Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market

Abstract

:1. Introduction

2. Materials and Methods

2.1. Download Value Quantification

2.2. Case Studies

2.2.1. Six Toy Product Comparisons

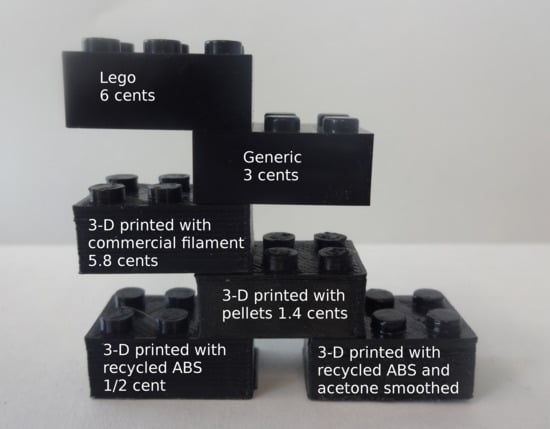

2.2.2. Lego Case Study

2.2.3. Board Game Comparison

3. Results and Discussion

3.1. Downloaded Value

3.1.1. Microeconomic Advantages of Home Manufacturing

3.1.2. Macroeconomic Impact of Home Manufacturing

3.2. Six Example Printable Toys

3.3. Lego Analysis

3.4. Board Game

3.5. Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Acronyms and Symbols

| ABS | acrylonitrile butadiene styrene |

| AM | additive manufacturing |

| CC | cost of the commercially available product USD |

| CE | average rate of electricity in the United States in USD/kWh |

| CF | cost of a given filament in USD/kg |

| Cs | marginal savings on each project USD |

| E | energy consumed in kWh |

| FFF | fused filament fabrication |

| mf | mass of the filament in grams |

| Nd | number of downloads |

| OL | operating cost |

| P | marginal percent change between the cost to print a product and the commercially available product |

| PLA | poly lactic acid |

| RepRap | self-REPlicating RAPid prototyper 3D printer |

| VD(t) | downloaded substitution valuation USD |

References

- Sells, E.; Bailard, S.; Smith, Z.; Bowyer, A.; Olliver, V. RepRap: The Replicating Rapid Prototyper-Maximizing Customizability by Breeding the Means of Production. In Proceedings of the World Conference on Mass Customization and Personalization, Cambridge, MA, USA, 7–10 October 2007. [Google Scholar]

- Jones, R.; Haufe, P.; Sells, E.; Iravani, P.; Olliver, V.; Palmer, C.; Bowyer, A. RepRap-the Replicating Rapid Prototyper. Robotica 2011, 29, 177–191. [Google Scholar] [CrossRef]

- Bowyer, A. 3D Printing and Humanity’s First Imperfect Replicator. 3D Print. Addit. Manuf. 2014, 1, 4–5. [Google Scholar] [CrossRef]

- Gibb, A.; Abadie, S. Building Open Source Hardware: DIY Manufacturing for Hackers and Makers, 1st ed.; Addison-Wesley Professional: Boston, MA, USA, 2014. [Google Scholar]

- Rundle, G. A Revolution in the Making; Simon and Schuster: New York, NY, USA, 2014. [Google Scholar]

- Wohlers, T. Wohlers Report 2016: 3D Printing and Additive Manufacturing State of the Industry Annual Worldwide Progress Report; Wohlers Associates Inc.: Fort Collins, CO, USA, 2016. [Google Scholar]

- Frauenfelder, M. Make: Ultimate Guide to 3D Printing 2014: Maker Media; O’Reilly Inc.: Sebastopol, CA, USA, 2013. [Google Scholar]

- Moilanen, J.; Vaden, T. 3D Printing Community and Emerging Practices of Peer Production. First Monday 2013. [Google Scholar] [CrossRef]

- Pearce, J.M. Building Research Equipment with Free, Open-Source Hardware. Science 2012, 337, 1303–1304. [Google Scholar] [CrossRef] [PubMed]

- Pearce, J. Open-Source Lab: How to Build Your Own Hardware and Reduce Research Costs, 1st ed.; Elsevier: Waltham, MA, USA, 2014. [Google Scholar]

- Baden, T.; Chagas, A.; Marzullo, T.; Prieto-Godino, L.; Euler, T. Open Laware: 3-D Printing Your Own Lab Equipment. PLoS Biol. 2015, 13, e1002086. [Google Scholar]

- Coakley, M.; Hurt, D.E. 3D Printing in the Laboratory Maximize Time and Funds with Customized and Open-Source Labware. J. Lab. Autom. 2016, 21, 489–495. [Google Scholar] [CrossRef] [PubMed]

- Kentzer, J.; Koch, B.; Thiim, M.; Jones, R.W.; Villumsen, E.; May. An Open Source Hardware-Based Mechatronics Project: The Replicating Rapid 3-D Printer. In Proceedings of the 2011 4th International Conference on Mechatronics, Kuala Lumpur, Malaysia, 17–19 May 2011; pp. 1–8. [Google Scholar]

- Irwin, J.L.; Oppliger, D.E.; Pearce, J.M.; Anzalone, G. Evaluation of RepRap 3D Printer Workshops in K-12 STEM. In Proceedings of the 122nd ASEE Annual Conference and Exposition, Seattle, MA, USA, 14–17 June 2015. [Google Scholar]

- Gonzalez-Gomez, J.; Valero-Gomez, A.; Prieto-Moreno, A.; Abderrahim, M. A new open source 3d-printable mobile robotic platform for education. In Advances in Autonomous Mini Robots; Springer: Berlin/Heidelberg, Germany, 2012; pp. 49–62. [Google Scholar]

- Grujović, N.; Radović, M.; Kanjevac, V.; Borota, J.; Grujović, G.; Divac, D. 3D Printing Technology in Education Environment. In Proceedings of the 34th International Conference on Production Engineering, Nis, Serbia, 28–30 September 2011; pp. 29–30. [Google Scholar]

- Schelly, C.; Anzalone, G.; Wijnen, B.; Pearce, J.M. Open-source 3-D printing technologies for education: Bringing additive manufacturing to the classroom. J. Visual Lang. Comput. 2015, 28, 226–237. [Google Scholar] [CrossRef]

- Pearce, J.M.; Blair, C.; Laciak, K.J.; Andrews, R.; Nosrat, A.; Zelenika-Zovko, I. 3-D Printing of Open Source Appropriate Technologies for Self-Directed Sustainable Development. J. Sustain. Dev. 2010, 3, 17–29. [Google Scholar] [CrossRef]

- Birtchnell, T.; Hoyle, W. 3D Printing for Development in the Global South: The 3D4D Challenge; Springer: Berlin, Germany, 2014. [Google Scholar]

- Wittbrodt, B.; Glover, A.; Laureto, J.; Anzalone, G.; Oppliger, D.; Irwin, J.; Pearce, J. Life-Cycle Economic Analysis of Distributed Manufacturing with Open-Source 3-D Printers. Mechatronics 2013, 23, 713–726. [Google Scholar] [CrossRef]

- Petersen, E.; Pearce, J. Emergence of Home Manufacturing in the Developed World: Return on Investment for Open-Source 3-D Printers. Technologies 2017, 5, 7. [Google Scholar] [CrossRef]

- Kelleher, K. Was 3D Printing Just a Passing Fad? Time 2015. Available online: time.com/3916323/3d-printer-stocks (accessed on 10 June 2015).

