Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Preparation of Niosomes

2.2.2. Preparation of Creams

2.2.3. Sensory Lexicons and Definitions

2.2.4. Instrumental Rheology and Sensory Characterization

- Yield Stress: pourability and spreadability—a stress range of 0.001 Pa to 10,000 Pa at a ramp time of 2 min and a decade of 10 was applied.

- Strain Amplitude Sweep with LVR Determination: firmness—the samples were oscillated over a shear stress range of 0.001 Pa to 10,000 Pa, at a frequency of 1 Hz and a decade of 10.

- Frequency Sweep: stickiness and elasticity or stretchability—the samples were oscillated over a frequency range of 50 to 0.05 Hz, at a % strain within the LVR.

2.2.5. Statistical Analysis

3. Results and Discussion

3.1. Rheology and Sensory Characterization

3.1.1. Yield Stress: Pourability and Spreadability

3.1.2. Stress (Strain) Amplitude Sweep with LVR Determination: Firmness

3.1.3. Frequency Sweep; Stickiness and Elasticity or Stretchability

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, W.C.; Wu, T.Y. Exploring types and characteristics of product forms. Int. J. Des. 2007, 1, 1–3. [Google Scholar]

- Liao, S.H.; Hsieh, C.L.; Huang, S.P. Mining product maps for new product development. Expert Syst. Appl. 2008, 34, 1–50. [Google Scholar] [CrossRef]

- Durán, S.S.; Sánchez, J.S. Sensory Studies. In Bee Products-Chemical and Biological Properties; Springer: Berlin/Heidelberg, Germany, 2017; pp. 21–41. [Google Scholar]

- Bonod, I.; Sandoz, J.C.; Loublier, Y.; Pham-Delègue, M.H. Learning and discrimination of honey odours by the honeybee. Apidologie 2003, 34, 2–147. [Google Scholar] [CrossRef] [Green Version]

- Galán-Soldevilla, H.; Ruiz-Pérez-Cacho, M.P.; Jimenez, S.S.; Villarejo, M.J.; Manzanares, A.B. Development of a preliminary sensory lexicon for floral honey. Food Qual. Prefer. 2005, 16, 1–71. [Google Scholar] [CrossRef]

- Serra Bonvehi, J.; Ventura Coll, F. Characterization of citrus honey (Citrus spp.) produced in Spain. J. Agric. Food Chem. 1995, 43, 2053–2057. [Google Scholar] [CrossRef]

- Piana, M.L.; Oddo, L.P.; Bentabol, A.; Bruneau, E.; Bogdanov, S.; Declerck, C.G. Sensory analysis applied to honey: State of the art. Apidologie 2004, 35, S26–S37. [Google Scholar] [CrossRef] [Green Version]

- ISO 6658:2017. Sensory Analysis—Methodology—General Guidance, International Organization for Standardization. ISO. 2019. Available online: https://www.iso.org/standard/65519.html (accessed on 20 September 2019).

- Murray, J.M.; Delahunty, C.M.; Baxter, I.A. Descriptive sensory analysis: Past, present and future. Food Res. Int. 2001, 34, 6–461. [Google Scholar] [CrossRef]

- Pensé-Lhéritier, A.M. Recent developments in the sensorial assessment of cosmetic products: A review. Int. J. Cosmet. Sci. 2015, 37, 465–473. [Google Scholar] [CrossRef] [PubMed]

- Gilbert, L.; Savary, G.; Grisel, M.; Picard, C. Predicting sensory texture properties of cosmetic emulsions by physical measurements. Chemom. Intell. Lab. Syst. 2013, 124, 21–31. [Google Scholar] [CrossRef]

- Montenegro, L.; Rapisarda, L.; Ministeri, C.; Puglisi, G. Effects of lipids and emulsifiers on the physicochemical and sensory properties of cosmetic emulsions containing vitamin E. Cosmetics 2015, 2, 35–47. [Google Scholar] [CrossRef]

- Varela, P.; Ares, G. Sensory profiling, the blurred line between sensory and consumer science. A review of novel methods for product characterization. Food Res. Int. 2012, 48, 2–893. [Google Scholar] [CrossRef]

- Tabilo-Munizaga, G.; Barbosa-Cánovas, G.V. Rheology for the food industry. J. Food Eng. 2005, 67, 147–156. [Google Scholar] [CrossRef]

