A Refractive Index Sensitive Liquid Level Monitoring Sensor Based on Multimode Interference

Abstract

:1. Introduction

2. Fabrication and Principle

3. Numerical Analysis

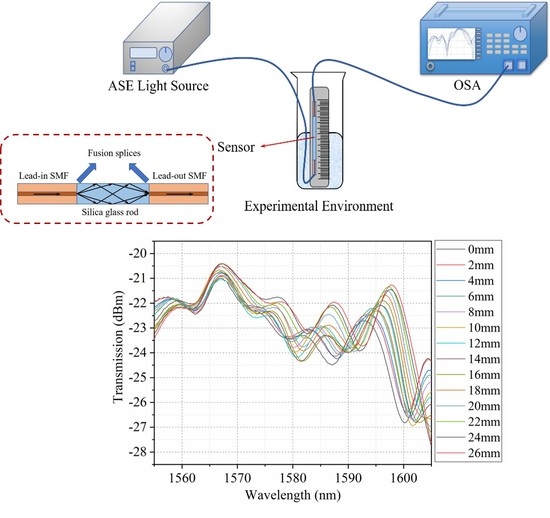

4. Experimental Results and Discussion

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Li, H.N.; Li, D.S.; Song, G.B. Recent applications of fiber optic sensors to health monitoring in civil engineering. Eng. Struct. 2004, 26, 1647–1657. [Google Scholar] [CrossRef]

- Habel, W.R.; Krebber, K. Fiber-optic sensor applications in civil and geotechnical engineering. Photonic Sens. 2011, 1, 268–280. [Google Scholar] [CrossRef] [Green Version]

- Leung, C.K.Y.; Wan, K.T.; Inaudi, D.; Bao, X.Y.; Habel, W.; Zhou, Z.; Ou, J.P.; Ghandehari, M.; Wu, H.C.; Imai, M. Optical fiber sensors for civil engineering applications. Mater. Struct. 2015, 48, 871–906. [Google Scholar] [CrossRef] [Green Version]

- Zamarreno, C.R.; Hernaez, M.; Del Villar, I.; Matias, I.R.; Arregui, F.J. Optical fiber pH sensor based on lossy-mode resonances by means of thin polymeric coatings. Sens. Actuators B-Chem. 2011, 155, 290–297. [Google Scholar] [CrossRef]

- Wang, X.D.; Wolfbeis, O.S. Fiber-optic chemical sensors and biosensors (2015–2019). Anal. Chem. 2019, 92, 397–430. [Google Scholar] [CrossRef]

- Joe, H.E.; Yun, H.; Jo, S.H.; Jun, M.B.G.; Min, B.K. A review on optical fiber sensors for environmental monitoring. Int. J. Precis. Eng. Manuf.-Green Technol. 2018, 5, 173–191. [Google Scholar] [CrossRef]

- Vaiano, P.; Carotenuto, B.; Pisco, M.; Ricciardi, A.; Quero, G.; Consales, M.; Crescitelli, A.; Esposito, E.; Cusano, A. Lab on fiber technology for biological sensing applications. Laser Photonics Rev. 2016, 10, 922–961. [Google Scholar] [CrossRef]

- Gandhi, M.S.A.; Chu, S.; Senthilnathan, K.; Babu, P.R.; Nakkeeran, K.; Li, Q. Recent advances in plasmonic sensor-based fiber optic probes for biological applications. Appl. Sci. 2019, 9, 949. [Google Scholar] [CrossRef] [Green Version]

- Liao, H.; Lu, P.; Fu, X.; Jiang, X.Y.; Ni, W.J.; Liu, D.M.; Zhang, J.S. Sensitivity amplification of fiber-optic in-line Mach–Zehnder Interferometer sensors with modified Vernier-effect. Opt. Express 2017, 25, 26898–26909. [Google Scholar] [CrossRef]

- Zhao, Y.; Chen, M.Q.; Xia, F.; Lv, R.Q. Small in-fiber Fabry-Perot low-frequency acoustic pressure sensor with PDMS diaphragm embedded in hollow-core fiber. Sens. Actuator A Phys. 2018, 270, 162–169. [Google Scholar] [CrossRef]

- Chu, R.; Guan, C.Y.; Bo, Y.T.; Shi, J.H.; Zhu, Z.; Li, P.; Yang, J.; Yuan, L.B. All-optical graphene-oxide humidity sensor based on a side-polished symmetrical twin-core fiber Michelson interferometer. Sens. Actuators B Chem. 2019, 284, 623–627. [Google Scholar] [CrossRef]

- Liu, T.; Zhang, H.; Xue, L.F.; Liu, B.; Liu, H.F.; Huang, B.C.; Sun, J.J.; Wang, D.B. Highly sensitive torsion sensor based on side-hole-fiber Sagnac interferometer. IEEE Sens. J. 2019, 19, 7378–7382. [Google Scholar] [CrossRef]

