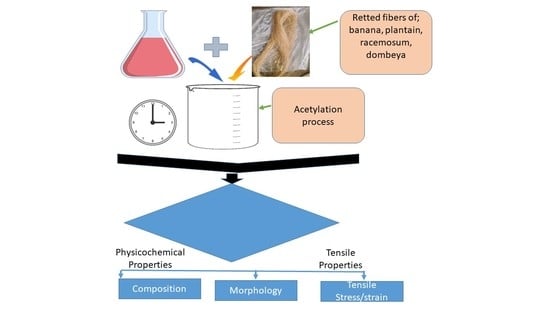

Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Preparation

2.2. Acetylation Treatment

2.3. Physico-Chemical Tests

2.3.1. Density Measurement

2.3.2. Aspect Ratio

- L = length of each fiber which is constant for all. D = average diameter for each fiber.

2.3.3. Evaluation of Fiber Fractions/Proximate Analysis

Determination of Neutral Detergent Fiber (NDF)

- W1 = weight of the crucible when empty. W2 = total weight of crucible and residue.

- W3 = weight of dried sample.

Evaluation of Acid Detergent Fibers (ADF)

- W1 = weight of crucible (emptied). W2 = total weight of crucible and residues and;

- Ws = weight of dry samples.

Gravimetric Evaluation of Lignin Contents

- W1 = total weight of ash samples + crucibles, W2 = total weight of oven dried sample + crucibles,

- Ws = weight of dried extractive free sample, i.e., NDF residue.

Evaluation of Celluloses Content

Evaluation of Hemicellulose Contents

2.3.4. Mechanical (Tensile) Properties Evaluation

2.4. Scanning Electron Microscopy

3. Results and Discussions

3.1. Density of Selected Plant Fibers

3.2. Aspect Ratio of Plant Fibers

3.3. Effects of Acetylation on the Constituents of Selected Plant Fibers

3.3.1. Effects of Acetylation on the Constituent (Proximate) Composition of Dombeya Buettneri Fibers

3.3.2. Effects of Acetylation on the Constituent (Proximate) Composition of Combretum Racemosum Fibers

3.3.3. Effects of Acetylation on the Constituent (Proximate) Composition of Banana (Musa Acuminata) Fibers

3.3.4. Effects of Acetylation on the Constituent (Proximate) Composition of Plantain Fibers

3.3.5. Effects of Acetylation on the Cellulose Content of Selected Plant Fibers

3.3.6. Effects of Acetylation on the Hemicellulose Content of Selected Plant Fibers

3.3.7. Effects of Acetylation on the Lignin Content of Selected Plant Fibers

3.4. Effects of Acetylation on Tensilet Properties of Selected Plant Fibers

3.4.1. Comparing the Effects of Acetylation Treatment on the Tensile Strength of Fibers from the Selected Plants

3.4.2. Effects of Acetylation Treatment on Strains of Ultimate Tensile Stress in Fibers from Selected Plants

3.5. Effect of Acetylation on the Surface Morphology of Selected Plant Fibers

3.5.1. Effects of Acetylation on in Structure and Surface Morphology of Dombeya Buettnerri Fibers

3.5.2. Effects of Acetylation on in Structure and Surface Morphology of Combretum Racemosum Fibers

3.5.3. Effects of Acetylation on in Structure and Surface Morphology of Banana (Musa) Fiber

4. Conclusions

- Plantain fibers followed by banana fibers had the highest aspect ratios with values of about 1000 and 417, respectively. These two fibers (plantain and banana) have the least density and are thus great candidates for lightweight composite materials development. Banana fibers had the least density of about 1.38 g/cm3 while Dombeya Buettneri fibers possessed the highest value of 1.5 g/cm3.

- The treatment tends to promote improvement in cellulose content for Dombeya Buettneri, and plantain fibers, while it tends to reduce the cellulose content for banana and Combretum Racemosum fibers. This, in agreement with previous results, was due to the impact of the treatment on crystalline/amorphous cellulose content of the evaluated plant fibers as well as other non-cellulosic components. The treatment favours the enhancement of the ultimate tensile strength of combretum racemosum while the tensile strain was enhanced in most of the other fibers except banana.

- The type(s)/form(s) and the relative proportion of cellulose present in the raw and untreated fibers strongly determines the compositional and tensile property influence of acetylation on the fibers.

