angle: 4.1° | |

| mPitchCF 14 Wedge-shaped |  |

| Arc length: 10.4 µm|Median width: 3.3 µm|Mean width: (2.6 ± 0.8) µm, δ = 32%|Opening angle: 13.9° | |

| mPitchCF 14 Fiber-shaped |  |

| Arc length: 10.4 µm|Median width: 0.5 µm|Mean width: (0.5 ± 0.1) µm, δ = 17%|Opening angle: 0.1° | |

| Property Group | Original Material Property | Transformed Property of Improved Normality and Linear Dependence to ϱ | Original pKS-Value | Transformed pKS-Value | Original pPC-Value to ϱ | Transformed pPC-Value to ϱ |

|---|---|---|---|---|---|---|

| P1 | Microporosity | 0.43 | 0.000 | |||

| Density | 0.47 | 0.000 | ||||

| P2 | Partial Orientation | 0.69 | 0.007 | |||

| P3 | Interlayer Spacing | 0.99 | 0.003 | |||

| Tensile Modulus | 0.98 | 0.000 | ||||

| Crystallite Size | 0.40 | 0.69 | 0.006 | 0.000 | ||

| Crystallite Size | 0.51 | 0.59 | 0.000 | 0.000 | ||

| Thermal Conductivity | 0.09 | 0.96 | 0.028 | 0.000 | ||

| Raman Area Ratio | log(AG/AD) | 0.28 | 0.30 | 0.011 | 0.001 | |

| Elongation at Break | 0.73 | 0.001 | ||||

| P4 | Tensile Strength | 0.54 | 0.924 | |||

| P5 | Initial Diameter | 0.60 | 0.230 |

| -Value | WHOFOs per Milled CF Volume | HARFOs per Milled CF Volume | *WHOFOs 11,14 per Milled CF Volume | *HARFOs11,14 per Milled CF Volume | Mean Length of WHOFOs | Mean Length of HARFOs | Mean Aspect Ratio of WHOFOs | Mean Aspect Ratio of HARFOs | Mean Diameter of WHOFOs | Mean Diameter of HARFOs | WHOFOs per HARFOs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| WHOFOs per Milled CF Volume | +0.000 | +0.000 | +0.047 | −0.836 | −0.046 | +0.177 | +0.177 | −0.094 | −0.038 | +0.324 | |||||||||||||

| 0.16 | 68% | 100% | 69% | 100% | 100% | 100% | 100% | 100% | 100% | 0% | |||||||||||||

| 21% | 28% | 31% | >199% | 113% | >199% | 173% | 161% | 105% | 29% | ||||||||||||||

| HARFOs per Milled CF Volume | +0.000 | +0.047 | +0.000 | −0.677 | −0.041 | +0.306 | +0.313 | −0.144 | −0.042 | +0.522 | |||||||||||||

| 0.10 | 68% | 68% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 0% | |||||||||||||

| 21% | 30% | 27% | >199% | 111% | >199% | 197% | 184% | 106% | 80% | ||||||||||||||

| *WHOFOs11,14 per Milled CF Volume | +0.000 | +0.047 | +0.047 | +0.197 | −0.283 | +0.003 | +0.002 | −0.159 | −0.104 | +0.014 | |||||||||||||

| 0.16 | 100% | 68% | 69% | 100% | 100% | 100% | 100% | 100% | 100% | 74% | |||||||||||||

| 28% | 30% | 32% | >199% | 137% | >199% | 188% | 172% | 132% | 32% | ||||||||||||||

| *HARFOs11,14 per Milled CF Volume | +0.047 | +0.000 | +0.047 | +0.544 | −0.043 | +0.233 | +0.195 | −0.522 | −0.008 | +0.398 | |||||||||||||

| 0.10 | 69% | 100% | 69% | 100% | 100% | 100% | 100% | 100% | 100% | 13% | |||||||||||||

| 31% | 27% | 32% | >199% | 138% | >199% | >199% | 192% | 136% | 33% | ||||||||||||||

| Mean Length of WHOFOs | −0.836 | −0.677 | +0.197 | +0.544 | +0.692 | +0.110 | +0.193 | +0.563 | +0.748 | +0.315 | |||||||||||||

| 0.32 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |||||||||||||

| >199% | >199% | >199% | >199% | >199% | 185% | >199% | 175% | >199% | >199% | ||||||||||||||