- Bilton, R. 3D Printing Is a Gimmick, Says Foxconn Prez (and He’s Sorta Right). 2013. Available online: https://venturebeat.com/2013/06/26/3d-printing-is-a-gimmick-says-foxconn-prez-and-hes-sorta-right/ (accessed on 1 July 2017).

- Statistica. Average Amount Spent per Child on Toys by Country in 2013 (in U.S. Dollars). Available online: http://www.statista.com/statistics/194424/amount-spent-on-toys-per-child-by-country-since-2009/ (accessed on 1 July 2017).

- Brandongaille. 23 Toy Industry Statistics and Trends. 2013. Available online: http://brandongaille.com/23-toy-industry-statistics-and-trends/ (accessed on 1 July 2017).

- Toy Association. Annual U.S. Sales Data. Available online: http://www.toyassociation.org/tia/industry_facts/salesdata/industryfacts/sales_data/sales_data.aspx?hkey=6381a73a-ce46–4caf-8bc1–72b99567df1e#.WQqVLYjys2w (accessed on 1 July 2017).

- Global Industry Analysts, Inc. Press Release: Toys and Games—A Global Strategic Business Report. 2015. Available online: http://www.strategyr.com/pressMCP-2778.asp (accessed on 1 July 2017).

- LEGO: We Will Continue To Dominate The Global Toy Market. 2014. Available online: http://www.businessinsider.com/lego-we-will-continue-to-dominate-the-global-toy-market-2014–2 (accessed on 1 July 2017).

- Ultimaker. Software—All platforms. Available online: https://ultimaker.com/en/products/cura-software/list (accessed on 1 July 2017).

- Chilson, L. The Difference between ABS and PLA for 3D Printing. ProtoParadigm 2013. Available online: http://www.protoparadigm.com/news-updates/the-difference-between-abs-and-pla-for-3d-printing/ (accessed on 1 July 2017).

- Stephens, B.; Azimi, P.; El Orch, Z.; Ramos, T. Ultrafine Particle Emissions from Desktop 3D Printers. Atmos. Environ. 2013, 79, 334–339. [Google Scholar] [CrossRef]

- Tokiwa, Y.; Calabia, B.; Ugwu, C.; Aiba, S. Biodegradability of Plastics. Int. J. Mol. Sci. 2009, 10, 3722–3742. [Google Scholar] [CrossRef] [PubMed]

- Hoffman, T. LulzBot Mini 3D Printer. PCMAG. 2015. Available online: http://www.pcmag.com/article2/0,2817,2476575,00.asp (accessed on 1 July 2017).

- U.S. Energy Information Administration Independent Short-Term Energy Outlook (STEO). Available online: https://www.eia.gov/forecasts/steo/pdf/steo_full.pdf (accessed on 1 July 2017).

- Amazon Hatchbox 3D PLA-1kg 3.00-BLK PLA 3D Printer filament Dimensional Accuracy ±0.05 Mm, 1 Kg Spool, 3.00 Mm, Black. Available online: http://www.amazon.com/HATCHBOX-3D-PLA-1KG3–00-BLK-Filament-Dimensional/dp/B00MEZE7XU (accessed on 1 July 2017).

- Alibaba. PLA plastic pellets. Available online: https://www.alibaba.com/showroom/pla-plastic-pellets.html (accessed on 16 May 2017).

- Baechler, C.; DeVuono, M.; Pearce, J.M. Distributed Recycling of Waste Polymer into RepRap Feedstock. Rapid Prototyp. J. 2013, 19, 118–125. [Google Scholar] [CrossRef]

- Zhong, S.L.; Pearce, J.M. Tightening the Loop on the Circular Economy: Coupled Distributed Recycling and Manufacturing with Recyclebot and RepRap 3-D Printing. to be published.

- Pearce, J. Quantifying the Value of Open Source Hardware Development. Mod. Econ. 2015, 6, 1–11. [Google Scholar] [CrossRef]

- Pearce, J.M. Return on investment for open source scientific hardware development. Sci. Public Policy 2016, 43, 192–195. [Google Scholar] [CrossRef]

- Wang, Z. Mattell: Buy the Toys While They’re on Sale. 2015. Available online: http://seekingalpha.com/article/3160396-mattel-buy-the-toys-while-theyre-on-sale (accessed on 1 July 2017).

- Allain, R. How Much Does One Lego Piece Cost? 2014. Available online: https://www.wired.com/2014/08/lego-cost/ (accessed on 1 July 2017).

- Griepp, M. Hobby Games Market Nearly $1.2 Billion. ICv2. 2016. Available online: https://icv2.com/articles/news/view/35150/hobby-games-market-nearly-1–2-billion (accessed on 1 July 2017).

- Wong, J.I. Old-fashioned board games, not tech, are attracting the most money on Kickstarter. 2016. Available online: https://qz.com/688843/old-fashioned-board-games-not-tech-are-attracting-the-most-money-on-kickstarter/ (accessed on 1 July 2017).

- Business Wire. Top 3 Trends Impacting the Global Board Games Market Through 2021: Technavio. 2016. Available online: http://www.businesswire.com/news/home/20161228005057/en/Top-3-Trends-Impacting-Global-Board-Games (accessed on 1 July 2017).

- Appropedia. Save the Planet Board Game. Available online: http://www.appropedia.org/Save_the_planet_board_game (accessed on 1 July 2017).

- Amazon Best Sellers. Board Games. Available online: https://www.amazon.com/Best-Sellers-Toys-Games-Board/zgbs/toys-and-games/166225011 (accessed on 3 May 2017).

- English Oxford Living Dictionaries- Cosplay. Available online: https://en.oxforddictionaries.com/definition/cosplay (accessed on 4 May 2017).

