On Adaptive Control for Electrical Discharge Machining Using Vibroacoustic Emission

Abstract

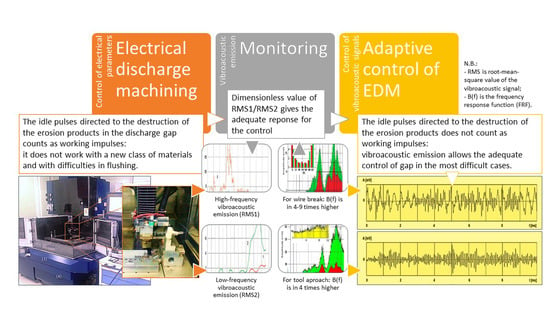

:1. Introduction

- (1)

- Research a fundamental possibility of vibroacoustic diagnostics of wire electrical discharge machining;

- (2)

- Adapt the existed method of in-situ vibroacoustic monitoring for EDM, make the comparison of the receive spectra of the signal with the electrical parameters of the machine;

- (3)

- Analyze the obtained spectra and make understandable the criteria of deciding for development of the adaptive control system based on vibroacoustic emission;

- (4)

- Demonstrate an opportunity of the in-situ adaptive control of EDM by specific examples of the machining.

2. Materials and Methods

3. Results

3.1. Research A Fundamental Possibility of Vibroacoustic Diagnostics of Wire Electrical Discharge Machining

3.1.1. Mathematical Approach and Evaluation of Wire Amplitude Under Discharge Impulses

3.1.2. Experiments on the Fundamental Possibility of Vibroacoustic Diagnostics

3.2. Adaption of the In-Situ Monitoring Method for the Needs of Electrical Discharge Machining

3.3. Analysis of the Obtained Data, Search for the Criteria for the Development of the Adaptive Control System Based on Vibroacoustic Emission

3.4. Demonstration of the Opportunity for The In-situ Adaptive Control of Edm by Specific Examples

4. Discussion

- (1)

- For the lower value of wire tension, the adequate flushing of the erosion products is hampered by bending of a wire tool during processing and higher wire amplitude due to the low circular frequency of the vibrations, when the circular frequency of the forced oscillations under electrical impulses is above the circular frequency of the self-oscillation;

- (2)

- For the higher value of wire tension, the flushing of the erosion products is adequate, but the stiffness of the system is higher, then wire amplitude is lower, at the same time, the circular frequency of the vibrations grows, when the circular frequency of the forced oscillations under electrical impulses is below the circular frequency of the self-oscillation;

- (3)

- For the value of wire tension associated with stable EDM processing, the circular frequency of forced oscillation may be compensated by the frequency of self-oscillation.

5. Conclusions

6. Patents

- Kozochkin, M.P.; Grigoriev, S.N.; Porvatov, A.N., Okunkova, A.A. The method of controlling the electrical discharge machining of parts on an automated cutting machine with a system of CNC; RU 2598022

- Kozochkin, M.P.; Khoteenkov, K.E.; Porvatov, A.N., Grigoriev, S.N. The method of EDM cutting of products; RU 2638607

- Grigoriev, S.N.; Kozochkin, M.P.; Okunkova, A.A. The method of positioning the wire electrode on the EDM cutting machines; RU 2572678

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Conde, A.; Arriandiaga, A.; Sanchez, J.A.; Portillo, E.; Plaza, S.; Cabanes, I. High-accuracy wire electrical discharge machining using artificial neural networks and optimization techniques. Robot. Cim-Int. Manuf. 2018, 49, 24–38. [Google Scholar] [CrossRef]

- Maradia, U.; Filisetti, E.; Boccadoro, M.; Rotenb, M.; Dutoit, J.-M.; Hengsberger, S. Increasing the Injection Moulding Productivity through EDM Surface Modulation. Proc. CIRP 2018, 68, 58–63. [Google Scholar] [CrossRef]

- Sahu, A.K.; Chatterjee, S.; Nayak, P.K.; Mahapatra, S.S. Study on effect of tool electrodes on surface finish during electrical discharge machining of Nitinol. IOP Conf. Ser. Mater. Sci. Eng. 2018, 338, 012033. [Google Scholar] [CrossRef] [Green Version]