- Cheng, D.C. Yield stress: A time-dependent property and how to measure it. Rheol. Acta 1986, 25, 5–542. [Google Scholar] [CrossRef]

- Barnes, H.A. The yield stress—A review or ‘παντα ρει’—Everything flows? J. Non-Newton. Fluid Mech. 1999, 81, 133–178. [Google Scholar] [CrossRef]

- Stokes, J.R.; Telford, J.H. Measuring the yield behaviour of structured fluids. J. Non-Newton. Fluid Mech. 2004, 124, 137–146. [Google Scholar] [CrossRef]

- Rueda, M.M.; Auscher, M.C.; Fulchiron, R.; Perie, T.; Martin, G.; Sonntag, P.; Cassagnau, P. Rheology and applications of highly filled polymers: A review of current understanding. Prog. Polym. Sci. 2017, 66, 22–53. [Google Scholar] [CrossRef]

- Ho, K.Y.; Dodou, K. Rheological studies on pressure-sensitive silicone adhesives and drug-in-adhesive layers as a means to characterise adhesive performance. Int. J. Pharm. 2007, 333, 24–33. [Google Scholar] [CrossRef]

- Souto, E.B.; Gohla, S.H.; Müller, R.H. Rheology of nanostructured lipid carriers (NLC®) suspended in a viscoelastic medium. Die Pharm. Int. J. Pharm. Sci. 2005, 60, 9–671. [Google Scholar]

- Mason, T.G. New fundamental concepts in emulsion rheology. Curr. Opin. Colloid Interface Sci. 1999, 4, 231–238. [Google Scholar] [CrossRef]

| Phase | INCI | Composition (%) | IA | IB | IIA | IIB | IIIA | IIIB | IVA | IVB |

|---|---|---|---|---|---|---|---|---|---|---|

| Oil | Stearyl Alcohol | Stearyl Alcohol | 1 | 1 | 1 | 1 | ||||

| Simmondsia Chinensis Seed Oil | Jojoba Oil | 4 | 4 | 5 | 5 | 5 | 5 | |||

| Adansonia Digitata Seed Oil | Baobab Oil | 4 | 4 | 5 | 5 | 5 | 5 | |||

| Cocos nucifera | Coconut Oil | 5 | 5 | 5 | 5 | |||||

| Water | Glycerin | Glycerine | 5 | 5 | 5 | 5 | 5 | 5 | ||

| Propylene Glycol | Propylene Glycol | 5 | 5 | |||||||

| Aqua | Water | 73.7 | 78.7 | 71.7 | 76.7 | 71.7 | 76.7 | 71.7 | 76.7 | |

| Active | - | Entrapped Active | 5 | 5 | 5 | 5 |

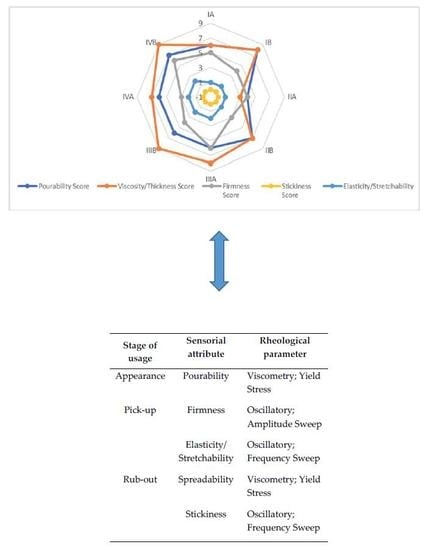

| Stage of Usage | Sensorial Attribute | Description | Rheological Parameter |

|---|---|---|---|

| Appearance | Pourability | Ability of a product to flow or be pumped out of the container when a force is applied. | Viscometry; Yield Stress |

| Pick-up | Firmness | The degree to which the product is able to hold its shape or structure in the presence of force. | Oscillatory; Amplitude Sweep |

| Elasticity/ Stretchability | It is the ability of the product to deform or expand (strain) by resisting an external force (stress). | Oscillatory; Frequency Sweep | |

| Rub-out | Spreadability | The force required to cause flow of the product. | Viscometry; Yield Stress |

| Stickiness | Ability of product to attach to the skin, yielding a sticky skin feel. | Oscillatory; Frequency Sweep |