- Seregina, A.; Weijo, H. Play at Any Cost: How Cosplayers Produce and Sustain Their Ludic Communal Consumption Experiences. J. Consum. Res. 2017, 44, 139–159. [Google Scholar] [CrossRef]

- Le Duigou, A.; Castro, M.; Bevan, R.; Martin, N. 3D printing of wood fibre biocomposites: From mechanical to actuation functionality. Mater. Des. 2016, 96, 106–114. [Google Scholar] [CrossRef]

- Rudnicki, M.; Pringle, A.M.; Pearce, J.M. Viability of Up-Cycling Wood Furniture Waste to 3-D Printing Filament. In Advancements in Fiber-Polymer Composites Symposium; 2017; in press. [Google Scholar]

- Kreiger, M.; Pearce, J.M. Environmental impacts of distributed manufacturing from 3-D printing of polymer components and products. In MRS Proceedings; Cambridge University Press: Cambridge, UK, 2013; Volume 1492, pp. 85–90. [Google Scholar]

- Kreiger, M.; Pearce, J.M. Environmental life cycle analysis of distributed three-dimensional printing and conventional manufacturing of polymer products. ACS Sustain. Chem. Eng. 2013, 1, 1511–1519. [Google Scholar] [CrossRef]

- Kostakis, V.; Papachristou, M. Commons-based peer production and digital fabrication: The case of a RepRap-based, Lego-built 3D printing-milling machine. Telemat. Inf. 2014, 31, 434–443. [Google Scholar] [CrossRef]

- Adapterz LLC. Lego to Lincoln Logs. Available online: https://www.myminifactory.com/object/lego-to-lincoln-logs-uck-05f06m-14924 (accessed on 5 May 2017).

- Amazon. Building Bricks 0 Regular Colors—1000 Pieces—Compatible with All Major Brands. Available online: https://www.amazon.com/Building-Bricks-Regular-Colors-Compatible/dp/B015EQIOCA/ref=sr_1_1 (accessed on 1 July 2017).

- STARTT 3D Printer. iMakr.com. Available online: https://www.imakr.com/us/en/startt-affordable-3d-printer/1146-startt-3d-printer.html (accessed on 1 July 2017).

- Bak, D. Rapid prototyping or rapid production? 3D printing processes move industry towards the latter. Assem. Autom. 2003, 23, 340–345. [Google Scholar] [CrossRef]

- Petrick, I.J.; Simpson, T.W. 3D printing disrupts manufacturing: How economies of one create new rules of competition. Res.-Technol. Manag. 2013, 56, 12–16. [Google Scholar] [CrossRef]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Kietzmann, J.; Pitt, L.; Berthon, P. Disruptions, decisions, and destinations: Enter the age of 3-D printing and additive manufacturing. Bus. Horiz. 2015, 58, 209–215. [Google Scholar] [CrossRef]

- Rifkin, J. The Zero Marginal Cost Society: The Internet of Things, the Collaborative Commons, and the Eclipse of Capitalism; Palgrave Macmillan: Basingstoke, UK, 2014. [Google Scholar]

- Laplume, A.O.; Petersen, B.; Pearce, J.M. Global value chains from a 3D printing perspective. J. Int. Bus. Stud. 2016, 47, 595–609. [Google Scholar] [CrossRef]

- Rehnberg, M.; Pointe, S. 3D Printing and Global Value Chains: How a New Technology May Restructure Global Production; Global Production Networks Centre: Singapore, 2016; GPN2016-010; Available online: http://gpn.nus.edu.sg/file/Stefano%20Ponte_GPN2016_010.pdf (accessed on 1 July 2017).

- Pîrjan, A.; Petrosanu, D.M. The Impact of 3D Printing Technology on the Society and Economy. J. Inf. Syst. Oper. Manag. 2013. Available online: ftp://ftp.repec.org/opt/ReDIF/RePEc/rau/jisomg/Wi13/JISOM-WI13-A19.pdf (accessed on 7 July 2017).

- Thiesse, F.; Wirth, M.; Kemper, H.G.; Moisa, M.; Morar, D.; Lasi, H.; Piller, F.; Buxmann, P.; Mortara, L.; Ford, S.; Minshall, T. Economic Implications of Additive Manufacturing and the Contribution of MIS. Bus. Inf. Syst. Eng. 2015, 57, 139. [Google Scholar] [CrossRef]

- Aitken-Palmer, W. A Market-Based Approach to 3d Printing for Economic Development in Ghana. Master’s Thesis, Michigan Technological University, Houghton, MI, USA, 2015. [Google Scholar]

- Pearce, J.M. Applications of open source 3-D printing on small farms. Org. Farming 2015, 1, 19–35. [Google Scholar] [CrossRef]

- Pearce, J.M. Emerging Business Models for Open Source Hardware. J. Open Hardw. 2017, 1, 2. [Google Scholar] [CrossRef]

- Reed, R.; Storrud-Barnes, S.; Jessup, L. How open innovation affects the drivers of competitive advantage: Trading the benefits of IP creation and ownership for free invention. Manag. Decis. 2012, 50, 58–73. [Google Scholar] [CrossRef]

- Peh, Z.K.; Yap, Y.L.; Yeong, W.Y.; Liow, H.H. Application of 3D printed medical aid for pediatric cancer patients. In Proceedings of the 2nd International Conference on Progress in Additive Manufacturing, Nanyang Technological University, Singapore, 16–19 May 2016; pp. 49–54. [Google Scholar]

- Saengchairat, N.; Tran, T.; Chua, C.K. A review: Additive manufacturing for active electronic components. Virtual Phys. Prototyp. 2017, 12, 31–46. [Google Scholar] [CrossRef]

- Anzalone, G.C.; Wijnen, B.; Pearce, J.M. Multi-material additive and subtractive prosumer digital fabrication with a free and open-source convertible delta RepRap 3-D printer. Rapid Prototyp. J. 2015, 21, 506–519. [Google Scholar] [CrossRef]

- Vidimče, K.; Wang, S.P.; Ragan-Kelley, J.; Matusik, W. OpenFab: A programmable pipeline for multi-material fabrication. ACM Trans. Graph. 2013, 32, 136. [Google Scholar] [CrossRef]

- Khoo, Z.X.; Teoh, J.E.M.; Liu, Y.; Chua, C.K.; Yang, S.; An, J.; Leong, K.F.; Yeong, W.Y. 3D printing of smart materials: A review on recent progresses in 4D printing. Virtual Phys. Prototyp. 2015, 10, 103–122. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Muller, L.; Camargo, M. Towards a standard experimental protocol for open source additive manufacturing: This paper proposes a benchmarking model for evaluating accuracy performance of 3D printers. Virtual Phys. Prototyp. 2014, 9, 151–167. [Google Scholar] [CrossRef]

- Gewirtz, D. Adding a Raspberry Pi Case and a Camera to Your LulzBot Mini—Watch Video Online—Watch Latest Ultra HD 4K Videos Online. 2016. Available online: http://www.zdnet.com/article/3d-printing-hands-on-adding-a-case-and-a-camera-to-the-raspberry-pi-and-lulzbot-mini/ (accessed on 30 November 2016).

