Optimization of Classification Prediction Performances of an Instrumental Odour Monitoring System by Using Temperature Correction Approach

Abstract

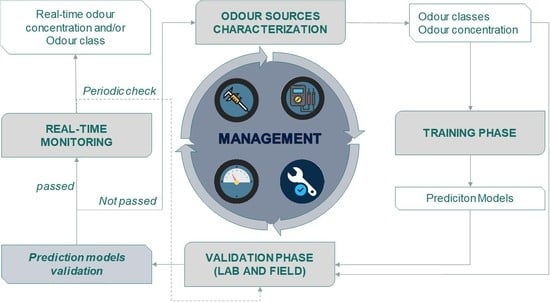

:1. Introduction

2. Materials and Methods

2.1. IOMS Device

2.2. Experimental Analyses

2.3. Elaboration of the Classification Predicitve Model

- m is the number of the sensors;

- TA (Acquisition time) is the time between two different acquisition of resistance equal to 2 s;

- a is the number of acquisition;

- TF (Flushing duration) is the acquisition time between which the values of resistances were taken in consideration for the calculation of the average value equal to 3 min.

- Differential Value of resistance (DVR)

2.4. Analysis of the Influence of the Temperature on the Sensors Detected Values

2.5. Optimization Studies and Performance Evaluation

- (a)

- Calculation of the interpolation curves equations Ri,j = aj Ti,j + bj (where Ri,j are the resistance values, Ti,j the corresponding temperature and aj and bj are the linear combination coefficients different for each j-esimo sensor);

- (b)

- Calculation of the benchmark values at 50 °C, for each sensor, using the corresponding equation of the interpolation curves (R50: reference value at temperature of 50 °C);

- (c)

- Calculation of the reference values for each value of temperature between 40 °C and 60 °C and for each sensor, using the corresponding equation of the interpolation curves (RTk: reference value at temperature Tk (40–60 °C));

- (d)

- Calculation of the corrective coefficients as the ratio between the RTk and R50, different for each j-esimo sensor and for k-esimo Temperature.

- Average System Accuracy corresponds to the average per class effectiveness in the recognition of samples by the classifier.

- System Error is the average error per class in the recognition of samples made by classifier.

- Precision (μ) represents the concordance of the labels of the data classes with those attributed by the classifier if calculated from the sums of the decisions per text.

- Recall (μ) indicates the effectiveness of a classifier in identifying class labels if calculated through the sum of the decisions per text.

- F-score (μ) identifies the relationships between positive data labels and those provided by a classifier based on the sum of decisions by text.

- -

- l = number of the classes;

- -

- tpi = true positive, represents the number of gaseous samples of the i-class correctly recognized in the i-class;

- -

- tni = true negative, represents the number of samples of a different class correctly recognized out of the i-class;

- -

- fpi = false positive, represents the number of samples of a different incorrectly attributed to the i-class;

- -

- fni = false negative, represents the number of samples of the i-class attributed to a different class.

3. Results and Discussion

3.1. Predicitve Model for Odour Classification

3.2. Influence of the Internal Temperature on the Measured Values of the Sensors in Terms of Resistance

3.3. Optimization of the Classification Models and Performance Parameters

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Oliva, G.; Zarra, T.; Pittoni, G.; Senatore, V.; Galang, M.G.; Castellani, M.; Belgiorno, V.; Naddeo, V. Next-Generation of Instrumental Odour Monitoring System (IOMS) for the Gaseous Emissions Control in Complex Industrial Plants. Chemosphere 2021, 271, 129768. [Google Scholar] [CrossRef] [PubMed]

- Giuliani, S.; Zarra, T.; Nicolas, J.; Naddeo, V.; Belgiorno, V.; Romain, A.C. An Alternative Approach of the E-Nose Training Phase in Odour Impact Assessment. Chem. Eng. Trans. 2012, 30, 139–144. [Google Scholar]

- Zarra, T.; Giuliani, S.; Naddeo, V.; Belgiorno, V. Control of Odour Emission in Wastewater Treatment Plants by Direct and Undirected Measurement of Odour Emission Capacity. Water Sci. Technol. 2012, 66, 1627–1633. [Google Scholar] [CrossRef] [Green Version]