- The treatment protocols enhanced the surface morphology and tensile properties of natural fibers with the optimum concentration of acetylation media being 4%.

- From this work, it is expected that more investigations are to be carried out on plantain, banana, Combretum Racemosum and Dombeya Buettneri fibers as they are potential plant fibers for engineering materials applications.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Yan, L. Effect of alkali treatment on vibration characteristics and mechanical properties of natural fabric reinforced composites. J. Reinf. Plast. Compos. 2012, 31, 887–896. [Google Scholar] [CrossRef]

- Salem, T.F.; Tirkes, S.; Akar, A.O.; Tayfun, U. Enhancement of mechanical, thermal and water uptake performance of TPU/jute fiber green composites via chemical treatments on fiber surface. e-Polymers 2020, 20, 133–143. [Google Scholar] [CrossRef] [Green Version]

- Baghban, M.H.; Mahjoub, R. Natural Kenaf Fiber and LC3 Binder for Sustainable Fiber-Reinforced Cementitious Composite: A Review. Appl. Sci. 2020, 10, 357. [Google Scholar] [CrossRef] [Green Version]

- Hussain, S.A.; Pandurangadu, V.; Kumar, K.P. Optimization of Mechanical Properties of Green Coconut Fiber/HDPE Composites by using flexural strength. Int. J. Adv. Sci. Technol. 2016, 92, 1–8. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K. Processing and characterization of natural cellulose fibers/thermoset polymer composites. Carbohydr. Polym. 2014, 109, 102–117. [Google Scholar] [CrossRef]

- Atiqah, A.; Jawaid, M.; Sapuan, S.M.; Ishak, M. Effect of Surface Treatment on the Mechanical Properties of Sugar Palm/Glass Fiber-reinforced Thermoplastic Polyurethane Hybrid Composites. Bioresources 2017, 13, 1174–1188. [Google Scholar] [CrossRef]

- Girijappa, Y.G.T.; Rangappa, S.M.; Parameswaranpillai, J.; Siengchin, S. Natural Fibers as Sustainable and Renewable Resource for Development of Eco-Friendly Composites: A Comprehensive Review. Front. Mater. 2019, 6. [Google Scholar] [CrossRef]

- Oladele, I.O.; Ayanleye, O.T.; Adediran, A.; Makinde-Isola, B.A.; Taiwo, A.S.; Akinlabi, E.T. Characterization of Wear and Physical Properties of Pawpaw–Glass Fiber Hybrid Reinforced Epoxy Composites for Structural Application. Fibers 2020, 8, 44. [Google Scholar] [CrossRef]

- Oladele, I.O.; Ibrahim, I.; Adediran, A.A.; Akinwekomi, A.; Adetula, Y.; Olayanju, T. Modified palm kernel shell fiber/particulate cassava peel hybrid reinforced epoxy composites. Results Mater. 2020, 5, 100053. [Google Scholar] [CrossRef]

- Mohammed, L.; Ansari, M.N.M.; Pua, G.; Jawaid, M.; Islam, M.S. A Review on Natural Fiber Reinforced Polymer Composite and Its Applications. Int. J. Polym. Sci. 2015, 2015, 1–15. [Google Scholar] [CrossRef] [Green Version]

- George, J.; Sabapathi, S.N. Cellulose nanocrystals: Synthesis, functional properties, and applications. Nanotechnol. Sci. Appl. 2015, 8, 45–54. [Google Scholar] [CrossRef] [Green Version]

- Ayyachamy, M.; Cliffe, F.E.; Coyne, J.M.; Collier, J.; Tuohy, M.G. Lignin: Untapped biopolymers in biomass conversion technologies. Biomass-Convers. Biorefinery 2013, 3, 255–269. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Oladele, I.; Michael, O.; Olusegun, S. Influence of Chemical Treatment on the Constituents and Tensile Properties of Selected Agro-Fibres. West Indian J. Eng. 2015, 38, 4–12. [Google Scholar]

- Alotaibi, M.D.; Alshammari, B.A.; Saba, N.; Alothman, O.Y.; Sanjay, M.; Almutairi, Z.; Jawaid, M. Characterization of natural fiber obtained from different parts of date palm tree (Phoenix dactylifera L.). Int. J. Biol. Macromol. 2019, 135, 69–76. [Google Scholar] [CrossRef] [PubMed]