| Mean Length of HARFOs | −0.046 | −0.041 | −0.283 | −0.043 | +0.692 | −0.442 | −0.419 | +0.245 | +0.000 | −0.369 | |||||||||||||

| 0.97 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 99% | |||||||||||||

| 113% | 111% | 137% | 138% | >199% | >199% | >199% | 151% | 117% | >199% | ||||||||||||||

| Mean Aspect Ratio of WHOFOs | +0.177 | +0.306 | +0.003 | +0.233 | +0.110 | −0.442 | +0.000 | −0.055 | −0.222 | +0.006 | |||||||||||||

| 0.29 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |||||||||||||

| >199% | >199% | >199% | >199% | 185% | >199% | 166% | 172% | >199% | 195% | ||||||||||||||

| Mean Aspect Ratio of HARFOs | +0.177 | +0.313 | +0.002 | +0.195 | +0.193 | −0.419 | +0.000 | −0.038 | −0.169 | +0.002 | |||||||||||||

| 0.58 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |||||||||||||

| 173% | 197% | 188% | >199% | >199% | >199% | 166% | 181% | >199% | 178% | ||||||||||||||

| Mean Diameter of WHOFOs | −0.094 | −0.144 | −0.159 | −0.522 | +0.563 | +0.245 | −0.055 | −0.038 | +0.089 | −0.044 | |||||||||||||

| 0.98 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | |||||||||||||

| 161% | 184% | 172% | 192% | 175% | 151% | 172% | 181% | 148% | 132% | ||||||||||||||

| Mean Diameter of HARFOs | −0.038 | −0.042 | −0.104 | −0.008 | +0.748 | +0.000 | −0.222 | −0.169 | +0.089 | −0.193 | |||||||||||||

| 0.91 | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 100% | 98% | |||||||||||||

| 105% | 106% | 132% | 136% | >199% | 117% | >199% | >199% | 148% | 187% | ||||||||||||||

| WHOFOs per HARFOs | +0.324 | +0.522 | +0.014 | +0.398 | +0.315 | −0.369 | +0.006 | +0.002 | −0.044 | −0.193 | |||||||||||||

| 0.63 | 0% | 0% | 74% | 13% | 100% | 99% | 100% | 100% | 100% | 98% | |||||||||||||

| 29% | 31% | 32% | 33% | >199% | >199% | 195% | 178% | 132% | 187% |

| ndf = 7: χ2/ndf | 0.00 | 0.12 | 0.18 | 0.30 | 0.40 | 0.55 | 0.69 | 0.91 | 1.00 | 1.40 | 1.72 | 2.01 | 2.64 | 3.47 | 4.27 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pndf(χ2) [%] | 100.00 | 99.73 | 99.00 | 95.45 | 90.00 | 80.00 | 68.27 | 50.00 | 42.89 | 20.00 | 10.00 | 5.00 | 1.00 | 0.10 | 0.01 |

| P1 | P2 | P4 | P4 | P5 | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Property Group | Microporosity | Specific Density | Partial Orientation | Interlayer Spacing | Tensile Modulus | Crystallite Size | Crystallite Size | Thermal Conductivity | Raman Area Ratio | Elongation at Break | Tensile Strength | Initial CF Diameter | |||||||||||||

| P1 | Micro- porosity | +0.000 | −0.010 | +0.006 | −0.001 | −0.001 | +0.000 | −0.001 | −0.001 | +0.002 | +0.873 | −0.193 | |||||||||||||

| 100% | 84% | 94% | 97% | 98% | 100% | 96% | 95% | 95% | 17% | 41% | |||||||||||||||

| 41% | 38% | 41% | 35% | 35% | 33% | 36% | 35% | 36% | >199% | 53% | |||||||||||||||

| Specific Density | +0.000 | +0.007 | −0.003 | +0.000 | +0.000 | +0.000 | +0.000 | +0.001 | −0.001 | −0.924 | +0.230 | ||||||||||||||

| 100% | 79% | 95% | 98% | 98% | 100% | 96% | 94% | 95% | 6% | 21% | |||||||||||||||

| 41% | 33% | 37% | 31% | 30% | 29% | 31% | 30% | 32% | >199% | 47% | |||||||||||||||

| P2 | Partial Orientation | −0.010 | +0.007 | −0.002 | +0.003 | +0.009 | +0.011 | +0.001 | +0.040 | −0.008 | +0.240 | −0.838 | |||||||||||||