- Printer3D. Free IP Camera Monitoring for 3D Printer with Old Webcam usb in 5min—3D Printers English French & FAQ Wanhao Duplicator D6 Monoprice Maker Ultimate & D4, D5, Duplicator 7, 2017. Available online: http://www.printer3d.one/en/forums/topic/free-ip-camera-monitoring-for-3d-printer-with-old-webcam-usb-in-5min/ (accessed on 18 March 2017).

- Simon, J. Monitoring Your 3D Prints|3D Universe. 2017. Available online: https://3duniverse.org/2014/01/06/monitoring-your-3d-prints/ (accessed on 18 March 2017).

- Nuchitprasitchai, S.; Roggemann, M.; Pearce, J. Factors Effecting Real Time Optical Monitoring of Fused Filament 3-D Printing. Prog. Addit. Manuf. 2017, 1–17. [Google Scholar] [CrossRef]

- Nuchitprasitchai, S.; Roggemann, M.; Pearce, J. Three Hundred and Sixty Degree Real-Time Monitoring of 3-D Printing Using Computer Analysis of Two Camera Views. J. Manuf. Mater. Process. 2017, 1, 2. [Google Scholar] [CrossRef]

- Nuchitprasitchai, S.; Roggemann, M.; Pearce, J. An Open Source Algorithm for Reconstruction 3-D images for Low-cost, Reliable Real-time Monitoring of FFF-based 3-D Printing. to be published.

- Cruz, F.; Lanza, S.; Boudaoud, H.; Hoppe, S.; Camargo, M. Polymer Recycling and Additive Manufacturing in an Open Source context: Optimization of Processes and Methods. In Proceedings of the 2015 Annual International Solid Freeform Fabrication Symposium-An Additive Manufacturing Conference, Austin, TX, USA, 7–9 August 2015; pp. 10–12. [Google Scholar]

- Rayna, T.; Striukova, L. From rapid prototyping to home fabrication: How 3D printing is changing business model innovation. Technol. Forecast. Soc. Chang. 2016, 102, 214–224. [Google Scholar] [CrossRef]

| Open Source 3D Printed Design | URL (www.myminifactory.com/object) | Nd |

|---|---|---|

| Pokemon Go aimer | pokeball-aimer-pokemon-go-23009 | 20583 |

| Clash of Clans barbarian | barbarian-lv-1-clash-of-clans-858 | 8107 |

| Voltron figure | voltron-defender-of-the-universe-22430 | 3881 |

| Overwatch tracer gun | tracer-gun-overwatch-19011 | 3602 |

| Overwatch reaper mask | reaper-mask-19004 | 3457 |

| Overwatch McCree revolver | updated-mccree-revolver-by-jeff-lagant-not-me-19543 | 3303 |

| Star Wars AT-AT | detailed-at-at-17606 | 3218 |

| Last Word Destiny Hand Cannon | destiny-last-word-exotic-hand-cannon-6546 | 3140 |

| Overwatch D.VA Light Gun | d-va-s-light-gun-18920 | 3135 |

| Overwatch Reaper Shotgun | reaper-s-hellfire-shotguns-overwatch-19096 | 2943 |

| Batman cowl | batman-cowl-20596 | 2926 |

| Destiny Hawkmoon gun | destiny-hawkmoon-exotic-hand-cannon-6545 | 2885 |

| Destiny thorn gun | thorn-from-destiny-4494 | 2846 |

| Star Wars VII Storm Trooper Helmet | star-wars-storm-trooper-vii-fully-wearable-helmet-12992 | 2588 |

| Kylo Ren helmet | jj-industries-kylo-ren-helmet-14106 | 2451 |

| Wall outlet shelf | wall-outlet-shelf-6382 | 2350 |

| Kylo Ren lightsaber | kylo-ren-s-lightsaber-star-wars-6791 | 2347 |

| Blade Runner blaster | deckards-blaster-blade-runner-5694 | 2337 |

| Fallout 3 T45-d helmet | fallout-3-t45-d-power-armour-helmet-15253 | 2318 |

| Venus de Milo figurine | venus-de-milo-at-louvre-paris-1657 | 2073 |

| Warcraft Frostmourne sword | frostmourne-from-warcraft-4156 | 1999 |

| 3DR Iris+ quadcopter | 3drobotics-iris-19615 | 1871 |

| Pieta figurine | pieta-in-st-peter-s-basilica-vatican-3796 | 1862 |

| P08 Luger gun | p08-luger-functional-assembly-5545 | 1798 |

| Game of Thrones iron throne | game-of-thrones-iron-throne-1945 | 1786 |

| The Thinker figurine | the-thinker-at-the-muse-rodin-france-2127 | 1755 |

| Overwatch McCree Peacemaker gun | mccree-peacemaker-overwatch-19152 | 1723 |

| Fallout 4 Pipboy 3000 MkIV | fallout-4-pipboy-3000-mkiv-16884 | 1705 |

| Articulated lamp | articulated-lamp-6790 | 1704 |

| Overwatch throwing star | genji-s-shuriken-18918 | 1695 |

| Strong bolt | support-free-bolt-1281 | 1571 |

| Mazigner Z Super Robot | mazigner-z-super-robot-24533 | 1570 |

| Secret shelf | secret-shelf-3504 | 1564 |

| Sombra pistol | sombra-s-machine-pistol-25186 | 1544 |

| Han Solo blaster | han-solo-s-blaster-star-wars-1546 | 1520 |

| Overwatch D.VA headset | d-va-headset-22077 | 1502 |

| Overwatch Mercy staff | mercy-s-staff-22079 | 1484 |

| Overwatch Mercy blaster | mercy-s-caduceus-blaster-18912 | 1481 |

| Han Solo blaster | hans-solo-blaster-2488 | 1461 |

| Gears of War Chainsaw gun | gears-of-war-lancer-chainsaw-gun-11478 | 1437 |

| Destiny Duke MK.44 gun | duke-mk-44-hand-cannon-from-destiny-2140 | 1418 |

| Fallout 4 Laser pistol | fallout-4-laser-pistol-18978 | 1417 |

| Overwatch loot box | overwatch-loot-box-21670 | 1412 |

| Cat at British Museum | gayer-anderson-cat-at-the-british-museum-london-4010 | 1364 |

