Design of a Cylindrical Winding Structure for Wireless Power Transfer Used in Rotatory Applications

Abstract

:1. Introduction

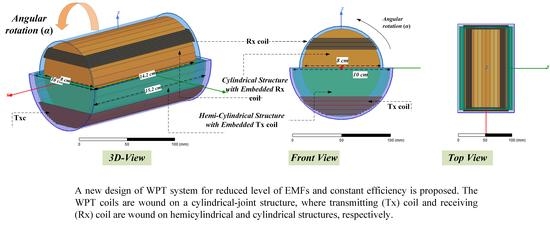

2. Design of Proposed WPT System

3. Design Procedures for High Efficiency

4. Design Procedures for Low-Leakage Magnetic Fields

5. Experiment Results and Validation

6. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Mei, H.; Thackston, K.A.; Bercich, R.A.; Jefferys, J.G.R.; Irazoqui, P.P. Cavity Resonator Wireless Power Transfer System for Freely Moving Animal Experiments. IEEE Trans. Biomed. Eng. 2017, 64, 775–785. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Abdulfattah, A.N.; Tsimenidis, C.C.; Al-Jewad, B.Z.; Yakovlev, A. Performance Analysis of MICS-based RF Wireless Power Transfer System for Implantable Medical Devices. IEEE Access 2019, 7, 11775–11784. [Google Scholar] [CrossRef]

- Ben Fadhel, Y.; Ktata, S.; Sedraoui, K.; Rahmani, S.; Al-Haddad, K. A Modified Wireless Power Transfer System for Medical Implants. Energies 2019, 12, 1890. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Joo, D.M.; Lee, B.K. Design and control of inductive power transfer system for electric vehicles considering wide variation of output voltage and coupling coefficient. IEEE Trans. Power Electron. 2019, 34, 1197–1208. [Google Scholar] [CrossRef]

- Luo, Z.; Wei, X. Analysis of Square and Circular Planar Spiral Coils in Wireless Power Transfer System for Electric Vehicles. IEEE Trans. Ind. Electron. 2018, 65, 331–341. [Google Scholar] [CrossRef]

- Rozman, M.; Ikpehai, A.; Adebisi, B.; Rabie, K.M.; Gacanin, H.; Ji, H.; Fernando, M. Smart wireless power transmission system for autonomous EV charging. IEEE Access 2019, 7, 112240–112248. [Google Scholar] [CrossRef]

- Mou, X.; Groling, O.; Sun, H. Energy-efficient and adaptive design for wireless power transfer in electric vehicles. IEEE Trans. Ind. Electron. 2017, 64, 7250–7260. [Google Scholar] [CrossRef] [Green Version]

- Shah, I.A.; Yoo, H. Assessing Human Exposure with Medical Implants to Electromagnetic Fields from a Wireless Power Transmission System in an Electric Vehicle. IEEE Trans. Electromagn. Compat. 2019, 1–8. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Pacemaker Lead Coupling with an Automotive Wireless Power Transfer System. IEEE Trans. Electromagn. Compat. 2019, 61, 1935–1943. [Google Scholar] [CrossRef]

- Yan, Z.; Song, B.; Zhang, Y.; Zhang, K.H.; Mao, Z.; Hu, Y. A Rotation-Free Wireless Power Transfer System with Stable Output Power and Efficiency for Autonomous Underwater Vehicles. IEEE Trans. Power Electron. 2018, 34, 4005–4008. [Google Scholar] [CrossRef]

- Xu, J.; Zeng, Y.; Zhang, R. UAV-enabled wireless power transfer: Trajectory design and energy optimization. IEEE Trans. Wirel. Commun. 2018, 17, 5092–5106. [Google Scholar] [CrossRef] [Green Version]

- Sugino, M.; Kondo, H.; Takeda, S. Linear motion type transfer robot using the wireless power transfer system. In Proceedings of the IEEE International Symposium on Antennas and Propagation (ISAP), Okinawa, Japan, 24–28 October 2016; pp. 508–509. [Google Scholar]

- Cardoso, L.A.L.; Monteiro, V.; Pinto, J.G.; Nogueira, M.; Abreu, A.; Afonso, J.A.; Afonso, J.L. Design of an Intrinsically Safe Series-Series Compensation WPT System for Automotive LiDAR. Electronics 2020, 9, 86. [Google Scholar] [CrossRef] [Green Version]