- Trung, K.H. Development of a WEDM system with high machining efficiency. In Proceedings of the 2017 International Conference on System Science and Engineering (ICSSE), Ho Chi Minh City, Vietnam, 21–23 July 2017; pp. 397–399. [Google Scholar] [CrossRef]

- Ho, K.H.; Newman, S.T.; Rahimifard, S.; Allen, R.D. State of the Art in Wire Electrical Discharge Machining (WEDM). Int. J. Mach. Tool Manuf. 2004, 44, 1247–1259. [Google Scholar] [CrossRef]

- Han, F.; Chen, L.; Yu, D.; Zhou, X. Basic study on pulse generator for micro-EDM. Int. J. Adv. Manuf. Technol. 2007, 33, 474–479. [Google Scholar] [CrossRef]

- Faisal, N.; Kumar, K. Optimization of Machine Process Parameters in EDM for EN 31 Using Evolutionary Optimization Techniques. Technologies 2018, 6, 54. [Google Scholar] [CrossRef]

- Gavrin, V.N.; Kozlova, Y.P.; Veretenkin, E.P.; Logachev, A.V.; Logacheva, A.I.; Lednev, I.S.; Okunkova, A.A. Reactor target from metal chromium for “pure” high-intensive artificial neutrino source. Phys. Part. Nucl. Lett. 2016, 13, 267–273. [Google Scholar] [CrossRef]

- Prathipati, R.P.; Devuri, V.; Cheepu, M.; Gudimetla, K.; Kiran, R.U. Machining of AISI D2 Tool Steel with Multiple Hole Electrodes by EDM Process. IOP Conf. Ser. Mater. Sci. Eng. 2018, 330, 012067. [Google Scholar] [CrossRef] [Green Version]

- Volosova, M.A.; Okunkova, A.A.; Povolotskiy, D.E.; Podrabinnik, P.A. Study of electrical discharge machining for the parts of nuclear industry usage. Mech. Ind. 2015, 16, 706. [Google Scholar] [CrossRef] [Green Version]

- Ozerkan, H.B. Simultaneous machining and surface alloying of AISI 1040 steel by electrical discharge machining with boron oxide powders. J. Mech. Sci. Technol. 2018, 32, 4357–4364. [Google Scholar] [CrossRef]

- Bhattacharya, S.; Abraham, G.J.; Mishra, A.; Kain, V.; Dey, G.K. Corrosion Behavior of Wire Electrical Discharge Machined Surfaces of P91 Steel. J. Mater. Eng. Perform. 2018, 27, 4561–4570. [Google Scholar] [CrossRef]

- Nguyen, H.P.; Pham, V.D.; Ngo, N.V. Application of TOPSIS to Taguchi method for multi-characteristic optimization of electrical discharge machining with titanium powder mixed into dielectric fluid. Int. J. Adv. Manuf. Technol. 2018, 98, 1179. [Google Scholar] [CrossRef]

- Uhlmann, E.; Oberschmidt, D.; Bolz, R. Application of Micro Structured, Boron Doped CVD-diamond as μEDM Tool Electrodes. Proc. CIRP 2018, 68, 649–653. [Google Scholar] [CrossRef]

- Jayalakshmi, S.; Singh, R.A.; Gupta, M. Metallic Glasses as Potential Reinforcements in Al and Mg Matrices: A Review. Technologies 2018, 6, 40. [Google Scholar] [CrossRef]

- Veronesi, P.; Leonelli, C.; Bondioli, F. Energy Efficiency in the Microwave-Assisted Solid-State Synthesis of Cobalt Aluminate Pigment. Technologies 2017, 5, 42. [Google Scholar] [CrossRef]

- Fleischer, J.; Teti, R.; Lanza, G.; Mativenga, P.; Möhring, H.C.; Caggiano, A. Composite materials parts manufacturing. CIRP Ann. 2018, 67, 603–626. [Google Scholar] [CrossRef]

- Nakamura, M.; Takeo, K.; Osada, T.; Ozaki, S. Finite Element Analysis of Self-Healing and Damage Processes in Alumina/SiC Composite Ceramics. Technologies 2017, 5, 40. [Google Scholar] [CrossRef]

- Aimable, A.; Doubi, H.G.; Stuer, M.; Stuer, M.; Zhao, Z.; Bowen, P. Synthesis and Sintering of ZnO Nanopowders. Technologies 2017, 5, 28. [Google Scholar] [CrossRef]