- Varghese, A.M.; Mittal, V. Surface Modification of Natural Fibers. In Biodegradable and Biocompatible Polymer Composites; Elsevier: Cambridge, UK, 2017; p. 115. [Google Scholar] [CrossRef]

- Várdai, R.; Lummerstorfer, T.; Pretschuh, C.; Jerabek, M.; Gahleitner, M.; Faludi, G.; Móczó, J.; Pukánszky, B. Comparative study of fiber reinforced PP composites: Effect of fiber type, coupling and failure mechanisms. Compos. Part A Appl. Sci. Manuf. 2020, 133, 105895. [Google Scholar] [CrossRef]

- Wang, X.; Petru, M.; Yu, H. The effect of surface treatment on the creep behavior of flax fiber reinforced composites under hygrothermal aging conditions. Constr. Build. Mater. 2019, 208, 220–227. [Google Scholar] [CrossRef]

- Athith, D.; Sanjay, M.; Gowda, T.Y.; Madhu, P.; Arpitha, G.; Yogesha, B.; Omri, M.A. Effect of tungsten carbide on mechanical and tribological properties of jute/sisal/E-glass fabrics reinforced natural rubber/epoxy composites. J. Ind. Text. 2017, 48, 713–737. [Google Scholar] [CrossRef]

- Debeli, D.K.; Qin, Z.; Guo, J. Study on the Pre-Treatment, Physical and Chemical Properties of Ramie Fibers Reinforced Poly (Lactic Acid) (PLA) Biocomposite. J. Nat. Fibers 2017, 15, 596–610. [Google Scholar] [CrossRef]

- Dolez, P.I.; Arfaoui, M.A.; Dubé, M.; David, É. Hydrophobic treatments for natural fibers based on metal oxide nanoparticles and fatty acids. Procedia Eng. 2017, 200, 81–88. [Google Scholar] [CrossRef]

- Halip, J.A.; Hua, L.S.; Ashaari, Z.; Tahir, P.M.; Chen, L.W.; Uyup, M.K.A. Effect of Treatment on Water Absorption Behavior of Natural Fiber–Reinforced Polymer Composites. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Elsevier: Cambridge, UK, 2019; pp. 141–156. [Google Scholar] [CrossRef]

- Mahjoub, R.; Yatim, J.M.; Sam, A.R.M.; Hashemi, S.H. Tensile properties of kenaf fiber due to various conditions of chemical fiber surface modifications. Constr. Build. Mater. 2014, 55, 103–113. [Google Scholar] [CrossRef]

- Manimaran, P.; Senthamaraikannan, P.; Sanjay, M.; Marichelvam, M.; Jawaid, M. Study on characterization of Furcraea foetida new natural fiber as composite reinforcement for lightweight applications. Carbohydr. Polym. 2018, 181, 650–658. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Dhawan, V.; Singh, S.; Jangid, K. Study of Effect of Surface Treatment on Mechanical Properties of Natural Fiber Reinforced Composites. Mater. Today Proc. 2017, 4, 2793–2799. [Google Scholar] [CrossRef]

- Chukwudi, A.D.; Uzoma, O.T.; Azuka, U.-A.A.; Sunday, E.C.; Cyprian, S. Comparison of Acetylation and Alkali Treatments on the Physical and Morphological Properties of Raffia Palm Fibre Reinforced Composite. Sci. J. Chem. 2015, 3, 72. [Google Scholar] [CrossRef] [Green Version]

- Sreekala, M.; Thomas, S. Effect of fibre surface modification on water-sorption characteristics of oil palm fibres. Compos. Sci. Technol. 2003, 63, 861–869. [Google Scholar] [CrossRef]

- Joseph, S.; Koshy, P.; Thomas, S. The role of interfacial interactions on the mechanical properties of banana fibre reinforced phenol formaldehyde composites. Compos. Interfaces 2005, 12, 581–600. [Google Scholar] [CrossRef]

- Tserki, V.; Panayiotou, C.; Zafeiropoulos, N.E. A Study of the Effect of Acetylation and Propionylation on the Interface of Natural Fibre Biodegradable Composites. Adv. Compos. Lett. 2005, 14, 096369350501400202. [Google Scholar] [CrossRef] [Green Version]

