Preparation of Hydroxytyrosol by Acid Hydrolysis from Olive Leaves

Abstract

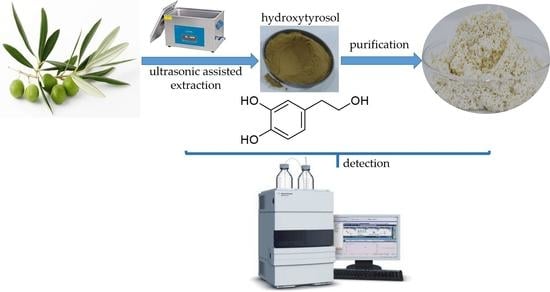

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Chromatographic Conditions

2.2.1. Determination of HT

2.2.2. Determination of Oleuropein

2.3. Determination of the Extraction Method

2.3.1. Ethanol Digestion for HT and OE

2.3.2. Ultrasonic-Assisted Extraction for HT and OE

2.4. Ultrasonic-Assisted Hydrolysis Olive Leaves for HT

2.4.1. Single Factors Assays

2.4.2. Designing the Response Surface

2.4.3. Verification Conduction

2.5. Enrichment n of HT by Macroporous Resins

2.5.1. Selection a Suitable Macroporous Resin

2.5.2. Static Adsorption and Desorption

2.5.3. Dynamic Adsorption and Desorption

Determination of Leakage Curve

Effect of Load Rates

Determination of Elution Curve

Effect of Elution Flow Rates

2.6. Statistical Analyses

3. Results

3.1. Determination of Extraction Method

3.2. Analysis of Single-Factor Test Results

3.3. Analysis of Response Surface Test Results

3.4. Optimization and Verification of Extraction Process

3.5. Screening of Macroporous Resin

3.6. Effect of Ethanol Concentration on Resin Adsorption and Desorption

3.7. Defination of Leakage Point

3.8. Effect of Loading Speed on Adsorption of Macroporous Resin

3.9. Determination of Elution Curve and Influence of Elution Flow Rate

3.10. Investigation on Enrichment Process of HT by Macroporous Resin

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Robles, A.M.; Pulido, M.M.; Moreno, F.J.; Ramirez, T.C.; Rodriguez, G.C.; Quiles, J.L.; Ramirez, T.M. Hydroxytyrosol: Bioavailability, toxicity, and clinical applications. Food Res. Int. 2018, 105, 654–667. [Google Scholar] [CrossRef]

- Corona, G.; Deiana, M.; Incani, A.; Vauzour, D.; Spencer, J.P.E. Hydroxytyrosol inhibits the proliferation of human colon adenocarcinoma cells through inhibition of erk1/2 and cyclin d1. Mol. Nutr. Food Res. 2009, 53, 897–903. [Google Scholar] [CrossRef] [PubMed]

- Han, J.; Talorete, T.P.N.; Yamada, P.; Isoda, H. Anti-proliferative and apoptotic effects of oleuropein and hydroxytyrosol on human breast cancer MCF-7 cells. Cytotechnology 2009, 59, 45–53. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Guo, W.; An, Y.; Jiang, L.; Geng, C.; Zhong, L. The protective effects of hydroxytyrosol against uvb-induced dna damage in hacat cells. Phytother. Res. 2010, 24, 352–359. [Google Scholar] [CrossRef]

- Ke, C.; Jie, X.; Xuan, Z.; Yuan, L.; Cong, C.; Adi, Z.; Hao, L.; Hua, L.; Ignatius, M.Y.S.; Yujie, S.; et al. Hydroxytyrosol prevents diet-induced metabolic syndrome and attenuates mitochondrial abnormalities in obese mice. Free Radic. Biol. Med. 2014, 67, 396–407. [Google Scholar] [CrossRef]

- Ángeles, G.; José, M.C.; Teresa, D.H.; Pilar, G.A.; Mirela, R. Determination of major bioactive compounds from olive leaf. LWT-Food Sci. Technol. 2015, 64, 431–438. [Google Scholar] [CrossRef] [Green Version]

- Bianco, A.; Buiarelli, F.; Cartoni, G.; Coccioli, F.; Jasionowska, R.; Margherita, P. Analysis by liquid chromatography-tandem mass spectrometry of biophenolic compounds in olives and vegetation waters, part I. J. Sep. Sci. 2003, 26, 409–416. [Google Scholar] [CrossRef]

- Bouaziz, M.; Sayadi, S. Isolation and evaluation of antioxidants from leaves of a Tunisian cultivar olive tree. Eur. J. Lipid Sci. Technol. 2005, 107, 497–504. [Google Scholar] [CrossRef]

- Rigane, G.; Bouaziz, M.; Baccar, N.; Abidi, S.; Sayadi, S.; Salem, R.B. Recovery of hydroxytyrosol rich extract from two-phase Chemlali olive pomace by chemical treatment. J. Food Sci. 2012, 77, 1077–1083. [Google Scholar] [CrossRef] [PubMed]