| Halo 5 assault rifle | halo-5-assault-rifle-11734 | 1334 |

| Portal gun | portal-gun-18342 | 1328 |

| Destiny hawkmoon gun | hawkmoon-from-destiny-full-scale-and-moving-6863 | 1327 |

| Clash of Clans figurine | p-e-k-k-a-lv-1-clash-of-clans-857 | 1314 |

| Harry Potter elder wand | dumbledore-s-elder-wand-2057 | 1299 |

| Groot flower pot | baby-groot-flower-pot-gardens-of-the-galaxy-2-26442 | 1269 |

| Melted Darth Vader mask | darth-vader-melted-mask-6685 | 1264 |

| Fallout 4 10mm pistol | fallout-4-10mm-pistol-10475 | 1264 |

| Starcraft Kerrigan statue | starcraft-kerrigan-statue-10432 | 1263 |

| Destiny ghost | destiny-ghost-6038 | 1248 |

| Lich king figurine | the-lich-king-6174 | 1212 |

| Micro game bit | micro-bit-game-bit-13822 | 1199 |

| Ant Man helmet | ant-man-mask-wearable-5322 | 1193 |

| Game of Thrones House emblem | house-stark-game-of-thrones-1154 | 1182 |

| Planetary gears | planetary-gears-1557 | 1163 |

| Clash of Clans king figure | barbarian-king-clash-of-clans-871 | 1160 |

| Tooth toothbrush holder | the-big-tooth-2-0-5759 | 1141 |

| Halo 3 ODST helmet | halo-3-odst-helmet-wearable-cosplay-17614 | 1134 |

| Fallout 4 protectron figure | fallout-4-protectron-action-figure-15585 | 1129 |

| BFG Doom | bfg-21395 | 1122 |

| Discobolus figurine | discobolus-at-the-british-museum-london-7896 | 1118 |

| Anonymous mask | guy-fawkes-anonymous-mask-2582 | 1092 |

| Guardian of the Galaxy Star Lord mask | guardians-of-the-galaxy-star-lord-s-mask-version-2-3045 | 1091 |

| Pokeball | pokeball-high-detail-version-23506 | 1064 |

| Witcher 3 wall plaque | the-witcher-3-wall-plaque-8882 | 1063 |

| Overwatch widowmaker rifle | overwatch-widowmaker-sniper-rifle-21702 | 1029 |

| Fallout 4 combat rifle and shotgun | fallout-4-combat-rifle-and-combat-shotgun-18428 | 1025 |

| Michelangelo’s David | michelangelo-s-david-in-florence-italy-2052 | 1023 |

| Destiny ghost | ghost-destiny-2396 | 1022 |

| Triceratops skull | triceratops-skull-in-colorado-usa-6225 | 1019 |

| Skull ring | skull-ring-20782 | 1014 |

| Star Wars NN-44 Rey’s Blaster | star-wars-nl-44-reys-blaster-17422 | 1012 |

| Joker mask | joker-mask-9743 | 1010 |

| Fork/spoon support for disability | fork-and-spoon-support-for-person-with-disabilities-5480 | 1007 |

| BFG Doom | bfg-parts-19092 | 1006 |

| Gryffindor coat of arms | gryffindor-coat-of-arms-wall-desk-display-harry-potter-11834 | 994 |

| Destiny Gjallahorn | gjallarhorn-2-0-destiny-19160 | 985 |

| Pokemon figurines | low-poly-pokemon-collection-15905 | 983 |

| Rubik’s cube | 3d-printable-rubik-s-cube-9734 | 980 |

| Destiny bad juju pulse rifle | destiny-s-bad-juju-exotic-pulse-rifle-6618 | 977 |

| Fallout 4 Kellogg’s pistol | kellogg-s-pistol-fallout-4-21556 | 975 |

| Dobby the Elf figurine | dobby-from-harry-potter-full-model-3294 | 970 |

| Statue of Liberty figurine | statue-of-liberty-in-manhatten-new-york-2077 | 960 |

| Nutcracker | nutcracker-v2-4361 | 946 |

| Minions figurines | minion-movie-trio-10140 | 940 |

| Destiny sleeper simulant | the-sleeper-simulant-from-destiny-14769 | 930 |

| Frozen Elsa figurine | elsa-from-disney-s-frozen-6573 | 919 |

| Star Wars storm trooper rifle | blaster-rifle-star-wars-storm-trooper-12097 | 914 |

| Vitruvian Man scuplture | the-vetruvian-man-sculpture-at-belgrave-square-london-1669 | 908 |

| Robocop ED209 figure | ed209-from-robocop-5090 | 904 |

| Harry Potter wand | harry-potter-s-wand-10391 | 898 |

| Cable guards | icableguards-21235 | 894 |

| Game of Thrones dice cup | stark-dice-cup-1847 | 893 |

| Overwatch McCree flashbang | mccree-flashbang-from-overwatch-21595 | 890 |

| B2 bomber glider | b2-stealth-bomber-glider-improved-flight-powered-by-an-elastic-band-13337 | 886 |

| Star Wars X Wing helmet | x-wing-pilot-helmet-starwars-episode-vii-the-force-awakens-9074 | 859 |

| Design | Mass (g) | Cost: Commercial Filament | Cost: Pellet | Cost: Recyclebot | Commercially Available Alternative (USD) |