- Gostelow, P.; Parsons, S.A.; Stuetz, R.M. Odour Measurements for Sewage Treatment Works. Water Res. 2001, 35, 579–597. [Google Scholar] [CrossRef]

- Oliva, G.; Ángeles, R.; Rodríguez, E.; Turiel, S.; Naddeo, V.; Zarra, T.; Belgiorno, V.; Muñoz, R.; Lebrero, R. Comparative evaluation of a biotrickling filter and a tubular photobioreactor for the continuous abatement of toluene. J. Hazard. Mater. 2019, 380, 120860. [Google Scholar] [CrossRef]

- Naddeo, V.; Zarra, T.; Oliva, G.; Kubo, A.; Uchida, N.; Higuchi, T. Odour Measurement in Wastewater Treatment Plant by a New Prototype of e.Nose: Correlation and Comparison Study with Reference to Both European and Japanese Approaches. Chem. Eng. Trans. 2016, 54, 85–90. [Google Scholar] [CrossRef]

- Naddeo, V.; Belgiorno, V.; Zarra, T. (Eds.) Odour Impact Assessment Handbook; John Wiley & Sons: Chichester, UK; Hoboken, NJ, USA, 2013; ISBN 978-1-118-48128-8. [Google Scholar]

- Naddeo, V.; Zarra, T.; Oliva, G.; Chiavola, A.; Vivarelli, A. Environmental Odour Impact Assessment of Landfill Expansion Scenarios: Case Study of Borgo Montello (Italy). Chem. Eng. Trans. 2016, 54, 73–78. [Google Scholar] [CrossRef]

- Bokowa, A.; Diaz, C.; Koziel, J.A.; McGinley, M.; Barclay, J.; Schauberger, G.; Guillot, J.-M.; Sneath, R.; Capelli, L.; Zorich, V.; et al. Summary and Overview of the Odour Regulations Worldwide. Atmosphere 2021, 12, 206. [Google Scholar] [CrossRef]

- Senatore, V.; Zarra, T.; Oliva, G.; Belgiorno, V.; Naddeo, V. Volatile Organic Compounds (Vocs) Removal by Combining Bioscrubber and Ozone Pretreatment. Glob. Nest J. 2020, 22, 143–146. [Google Scholar] [CrossRef]

- Blanco-Rodríguez, A.; Camara, V.F.; Campo, F.; Becherán, L.; Durán, A.; Vieira, V.D.; de Melo, H.; Garcia-Ramirez, A.R. Development of an Electronic Nose to Characterize Odours Emitted from Different Stages in a Wastewater Treatment Plant. Water Res. 2018, 134, 92–100. [Google Scholar] [CrossRef]

- Cadena, E.; Adani, F.; Font, X.; Artola, A. Including an Odor Impact Potential in Life Cycle Assessment of waste treatment plants. Int. J. Environ. Sci. Technol. 2018, 15, 2193–2202. [Google Scholar] [CrossRef] [Green Version]

- Zarra, T.; Galang, M.G.; Ballesteros, F.; Belgiorno, V.; Naddeo, V. Environmental Odour Management by Artificial Neural Network—A Review. Environ. Int. 2019, 133, 105189. [Google Scholar] [CrossRef]

- Okur, S.; Sarheed, M.; Huber, R.; Zhang, Z.; Heinke, L.; Kanbar, A.; Wöll, C.; Nick, P.; Lemmer, U. Identification of Mint Scents Using a QCM Based E-Nose. Chemosensors 2021, 9, 31. [Google Scholar] [CrossRef]

- Wilson, A.D. Applications of Electronic-Nose Technologies for Noninvasive Early Detection of Plant, Animal and Human Diseases. Chemosensors 2018, 6, 45. [Google Scholar] [CrossRef] [Green Version]

- Huang, J.; Wu, J. Robust and Rapid Detection of Mixed Volatile Organic Compounds in Flow Through Air by a Low Cost Electronic Nose. Chemosensors 2020, 8, 73. [Google Scholar] [CrossRef]

- Gardner, J.W.; Bartlett, P.N. A Brief History of Electronic Noses. Sens. Actuators B Chem. 1994, 18, 210–211. [Google Scholar] [CrossRef]

- Mota, I.; Teixeira-Santos, R.; Rufo, J.C. Detection and Identification of Fungal Species by Electronic Nose Technology: A Systematic Review. Fungal Biol. Rev. 2021, S1749461321000142. [Google Scholar] [CrossRef]

