Numerical Simulation and Experimental Study of a Multistage Multiphase Separation System

Abstract

:1. Introduction

2. Methods and Theories

2.1. Coagulation and Separation Mechanism

2.2. Isoflow Theory

2.3. Shallow Pool Theory

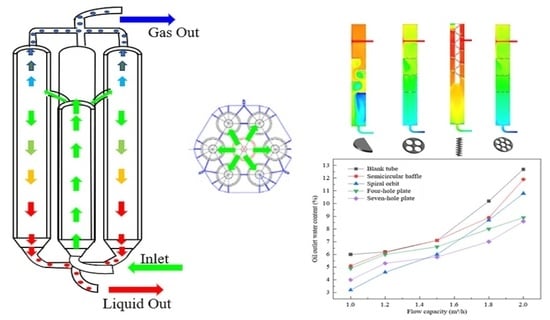

3. Multistage Multiphase Oil–Water Separation System

4. Numerical Simulation

4.1. Numerical Simulation Setup

4.2. Geometric Modeling and Meshing

4.3. Numerical Simulation Results and Analysis

5. Laboratory Experiment

5.1. Experimental Procedures

5.2. Experimental Results and Analysis

5.2.1. Separation Effect of the Separation System

5.2.2. Separation Efficiency of Different Coalescing Components

5.2.3. Influence of Coalescing Components on System Separation Efficiency at Different Volumetric Flow Rates

6. Conclusions

- (1)

- Numerical simulation of the vertical separator was carried out by Fluent software. In order to clarify the separation mechanism of parallel risers and the separation ability of a single pipe, the flow fields of pipes with different coalescing components were studied. The results show that the oil phase volume fraction distribution of the semicircle flapper is the most uneven, while the flow field of the orifice coalescing component is the most stable. Affected by contact with coalescence, the oil phase volume fraction in the vicinity of the spiral orbit coalescing component is at a high level.

- (2)

- Laboratory experiments were carried out to study the separation effect of the multiphase oil–water separation system. The results show that the water content at the oil outlet of the new separation system is 3% less than the horizontal separator, and the new separation system has a better separation effect than the horizontal separator.

- (3)

- The numerical simulation results of the parallel vertical separator are in good agreement with the experimental results. The semicircular coalescing component has the worst separation effect. Under the condition that the inlet flow is less than 1.6 m3/h, the water content at the oil outlet of the spiral track is the lowest. It can be seen that the spiral track is suitable for small volumetric flow rate separation. In contrast, the orifice coalescing component can still maintain a lower water content at the oil outlet under the condition of large flow, which performs well at a large volumetric flow rate.

- (4)

- There are still some deviations in this experiment. There is a certain error of time in the sampling and measurement at the outlet, which affects the droplet morphology in the emulsion. In addition, different temperatures in the laboratory will also have an impact on the oil viscosity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, Y.; Xu, J. Oil and water separation technology. Adv. Mech. 2015, 45, 179–216. [Google Scholar]

- Lv, J.; Kang, Y.; Wang, Z.; Peng, F. Research progress of oil-water separation technology and equipment in oilfield. Petro-Chem. Equip. 2019, 48, 69–75. [Google Scholar]

- Gupta, R.K.; Dunderdale, G.J.; England, M.W.; Hozumi, A. Oil/water separation techniques: A review of recent progresses and future directions. J. Mater. Chem. A 2017, 5, 16025–16058. [Google Scholar] [CrossRef]

- Behin, J.; Aghajari, M. Influence of water level on oil–water separation by residence time distribution curves investigations. Sep. Purif. Technol. 2008, 64, 48–55. [Google Scholar] [CrossRef]

- Mostafaiyan, M.; Saeb, M.R.; Alorizi, A.E.; Farahani, M. Application of evolutionary computational approach in design of horizontal three-phase gravity separators. J. Pet. Sci. Eng. 2014, 119, 28–35. [Google Scholar] [CrossRef]

- Frising, T.; Noïk, C.; Dalmazzone, C. The liquid/liquid sedimentation process: From droplet coalescence to technologically enhanced water/oil emulsion gravity separators: A review. J. Dispers. Sci. Technol. 2006, 27, 1035–1057. [Google Scholar] [CrossRef]

- Zhang, L.; He, L.; Wang, T.; Lv, Y.; He, Z. Researches on the numerical simulation and optimum of the coalescing components of gravity separators. Chem. Eng. Mach. 2008, 35, 17–21. [Google Scholar]

- Wang, Z.; Zhang, K.; Zhang, J.; Chen, G.; Ma, X.; Xin, G.; Kang, J.; Zhao, H.; Yang, Y. Deep reinforcement learning and adaptive policy transfer for generalizable well control optimization. J. Pet. Sci. Eng. 2022, 217, 110868. [Google Scholar] [CrossRef]

- Wang, G.; He, L.; Lv, Y.; Chen, Z. Study on oil water separation behavior of gravity separator. Pet. J. 2006, 27, 112–115. [Google Scholar]