- Choi, K.W.; Aziz, A.A.; Setiawan, D.; Tran, N.M.; Ginting, L.; Kim, D.I. Distributed Wireless Power Transfer System for Internet of Things Devices. IEEE Internet Things J. 2018, 5, 2657–2671. [Google Scholar] [CrossRef]

- Wang, W.; Zhang, Q.; Lin, H.; Liu, M.; Liang, X.; Liu, Q. Wireless Energy Transmission Channel Modeling in Resonant Beam Charging for IoT Devices. IEEE Internet Things J. 2019, 6, 3976–3986. [Google Scholar] [CrossRef] [Green Version]

- Liu, B.; Xu, H.; Zhou, X. Resource Allocation in Wireless-Powered Mobile Edge Computing Systems for Internet of Things Applications. Electronics 2019, 8, 206. [Google Scholar] [CrossRef] [Green Version]

- Jeong, S.; Kim, D.H.; Song, J.; Kim, H.; Lee, S.; Song, C.; Lee, J.; Song, J.; Kim, J. Smartwatch Strap Wireless Power Transfer System with Flexible PCB Coil and Shielding Material. IEEE Trans. Ind. Electron. 2019, 66, 4054–4064. [Google Scholar] [CrossRef]

- Park, J.; Kim, D.; Hwang, K.; Park, H.H.; Kwak, S.I.; Kwon, J.H.; Ahn, S. A Resonant Reactive Shielding for Planar Wireless Power Transfer System in Smartphone Application. IEEE Trans. Electromagn. Compat. 2017, 59, 695–703. [Google Scholar] [CrossRef]

- Wang, T.; Liu, X.; Jin, N.; Tang, H.; Yang, X.; Ali, M. Wireless Power Transfer for Battery Powering System. Electronics 2018, 7, 178. [Google Scholar] [CrossRef] [Green Version]

- Song, C.; Kim, H.; Kim, Y.; Kim, D.; Jeong, S.; Cho, Y.; Lee, S.; Ahn, S.; Kim, J. EMI reduction methods in wireless power transfer system for drone electrical charger using tightly coupled three-phase resonant magnetic field. IEEE Trans. Ind. Electron. 2018, 65, 6839–6849. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Innovative Design of Drone Landing Gear Used as a Receiving Coil in Wireless Charging Application. Energies 2019, 12, 3483. [Google Scholar] [CrossRef] [Green Version]

- Yang, L.; Li, X.; Liu, S.; Xu, Z.; Cai, C.; Guo, P. Analysis and Design of Three-Coil Structure WPT System with Constant Output Current and Voltage for Battery Charging Applications. IEEE Access 2019, 7, 87334–87344. [Google Scholar] [CrossRef]

- Shi, Z.H.; Chen, X.Y.; Qiu, Z.C. Modeling of mutual inductance between superconducting pancake coils used in wireless power transfer (WPT) systems. IEEE Trans. Appl. Supercond. 2019, 29, 1–4. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.H.; Choi, J.; Kim, K.H.; Park, Y.J. Free-positioning wireless charging system for small electronic devices using a bowl-shaped transmitting coil. IEEE Trans. Microw. Theory Tech. 2015, 63, 791–800. [Google Scholar] [CrossRef]

- Hou, T.; Xu, J.; Elkhuizen, W.S.; Wang, C.C.; Jiang, J.; Geraedts, J.M.; Song, Y. Design of 3D Wireless Power Transfer System Based on 3D Printed Electronics. IEEE Access 2019, 7, 94793–94805. [Google Scholar] [CrossRef]

- Ha-Van, N.; Seo, C. Analytical and Experimental Investigations of Omnidirectional Wireless Power Transfer Using a Cubic Transmitter. IEEE Trans. Ind. Electron. 2018, 65, 1358–1366. [Google Scholar] [CrossRef]

- Abou Houran, M.; Yang, X.; Chen, W. Magnetically Coupled Resonance WPT: Review of Compensation Topologies, Resonator Structures with Misalignment, and EMI Diagnostics. Electronics 2018, 7, 296. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Lin, D.; Hui, S.R. Ball-Joint Wireless Power Transfer Systems. IEEE Trans. Power Electron. 2018, 33, 65–72. [Google Scholar] [CrossRef]