- Song, C.; Cheng, L.; Liu, Y.; Zhao, M.; Ye, F. Microstructure and electromagnetic wave absorption properties of RGO-SiBCN composites via PDC technology. Ceram. Int. 2018, 44, 18759–18769. [Google Scholar] [CrossRef]

- Zhang, C.; Shi, Z.; Mao, F.; Yang, C.; Yang, J.; Zhu, X.; Zuo, H. Polymer composites with balanced dielectric constant and loss via constructing trilayer architecture. J. Mater. Sci. 2018, 53, 13230. [Google Scholar] [CrossRef]

- Yan, Z.; Sun, H.; Chen, X.; Fu, X.; Chen, C.; Cheng, F.; Chen, J. Rapid low-temperature synthesis of perovskite/carbon nanocomposites as superior electrocatalysts for oxygen reduction in Zn-air batteries. Nano Res. 2018, 11, 3282. [Google Scholar] [CrossRef]

- Mishra, M.K.; Moharana, S.; Mahaling, R.N. Fabrication of SiC-Treated P(VDF-HFP)-(BFO-SO3H) Composite Films for High Performance Energy Storage Device (HPESD) Applications. Phys. Status Solidi A 2018, 215, 1701057. [Google Scholar] [CrossRef]

- Jang, J.-S.; Lee, G.Z.; Kim, H.; Hong, S.Y.; Ci, L.; Nam, J.D.; Suhr, J. High-damping and conducting epoxy nanocomposite using both zinc oxide particles and carbon nanofibers. J. Mater. 2018, 4, 187–193. [Google Scholar] [CrossRef]

- Sato, K.; Tominaga, Y.; Hotta, Y.; Shibuya, H.; Sugie, M.; Saruyama, T. Cellulose nanofiber/nanodiamond composite films: Thermal conductivity enhancement achieved by a tuned nanostructure. Adv. Powder Technol. 2018, 29, 972–976. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Gurin, V.D.; Seleznev, A.E. Wear of replaceable indexable inserts made of mixed cutting ceramics CC650 as a function of force parameters of steel ShKh15 face milling. J. Frict. Wear 2015, 36, 521–527. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Gurin, V.D.; Volosova, M.A.; Cherkasova, N.Y. Development of residual cutting tool life prediction algorithm by processing on CNC machine tool. Materialwiss. Werkst. 2013, 44, 790–796. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Sinopalnikov, V.A.; Tereshin, M.V.; Gurin, V.D. Control of parameters of the cutting process on the basis of diagnostics of the machine tool and workpiece. Meas. Tech. 2012, 55, 555–558. [Google Scholar] [CrossRef]

- Volosova, M.; Grigoriev, S.; Metel, A.; Shein, A. The Role of Thin-Film Vacuum-Plasma Coatings and Their Influence on the Efficiency of Ceramic Cutting Inserts. Coatings 2018, 8, 287. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Volosova, M.A.; Gurin, V.D.; Seleznyov, A.Y. Investigation of force parameters acting on a single cutting insert made of ceramics in face milling of hardened steel. Mech. Ind. 2015, 16, 702. [Google Scholar] [CrossRef] [Green Version]

- He, Y.; Chen, X.; Liu, Z.; Qin, Y. Piezoelectric self-sensing actuator for active vibration control of motorized spindle based on adaptive signal separation. Smart Mater. Struct. 2018, 27, 065011. [Google Scholar] [CrossRef] [Green Version]

- Schneider, F.; Mummert, K. Chemical aspects of stress corrosion cracking of AISI 321 stainless steel in hot aqueous chloride solutions. ChemInform 1997, 28. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Kropotkina, E.Y.; Okunkova, A.A. Study of wire tool-electrode behavior during electrical discharge machining by vibroacoustic monitoring. Mech. Ind. 2016, 17, 717. [Google Scholar] [CrossRef] [Green Version]

- Kustas, F.; Molian, P.; Kumar, A.S.; Besser, M.; Sordelet, D. Laser crystallization of amorphous sputter-deposited quasicrystalline coatings. Surf. Coat. Technol. 2004, 188, 274–280. [Google Scholar] [CrossRef]

- Gautam, A.; Ajit, K.P.; Sarkar, P.K. A nonlinear CDM based damage growth law for ductile materials. Mater. Res. Express 2018, 5, 026518. [Google Scholar] [CrossRef] [Green Version]