|---|---|---|---|---|---|

| Pokemon Go aimer | 27 | $0.66 | $0.18 | $0.09 | $4.99 |

| Clash of Clans barbarian | 21 | $0.51 | $0.14 | $0.07 | $19.00 |

| Voltron figure | 1247 | $30.26 | $8.44 | $4.27 | $9.99 |

| Overwatch tracer gun | 190 | $4.61 | $1.29 | $0.65 | $26.59 |

| Overwatch reaper mask | 333 | $8.08 | $2.25 | $1.14 | $25.00 |

| Star Wars AT-AT | 683 | $16.57 | $4.62 | $2.34 | $7.50 |

| Last Word Destiny Hand Cannon | 367 | $8.91 | $2.48 | $1.26 | $100.00 |

| Overwatch D.VA Light Gun | 261 | $6.33 | $1.77 | $0.89 | $55.00 |

| Overwatch Reaper Shotgun | 269 | $6.53 | $1.82 | $0.92 | $40.38 |

| Batman cowl | 147 | $3.57 | $0.99 | $0.50 | $6.76 |

| Destiny Hawkmoon gun | 473 | $11.48 | $3.20 | $1.62 | $99.99 |

| Destiny thorn gun | 425 | $10.31 | $2.88 | $1.46 | $17.99 |

| Star Wars VII Storm Trooper Helmet | 948 | $23.01 | $6.42 | $3.25 | $20.20 |

| Kylo Ren helmet | 550 | $13.35 | $3.72 | $1.88 | $4.08 |

| Wall outlet shelf | 69 | $1.67 | $0.47 | $0.24 | $10.00 |

| Kylo Ren lightsaber | 319 | $7.74 | $2.16 | $1.09 | $20.00 |

| Blade Runner blaster | 249 | $6.04 | $1.68 | $0.85 | $12.99 |

| Fallout 3 T45-d helmet | 1586 | $38.49 | $10.73 | $5.44 | $185.91 |

| Venus de Milo figurine | 28 | $0.68 | $0.19 | $0.10 | $9.00 |

| Warcraft Frostmourne sword | 1233 | $29.92 | $8.34 | $4.23 | $133.00 |

| 3DR Iris+ quadcopter | 255 | $6.19 | $1.73 | $0.87 | $13.89 |

| Pieta figurine | 164 | $3.98 | $1.11 | $0.56 | $16.88 |

| P08 Luger gun | 138 | $3.35 | $0.93 | $0.47 | $79.00 |

| Game of Thrones iron throne | 124 | $3.01 | $0.84 | $0.42 | $15.25 |

| The Thinker figurine | 92 | $2.23 | $0.62 | $0.32 | $22.32 |

| Overwatch McCree Peacemaker gun | 301 | $7.30 | $2.04 | $1.03 | $69.99 |

| Fallout 4 Pipboy 3000 MkIV | 884 | $21.45 | $5.98 | $3.03 | $74.99 |

| Articulated lamp | 180 | $4.37 | $1.22 | $0.62 | $7.97 |

| Overwatch throwing star | 13 | $0.32 | $0.09 | $0.04 | $6.99 |

| Strong bolt | 9 | $0.22 | $0.06 | $0.03 | $19.14 |

| Mazigner Z Super Robot | 117 | $2.84 | $0.79 | $0.40 | $9.99 |

| Sombra pistol | 495 | $12.01 | $3.35 | $1.70 | $85.00 |

| Han Solo blaster | 216 | $5.24 | $1.46 | $0.74 | $10.12 |

| Overwatch D.VA headset | 65 | $1.58 | $0.44 | $0.22 | $18.99 |

| Overwatch Mercy staff | 1768 | $42.90 | $11.96 | $6.06 | $165.89 |

| Overwatch Mercy blaster | 411 | $9.97 | $2.78 | $1.41 | $19.49 |

| Gears of War Chainsaw gun | 1556 | $37.76 | $10.53 | $5.33 | $199.99 |

| Destiny Duke MK.44 gun | 325 | $7.89 | $2.20 | $1.11 | $125.00 |

| Fallout 4 Laser pistol | 1322 | $32.08 | $8.95 | $4.53 | $89.99 |

| Overwatch loot box | 124 | $3.01 | $0.84 | $0.42 | $8.98 |

| Cat at British Museum | 62 | $1.50 | $0.42 | $0.21 | $75.99 |

| Halo 5 assault rifle | 2295 | $55.69 | $15.53 | $7.86 | $50.00 |

| Portal gun | 1528 | $37.08 | $10.34 | $5.24 | $279.99 |

| Clash of Clans figurine | 2 | $0.05 | $0.01 | $0.01 | $29.99 |

| Harry Potter elder wand | 17 | $0.41 | $0.12 | $0.06 | $4.79 |

| Groot flower pot | 57 | $1.38 | $0.39 | $0.20 | $8.99 |

| Melted Darth Vader mask | 172 | $4.17 | $1.16 | $0.59 | $8.00 |

| Fallout 4 10mm pistol | 793 | $19.24 | $5.37 | $2.72 | $24.99 |

| Starcraft Kerrigan statue | 112 | $2.72 | $0.76 | $0.38 | $55.79 |

| Destiny ghost | 116 | $2.81 | $0.78 | $0.40 | $7.00 |

| Lich king figurine | 487 | $11.82 | $3.30 | $1.67 | $15.00 |

| Ant Man helmet | 367 | $8.91 | $2.48 | $1.26 | $44.59 |

| Game of Thrones House emblem | 34 | $0.83 | $0.23 | $0.12 | $9.95 |

| Clash of Clans king figure | 24 | $0.58 | $0.16 | $0.08 | $19.00 |