| 84% | 79% | 82% | 7% | 5% | 1% | 30% | 0% | 6% | 0% | 0% | |||||||||||||||

| 38% | 33% | 26% | 14% | 15% | 14% | 15% | 15% | 17% | 15% | 31% | |||||||||||||||

| P3 | Interlayer Spacing | +0.006 | −0.003 | −0.002 | +0.000 | +0.000 | −0.001 | +0.000 | −0.001 | +0.001 | −0.640 | −0.795 | |||||||||||||

| 94% | 95% | 82% | 99% | 97% | 82% | 99% | 79% | 86% | 1% | 1% | |||||||||||||||

| 41% | 37% | 26% | 25% | 25% | 26% | 25% | 25% | 27% | 92% | 89% | |||||||||||||||

| Tensile Modulus | −0.001 | +0.000 | +0.003 | +0.000 | +0.000 | +0.001 | +0.000 | +0.000 | −0.001 | +0.821 | +0.392 | ||||||||||||||

| 97% | 98% | 7% | 99% | 75% | 22% | 97% | 2% | 35% | 0% | 0% | |||||||||||||||

| 35% | 31% | 14% | 25% | 15% | 14% | 14% | 11% | 17% | 18% | 64% | |||||||||||||||

| Crystallite Size | −0.001 | +0.000 | +0.009 | +0.000 | +0.000 | +0.000 | +0.000 | +0.000 | +0.000 | −0.871 | +0.340 | ||||||||||||||

| 98% | 98% | 5% | 97% | 75% | 20% | 42% | 1% | 70% | 0% | 0% | |||||||||||||||

| 35% | 30% | 15% | 25% | 15% | 12% | 11% | 9% | 16% | 18% | 64% | |||||||||||||||

| Crystallite Size | +0.000 | +0.000 | +0.011 | −0.001 | +0.001 | +0.000 | +0.001 | +0.001 | +0.000 | −0.707 | +0.283 | ||||||||||||||

| 100% | 100% | 1% | 82% | 22% | 20% | 0% | 0% | 86% | 0% | 0% | |||||||||||||||

| 33% | 29% | 14% | 26% | 14% | 12% | 11% | 10% | 16% | 17% | 55% | |||||||||||||||

| Thermal Conductivity | −0.001 | +0.000 | +0.001 | +0.000 | +0.000 | +0.000 | +0.001 | +0.001 | −0.003 | +0.590 | +0.567 | ||||||||||||||

| 96% | 96% | 30% | 99% | 97% | 42% | 0% | 1% | 6% | 0% | 0% | |||||||||||||||

| 36% | 31% | 15% | 25% | 14% | 11% | 11% | 6% | 16% | 17% | >199% | |||||||||||||||

| Raman Area Ratio | −0.001 | +0.001 | +0.040 | −0.001 | +0.000 | +0.000 | +0.001 | +0.001 | −0.003 | −0.718 | +0.221 | ||||||||||||||

| 95% | 94% | 0% | 79% | 2% | 1% | 0% | 1% | 3% | 0% | 0% | |||||||||||||||

| 35% | 30% | 15% | 25% | 11% | 9% | 10% | 6% | 15% | 113% | 85% | |||||||||||||||

| Elongation at Break | +0.002 | −0.001 | −0.008 | +0.001 | −0.001 | +0.000 | +0.000 | −0.003 | −0.003 | +0.696 | −0.432 | ||||||||||||||

| 95% | 95% | 6% | 86% | 35% | 70% | 86% | 6% | 3% | 0% | 0% | |||||||||||||||

| 36% | 32% | 17% | 27% | 17% | 16% | 16% | 16% | 15% | 38% | 102% | |||||||||||||||

| P4 | Tensile Strength | +0.873 | −0.924 | +0.240 | −0.640 | +0.821 | −0.871 | −0.707 | +0.590 | −0.718 | +0.696 | −0.035 | |||||||||||||

| 17% | 6% | 0% | 1% | 0% | 0% | 0% | 0% | 0% | 0% | 3% | |||||||||||||||

| >199% | >199% | 15% | 92% | 18% | 20% | 23% | 19% | 113% | 38% | 22% | |||||||||||||||

| P5 | Initial Diameter | −0.193 | +0.230 | −0.838 | −0.795 | +0.392 | +0.340 | +0.283 | +0.567 | +0.221 | −0.432 | −0.035 | |||||||||||||