- Weidner, A.; Lippmann, T.; Biermann, H. Crack initiation in the very high cycle fatigue regime of nitrided 42CrMo4 steel. J. Mater. Res. 2017, 32, 4305–4316. [Google Scholar] [CrossRef] [Green Version]

- Takada, N.; Hayashi, Y.; Goto, M.; Sasaki, K. An Attempt to Produce Electrical Discharges in Acoustic Cavitation Bubbles. Plasma Fusion Res. 2016, 11, 1406113. [Google Scholar] [CrossRef]

- Yu, X.; Qiu, M.; Fu, J.; Kong, L.; Han, Y. Multi-channel aerosol dielectric electrical discharge machining ablation based on discrete electrode. Int. J. Adv. Manuf. Technol. 2018, 99, 1037–1045. [Google Scholar] [CrossRef]

- Pinahin, I.A.; Chernigovskij, V.A.; Bracihin, A.A.; Yagmurov, M.A. Improvement of wear resistance of VK6, VK8, T5K10, and T15K6 hard alloys by volume pulsed laser hardening. J. Frict. Wear 2015, 36, 330–333. [Google Scholar] [CrossRef]

- Blinkov, I.V.; Belov, D.S.; Volkhonskii, A.O.; Blinkov, V.I.; Shatalov, R.L. Structure of Nanocrystalline Arc-PVD (Ti, Al)N Coatings Modified with Nickel. Russ. Metall. 2015, 5, 421–427. [Google Scholar] [CrossRef]

- Sheleg, V.K.; Shaturov, D.G.; Shaturov, G.F. Analysis and Selection of Rational Cutting Modes while Using Hard-Alloy Tool for Shaft Turning. Sci. Tech. 2018, 17, 14–20. [Google Scholar] [CrossRef]

- Sokolov, A.G.; Bobylyov, E.E. The element-phase composition and properties of the surface layers of carbide-tipped tools made of TK and WC-Co alloys. Lett. Mater. 2017, 7, 222–228. [Google Scholar] [CrossRef]

- Lin, Y.-C.; Hung, J.-C.; Lee, H.-M.; Wang, A.C.; Chen, J.T. Machining characteristics of a hybrid process of EDM in gas combined with ultrasonic vibration. Int. J. Adv. Manuf. Technol. 2017, 92, 2801–2808. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N.; Grigor’ev, S.N. Vibroacoustic Monitoring of the Major Parameters of Electrical Discharge Machining. Meas. Tech. 2017, 59, 1228–1233. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, M.; Liao, Y.; Su, Z.; Xiao, Y. Contact acoustic nonlinearity (CAN)-based continuous monitoring of bolt loosening: Hybrid use of high-order harmonics and spectral sidebands. Mech. Syst. Signal. Proc. 2018, 103, 280–294. [Google Scholar] [CrossRef]

- Liang, J.F.; Liao, Y.S.; Kao, J.Y.; Huang, C.H.; Hsu, C.Y. Study of the EDM performance to produce a stable process and surface modification. Int. J. Adv. Manuf. Technol. 2018, 95, 1743–1750. [Google Scholar] [CrossRef]

- Jain, P.S.; Ravindra, H.V.; Ugrasen, G.; Prakash, G.N.; Rammohan, Y.S. Study of Surface Roughness and AE Signals while Machining Titanium Grade-2 Material using ANN in WEDM. Mater. Today Proc. 2017, 4, 9557–9560. [Google Scholar] [CrossRef]

- Grigoriev, S.N.; Kozochkin, M.P.; Porvatov, A.N.; Pinargote, S.; Washington, N. Features of Vibro-Acoustic Monitoring EDM of Conductive Ceramics. Mater. Sci. Forum 2016, 876, 8–13. [Google Scholar] [CrossRef]

- Corný, I.; Pitel, J.; Hašová, S. Statistical Approach to Optimize the Process Parameters of HAZ of Tool Steel EN X32CrMoV12-28 after Die-Sinking EDM with SF-Cu Electrode. Metals 2017, 7, 35. [Google Scholar] [CrossRef]

- Salinas, C.F.P.; Moya, E.; Coello, D. Use of an orthogonal arrangement for the analysis of the process of die sink electrical discharge machining with shape electrodes of graphite and copper on aluminum micro-casting. Enfoque UTE 2018, 9, 67–79. [Google Scholar]