- Röck, F.; Barsan, N.; Weimar, U. Electronic Nose: Current Status and Future Trends. Chem. Rev. 2008, 108, 705–725. [Google Scholar] [CrossRef]

- Baietto, M.; Wilson, A. Electronic-Nose Applications for Fruit Identification, Ripeness and Quality Grading. Sensors 2015, 15, 899–931. [Google Scholar] [CrossRef] [PubMed]

- Kiani, S.; Minaei, S.; Ghasemi-Varnamkhasti, M. Application of Electronic Nose Systems for Assessing Quality of Medicinal and Aromatic Plant Products: A Review. J. Appl. Res. Med. Aromat. Plants 2016, 3, 1–9. [Google Scholar] [CrossRef]

- Montuschi, P.; Mores, N.; Trové, A.; Mondino, C.; Barnes, P.J. The Electronic Nose in Respiratory Medicine. Respiration 2013, 85, 72–84. [Google Scholar] [CrossRef]

- Jia, P.; Tian, F.; He, Q.; Fan, S.; Liu, J.; Yang, S.X. Feature Extraction of Wound Infection Data for Electronic Nose Based on a Novel Weighted KPCA. Sens. Actuators B Chem. 2014, 201, 555–566. [Google Scholar] [CrossRef]

- Deshmukh, S.; Bandyopadhyay, R.; Bhattacharyya, N.; Pandey, R.A.; Jana, A. Application of Electronic Nose for Industrial Odors and Gaseous Emissions Measurement and Monitoring—An Overview. Talanta 2015, 144, 329–340. [Google Scholar] [CrossRef] [PubMed]

- Licen, S.; Barbieri, G.; Fabbris, A.; Briguglio, S.C.; Pillon, A.; Stel, F.; Barbieri, P. Odor Control Map: Self Organizing Map Built from Electronic Nose Signals and Integrated by Different Instrumental and Sensorial Data to Obtain an Assessment Tool for Real Environmental Scenarios. Sens. Actuators B Chem. 2018, 263, 476–485. [Google Scholar] [CrossRef]

- Gobbi, E.; Falasconi, M.; Zambotti, G.; Sberveglieri, V.; Pulvirenti, A.; Sberveglieri, G. Rapid Diagnosis of Enterobacteriaceae in Vegetable Soups by a Metal Oxide Sensor Based Electronic Nose. Sens. Actuators B Chem. 2015, 207, 1104–1113. [Google Scholar] [CrossRef]

- Loutfi, A.; Coradeschi, S.; Mani, G.K.; Shankar, P.; Rayappan, J.B.B. Electronic Noses for Food Quality: A Review. J. Food Eng. 2015, 144, 103–111. [Google Scholar] [CrossRef]

- Korsa, M.T.; Domingo, J.M.C.; Nsubuga, L.; Hvam, J.; Niekiel, F.; Lofink, F.; Rubahn, H.-G.; Adam, J.; Hansen, R.D.O. Optimizing Piezoelectric Cantilever Design for Electronic Nose Applications. Chemosensors 2020, 8, 114. [Google Scholar] [CrossRef]

- Suchorab, Z.; Frąc, M.; Guz, Ł.; Oszust, K.; Łagód, G.; Gryta, A.; Bilińska-Wielgus, N.; Czerwiński, J. A Method for Early Detection and Identification of Fungal Contamination of Building Materials Using E-Nose. PLoS ONE 2019, 14, e0215179. [Google Scholar] [CrossRef] [Green Version]

- Giungato, P.; Di Gilio, A.; Palmisani, J.; Marzocca, A.; Mazzone, A.; Brattoli, M.; Giua, R.; de Gennaro, G. Synergistic Approaches for Odor Active Compounds Monitoring and Identification: State of the Art, Integration, Limits and Potentialities of Analytical and Sensorial Techniques. TrAC Trends Anal. Chem. 2018, 107, 116–129. [Google Scholar] [CrossRef]

- Moufid, M.; Bouchikhi, B.; Tiebe, C.; Bartholmai, M.; El Bari, N. Assessment of Outdoor Odor Emissions from Polluted Sites Using Simultaneous Thermal Desorption-Gas Chromatography-Mass Spectrometry (TD-GC-MS), Electronic Nose in Conjunction with Advanced Multivariate Statistical Approaches. Atmos. Environ. 2021, 256, 118449. [Google Scholar] [CrossRef]