- OECD/FAO. OECD-FAO Agricultural Outlook 2020–2029; OECD Publishing: Paris, France, 2020. [Google Scholar] [CrossRef]

- Preisner, M.; Kulma, A.; Zebrowski, J.; Dymińska, L.; Hanuza, J.; Arendt, M.; Starzycki, M.; Szopa, J. Manipulating cinnamyl alcohol dehydrogenase (CAD) expression in flax affects fibre composition and properties. BMC Plant Biol. 2014, 14, 50. [Google Scholar] [CrossRef] [Green Version]

- Ovat, F.A. Environmental Degradability of Nigerian Long Bamboo Fibre-Reinforced Polymer Composite (NLBFRPC). Eur. J. Eng. Res. Sci. 2017, 2, 48–53. [Google Scholar] [CrossRef]

- Oladele, I.; Omotoyinbo, J.; Adewara, J. Investigating the Effect of Chemical Treatment on the Constituents and Tensile Properties of Sisal Fibre. J. Miner. Mater. Charact. Eng. 2010, 9, 569–582. [Google Scholar] [CrossRef]

- D13 Committee Test Method for Tensile Properties of Single Textile Fibers. ASTM Int. 2008, ASTMD3822M. [CrossRef]

- Yang, W.; Li, Y. Sound absorption performance of natural fibers and their composites. Sci. China Ser. E Technol. Sci. 2012, 55, 2278–2283. [Google Scholar] [CrossRef]

- Pandita, S.D.; Yuan, X.; Manan, M.A.; Lau, C.H.; Subramanian, A.S.; Wei, J. Evaluation of jute/glass hybrid composite sandwich: Water resistance, impact properties and life cycle assessment. J. Reinf. Plast. Compos. 2013, 33, 14–25. [Google Scholar] [CrossRef]

- Lu, N.; Swan, R.H.; Ferguson, I.T. Composition, structure, and mechanical properties of hemp fiber reinforced composite with recycled high-density polyethylene matrix. J. Compos. Mater. 2011, 46, 1915–1924. [Google Scholar] [CrossRef]

- Tewari, M.; Singh, V.; Gope, P.; Chaudhary, A. Evaluation of Mechanical Properties of Bagasse-Glass Fiber Reinforced Composite. J. Mater. Environ. Sci. 2011, 3, 171–184. [Google Scholar]

- Aslan, M.; Tufan, M.; Küçükömeroğlu, T. Tribological and mechanical performance of sisal-filled waste carbon and glass fibre hybrid composites. Compos. Part B Eng. 2018, 140, 241–249. [Google Scholar] [CrossRef]

- Amir, M.; Irmawaty, R.; Hustim, M.; Rahim, I.R. Tensile strength of glass fiber-reinforced waste PET and Kenauf hybrid composites. IOP Conf. Ser. Earth Environ. Sci. 2020, 419, 012061. [Google Scholar] [CrossRef]

- Oladele, I.O.; Oladejo, M.O.; Adediran, A.; Makinde-Isola, B.A.; Owa, A.F.; Akinlabi, E.T. Influence of designated properties on the characteristics of Dombeya Combretum Racemosum fiber/graphite hybrid reinforced polypropylene composites. Sci. Rep. 2020, 10, 1–13. [Google Scholar] [CrossRef]

- Castro, C.; Zuluaga, R.; Vélez, L.; Retegi, A.; Mondragon, I.; Gañán, P. Biodegradability of Banana and Plantain Cellulose Microfibrils Films in Anaerobic Conditions. J. Polym. Environ. 2012, 20, 774–782. [Google Scholar] [CrossRef]

- Gopinathan, P.; Subramanian, K.S.; Paliyath, G.; Subramanian, J. Genotypic variations in characteristics of nano-fibrillated cellulose derived from banana pseudostem. BioResources 2017, 12, 6984–7001. [Google Scholar] [CrossRef]

- Akpabio, U.; Udiong, D.; Akpakpan, A. The Physicochemical Characteristics of Plantain (Musa Paradisiaca) and Banana (Musa Sapientum) Pseudostem Wastes. Adv. Nat. Appl. Sci. 2012, 6, 167–172. [Google Scholar]

