Wicking in Paper Strips under Consideration of Liquid Absorption Capacity

Abstract

:1. Introduction

2. Theoretical Model

3. Materials and Method

3.1. Materials and Instrumentation

3.2. Paper Strip Preparation

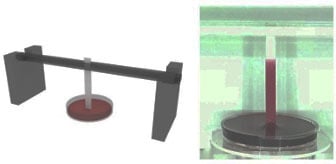

3.3. Experiment Setup and Data Acquisition

3.4. Fitting Curve Settings

3.5. Direct Measurement for Liquid Absorption Capacity

4. Result and Discussion

4.1. Fitting for Cellulose Fiber Paper

4.2. Fitting for Nitrocellulose Paper

4.3. Absorption Capacity

4.4. Fluidic Resistance Function

4.5. Capillary Pressure

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

Appendix A

References

- Eaidkong, T.; Mungkarndee, R.; Phollookin, C.; Tumcharern, G.; Sukwattanasinitt, M.; Wacharasindhu, S. Polydiacetylene paper-based colorimetric sensor array for vapor phase detection and identification of volatile organic compounds. J. Mater. Chem. 2012, 22, 5970–5977. [Google Scholar] [CrossRef]

- Hossain, S.M.Z.; Brennan, J.D. β-Galactosidase-Based Colorimetric Paper Sensor for Determination of Heavy Metals. Anal. Chem. 2011, 83, 8772–8778. [Google Scholar] [CrossRef]

- Jokerst, J.C.; Adkins, J.A.; Bisha, B.; Mentele, M.M.; Goodridge, L.D.; Henry, C.S. Development of a Paper-Based Analytical Device for Colorimetric Detection of Select Foodborne Pathogens. Anal. Chem. 2012, 84, 2900–2907. [Google Scholar] [CrossRef]

- Vella, S.J.; Beattie, P.; Cademartiri, R.; Laromaine, A.; Martinez, A.W.; Phillips, S.T.; Mirica, K.A.; Whitesides, G.M. Measuring Markers of Liver Function Using a Micropatterned Paper Device Designed for Blood from a Fingerstick. Anal. Chem. 2012, 84, 2883–2891. [Google Scholar] [CrossRef] [Green Version]

- Sajid, M.; Kawde, A.-N.; Daud, M. Designs, formats and applications of lateral flow assay: A literature review. J. Saudi Chem. Soc. 2015, 19, 689–705. [Google Scholar] [CrossRef] [Green Version]

- Wong, R.; Tse, H. Lateral Flow Immunoassay, 1st ed.; Humana Press: Totowa, NJ, USA, 2009. [Google Scholar] [CrossRef]

- Kasetsirikul, S.; Shiddiky, M.J.A.; Nguyen, N.-T. Challenges and perspectives in the development of paper-based lateral flow assays. Microfluid Nanofluidics 2020, 24, 17. [Google Scholar] [CrossRef]

- Dungchai, W.; Chailapakul, O.; Henry, C.S. Use of multiple colorimetric indicators for paper-based microfluidic devices. Anal. Chim. Acta 2010, 674, 227–233. [Google Scholar] [CrossRef]

- Avoundjian, A.; Jalali-Heravi, M.; Gomez, F.A. Use of chemometrics to optimize a glucose assay on a paper microfluidic platform. Anal. Bioanal. Chem. 2017, 409, 2697–2703. [Google Scholar] [CrossRef]

- Hamedpour, V.; Oliveri, P.; Leardi, R.; Citterio, D. Chemometric challenges in development of paper-based analytical devices: Optimization and image processing. Anal. Chim. Acta 2020, 1101, 1–8. [Google Scholar] [CrossRef]

- Jalali-Heravi, M.; Arrastia, M.; Gomez, F.A. How Can Chemometrics Improve Microfluidic Research? Anal. Chem. 2015, 87, 3544–3555. [Google Scholar] [CrossRef]

- Scampicchio, M.; Mannino, S.; Zima, J.; Wang, J. Chemometrics on Microchips: Towards the Classification of Wines. Electroanalysis 2005, 17, 1215–1221. [Google Scholar] [CrossRef]

- Shariati-Rad, M.; Irandoust, M.; Mohammadi, S. Multivariate analysis of digital images of a paper sensor by partial least squares for determination of nitrite. Chemom. Intell. Lab. Syst. 2016, 158, 48–53. [Google Scholar] [CrossRef]

- Liu, Z.; He, X.; Han, J.; Zhang, X.; Li, F.; Li, A.; Qu, Z.; Xu, F. Liquid wicking behavior in paper-like materials: Mathematical models and their emerging biomedical applications. Microfluid Nanofluidics 2018, 22, 132. [Google Scholar] [CrossRef]