- Kalogerakis, N.; Politi, M.; Foteinis, S.; Chatzisymeon, E.; Mantzavinos, D. Recovery of antioxidants from olive mill wastewaters: Aviable solution that promotes their overall sustainable management. J. Environ. Manag. 2013, 128, 749–758. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Visioli, F.; Romani, A.; Mulinacci, N.; Zarini, S.; Conte, D.; Vincieri, F.F. Antioxidant and other biological activities of olive mill waste waters. J. Agric. Food Chem. 1999, 47, 3397–3401. [Google Scholar] [CrossRef] [PubMed]

- Jianzhong, Y.; Chengzhang, W.; Hongxia, C.; Hao, Z. Variation rule of hydroxytyrosol content in olive leaves. Chem. Ind. For. Prod. 2011, 31, 69–74. [Google Scholar] [CrossRef]

- Jemai, H.; Fki, I.; Bouaziz, M.; Bouallagui, Z.; El Feki, A.; Isoda, H. Lipid-lowering and antioxidant effects of hydroxytyrosol and its triacetylated derivative recovered from olive tree leaves in cholesterol-fed rats. J. Agric. Food Chem. 2008, 56, 2630–2636. [Google Scholar] [CrossRef] [PubMed]

- Eva, R.; Manuel, B.; Pedro, G.; Eduardo, M.; Concepción, R. Oleuropein hydrolysis in natural green olives: Importance of the endogenous enzymes. Food Chem. 2016, 206, 204–209. [Google Scholar] [CrossRef] [Green Version]

- De, L.A.; Aretini, A.; Alfano, G.; Macciola, V.; Ranalli, G. Isolation of a hydroxytyrosol-rich extract from olive leaves (Olea europaea L.) and evaluation of its antioxidant properties and bioactivity. Eur. Food Res. Technol. 2007, 226, 653–659. [Google Scholar] [CrossRef]

- Yuan, J.J.; Ye, J.Z.; Wang, C.Z.; Liu, Y.H. Thermal stability and decomposition kinetics of hydroxytyrosol. Chem. Ind. For. Prod. 2016, 36, 87–92. [Google Scholar] [CrossRef]

- Liu, W.; Zhang, S.; Zu, Y.G.; Fu, Y.J.; Ma, W.; Zhang, D.Y. Preliminary enrichment and separation of genistein and apigenin from extracts of pigeon pea roots by macroporous resins. Bioresour. Technol. 2010, 101, 4667–4675. [Google Scholar] [CrossRef] [PubMed]

- Tong, X.; Zhang, R.F.; Deng, Y.Y.; Xiao, J.; Liu, L.; Zhang, Y.; Wei, Z.C.; Zhang, M.W. Separation and purification of polyphenols in rice bran by macroporous resins. Sci. Agric. Sin. 2016, 49, 3818–3830. [Google Scholar] [CrossRef]

| Level | Factors | ||

|---|---|---|---|

| Extraction Time (min) (A) | Concentration of Hydrochloric Acid (mol/L) (B) | Liquid-to-Material Ratio mL/g (C) | |

| −1 | 80 | 0.8 | 40 |

| 0 | 120 | 1.2 | 50 |

| 1 | 160 | 1.6 | 60 |

| Run | Extraction Rate (mg/g) | |||

|---|---|---|---|---|

| OE | HT | |||

| Ethanol Maceration | Ultrasound-Assisted Extraction | Ethanol Maceration | Ultrasound-Assisted Extraction | |

| 1 | 13.362 | 13.467 | 0.145 | 0.198 |

| 2 | 11.894 | 12.211 | 0.000 | 0.410 |

| 3 | 11.766 | 11.253 | 0.236 | 0.381 |

| 4 | 13.049 | 12.159 | 0.115 | 0.243 |

| 5 | 11.683 | 13.086 | 0.000 | 0.249 |

| 6 | 13.661 | 12.840 | 0.101 | 0.341 |

| 7 | 12.865 | 12.603 | 0.100 | 0.195 |

| 8 | 11.901 | 13.638 | 0.000 | 0.257 |

| 9 | 13.148 | 12.822 | 0.117 | 0.257 |

| 10 | 11.685 | 11.066 | 0.255 | 0.389 |

| 11 | 14.051 | 13.394 | 0.146 | 0.234 |

| 12 | 12.983 | 12.916 | 0.000 | 0.270 |

| 13 | 13.184 | 13.376 | 0.000 | 0.262 |

| 14 | 13.686 | 13.492 | 0.000 | 0.253 |

| 15 | 12.045 | 13.522 | 0.000 | 0.369 |

| 16 | 11.976 | 11.302 | 0.390 | 0.276 |

| 17 | 13.632 | 12.075 | 0.000 | 0.479 |

| Run | Ultrasonic Extraction Time (min) (A) | Hydrochloric Acid Concentration (mol/L) (B) | Liquid-to-Material Ratio (mL/g) (C) | Yield (mg/g) (Y) |