| 41% | 21% | 0% | 1% | 0% | 0% | 0% | 0% | 0% | 0% | 3% | |||||||||||||||

| 53% | 47% | 31% | 89% | 64% | 64% | 55% | >199% | 85% | 102% | 22% | |||||||||||||||

| Property Group | WHOFOs per Milled CF Volume | HARFOs per Milled CF Volume | *WHOFOs11,14 per Milled CF Volume | *HARFOs11,14 per Milled CF Volume | Mean Length of WHOFOs | Mean Length of HARFOs | Mean Aspect Ratio of WHOFOs | Mean Aspect Ratio of HARFOs | Mean Diameter of WHOFOs | Mean Diameter of HARFOs | WHOFOs per HARFOs | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P1 | Micro- porosity | −0.011 | −0.028 | −0.003 | −0.088 | −0.711 | +0.066 | −0.010 | −0.004 | +0.016 | +0.021 | −0.037 | |||||||||||

| 80% | 66% | 97% | 84% | 100% | 100% | 100% | 100% | 100% | 100% | 81% | |||||||||||||

| 44% | 47% | 53% | 56% | >199% | 135% | 189% | 158% | 125% | 104% | 39% | |||||||||||||

| Specific Density | +0.018 | +0.043 | +0.004 | +0.106 | +0.724 | −0.073 | +0.010 | +0.004 | −0.014 | −0.025 | +0.029 | ||||||||||||

| 59% | 42% | 94% | 74% | 100% | 100% | 100% | 100% | 100% | 100% | 77% | |||||||||||||

| 41% | 44% | 47% | 48% | >199% | 142% | >199% | 163% | 124% | 108% | 35% | |||||||||||||

| P2 | Partial Orientation | +0.144 | +0.185 | +0.146 | +0.191 | −0.368 | −0.060 | +0.194 | +0.093 | −0.003 | −0.016 | +0.099 | |||||||||||

| 0% | 0% | 3% | 5% | 100% | 100% | 100% | 100% | 100% | 99% | 3% | |||||||||||||

| 32% | 28% | 36% | 31% | >199% | 135% | >199% | >199% | 113% | 111% | 23% | |||||||||||||

| P3 | Interlayer Spacing | −0.253 | −0.374 | −0.055 | −0.300 | +0.969 | +0.196 | −0.067 | −0.026 | +0.019 | +0.112 | −0.020 | |||||||||||

| 2% | 1% | 29% | 22% | 100% | 99% | 100% | 100% | 100% | 98% | 58% | |||||||||||||

| 53% | 67% | 41% | 37% | >199% | >199% | >199% | >199% | 125% | 188% | 30% | |||||||||||||

| Tensile Modulus | +0.172 | +0.276 | +0.010 | +0.139 | +0.704 | −0.141 | +0.010 | +0.003 | −0.013 | −0.059 | +0.012 | ||||||||||||

| 0% | 0% | 13% | 19% | 100% | 99% | 100% | 100% | 100% | 99% | 35% | |||||||||||||

| 27% | 25% | 31% | 28% | >199% | >199% | >199% | >199% | 124% | 147% | 21% | |||||||||||||

| Crystallite Size | +0.104 | +0.188 | +0.018 | +0.244 | +0.631 | −0.109 | +0.013 | +0.007 | −0.018 | −0.062 | +0.006 | ||||||||||||

| 0% | 0% | 10% | 9% | 100% | 99% | 100% | 100% | 100% | 99% | 28% | |||||||||||||

| 31% | 28% | 35% | 31% | >199% | >199% | >199% | >199% | 126% | 137% | 20% | |||||||||||||

| Crystallite Size | +0.021 | +0.047 | +0.031 | +0.287 | +0.819 | −0.086 | +0.023 | +0.015 | −0.019 | −0.056 | +0.035 | ||||||||||||

| 0% | 0% | 5% | 11% | 100% | 99% | 100% | 100% | 100% | 99% | 3% | |||||||||||||

| 31% | 26% | 36% | 30% | >199% | 159% | >199% | >199% | 126% | 125% | 22% | |||||||||||||

| Thermal Conductivity | +0.180 | +0.283 | +0.017 | +0.162 | +0.898 | −0.163 | +0.022 | +0.005 | −0.008 | −0.059 | +0.013 | ||||||||||||

| 0% | 0% | 6% | 11% | 100% | 99% | 100% | 100% | 100% | 99% | 24% | |||||||||||||