- Liu, Y.; Chang, H.; Zhang, W.; Ma, F.; Sha, Z.; Zhang, S. A Simulation Study of Debris Removal Process in Ultrasonic Vibration Assisted Electrical Discharge Machining (EDM) of Deep Holes. Micromachines 2018, 9, 378. [Google Scholar] [CrossRef]

- Xiao, X.; Zheng, X.; Wang, Y.; Xu, S.; Zheng, Z. A Method for Utility Harmonic Impedance Estimation Based on Constrained Complex Independent Component Analysis. Energies 2018, 11, 2247. [Google Scholar] [CrossRef]

- Herrojo, C.; Moras, M.; Paredes, F.; Núñez, A.; Ramon, E.; Mata-Contreras, J.; Martín, F. Very Low-Cost 80-Bit Chipless-RFID Tags Inkjet Printed on Ordinary Paper. Technologies 2018, 6, 52. [Google Scholar] [CrossRef]

- Tamura, T.; Kobayashi, Y. Measurement of impulsive forces and crater formation in impulse discharge. J. Mater. Process. Technol. 2004, 149, 212–216. [Google Scholar] [CrossRef]

- Mohri, N.; Yamada, H.; Furutani, K.; Narikiyo, T.; Magara, T. System identification of wire electrical discharge machining. CIRP Ann. 1998, 47, 173–176. [Google Scholar] [CrossRef]

- Pang, L.; Hosseini, A.; Hussein, H.M.; Deiab, I.; Kishawy, H.A. Application of a new thick zone model to the cutting mechanics during end-milling. Int. J. Mech. Sci. 2015, 96, 91–100. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N.; Sabirov, F.S. Vibration Testing of Technological Processes in Automated Machining Equipment. Meas. Tech. 2014, 56, 1414–1420. [Google Scholar] [CrossRef]

- Artamonov, B.A.; Volkov, Y.S. Analiz Modelei Elektrokhimicheskoi I Elektroerozionnoi Obrabotki. Chast’ 2, Modeli Protsessov Elektroerozionnoi Obrabotki. Provolochnaya Vyrezka (Analysis of Models of Electrochemical and Electrodischarge Treatment, Part 2: Models of Electrodischarge Treatment. Wire Cutting), 1st ed.; Vseross. Nauchno-issled. Inst. Patent. Inform.: Moscow, Russia, 1991; pp. 98–101. (In Russian) [Google Scholar]

- Gutkin, B.G. Avtomatizatsiya Elektroerozionnykh Stankov (Automation of Electrical Discharge Machines); Mashinostroenie: Leningrad, USSR, 1971; pp. 28–29. (In Russian) [Google Scholar]

- Maity, K.; Mishra, H. ANN modelling and Elitist teaching learning approach for multi-objective optimization of mu-EDM. J. Intell. Manuf. 2018, 29, 1599–1616. [Google Scholar] [CrossRef]

- Grigor’ev, S.N.; Kozochkin, M.P. Improvement of Machining by the Vibroacoustic Diagnostics of Electrophysical Processes. Rus. Eng. Res. 2015, 35, 801–806. [Google Scholar] [CrossRef]

- Fu, X.; Zhang, Q.; Gao, L.; Liu, Q.; Wang, K.; Zhang, Y.W. A novel micro-EDM-piezoelectric self-adaptive micro-EDM. Int. J. Adv. Manuf. Technol. 2016, 85, 817–824. [Google Scholar] [CrossRef]

- Yue, X.; Yang, X.; Tian, J.; He, Z.; Fan, Y. Thermal, mechanical and chemical material removal mechanism of carbon fiber reinforced polymers in electrical discharge machining. Int. J. Mach. Tools Manuf. 2018, 133, 4–17. [Google Scholar] [CrossRef]

- Abdelmalek, A.; Bedrane, Z.; Amara, E.-H.; Sotillo, B.; Bharadwaj, V.; Ramponi, R.; Eaton, S. Ablation of Copper Metal Films by Femtosecond Laser Multipulse Irradiation. Appl. Sci. 2018, 8, 1826. [Google Scholar] [CrossRef]

- Isaev, A.; Grechishnikov, V.; Pivkin, P.; Mihail, K.; Yuriy, I.; Andrey, V. Machining of thin-walled parts produced by additive manufacturing technologies. Proc. CIRP 2016, 41, 1023–1026. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Porvatov, A.N. Effect of adhesion bonds in friction contact on vibroacoustic signal and autooscillations. J. Frict. Wear 2014, 35, 389–395. [Google Scholar] [CrossRef]