- Abou Houran, M.; Yang, X.; Chen, W. Free Angular-Positioning Wireless Power Transfer Using a Spherical Joint. Energies 2018, 11, 3488. [Google Scholar] [CrossRef] [Green Version]

- Han, H.; Mao, Z.; Zhu, Q.; Su, M.; Hu, A.P. A 3D Wireless Charging Cylinder with Stable Rotating Magnetic Field for Multi-Load Application. IEEE Access 2019, 7, 35981–35997. [Google Scholar] [CrossRef]

- Campi, T.; Cruciani, S.; Maradei, F.; Feliziani, M. Near-Field Reduction in a Wireless Power Transfer System Using LCC Compensation. IEEE Trans. Electromagn. Compat. 2017, 59, 686–694. [Google Scholar] [CrossRef]

- Cirimele, V.; Freschi, F.; Giaccone, L.; Pichon, L.; Repetto, M. Human exposure assessment in dynamic inductive power transfer for automotive applications. IEEE Trans. Magn. 2017, 53, 1–4. [Google Scholar] [CrossRef]

- ICNIRP. Guidelines for limiting exposure to time-varying electric and magnetic fields (1 Hz to 10 MHz). Health Phys. 2010, 99, 818–836. [Google Scholar]

- Besnoff, J.; Chabalko, M.; Ricketts, D.S. A Frequency-Selective Zero-Permeability Metamaterial Shield for Reduction of Near-Field Electromagnetic Energy. IEEE Antennas Wirel. Propag. Lett. 2016, 15, 654–657. [Google Scholar] [CrossRef]

- Lu, C.; Rong, C.; Huang, X.; Hu, Z.; Tao, X.; Wang, S.; Chen, J.; Liu, M. Investigation of Negative and Near-Zero Permeability Metamaterials for Increased Efficiency and Reduced Electromagnetic Field Leakage in a Wireless Power Transfer System. IEEE Trans. Electromagn. Compat. 2018, 99, 1–9. [Google Scholar] [CrossRef]

- Das, R.K.; Basir, A.; Yoo, H. A Metamaterial-Coupled Wireless Power Transfer System Based on Cubic High Dielectric Resonators. IEEE Trans. Ind. Electron. 2018, 66, 7397–7406. [Google Scholar] [CrossRef] [Green Version]

- Kim, M.; Kim, H.; Kim, D.; Jeong, Y.; Park, H.H.; Ahn, S. A Three-Phase Wireless-Power-Transfer System for Online Electric Vehicles with Reduction of Leakage Magnetic Fields. IEEE Trans Micro. Theory. Tech. 2015, 63, 3806–3813. [Google Scholar] [CrossRef]

- Choi, S.Y.; Gu, B.W.; Lee, S.W.; Lee, W.Y.; Huh, J.; Rim, C.T. Generalized active EMF cancel methods for wireless electric vehicles. IEEE Trans. Power Electron. 2014, 29, 5770–5783. [Google Scholar] [CrossRef]

| WPT Prototype | N1/ N2 | f0 (kHz) | LTx, LRx (µH) | R1, R2 (Ω) | M µH, k at α = 0° | CTx CRx, (nF) |

|---|---|---|---|---|---|---|

| Tx | 23 | 943 | 139 | 0.64 | 9.94 | 0.2 |

| Rx | 16 | 58.8 | 0.25 | 0.11 | 0.48 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Abou Houran, M.; Yang, X.; Chen, W. Design of a Cylindrical Winding Structure for Wireless Power Transfer Used in Rotatory Applications. Electronics 2020, 9, 526. https://doi.org/10.3390/electronics9030526

Abou Houran M, Yang X, Chen W. Design of a Cylindrical Winding Structure for Wireless Power Transfer Used in Rotatory Applications. Electronics. 2020; 9(3):526. https://doi.org/10.3390/electronics9030526

Chicago/Turabian StyleAbou Houran, Mohamad, Xu Yang, and Wenjie Chen. 2020. "Design of a Cylindrical Winding Structure for Wireless Power Transfer Used in Rotatory Applications" Electronics 9, no. 3: 526. https://doi.org/10.3390/electronics9030526

APA StyleAbou Houran, M., Yang, X., & Chen, W. (2020). Design of a Cylindrical Winding Structure for Wireless Power Transfer Used in Rotatory Applications. Electronics, 9(3), 526. https://doi.org/10.3390/electronics9030526