| Tooth toothbrush holder | 120 | $2.91 | $0.81 | $0.41 | $2.00 |

| Halo 3 ODST helmet | 1118 | $27.13 | $7.57 | $3.83 | $9.99 |

| Fallout 4 protectron figure | 98 | $2.38 | $0.66 | $0.34 | $24.99 |

| Discobolus figurine | 35 | $0.85 | $0.24 | $0.12 | $7.25 |

| Anonymous mask | 383 | $9.29 | $2.59 | $1.31 | $4.95 |

| Guardian of the Galaxy Star Lord mask | 351 | $8.52 | $2.38 | $1.20 | $5.99 |

| Pokeball | 221 | $5.36 | $1.50 | $0.76 | $1.00 |

| Witcher 3 wall plaque | 100 | $2.43 | $0.68 | $0.34 | $45.00 |

| Overwatch widowmaker rifle | 1364 | $33.10 | $9.23 | $4.67 | $145.89 |

| Fallout 4 combat rifle and shotgun | 351 | $8.52 | $2.38 | $1.20 | $85.00 |

| Michelangelo’s David | 75 | $1.82 | $0.51 | $0.26 | $29.93 |

| Triceratops skull | 66 | $1.60 | $0.45 | $0.23 | $40.00 |

| Skull ring | 5 | $0.12 | $0.03 | $0.02 | $9.95 |

| Star Wars NN-44 Rey’s Blaster | 141 | $3.42 | $0.95 | $0.48 | $45.00 |

| Joker mask | 751 | $18.22 | $5.08 | $2.57 | $11.56 |

| Fork/spoon support for disability | 17 | $0.41 | $0.12 | $0.06 | $11.00 |

| Gryffindor coat of arms | 48 | $1.16 | $0.32 | $0.16 | $8.00 |

| Pokemon figurines | 63 | $1.53 | $0.43 | $0.22 | $30.00 |

| Rubik’s cube | 12 | $0.29 | $0.08 | $0.04 | $4.99 |

| Fallout 4 Kellogg’s pistol | 152 | $3.69 | $1.03 | $0.52 | $100.00 |

| Dobby the Elf figurine | 365 | $8.86 | $2.47 | $1.25 | $31.36 |

| Statue of Liberty figurine | 85 | $2.06 | $0.58 | $0.29 | $6.44 |

| Nutcracker | 61 | $1.48 | $0.41 | $0.21 | $4.99 |

| Minions figurines | 121 | $2.94 | $0.82 | $0.41 | $26.80 |

| Destiny sleeper simulant | 1274 | $30.92 | $8.62 | $4.37 | $211.66 |

| Frozen Elsa figurine | 33 | $0.80 | $0.22 | $0.11 | $7.99 |

| Star Wars storm trooper rifle | 486 | $11.79 | $3.29 | $1.67 | $170.00 |

| Vitruvian Man scuplture | 12 | $0.29 | $0.08 | $0.04 | $31.49 |

| Robocop ED209 figure | 736 | $17.86 | $4.98 | $2.52 | $21.99 |

| Harry Potter wand | 8 | $0.19 | $0.05 | $0.03 | $13.55 |

| Cable guards | 7 | $0.17 | $0.05 | $0.02 | $1.25 |

| Game of Thrones dice cup | 59 | $1.43 | $0.40 | $0.20 | $8.32 |

| B2 bomber glider | 20 | $0.49 | $0.14 | $0.07 | $10.57 |

| Star Wars X Wing helmet | 949 | $23.03 | $6.42 | $3.25 | $41.40 |

| Hawkmoon #2 | 621 | $15.07 | $4.20 | $2.13 | $99.99 |

| Destiny ghost #2 | 48 | $1.16 | $0.32 | $0.16 | $7.00 |

| Average | 382.29 | $9.28 | $2.59 | $1.31 | $42.44 |

| Total | 34,406 | $834.93 | $232.83 | $117.91 | $3819.59 |

| Design | Cost Savings (USD) | Percent Savings (%) | ||||

|---|---|---|---|---|---|---|

| Commercial Filament | Pellets | Recyclebot | Commercial Filament | Pellets | Recyclebot | |

| Pokemon Go aimer | $4.33 | $4.81 | $4.90 | 87% | 96% | 98% |

| Clash of Clans barbarian | $18.49 | $18.86 | $18.93 | 97% | 99% | 100% |

| Voltron figure | $(20.27) | $1.55 | $5.72 | −203% | 16% | 57% |

| Overwatch tracer gun | $21.98 | $25.30 | $25.94 | 83% | 95% | 98% |

| Overwatch reaper mask | $16.92 | $22.75 | $23.86 | 68% | 91% | 95% |

| Star Wars AT-AT | $(9.07) | $2.88 | $5.16 | −121% | 38% | 69% |

| Last Word Destiny Hand Cannon | $91.09 | $97.52 | $98.74 | 91% | 98% | 99% |

| Overwatch D.VA Light Gun | $48.67 | $53.23 | $54.11 | 88% | 97% | 98% |

| Overwatch Reaper Shotgun | $33.85 | $38.56 | $39.46 | 84% | 95% | 98% |

| Batman cowl | $3.19 | $5.77 | $6.26 | 47% | 85% | 93% |

| Destiny Hawkmoon gun | $88.51 | $96.79 | $98.37 | 89% | 97% | 98% |

| Destiny thorn gun | $7.68 | $15.11 | $16.53 | 43% | 84% | 92% |

| Star Wars VII Storm Trooper Helmet | $(2.81) | $13.78 | $16.95 | −14% | 68% | 84% |