- Acharya, T.; Casimiro, L. Evaluation of flow characteristics in an onshore horizontal separator using computational fluid dynamics. J. Ocean Eng. Sci. 2020, 5, 261–268. [Google Scholar] [CrossRef]

- Ye, W.; Qiu, T.; Chen, J.; Han, D.; Gao, Y. The structure optimization and separation performance simulation of single-double stage gas-liquid gravity separator. Chem. Eng. Mach. 2017, 44, 322–327. [Google Scholar]

- He, L.; Yang, G.; Xiaohan, P.; Guoxing, Z.; Lichen, Z. Progress and prospect of downhole cyclone oil-water separation with single-well injection-production technology. Acta Pet. Sin. 2018, 39, 463. [Google Scholar]

- Zhou, N.; Gao, Y.; An, W.; Yang, M. Numerical simulation of oil-water separation efficiency of a hydrocyclone. Chin. J. Environ. Eng. 2012, 6, 2953–2957. [Google Scholar]

- Ai, Z.; He, H.; Nu, G.; Xiao, L.; Ma, H. Optimization Study of the Entrance Structure of Oil-Water Separation Hydrocyclone. China Pet. Mach. 2007, 35, 5–9. [Google Scholar]

- Yin, F.; Xue, X.; Zhang, C.; Zhang, K.; Han, J.; Liu, B.; Wang, J.; Yao, J. Multifidelity genetic transfer: An efficient framework for production optimization. SPE J. 2021, 26, 1614–1635. [Google Scholar] [CrossRef]

- Zeng, R.; Yang, Y. The numerical simulation of the flow field of the oil-water cyclone separator. China Pet. Mach. 2011, 39, 24–27+96. [Google Scholar]

- Zhang, J.; Chen, D.; Lv, R.; Li, Y.; Chen, L.; Kong, X. Influence of Structural Parameters on Separation Performance of Gas-liquid Cyclone Separator for Hydraulic Oil Tank. Res. Sq. 2022, in press. [Google Scholar]

- de Luna, F.D.T.; Santos, B.R.G.; de Araújo, M.V.; dos Santos, E.B.; de Farias Neto, S.R.; de Lima, A.G.B. Numerical study of water-oil separation in cyclonic separators. Int. J. Model. Simul. Pet. Ind. 2015, 9, 13–19. [Google Scholar]

- Liu, T.; Fan, Y.; Yuan, S.; Yu, X. Effect of PEX coalescer on oil-water separation performance. Nat. Gas Chem. Industry. C1 Chem. Chem. Ind. 2019, 44, 104–108. [Google Scholar]

- Zhang, L.; He, L.; Wang, T.; Lv, Y.; He, Z. Separating behavior with coalescence internals in separator. J. Chem. Eng. High. Educ. Inst. 2009, 23, 345–350. [Google Scholar]

- Jia, P.; Chen, J.; Cai, X.; Kong, L.; Wang, C.; Shang, C.; Zhang, M.; Shi, Y. Study on oil-water separation characteristics of hydrocyclone based on CFD⁃PBM numerical simulation. J. Petrochem. Univ. 2021, 34, 58–65. [Google Scholar]

- Liang, L.; Zhang, W.; Bai, Z.; Yang, X.; Luo, H.; Zhang, B. Experimental and simulation study on separation performance of coalescing structural parts within oil-water gravity separator. Mod. Chem. Ind. 2018, 38, 211–215. [Google Scholar]

- Gao, Z.; Liu, J.; Wang, D.; Shao, W.; Liu, N.; Fang, B. The detecting method for oil-water separation performance of coalescence. J. Filtr. Sep. 2016, 26, 6–10. [Google Scholar]

- Yang, Q.; Lu, H.; Li, Y.; Dai, P.; Pan, Z.; Liu, Y. Application and research progress of coalescence separation in oily wastewater treatment. Chin. J. Environ.-Ment. Eng. 2021, 15, 767–781. [Google Scholar]

- Qu, J.; Ni, L.; Liu, X.; Zhu, W. Reserch on the factors of impacting the coalescence efficiency. J. Filtr. Sep. 2009, 19, 14–16. [Google Scholar]

- Zhang, L.; Zhao, Y.; Zhang, K.; Qi, J. Experimental design on flow field of different components in gravity separator. Lab. Res. Explor. 2019, 38, 25–27+39. [Google Scholar]

- Pan, C.; Zhao, H.; Yu, P.; Zou, W.; Li, Y. Simulation study on influencing factors of oil-water separation in coalescing plate separator. China Pet. Mach. 2021, 49, 93–102. [Google Scholar]

- Huang, W.; He, X.; Deng, C.; Xu, B. Study on the intensification mechanism of oil-water separation process by using inclined plate pack. Adv. Eng. Sci. 2017, 49, 191–196. [Google Scholar]

- Zhu, M.; Wang, D.; Yin, X. Influencing factors of air-flotation process for treatment of polymer flooding oil-extraction wastewate. Water Purif. Technol. 2012, 31, 43–45. [Google Scholar]

- Saththasivam, J.; Loganathan, K.; Sarp, S. An overview of oil–water separation using gas flotation systems. Chemosphere 2016, 144, 671–680. [Google Scholar] [CrossRef]