- De Vito, S.; Massera, E.; Piga, M.; Martinotto, L.; Di Francia, G. On Field Calibration of an Electronic Nose for Benzene Estimation in an Urban Pollution Monitoring Scenario. Sens. Actuators B Chem. 2008, 129, 750–757. [Google Scholar] [CrossRef]

- Ghasemi-Varnamkhasti, M.; Mohtasebi, S.S.; Rodriguez-Mendez, M.L.; Lozano, J.; Razavi, S.H.; Ahmadi, H. Potential Application of Electronic Nose Technology in Brewery. Trends Food Sci. Technol. 2011, 22, 165–174. [Google Scholar] [CrossRef]

- Burlachenko, J.; Kruglenko, I.; Snopok, B.; Persaud, K. Sample Handling for Electronic Nose Technology: State of the Art and Future Trends. TrAC Trends Anal. Chem. 2016, 82, 222–236. [Google Scholar] [CrossRef] [Green Version]

- Makarichian, A.; Amiri Chayjan, R.; Ahmadi, E.; Mohtasebi, S.S. Assessment the Influence of Different Drying Methods and Pre-Storage Periods on Garlic (Allium Sativum L.) Aroma Using Electronic Nose. Food Bioprod. Process. 2021, 127, 198–211. [Google Scholar] [CrossRef]

- Laga, S.A.; Sarno, R. Temperature Effect of Electronic Nose Sampling for Classifying Mixture of Beef and Pork. Indones. J. Electr. Eng. Comput. Sci. 2020, 19, 1626–1634. [Google Scholar] [CrossRef]

- Liang, Z.; Tian, F.; Yang, S.X.; Zhang, C.; Sun, H.; Liu, T. Study on Interference Suppression Algorithms for Electronic Noses: A Review. Sensors 2018, 18, 1179. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Tian, H.; Yu, B.; Yu, H.; Chen, C. Evaluation of the Synergistic Olfactory Effects of Diacetyl, Acetaldehyde, and Acetoin in a Yogurt Matrix Using Odor Threshold, Aroma Intensity, and Electronic Nose Analyses. J. Dairy Sci. 2020, 103, 7957–7967. [Google Scholar] [CrossRef] [PubMed]

- Majchrzak, T.; Wojnowski, W.; Dymerski, T.; Gębicki, J.; Namieśnik, J. Electronic Noses in Classification and Quality Control of Edible Oils: A Review. Food Chem. 2018, 246, 192–201. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Wang, J.; Zhang, H.; Yu, Y.; Yao, C. Identification of Green Tea Grade Using Different Feature of Response Signal from E-Nose Sensors. Sens. Actuators B Chem. 2008, 128, 455–461. [Google Scholar] [CrossRef]

- Sanaeifar, A.; Mohtasebi, S.S.; Ghasemi-Varnamkhasti, M.; Ahmadi, H. Application of MOS Based Electronic Nose for the Prediction of Banana Quality Properties. Measurement 2016, 82, 105–114. [Google Scholar] [CrossRef]

- Tharwat, A.; Gaber, T.; Ibrahim, A.; Hassanien, A.E. Linear Discriminant Analysis: A Detailed Tutorial. AI Commun. 2017, 30, 169–190. [Google Scholar] [CrossRef] [Green Version]

- Rousson, V.; Goşoniu, N.F. An R-Square Coefficient Based on Final Prediction Error. Stat. Methodol. 2007, 4, 331–340. [Google Scholar] [CrossRef]

- Sokolova, M.; Lapalme, G. A Systematic Analysis of Performance Measures for Classification Tasks. Inf. Process. Manag. 2009, 45, 427–437. [Google Scholar] [CrossRef]

- Mahmodi, K.; Mostafaei, M.; Mirzaee-Ghaleh, E. Detection and Classification of Diesel-Biodiesel Blends by LDA, QDA and SVM Approaches Using an Electronic Nose. Fuel 2019, 258, 116114. [Google Scholar] [CrossRef]