| Score | Yield Stress Values (Pa) | Viscosity/Thickness (Pa S) | Strain Amplitude Sweep (Pa) |

|---|---|---|---|

| 0 | 181–200 | 171,000–190,000 | <0.010 |

| 1 | 161–180 | 151,000–170,000 | 0.011–0.020 |

| 2 | 141–160 | 131,000–150,000 | 0.021–0.040 |

| 3 | 121–140 | 111,000–130,000 | 0.041–0.060 |

| 4 | 101–120 | 91,000–110,000 | 0.061–0.080 |

| 5 | 81–100 | 71,000–90,000 | 0.081–0.100 |

| 6 | 61–80 | 51,000–70,000 | 0.101–0.200 |

| 7 | 41–60 | 31,000–50,000 | 0.201–0.400 |

| 8 | 21–40 | 11,000–30,000 | 0.401–0.600 |

| 9 | 0–20 | <10,000 | 0.601–0.800 |

| Score | Yield Stress Values (Pa)—Pourability | Viscosity/Thickness (Pa S)—Spreadability | Strain Amplitude Sweep (Pa)—Firmness |

|---|---|---|---|

| 0 | 151–200 | 151,000–200,000 | <0.200 |

| 1 | 101–150 | 101,000–150,000 | 0.201–0.400 |

| 2 | 51–100 | 51,000–100,000 | 0.401–0.600 |

| 3 | 0–50 | <50,000 | 0.601–0.800 |

| Model | Mean Yield Stress (Pa) | Pourability Score | Mean Viscosity/ Thickness (PaS) | Spreadability Score | Mean Shear Strain within the LVR | Firmness Score |

|---|---|---|---|---|---|---|

| IA | 79 ± 15.8 | 6 | 53,270 ± 3010 | 6 | 9.755E−002 ± 6.028E−003 | 5 |

| IB | 26 ± 15.5 | 8 | 21,590 ± 1090 | 8 | 7.206E−002 ± 6.513E−003 | 4 |

| IIA | 112 ± 22.3 | 4 | 117,302 ± 36,498 | 3 | 7.268E−002 ± 6.628E−003 | 4 |

| IIB | 48 ± 15.2 | 7 | 34,358 ± 9249 | 7 | 5.077E−002 ± 2.341E−002 | 3 |

| IIIA | 66 ± 10.5 | 6 | 20,100 ± 3874 | 8 | 1.022E−001 ± 9.295E−003 | 6 |

| IIIB | 67 ± 10.5 | 6 | 8085 ± 15 | 9 | 6.844E−002 ± 2.498E−002 | 4 |

| IVA | 75 ± 7.5 | 6 | 38,050 ± 4550 | 7 | 4.910E−002 ± 1.007E−002 | 3 |

| IVB | 46 ± 9.2 | 7 | 4767 ± 1067 | 9 | 1.272E−001 ± 1.905E−003 | 6 |

| Score | Elasticity/Stretchability | Stickiness |

|---|---|---|

| 0 | Non-Stretchy | Non-Sticky |

| 1 | Moderately Stretchy | Moderately Sticky |

| 2 | Stretchy | Sticky |

| 3 | Very Stretchy | Very Sticky |

| Model | Stickiness | Score | Elasticity/Stretchability | Score |

|---|---|---|---|---|

| IA | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IB | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIA | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIB | Non-Sticky | 0 | Moderately Stretchy | 1 |

| IIIA | Non-Sticky | 0 | Stretchy | 2 |

| IIIB | Non-Sticky | 0 | Stretchy | 2 |

| IVA | Non-Sticky | 0 | Stretchy | 2 |

| IVB | Non-Sticky | 0 | Stretchy | 2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Adejokun, D.A.; Dodou, K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics 2020, 7, 2. https://doi.org/10.3390/cosmetics7010002

Adejokun DA, Dodou K. Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics. 2020; 7(1):2. https://doi.org/10.3390/cosmetics7010002

Chicago/Turabian StyleAdejokun, Deborah Adefunke, and Kalliopi Dodou. 2020. "Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation" Cosmetics 7, no. 1: 2. https://doi.org/10.3390/cosmetics7010002

APA StyleAdejokun, D. A., & Dodou, K. (2020). Quantitative Sensory Interpretation of Rheological Parameters of a Cream Formulation. Cosmetics, 7(1), 2. https://doi.org/10.3390/cosmetics7010002