- Chethana, K.; Guru Prasad, A.S.; Omkar, S.N.; Asokan, S. Fiber bragg grating sensor based device for simultaneous measurement of respiratory and cardiac activities. J. Biophotonics 2017, 10, 278–285. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.Z.; Tang, F.J.; Bao, Y.; Tang, Y.; Chen, G.D. A Fe-C coated long-period fiber grating sensor for corrosion-induced mass loss measurement. Opt. Lett. 2016, 41, 2306–2309. [Google Scholar] [CrossRef] [PubMed]

- Guo, T.; Liu, F.; Guan, B.O.; Albert, J. Tilted fiber grating mechanical and biochemical sensors. Opt. Laser Technol. 2016, 78, 19–33. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Li, X.G.; Cheng, T.L.; Li, S.G.; An, G.W. Graphene enhanced optical fiber SPR sensor for liquid concentration measurement. Opt. Fiber Technol. 2018, 43, 62–66. [Google Scholar] [CrossRef]

- Li, X.D.; Li, S.G.; Yan, X.; Sun, D.M.; Liu, Z.; Cheng, T.L. High sensitivity photonic crystal fiber refractive index sensor with gold coated externally based on surface plasmon resonance. Micromachines 2018, 9, 640. [Google Scholar] [CrossRef] [Green Version]

- Zhou, X.; Li, X.G.; Li, S.G.; An, G.W.; Cheng, T.L. Magnetic field sensing based on SPR optical fiber sensor interacting with magnetic fluid. IEEE T. Instrum. Meas. 2018, 68, 234–239. [Google Scholar] [CrossRef]

- Huang, J.; Lan, X.W.; Wang, H.Z.; Yuan, L.; Wei, T.; Gao, Z.; Xiao, H. Polymer optical fiber for large strain measurement based on multimode interference. Opt. Lett. 2012, 37, 4308–4310. [Google Scholar] [CrossRef]

- Wang, P.F.; Ding, M.; Bo, L.; Guan, C.Y.; Semenova, Y.; Wu, Q.; Farrell, G.; Brambilla, G. Ultrahigh-sensitivity temperature fiber sensor based on multimode interference. Appl. Optics 2012, 51, 3236–3242. [Google Scholar]

- Gong, Y.; Zhao, T.; Rao, Y.J.; Wu, Y. All-fiber curvature sensor based on multimode interference. IEEE Photon. Technol. Lett. 2011, 23, 679–681. [Google Scholar] [CrossRef]

- Antonio-Lopez, J.E.; Sanchez-Mondragon, J.J.; LiKamWa, P.; May-Arrioja, D.A. Fiber-optic sensor for liquid level measurement. Opt. Lett. 2011, 36, 3425–3427. [Google Scholar] [CrossRef] [PubMed]

- Zhou, X.L.; Chen, K.; Mao, X.F.; Peng, W.; Yu, Q.X. A reflective fiber-optic refractive index sensor based on multimode interference in a coreless silica fiber. Opt. Commun. 2015, 340, 50–55. [Google Scholar] [CrossRef]

- Janczuk-Richter, M.; Dominik, M.; Razniecka, E.; Koba, M.; Mikulic, P.; Bock, W.J.; Los, M.; Smietana, M.; Niedziolka-Jonsson, J. Long-period fiber grating sensor for detection of viruses. Sens. Actuators B Chem. 2017, 250, 32–38. [Google Scholar] [CrossRef]

- Osorio, J.H.; Oliveira, R.; Aristilde, S.; Chesini, G.; Franco, M.A.R.; Nogueira, R.N.; Cordeiro, C.M.B. Bragg gratings in surface-core fibers: Refractive index and directional curvature sensing. Opt. Fiber Technol. 2017, 34, 86–90. [Google Scholar] [CrossRef]

- Jing, N.; Teng, C.X.; Zheng, J.; Wang, G.J.; Chen, Y.Y.; Wang, Z.B. A liquid level sensor based on a race-track helical plastic optical fiber. IEEE Photon. Technol. Lett. 2017, 29, 158–160. [Google Scholar] [CrossRef]

- Zhang, Y.J.; Zhang, Y.Z.; Hou, Y.L.; Zhang, L.; Hu, Y.J.; Gao, X.L.; Zhang, H.X.; Liu, W.Y. An optical fiber liquid level sensor based on side coupling induction technology. J. Sens. 2018, 2018, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Aristilde, S.; Cordeiro, C.M.B.; Jonas, H.O. Gasoline quality sensor based on tilted fiber Bragg gratings. Photonics 2019, 6, 51. [Google Scholar] [CrossRef] [Green Version]

- Teng, C.X.; Liu, H.Q.; Deng, H.C.; Deng, S.J.; Yang, H.Y.; Xu, R.H.; Chen, M.; Yuan, L.B.; Zheng, J. Liquid level sensor based on a V-groove structure plastic optical fiber. Sensors 2018, 18, 3111. [Google Scholar] [CrossRef] [Green Version]

- Gomez-Cardona, N.; Reyes-Vera, E.; Torres, P. High sensitivity refractive index sensor based on the excitation of long-range surface plasmon polaritons in H-shaped optical fiber. Sensors 2020, 20, 2111. [Google Scholar] [CrossRef] [Green Version]