- Liu, Z.; Hu, J.; Zhao, Y.; Qu, Z.; Xu, F. Experimental and numerical studies on liquid wicking into filter papers for paper-based diagnostics. Appl. Therm. Eng. 2015, 88, 280–287. [Google Scholar] [CrossRef]

- Jahanshahi-Anbuhi, S.; Chavan, P.; Sicard, C.; Leung, V.; Hossain, S.M.Z.; Pelton, R.; Brennan, J.D.; Filipe, C.D.M. Creating fast flow channels in paper fluidic devices to control timing of sequential reactions. Lab. A Chip 2012, 12, 5079–5085. [Google Scholar] [CrossRef]

- Hong, S.; Kim, W. Dynamics of water imbibition through paper channels with wax boundaries. Microfluid Nanofluidics 2015, 19, 845–853. [Google Scholar] [CrossRef]

- Lioumbas, J.S.; Zamanis, A.; Karapantsios, T.D. Towards a wicking rapid test for rejection assessment of reused fried oils: Results and analysis for extra virgin olive oil. J. Food Eng. 2013, 119, 260–270. [Google Scholar] [CrossRef]

- Ponomarenko, A.; QuÉRÉ, D.; Clanet, C. A universal law for capillary rise in corners. J. Fluid Mech. 2011, 666, 146–154. [Google Scholar] [CrossRef] [Green Version]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Elizalde, E.; Urteaga, R.; Berli, C.L.A. Rational design of capillary-driven flows for paper-based microfluidics. Lab. A Chip 2015, 15, 2173–2180. [Google Scholar] [CrossRef]

- Fu, E.; Ramsey, S.A.; Kauffman, P.; Lutz, B.; Yager, P. Transport in two-dimensional paper networks. Microfluid Nanofluidics 2011, 10, 29–35. [Google Scholar] [CrossRef] [Green Version]

- Parolo, C.; Medina-Sánchez, M.; de la Escosura-Muñiz, A.; Merkoçi, A. Simple paper architecture modifications lead to enhanced sensitivity in nanoparticle based lateral flow immunoassays. Lab. A Chip 2013, 13, 386–390. [Google Scholar] [CrossRef] [Green Version]

- Richards, L.A. CAPILLARY CONDUCTION OF LIQUIDS THROUGH POROUS MEDIUMS. Physics 1931, 1, 318–333. [Google Scholar] [CrossRef]

- Whitaker, S. Flow in porous media I: A theoretical derivation of Darcy’s law. Transp. Porous Media 1986, 1, 3–25. [Google Scholar] [CrossRef]

- Ge, W.-K.; Lu, G.; Xu, X.; Wang, X.-D. Droplet spreading and permeating on the hybrid-wettability porous substrates: A lattice Boltzmann method study. Open Phys. 2016, 14, 483. [Google Scholar]

- Hyväluoma, J.; Raiskinmäki, P.; Jäsberg, A.; Koponen, A.; Kataja, M.; Timonen, J. Simulation of liquid penetration in paper. Phys. Rev. E 2006, 73, 036705. [Google Scholar] [CrossRef]

- Sadeghi, M.A.; Aghighi, M.; Barralet, J.; Gostick, J.T. Pore network modeling of reaction-diffusion in hierarchical porous particles: The effects of microstructure. Chem. Eng. J. 2017, 330, 1002–1011. [Google Scholar] [CrossRef] [Green Version]

- Tang, R.; Yang, H.; Gong, Y.; Liu, Z.; Li, X.; Wen, T.; Qu, Z.; Zhang, S.; Mei, Q.; Xu, F. Improved Analytical Sensitivity of Lateral Flow Assay using Sponge for HBV Nucleic Acid Detection. Sci. Rep. 2017, 7, 1360. [Google Scholar] [CrossRef] [Green Version]

- Toley, B.J.; McKenzie, B.; Liang, T.; Buser, J.R.; Yager, P.; Fu, E. Tunable-delay shunts for paper microfluidic devices. Anal. Chem. 2013, 85, 11545–11552. [Google Scholar] [CrossRef] [Green Version]

- Fries, N. Capillary Transport Processes in Porous Materials–Experiment and Model. Ph.D. Thesis, Universität Bremen, Göttingen, Germany, 2010. [Google Scholar]