- Huerta, R.; Mosqueiro, T.S.; Fonollosa, J.; Rulkov, N.F.; Rodriguez-Lujan, I. Online Decorrelation of Humidity and Temperature in Chemical Sensors for Continuous Monitoring. Chemom. Intell. Lab. Syst. 2016, 157, 169–176. [Google Scholar] [CrossRef] [Green Version]

| Type of Sensor | Position |

|---|---|

| TGS813 (Combustible Gases) | (Level I, channel j3–Level II, channel j12) |

| TGS2620 (Solvent Vapors) | (Level I, channel j2–Level II, channel j10) |

| TGS2602 (VOCs and odorous gases) | (Level I, channel j15–Level II, channel j9) |

| TGS822 (Organic Solvent Vapors) | (Level I, channel j13–Level II, channel j7) |

| TGS880 (alcohol, odor) | (Level I, channel j8–Level II, channel j1) |

| TGS2600 (hydrogen and carbon monoxide) | (Level I, channel j6–Level II, channel j14) |

| TGS2603 (Odor and Air Contaminants) | (Level II, channel j5) |

| TGS2611 (Methane) | (Level II, channel j4) |

| PID sensor (miniPID 2, Ion Science) | (Level I) |

| Humidity-Temperature Module (HYT271, IST) | (Level I) |

| Odour Classes | RP | OF | CA | AA |

|---|---|---|---|---|

| Number of samples | 24 | 38 | 40 | 44 |

| Total | 146 | |||

| TS | Classes | Predicted | ||||

|---|---|---|---|---|---|---|

| Actual | RP | OF | CA | AA | TOT | |

| RP | 19 | 0 | 3 | 0 | 22 | |

| OF | 2 | 34 | 0 | 0 | 36 | |

| CA | 2 | 0 | 35 | 1 | 38 | |

| AA | 3 | 0 | 0 | 39 | 42 | |

| Total | 138 | |||||

| TS + VS | Classes | Predicted | ||||

|---|---|---|---|---|---|---|

| Actual | RP | OF | CA | AA | TOT | |

| RP | 21 | 0 | 3 | 0 | 24 | |

| OF | 2 | 36 | 0 | 0 | 38 | |

| CA | 2 | 0 | 37 | 1 | 40 | |

| AA | 3 | 0 | 0 | 41 | 44 | |

| Total | 146 | |||||

| Class | Average Temperature [°C] |

|---|---|

| RP | 48 ± 4 |

| OF | 47 ± 5 |

| CA | 46 ± 2 |

| AA | 47 ± 3 |

| TS + VS | Classes | Predicted | ||||

|---|---|---|---|---|---|---|

| Actual | RP | OF | CA | AA | TOT | |

| RP | 23 | 0 | 1 | 0 | 24 | |

| OF | 2 | 36 | 0 | 0 | 38 | |

| CA | 0 | 0 | 40 | 0 | 40 | |

| AA | 2 | 0 | 0 | 42 | 44 | |

| Total | 146 | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oliva, G.; Zarra, T.; Massimo, R.; Senatore, V.; Buonerba, A.; Belgiorno, V.; Naddeo, V. Optimization of Classification Prediction Performances of an Instrumental Odour Monitoring System by Using Temperature Correction Approach. Chemosensors 2021, 9, 147. https://doi.org/10.3390/chemosensors9060147

Oliva G, Zarra T, Massimo R, Senatore V, Buonerba A, Belgiorno V, Naddeo V. Optimization of Classification Prediction Performances of an Instrumental Odour Monitoring System by Using Temperature Correction Approach. Chemosensors. 2021; 9(6):147. https://doi.org/10.3390/chemosensors9060147

Chicago/Turabian StyleOliva, Giuseppina, Tiziano Zarra, Raffaele Massimo, Vincenzo Senatore, Antonio Buonerba, Vincenzo Belgiorno, and Vincenzo Naddeo. 2021. "Optimization of Classification Prediction Performances of an Instrumental Odour Monitoring System by Using Temperature Correction Approach" Chemosensors 9, no. 6: 147. https://doi.org/10.3390/chemosensors9060147

APA StyleOliva, G., Zarra, T., Massimo, R., Senatore, V., Buonerba, A., Belgiorno, V., & Naddeo, V. (2021). Optimization of Classification Prediction Performances of an Instrumental Odour Monitoring System by Using Temperature Correction Approach. Chemosensors, 9(6), 147. https://doi.org/10.3390/chemosensors9060147