|---|---|---|---|---|

| 1 | 160.00 | 1.20 | 60.00 | 12.9703 |

| 2 | 120.00 | 1.20 | 50.00 | 12.8739 |

| 3 | 120.00 | 1.60 | 40.00 | 13.2158 |

| 4 | 160.00 | 1.60 | 50.00 | 13.6306 |

| 5 | 120.00 | 1.20 | 50.00 | 13.3067 |

| 6 | 80.00 | 1.60 | 50.00 | 12.7745 |

| 7 | 120.00 | 1.20 | 50.00 | 13.4054 |

| 8 | 120.00 | 1.20 | 50.00 | 13.8363 |

| 9 | 120.00 | 1.20 | 50.00 | 13.7524 |

| 10 | 120.00 | 0.80 | 60.00 | 12.7648 |

| 11 | 160.00 | 0.80 | 50.00 | 13.011 |

| 12 | 160.00 | 1.20 | 40.00 | 13.8602 |

| 13 | 80.00 | 1.20 | 60.00 | 13.0687 |

| 14 | 80.00 | 1.20 | 40.00 | 12.3326 |

| 15 | 80.00 | 0.80 | 50.00 | 12.0391 |

| 16 | 120.00 | 1.60 | 60.00 | 13.8926 |

| 17 | 120.00 | 0.80 | 40.00 | 13.3041 |

| Source | Sum of Squares | Mean Square | F-Value | p-Value |

|---|---|---|---|---|

| Model | 3.91 | 0.43 | 4.78 | 0.0256 * |

| A | 1.33 | 1.33 | 14.57 | 0.0066 ** |

| B | 0.72 | 0.72 | 7.88 | 0.0263 * |

| C | 0.00003316 | 0.00003316 | 0.0003645 | 0.9853 |

| AB | 0.003355 | 0.003355 | 0.037 | 0.8532 |

| AC | 0.66 | 0.66 | 7.26 | 0.0309 * |

| BC | 0.37 | 0.37 | 4.06 | 0.0836 |

| A2 | 0.69 | 0.69 | 7.54 | 0.0286 * |

| B2 | 0.12 | 0.12 | 1.30 | 0.2923 |

| C2 | 0.003010 | 0.003010 | 0.033 | 0.8608 |

| Residual | 0.64 | 0.091 | ||

| Lack of fit | 0.043 | 0.014 | 0.096 | 0.9580 |

| Pure error | 0.59 | 0.15 | ||

| Cor total | 4.55 | |||

| R2 | 0.8600 |

| Type of Resins | Adsorption Rate | Desorption Rate |

|---|---|---|

| AB-8 | 47.83 ± 0.38% | 87.48 ± 0.53% |

| D101 | 49.19 ± 0.26% | 86.29 ± 0.04% |

| DA201 | 50.55 ± 0.66% | 95.62 ± 1.68% |

| DM-2 | 48.09 ± 0.27% | 88.47 ± 0.34% |

| DM301 | 50.83 ± 0.26% | 87.74 ± 0.77% |

| H103 | 97.34 ± 0.10% | 45.62 ± 0.22% |

| NKA-Ⅱ | 97.43 ± 0.08% | 49.85 ± 0.41% |

| XAD4 | 52.66 ± 1.32% | 82.84 ± 1.97% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Luo, S.; Luo, J.; Qu, J.; Feng, S.; Chen, T.; Zhou, L.; Yuan, M.; Yang, H.; Li, T.; et al. Preparation of Hydroxytyrosol by Acid Hydrolysis from Olive Leaves. Separations 2021, 8, 159. https://doi.org/10.3390/separations8090159

Wang Y, Luo S, Luo J, Qu J, Feng S, Chen T, Zhou L, Yuan M, Yang H, Li T, et al. Preparation of Hydroxytyrosol by Acid Hydrolysis from Olive Leaves. Separations. 2021; 8(9):159. https://doi.org/10.3390/separations8090159

Chicago/Turabian StyleWang, Yujie, Siyuan Luo, Jieling Luo, Jipeng Qu, Shiling Feng, Tao Chen, Lijun Zhou, Ming Yuan, Hongyu Yang, Tian Li, and et al. 2021. "Preparation of Hydroxytyrosol by Acid Hydrolysis from Olive Leaves" Separations 8, no. 9: 159. https://doi.org/10.3390/separations8090159

APA StyleWang, Y., Luo, S., Luo, J., Qu, J., Feng, S., Chen, T., Zhou, L., Yuan, M., Yang, H., Li, T., Lan, B., & Ding, C. (2021). Preparation of Hydroxytyrosol by Acid Hydrolysis from Olive Leaves. Separations, 8(9), 159. https://doi.org/10.3390/separations8090159