| 35% | 30% | 38% | 33% | >199% | >199% | >199% | >199% | 118% | 152% | 19% | |||||||||||||

| Raman Area Ratio | +0.192 | +0.305 | +0.027 | +0.243 | +0.415 | −0.312 | +0.010 | +0.005 | −0.074 | −0.202 | +0.038 | ||||||||||||

| 0% | 0% | 1% | 3% | 100% | 99% | 100% | 100% | 100% | 98% | 10% | |||||||||||||

| 35% | 28% | 41% | 32% | >199% | >199% | >199% | >199% | 149% | 197% | 19% | |||||||||||||

| Elongation at Break | −0.058 | −0.099 | −0.110 | −0.406 | +0.992 | +0.084 | −0.053 | −0.052 | +0.013 | +0.070 | −0.055 | ||||||||||||

| 0% | 0% | 2% | 4% | 100% | 99% | 100% | 100% | 100% | 99% | 3% | |||||||||||||

| 29% | 30% | 40% | 34% | >199% | 162% | >199% | >199% | 121% | 134% | 23% | |||||||||||||

| P4 | Tensile Strength | −0.564 | −0.596 | +0.760 | +0.380 | −0.128 | −0.680 | −0.497 | −0.877 | −0.648 | −0.447 | +0.935 | |||||||||||

| 0% | 0% | 2% | 2% | 100% | 98% | 100% | 100% | 99% | 97% | 0% | |||||||||||||

| 38% | 33% | 38% | 34% | >199% | >199% | >199% | >199% | >199% | >199% | 35% | |||||||||||||

| P5 | Initial Diameter | +0.233 | +0.316 | +0.236 | +0.673 | +0.018 | −0.867 | +0.012 | +0.062 | −0.580 | −0.743 | +0.264 | |||||||||||

| 0% | 0% | 1% | 1% | 100% | 99% | 100% | 100% | 99% | 98% | 10% | |||||||||||||

| 52% | 45% | 52% | 45% | 159% | >199% | >199% | >199% | >199% | 176% | 27% |

| HARFOs | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Measurand | 12 iPitch | 1 PAN | 8 PAN | 5 PAN | 4 PAN | 15 PAN | 14 mPitch | 11 mPitch | 10 mPitch |

| Initial Diameter [µm] | 10.0 | 7.0 | 7.0 | 5.0 | 4.9 | 4.4 | 7.0 | 11.0 | 11.0 |

| Mean Length [µm] | 17.7 | 7.4 | 19.3 | 13.5 | 9.9 | 11.6 | 6.4 | 6.4 | 10.5 |

| Ratio [1] | 1.8 | 1.1 | 2.8 | 2.7 | 2.0 | 2.6 | 0.9 | 0.6 | 1.0 |

| Maximum Length [µm] | 42.5 | 45.6 | 132.9 | 92.2 | 22.4 | 28.8 | 43.0 | 46.4 | 59.2 |

| Ratio [1] | 4.3 | 6.5 | 19.0 | 18.4 | 4.6 | 6.5 | 6.1 | 4.2 | 5.4 |

| WHOFOs | |||||||||

| Measurand | 12 iPitch | 1 PAN | 8 PAN | 5 PAN | 4 PAN | 15 PAN | 14 mPitch | 11 mPitch | 10 mPitch |

| Initial Diameter [µm] | 10.0 | 7.0 | 7.0 | 5.0 | 4.9 | 4.4 | 7.0 | 11.0 | 11.0 |

| Mean Length [µm] | 10.4 | 8.8 | 7.9 | 7.5 | 7.6 | 7.1 | 8.0 | 8.0 | 10.9 |

| Ratio [1] | 1.0 | 1.3 | 1.1 | 1.5 | 1.6 | 1.6 | 1.1 | 0.7 | 1.0 |

| Maximum Length [µm] | 16.8 | 13.8 | 13.4 | 9.2 | 12.2 | 11.8 | 14.9 | 13.6 | 42.4 |

| Ratio [1] | 1.7 | 2.0 | 1.9 | 1.8 | 2.5 | 2.7 | 2.1 | 1.2 | 3.9 |

| Fiber ID | Mean HARFO Volume [µm3] | Mean Length of HARFOs [µm] | Mean Diameter of HARFOs [µm] | HARFOs per Milled CF Volume [1/pL] | LARPOs of Initial Diameter [%] | Total Volume of HARFOs per Milled Volume [%] | Total Volume of HARFSs per Milled Volume [%] | Total Volume of WHOFOs per Milled Volume [%] |