- Rajak, V.; Relish, K.; Kumar, S.; Mandal, A. Mechanism and kinetics of separation of oil from oil-in-water emulsion by air flotation. Pet. Sci. Technol. 2015, 33, 1861–1868. [Google Scholar] [CrossRef]

- Li, J.; Xue, Q.; He, C.; Shen, Z.; He, Z. Research progress of oily sewage with air flotation technology. Guangdong Chem. Ind. 2015, 42, 103–104+85. [Google Scholar]

- Wei, Y.; Qi, H.; Gong, X.; Zhao, S. Specially wettable membranes for oil–water separation. Adv. Mater. Interfaces 2018, 5, 1800576. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, S.; Zhang, K.; Zhang, X.; Sun, Z.; Zhang, H.; Chipecane, M.T.; Yao, J. Cooperative artificial bee colony algorithm with multiple populations for interval multiobjective optimization problems. IEEE Trans. Fuzzy Syst. 2018, 27, 1052–1065. [Google Scholar] [CrossRef]

- Lin, X.; Hong, J. Recent advances in robust superwettable membranes for oil–water separation. Adv. Mater. Interfaces 2019, 6, 1900126. [Google Scholar] [CrossRef]

- Nakamura, K.; Nakamura, J.; Matsumoto, K. Filtration and backwashing behaviors of the deep bed filtration using long length poly-propylene fiber filter media. J. Taiwan Inst. Chem. Eng. 2019, 94, 31–36. [Google Scholar] [CrossRef]

- Wei, J.; Duan, L.; Wei, J.; Hoffmann, E.; Song, Y.; Meng, X. Lead removal from water using organic acrylic amine fiber (AAF) and inorganic-organic P-AAF, fixed bed filtration and surface-induced precipitation. J. Environ. Sci. 2021, 101, 135–144. [Google Scholar] [CrossRef]

- Govedarica, D.D.; Sokolović, R.M.Š.; Sokolović, D.S.; Sokolović, S.M. A novel approach for the estimation of the efficiency of steady-state fiber bed coalescence. Sep. Purif. Technol. 2013, 104, 268–275. [Google Scholar] [CrossRef]

- Brothers, J.E. Stokes’ theorem. Am. J. Math. 1970, 92, 657–670. [Google Scholar] [CrossRef]

- Kumar, N.; Mandal, A. Thermodynamic and physicochemical properties evaluation for formation and characterization of oil-in-water nanoemulsion. J. Mol. Liq. 2018, 266, 147–159. [Google Scholar] [CrossRef]

- Han, Y.; He, L.; Luo, X.; Lü, Y.; Shi, K.; Chen, J.; Huang, X. A review of the recent advances in design of corrugated plate packs applied for oil–water separation. J. Ind. Eng. Chem. 2017, 53, 37–50. [Google Scholar] [CrossRef]

- Wang, X.; Han, H. The gas-liquid separation experimental study of multi-cups anchor. Offshore Oil 2007, 01, 64–67. [Google Scholar]

- Yang, L.; Wang, J.; Jiang, Y.; Zou, L. Oil–water flow splitting in eccentric annular T-junction tubes—Experimental and CFD analysis. Chem. Eng. Sci. 2020, 228, 116000. [Google Scholar] [CrossRef]

| Blank Tube /(μm) | Semicircular Baffle/(μm) | Spiral Orbit /(μm) | Four-Hole Plate/(μm) | Seven-Hole Plate/(μm) | All Risers Are Open |

|---|---|---|---|---|---|

| 69.03 | 71.49 | 75.80 | 72.99 | 78.24 | ∞ |

| Blank Tube | Semicircular Baffle | Spiral Orbit | Four-Hole Plate | Seven-Hole Plate | |

|---|---|---|---|---|---|

| Oil content reduction/% | 6.25 | 13.3 | 10.2 | 14.8 | 20 |

| Water content reduction/% | 6.9 | 15 | 13.7 | 15.5 | 17.6 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Zheng, J.; Jiang, J.; Peng, H.; Luo, Y.; Zhang, L. Numerical Simulation and Experimental Study of a Multistage Multiphase Separation System. Separations 2022, 9, 405. https://doi.org/10.3390/separations9120405

Chen X, Zheng J, Jiang J, Peng H, Luo Y, Zhang L. Numerical Simulation and Experimental Study of a Multistage Multiphase Separation System. Separations. 2022; 9(12):405. https://doi.org/10.3390/separations9120405

Chicago/Turabian StyleChen, Xuezhong, Jian Zheng, Jiayu Jiang, Hao Peng, Yanli Luo, and Liming Zhang. 2022. "Numerical Simulation and Experimental Study of a Multistage Multiphase Separation System" Separations 9, no. 12: 405. https://doi.org/10.3390/separations9120405

APA StyleChen, X., Zheng, J., Jiang, J., Peng, H., Luo, Y., & Zhang, L. (2022). Numerical Simulation and Experimental Study of a Multistage Multiphase Separation System. Separations, 9(12), 405. https://doi.org/10.3390/separations9120405