| Kylo Ren helmet | $(9.27) | $0.36 | $2.20 | −227% | 9% | 54% |

| Wall outlet shelf | $8.33 | $9.53 | $9.76 | 83% | 95% | 98% |

| Kylo Ren lightsaber | $12.26 | $17.84 | $18.91 | 61% | 89% | 95% |

| Blade Runner blaster | $6.95 | $11.31 | $12.14 | 53% | 87% | 93% |

| Fallout 3 T45-d helmet | $147.42 | $175.18 | $180.47 | 79% | 94% | 97% |

| Venus de Milo figurine | $8.32 | $8.81 | $8.90 | 92% | 98% | 99% |

| Warcraft Frostmourne sword | $103.08 | $124.66 | $128.77 | 78% | 94% | 97% |

| 3DR Iris+ quadcopter | $7.70 | $12.16 | $13.02 | 55% | 88% | 94% |

| Pieta figurine | $12.90 | $15.77 | $16.32 | 76% | 93% | 97% |

| P08 Luger gun | $75.65 | $78.07 | $78.53 | 96% | 99% | 99% |

| Game of Thrones iron throne | $12.24 | $14.41 | $14.83 | 80% | 94% | 97% |

| The Thinker figurine | $20.09 | $21.70 | $22.00 | 90% | 97% | 99% |

| Overwatch McCree Peacemaker gun | $62.69 | $67.95 | $68.96 | 90% | 97% | 99% |

| Fallout 4 Pipboy 3000 MkIV | $53.54 | $69.01 | $71.96 | 71% | 92% | 96% |

| Articulated lamp | $3.60 | $6.75 | $7.35 | 45% | 85% | 92% |

| Overwatch throwing star | $6.67 | $6.90 | $6.95 | 95% | 99% | 99% |

| Strong bolt | $18.92 | $19.08 | $19.11 | 99% | 100% | 100% |

| Mazigner Z Super Robot | $7.15 | $9.20 | $9.59 | 72% | 92% | 96% |

| Sombra pistol | $72.99 | $81.65 | $83.30 | 86% | 96% | 98% |

| Han Solo blaster | $4.88 | $8.66 | $9.38 | 48% | 86% | 93% |

| Overwatch D.VA headset | $17.41 | $18.55 | $18.77 | 92% | 98% | 99% |

| Overwatch Mercy staff | $122.99 | $153.93 | $159.83 | 74% | 93% | 96% |

| Overwatch Mercy blaster | $9.52 | $16.71 | $18.08 | 49% | 86% | 93% |

| Gears of War Chainsaw gun | $162.23 | $189.46 | $194.66 | 81% | 95% | 97% |

| Destiny Duke MK.44 gun | $117.11 | $122.80 | $123.89 | 94% | 98% | 99% |

| Fallout 4 Laser pistol | $57.91 | $81.04 | $85.46 | 64% | 90% | 95% |

| Overwatch loot box | $5.97 | $8.14 | $8.56 | 66% | 91% | 95% |

| Cat at British Museum | $74.49 | $75.57 | $75.78 | 98% | 99% | 100% |

| Halo 5 assault rifle | $(5.69) | $34.47 | $42.14 | −11% | 69% | 84% |

| Portal gun | $242.91 | $269.65 | $274.75 | 87% | 96% | 98% |

| Clash of Clans figurine | $29.94 | $29.98 | $29.98 | 100% | 100% | 100% |

| Harry Potter elder wand | $4.38 | $4.67 | $4.73 | 91% | 98% | 99% |

| Groot flower pot | $7.61 | $8.60 | $8.79 | 85% | 96% | 98% |

| Melted Darth Vader mask | $3.83 | $6.84 | $7.41 | 48% | 85% | 93% |

| Fallout 4 10mm pistol | $5.75 | $19.62 | $22.27 | 23% | 79% | 89% |

| Starcraft Kerrigan statue | $53.07 | $55.03 | $55.41 | 95% | 99% | 99% |

| Destiny ghost | $4.19 | $6.22 | $6.60 | 60% | 89% | 94% |

| Lich king figurine | $3.18 | $11.70 | $13.33 | 21% | 78% | 89% |

| Ant Man helmet | $35.68 | $42.11 | $43.33 | 80% | 94% | 97% |

| Game of Thrones House emblem | $9.12 | $9.72 | $9.83 | 92% | 98% | 99% |

| Clash of Clans king figure | $18.42 | $18.84 | $18.92 | 97% | 99% | 100% |

| Tooth toothbrush holder | $(0.91) | $1.19 | $1.59 | −46% | 59% | 79% |

| Halo 3 ODST helmet | $(17.14) | $2.42 | $6.16 | −172% | 24% | 62% |

| Fallout 4 protectron figure | $22.61 | $24.33 | $24.65 | 90% | 97% | 99% |

| Discobolus figurine | $6.40 | $7.01 | $7.13 | 88% | 97% | 98% |

| Anonymous mask | $(4.34) | $2.36 | $3.64 | −88% | 48% | 73% |

| Guardian of the Galaxy Star Lord mask | $(2.53) | $3.61 | $4.79 | −42% | 60% | 80% |

| Pokeball | $(4.36) | $(0.50) | $0.24 | −436% | −50% | 24% |

| Witcher 3 wall plaque | $42.57 | $44.32 | $44.66 | 95% | 98% | 99% |

| Overwatch widowmaker rifle | $112.79 | $136.66 | $141.22 | 77% | 94% | 97% |

| Fallout 4 combat rifle and shotgun | $76.48 | $82.62 | $83.80 | 90% | 97% | 99% |

| Michelangelo’s David | $28.11 | $29.42 | $29.67 | 94% | 98% | 99% |

| Triceratops skull | $38.40 | $39.55 | $39.77 | 96% | 99% | 99% |

| Skull ring | $9.83 | $9.92 | $9.93 | 99% | 100% | 100% |

| Star Wars NN-44 Rey’s Blaster | $41.58 | $44.05 | $44.52 | 92% | 98% | 99% |

| Joker mask | $(6.66) | $6.48 | $8.99 | −58% | 56% | 78% |

| Fork/spoon support for disability | $10.59 | $10.88 | $10.94 | 96% | 99% | 99% |

| Gryffindor coat of arms | $6.84 | $7.68 | $7.84 | 85% | 96% | 98% |

| Pokemon figurines | $28.47 | $29.57 | $29.78 | 95% | 99% | 99% |

| Rubik’s cube | $4.70 | $4.91 | $4.95 | 94% | 98% | 99% |

| Fallout 4 Kellogg’s pistol | $96.31 | $98.97 | $99.48 | 96% | 99% | 99% |

| Dobby the Elf figurine | $22.50 | $28.89 | $30.11 | 72% | 92% | 96% |

| Statue of Liberty figurine | $4.38 | $5.86 | $6.15 | 68% | 91% | 95% |

| Nutcracker | $3.51 | $4.58 | $4.78 | 70% | 92% | 96% |

| Minions figurines | $23.86 | $25.98 | $26.39 | 89% | 97% | 98% |

| Destiny sleeper simulant | $180.74 | $203.04 | $207.29 | 85% | 96% | 98% |

| Frozen Elsa figurine | $7.19 | $7.77 | $7.88 | 90% | 97% | 99% |

| Star Wars storm trooper rifle | $158.21 | $166.71 | $168.33 | 93% | 98% | 99% |

| Vitruvian Man sculpture | $31.20 | $31.41 | $31.45 | 99% | 100% | 100% |

| Robocop ED209 figure | $4.13 | $17.01 | $19.47 | 19% | 77% | 89% |

| Harry Potter wand | $13.36 | $13.50 | $13.52 | 99% | 100% | 100% |

| Cable guards | $1.08 | $1.20 | $1.23 | 86% | 96% | 98% |

| Game of Thrones dice cup | $6.89 | $7.92 | $8.12 | 83% | 95% | 98% |

| B2 bomber glider | $10.08 | $10.43 | $10.50 | 95% | 99% | 99% |

| Star Wars X Wing helmet | $18.37 | $34.98 | $38.15 | 44% | 84% | 92% |

| Hawkmoon #2 | $84.92 | $95.79 | $97.86 | 85% | 96% | 98% |

| Destiny ghost #2 | $5.84 | $6.68 | $6.84 | 83% | 95% | 98% |

| Item | Source (myminifactory.com/object/) | Mass/Sheets | Cost [USD] |

|---|---|---|---|

| Card holder | card-holder-for-save-the-planet-board-game-35620 | 39.15 | 0.90 |

| Dice | the-magnificent-dice-27043 | 1.68 | 0.04 |

| The Thinker | the-thinker-at-the-muse-rodin-france-2127 | 13.86 | 0.32 |

| Fox | fox-support-free-5865 | 8.04 | 0.18 |

| Open board game figurine | open-board-game-figurine-6013 | 7.50 | 0.17 |

| Superman bust | superman-bust-3518 | 6.46 | 0.15 |

| Game Boards | 2D printing costs | 5 sheets | 1.13 |

| Total | 2.89 | ||

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petersen, E.E.; Kidd, R.W.; Pearce, J.M. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies 2017, 5, 45. https://doi.org/10.3390/technologies5030045

Petersen EE, Kidd RW, Pearce JM. Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies. 2017; 5(3):45. https://doi.org/10.3390/technologies5030045

Chicago/Turabian StylePetersen, Emily E., Romain W. Kidd, and Joshua M. Pearce. 2017. "Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market" Technologies 5, no. 3: 45. https://doi.org/10.3390/technologies5030045

APA StylePetersen, E. E., Kidd, R. W., & Pearce, J. M. (2017). Impact of DIY Home Manufacturing with 3D Printing on the Toy and Game Market. Technologies, 5(3), 45. https://doi.org/10.3390/technologies5030045