- Kozochkin, M.P.; Sabirov, F.S. Attractors in cutting and their future use in diagnostics. Meas. Tech. 2009, 52, 166–171. [Google Scholar] [CrossRef]

- Schmitz, T.L.; Smith, K.S. Machining Dynamics. Frequency Response to Improved Productivity; Springer: New York, NY, USA, 2009; pp. 108–109. ISBN 978-0-387-09645-2. [Google Scholar]

- Altintas, Y. Manufacturing Automation: Metal Cutting Mechanics, Machine Tool Vibrations, and CNC Design, 2nd ed.; Cambridge University Press: Cambridge, UK, 2012; pp. 68–70. ISBN 978-0-511-84372-3. [Google Scholar]

- Webster, J.; Dong, W.P.; Lindsay, R. Raw Acoustic Emission Signal Analysis of Grinding Process. CIRP Ann. 1996, 45, 335–340. [Google Scholar] [CrossRef]

- Grabec, L.; Leskovar, P. Acoustic emission of a cutting process. Ultrasonic 1977, 15, 17–20. [Google Scholar] [CrossRef]

| Material | Fe | Cr | C | Ni | Mn | Ti | P | Cu | Si | Zn | Mg | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AISI 321 | 44.9–59.1 | 17–19 | ~12 | 9–11 | ~2 | ~0.8 | ~0.035 | ~0.03 | ~0.02 | - | - | - |

| AISI 2024 | ~0.5 | - | - | ~0.1 | 0.3-0.9 | ~0.1 | - | 3.8-4.9 | ~0.5 | ~0.3 | 1.2–1.8 | 90.8–94.7 |

| Material | WC | TaC | TiC | Co |

|---|---|---|---|---|

| M05 | 92 | 2 | - | 6 |

| P10 | 79 | - | 15 | 6 |

| Parameter | Value |

|---|---|

| Wire Mass | |

| A wire radius rw, m | 0.00125 |

| A height of the workpiece Hn, m | 0.016 |

| A distance between the nozzles Hn’, m | 0.020 |

| Brass density ς 1, kg/m3 | 8580 |

| A volume of the wire Qw, m3 | 9.8 × 10−8 |

| Wire mass mn, kg | 8.4 × 10−4 |

| Force of Medium Resistance | |

| Water density ς 1, kg/m3 | 997 |

| Resistance area Pn (=π·rw·Hn’) 1, m2 | 7.8 × 10−5 |

| Wire feed speed Sg, m/s | 1.7 × 10−5 |

| A force of medium resistance Fσ 2, N | 2.2 × 10−11 |

| Force of Impulses | |

| A force of impulses Fimp 3, N [54,55] | 4.8 × 10−3 |

| An Amplitude of Wire under Forced Impulses | |

| A frequency of forced impulses ffrc 4, Hz | 0.2 × 106 |

| System stiffness Kw, N/m | 1.1 × 106 |

| An amplitude of wire under forced impulses Afrc, m | 4.36 × 10−9 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Melnik, Y.A.; Kozochkin, M.P.; Porvatov, A.N.; Okunkova, A.A. On Adaptive Control for Electrical Discharge Machining Using Vibroacoustic Emission. Technologies 2018, 6, 96. https://doi.org/10.3390/technologies6040096

Melnik YA, Kozochkin MP, Porvatov AN, Okunkova AA. On Adaptive Control for Electrical Discharge Machining Using Vibroacoustic Emission. Technologies. 2018; 6(4):96. https://doi.org/10.3390/technologies6040096

Chicago/Turabian StyleMelnik, Yury A., Mikhail P. Kozochkin, Artur N. Porvatov, and Anna A. Okunkova. 2018. "On Adaptive Control for Electrical Discharge Machining Using Vibroacoustic Emission" Technologies 6, no. 4: 96. https://doi.org/10.3390/technologies6040096

APA StyleMelnik, Y. A., Kozochkin, M. P., Porvatov, A. N., & Okunkova, A. A. (2018). On Adaptive Control for Electrical Discharge Machining Using Vibroacoustic Emission. Technologies, 6(4), 96. https://doi.org/10.3390/technologies6040096