- Ogunsile, B.; Omotoso, M. Fibre and Chemical Properties of Some Nigerian Grown Musa Species for Pulp Production. Asian J. Mater. Sci. 2009, 1, 14–21. [Google Scholar] [CrossRef] [Green Version]

- Senwitz, C.; Kempe, A.; Neinhuis, C.; Mandombe, J.L.; Branquima, M.F.; Lautenschläger, T. Almost Forgotten Resources—Biomechanical Properties of Traditionally Used Bast Fibers from Northern Angola. BioResources 2016, 11, 7595–7607. [Google Scholar] [CrossRef] [Green Version]

- Waghmare, P.M.; Bedmutha, P.; Sollapur, S. Review on Mechanical Properties of Banana Fiber Biocomposite. Int. J. Res. Appl. Sci. Eng. Technol. 2017, 5, 847–850. [Google Scholar] [CrossRef]

| Constituent | Concentration of Acetylation Agent (v/v %) | |||

|---|---|---|---|---|

| Untreated | 2% | 4% | 6% | |

| Cellulose | 26.06 ± 1.14 | 30.30 ± 1.11 | 35.72 ± 1.23 | 40.31 ± 1.17 |

| Hemicellulose | 22.57 ± 1.10 | 14.20 ±1.26 | 12.39 ± 1.16 | 9.67 ± 1.17 |

| Lignin | 35.04 ± 1.53 | 29.15 ± 1.54 | 32.02 ± 1.54 | 33.65 ± 1.72 |

| Constituent (%) | Concentration of Acetylation Media (v/v %) | |||

|---|---|---|---|---|

| Untreated | 2 | 4 | 6 | |

| Cellulose | 32.09 ± 1.46 | 30.72 ± 1.32 | 29.39 ± 1.15 | 28.52 ± 1.26 |

| Hemicellulose | 21.42 ± 1.17 | 30.69 ± 1.13 | 41.58 ± 1.16 | 44.18 ± 1.10 |

| Lignin | 12.18 ± 1.65 | 20.61 ± 1.34 | 21.53 ± 1.27 | 22.49 ± 1.16 |

| Constituent | Concentration of Acetylation Media (v/v %) | |||

|---|---|---|---|---|

| Untreated | 2 | 4 | 6 | |

| Cellulose | 60.89 ± 1.32 | 36.12 ± 1.26 | 29.62 ± 1.06 | 21.51 ± 1.23 |

| Hemicellulose | 8.97 ± 1.05 | 11.15 ± 1.06 | 10.44 ± 1.03 | 10.11 ± 1.02 |

| Lignin | 26.61 ± 1.34 | 33.11 ± 1.32 | 49.53 ± 1.42 | 51.19 ± 1.32 |

| Constituent | Concentration of Acetylation Media (v/v %) | |||

|---|---|---|---|---|

| Untreated | 2 | 4 | 6 | |

| Cellulose | 24.76 ± 1.24 | 28.72 ± 1.27 | 32.82 ± 1.25 | 47.97 ± 1.22 |

| Hemicellulose | 10.93 ± 1.04 | 14.03 ± 1.03 | 15.79 ± 1.02 | 18.63 ± 1.03 |

| Lignin | 54.66 ± 1.32 | 47.6 ± 1.42 | 39.29 ± 1.47 | 20.53 ± 1.28 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oladele, I.O.; Michael, O.S.; Adediran, A.A.; Balogun, O.P.; Ajagbe, F.O. Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers. Fibers 2020, 8, 73. https://doi.org/10.3390/fib8120073

Oladele IO, Michael OS, Adediran AA, Balogun OP, Ajagbe FO. Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers. Fibers. 2020; 8(12):73. https://doi.org/10.3390/fib8120073

Chicago/Turabian StyleOladele, Isiaka Oluwole, Omokafe Seun Michael, Adeolu Adesoji Adediran, Oluwayomi Peter Balogun, and Folorunso Ojo Ajagbe. 2020. "Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers" Fibers 8, no. 12: 73. https://doi.org/10.3390/fib8120073

APA StyleOladele, I. O., Michael, O. S., Adediran, A. A., Balogun, O. P., & Ajagbe, F. O. (2020). Acetylation Treatment for the Batch Processing of Natural Fibers: Effects on Constituents, Tensile Properties and Surface Morphology of Selected Plant Stem Fibers. Fibers, 8(12), 73. https://doi.org/10.3390/fib8120073