- Li, X.; Zwanenburg, P.; Liu, X. Magnetic timing valves for fluid control in paper-based microfluidics. Lab. A Chip 2013, 13, 2609–2614. [Google Scholar] [CrossRef]

| Coefficient | Starting Points | Lower Boundary | Upper Boundary |

|---|---|---|---|

| a | 1 × 108–1 × 109 | 1 × 108 | 1 × 109 |

| b | 0.001–0.999 | 0 | 1 |

| d | 0.001–0.999 | 0 | 1 |

| Parameter | Value |

|---|---|

| Vs-Pressure-Capillary pressure in CFSP | 3000 Pa [30] |

| Vs-Pressure-Capillary pressure in Nitrocellulose (FF80HP) | 13,000 Pa [30] |

| Vs-Pressure-Capillary pressure in Nitrocellulose (FF170HP) | 2879 Pa * |

| Adsorption capacity in CFSP | 79.29 µL/cm2 [30] |

| Adsorption capacity in Nitrocellulose (FF170HP) | 10.06 µL/cm2 [30] |

| Viscosity | 8.94 × 10−4 Pa.s |

| Density | 1000 kg/m3 |

| Non-Laminated CFSP Size | a | b | d |

|---|---|---|---|

| 2 mm | 1.02 × 108 | 8.14 × 10−8 | 0.40 |

| 4 mm | 1.03 × 108 | 8.63 × 10−8 | 0.39 |

| 6 mm | 1.02 × 108 | 8.69 × 10−8 | 0.39 |

| Materials | Coefficient p for Washburn Relation | |||

|---|---|---|---|---|

| Width 2 mm | Width 4 mm | Width 6 mm | Average | |

| Non-laminated CFSP | 6.05 | 6.14 | 6.25 | 6.15 |

| One-side laminated CFSP | 4.47 | 4.86 | 4.96 | 4.76 |

| Two-side laminated CFSP | 5.08 | 4.93 | 5.08 | 5.03 |

| Non-Laminated NC Size | a | b | d |

|---|---|---|---|

| 2 mm | 1.02 × 108 | 3.03 × 10−8 | 0.50 |

| 4 mm | 1.02 × 108 | 3.41 × 10−8 | 0.48 |

| 6 mm | 1.01 × 108 | 3.00 × 10−8 | 0.52 |

| Materials | Coefficient p for Washburn Relation | |||

|---|---|---|---|---|

| Width 2 mm | Width 4 mm | Width 6 mm | Average | |

| Nitrocellulose membrane | 3.08 | 3.18 | 3.12 | 3.12 |

| Laminated nitrocellulose membrane | 2.75 | 2.94 | 2.80 | 2.83 |

| Non-Laminated CFSP (µL/cm2) | Nitrocellulose Membrane (µL/cm2) | |

|---|---|---|

| Absorption capacity from the model | 75.0 | 8.14 |

| Absorption capacity from the direct weighting experiment | 79.3 | 10.07 |

| Absorption capacity from literature | 83 [30] | 10 [30] |

| Materials | Absorption Capacity (µL/cm2) | Coefficient a | Capillary Pressure (Pa) |

|---|---|---|---|

| Non-laminated CFSP | 79.3 ± 1.60 | 1.14 × 108 | 2586 |

| One-side laminated CFSP | 76.7 ± 3.49 | 1.12 × 108 | 2881 |

| Two-side laminated CFSP | 65.2 ± 2.93 | 1.12 × 108 | 3522 |

| Nitrocellulose membrane | 10.1 ± 1.85 | 1.06 × 108 | 2345 |

| Laminated nitrocellulose membrane | 6.42 ± 0.25 | 1.06 × 108 | 3636 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kasetsirikul, S.; Shiddiky, M.J.A.; Nguyen, N.-T. Wicking in Paper Strips under Consideration of Liquid Absorption Capacity. Chemosensors 2020, 8, 65. https://doi.org/10.3390/chemosensors8030065

Kasetsirikul S, Shiddiky MJA, Nguyen N-T. Wicking in Paper Strips under Consideration of Liquid Absorption Capacity. Chemosensors. 2020; 8(3):65. https://doi.org/10.3390/chemosensors8030065

Chicago/Turabian StyleKasetsirikul, Surasak, Muhammad J. A. Shiddiky, and Nam-Trung Nguyen. 2020. "Wicking in Paper Strips under Consideration of Liquid Absorption Capacity" Chemosensors 8, no. 3: 65. https://doi.org/10.3390/chemosensors8030065

APA StyleKasetsirikul, S., Shiddiky, M. J. A., & Nguyen, N. -T. (2020). Wicking in Paper Strips under Consideration of Liquid Absorption Capacity. Chemosensors, 8(3), 65. https://doi.org/10.3390/chemosensors8030065