|---|---|---|---|---|---|---|---|---|

| 12 iPitch | 632 ± 890  | 17.7 ± 12.5 | 4.3 ± 3.0  | 1.3 ± 0.4  | 5.5 ± 1.1  | 82.1 ± 20.6  | 48.2 ± 12.3  | 1.3 ± 0.4  |

| 1 PAN | 104 ± 341  | 7.4 ± 8.6  | 1.7 ± 1.6  | 6.2 ± 1.7  | 2.9 ± 0.8  | 64.4 ± 16.1  | 14.4 ± 3.6  | 3.2 ± 0.8  |

| 8 PAN | 536 ± 896  | 19.3 ± 21.8  | 3.7 ± 2.7  | 1.7 ± 0.5  | 6.7 ± 1.2  | 89.5 ± 21.8  | 14.8 ± 3.6  | 0.8 ± 0.2  |

| 5 PAN | 197 ± 341  | 13.5 ± 15.9  | 2.7 ± 1.9  | 4.0 ± 1.1  | 5.5 ± 1.0  | 79.0 ± 19.2  | 7.9 ± 1.9  | 2.5 ± 0.6  |

| 4 PAN | 96 ± 130  | 9.9 ± 6.4  | 2.3 ± 1.6  | 2.5 ± 0.8  | 4.0 ± 0.9  | 24.2 ± 6.0  | 9.9 ± 2.5  | 2.1 ± 0.5  |

| 15 PAN | 139 ± 138  | 11.6 ± 7.6  | 2.8 ± 1.7  | 3.5 ± 0.9  | 10.5 ± 1.5  | 48.6 ± 11.7  | 2.3 ± 0.6  | 1.5 ± 0.4  |

| 14 mPitch | 56 ± 227  | 6.4 ± 5.9  | 1.4 ± 1.5  | 31.2 ± 7.7  | 1.0 ± 0.4  | 174.6 ± 41.7  | 55.4 ± 13.2  | 24.5 ± 5.8  |

| 11 mPitch | 62 ± 363  | 6.4 ± 5.3  | 1.3 ± 1.4  | 34.8 ± 8.6  | 0.9 ± 0.4  | 216.0 ± 51.5  | 115.1 ± 27.4  | 19.3 ± 4.6  |

| 10 mPitch | 89 ± 379  | 10.5 ± 7.4  | 1.8 ± 1.5  | 6.5 ± 1.6  | 0  | 57.5 ± 13.6  | 40.1 ± 9.5  | 10.0 ± 2.4  |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meyer-Plath, A.; Kehren, D.; Große, A.; Naumann, R.; Hofmann, M.; Schneck, T.; Ota, A.; Hermanutz, F.; Dziurowitz, N.; Thim, C.; et al. Investigation of the Tendency of Carbon Fibers to Disintegrate into Respirable Fiber-Shaped Fragments. Fibers 2023, 11, 50. https://doi.org/10.3390/fib11060050

Meyer-Plath A, Kehren D, Große A, Naumann R, Hofmann M, Schneck T, Ota A, Hermanutz F, Dziurowitz N, Thim C, et al. Investigation of the Tendency of Carbon Fibers to Disintegrate into Respirable Fiber-Shaped Fragments. Fibers. 2023; 11(6):50. https://doi.org/10.3390/fib11060050

Chicago/Turabian StyleMeyer-Plath, Asmus, Dominic Kehren, Anna Große, Romy Naumann, Marcel Hofmann, Tanja Schneck, Antje Ota, Frank Hermanutz, Nico Dziurowitz, Carmen Thim, and et al. 2023. "Investigation of the Tendency of Carbon Fibers to Disintegrate into Respirable Fiber-Shaped Fragments" Fibers 11, no. 6: 50. https://doi.org/10.3390/fib11060050

APA StyleMeyer-Plath, A., Kehren, D., Große, A., Naumann, R., Hofmann, M., Schneck, T., Ota, A., Hermanutz, F., Dziurowitz, N., Thim, C., Plitzko, S., & Bäger, D. (2023). Investigation of the Tendency of Carbon Fibers to Disintegrate into Respirable Fiber-Shaped Fragments. Fibers, 11(6), 50. https://doi.org/10.3390/fib11060050