- Lin, W.; Miao, Y.P.; Zhang, H.; Liu, B.; Liu, Y.G.; Song, B.B. Fiber-optic in-line magnetic field sensor based on the magnetic fluid and multimode interference effects. Appl. Phys. Lett. 2013, 103, 151101. [Google Scholar] [CrossRef]

- Zhao, C.R.; Ye, L.; Ge, J.F.; Zou, J.H.; Yu, X. Novel light-leaking optical fiber liquid-level sensor for aircraft fuel gauging. Opt. Eng. 2013, 52, 014402. [Google Scholar] [CrossRef]

- Liu, S.H.; Tian, J.; Liu, N.L.; Xia, J.J.; Lu, P.X. Temperature insensitive liquid level sensor based on antiresonant reflecting guidance in silica tube. J. Lightwave Technol. 2016, 34, 5239–5243. [Google Scholar] [CrossRef]

- Yun, B.F.; Chan, N.; Cui, Y.P. Highly sensitive liquid-level sensor based on etched fiber Bragg grating. IEEE Photon. Technol. Lett. 2007, 19, 1747–1749. [Google Scholar] [CrossRef]

- Lin, X.; Ren, L.Y.; Xu, Y.P.; Chen, N.N.; Ju, H.J.; Liang, J.; He, Z.Q.; Qu, E.S.; Hu, B.W.; Li, Y.L. Low-cost multipoint liquid-level sensor with plastic optical fiber. IEEE Photon. Technol. Lett. 2014, 26, 1613–1616. [Google Scholar] [CrossRef]

- Gong, H.P.; Song, H.F.; Zhang, S.L.; Ni, K.; Dong, X.Y. An optical liquid level sensor based on polarization-maintaining fiber modal interferometer. Sens. Actuator A Phys. 2014, 205, 204–207. [Google Scholar] [CrossRef]

- Zhang, Y.S.; Zhang, Y.X.; Zhang, W.G.; Chen, L.; Yu, L.; Kong, L.X.; Yan, T.Y. Ultra-high sensitivity liquid level sensor based on CO2 laser local refractive index curved modulation effect. Opt. Laser Technol. 2019, 120, 105755. [Google Scholar] [CrossRef]

- Li, L.; Xia, L.; Xie, Z.H.; Liu, D.M. All-fiber Mach-Zehnder interferometers for sensing applications. Opt. Express 2012, 20, 11109. [Google Scholar] [CrossRef]

- Yamauchi, J.; Shibayama, J.; Sekiguchi, M.; Nakano, H. Improved multistep method for wide-angle beam propagation. IEEE Photon. Technol. Lett. 1996, 8, 1361–1363. [Google Scholar] [CrossRef] [Green Version]

- Zheng, J.J.; Li, J.; Ning, T.G.; Li, L.; Jian, S.S.; Wen, Y.H. Improved self-imaging for multimode optical fiber involving cladding refractive index. Opt. Commun. 2013, 311, 350–353. [Google Scholar] [CrossRef]

- Basker, D. Relationship between refractive index and specific gravity of aqueous glycerol solutions. Analyst 1978, 103, 185–186. [Google Scholar] [CrossRef]

- Fu, H.Y.; Shu, X.W.; Zhang, A.P.; Liu, W.S.; Zhang, L.; He, S.L. Implementation and characterization of liquid-level sensor based on a long-period fiber grating Mach–Zehnder interferometer. IEEE Sens. J. 2011, 11, 2878–2882. [Google Scholar] [CrossRef]

- Xue, H.; Xu, Z.W.; Chen, H.; Yang, Y.Y.; You, J.Z.; Yan, J.R.; Fu, H.Y.; Zhang, D. Continuous liquid level sensor based on a reflective long period fiber grating interferometer. Meas. Sci. Technol. 2015, 26, 037001. [Google Scholar] [CrossRef]

- Xu, B.; Li, J.Q.; Li, Y.; Dong, X.Y. A thin-core fiber modal interferometer for liquid-level sensing. Chin. Phys. Lett. 2012, 29, 104209. [Google Scholar] [CrossRef]

- Jing, N. Liquid level measurement based on multi-S-bend plastic optical fiber. Sens. Rev. 2019, 39, 522–524. [Google Scholar] [CrossRef]

- Chang, H.Y.; Chang, Y.C.; Sheng, H.J.; Fu, M.Y.; Liu, W.F.; Kashyap, R. An ultra-sensitive liquid-level indicator based on an etched chirped-fiber Bragg grating. IEEE Photonics Technol. Lett. 2016, 28, 268–271. [Google Scholar] [CrossRef]

- Sun, T.T.; Liu, Z.G.; Liu, Y.; Zhang, Y.; Peng, W. All-fiber liquid-level sensor based on in-line MSM Fiber Structure. Photonic Sens. 2020, 4, 1–7. [Google Scholar] [CrossRef]

| Method | Sensitivity | Measurement Range | Reference |

|---|---|---|---|

| Long period fiber grating (LPFG) | 250 pm/mm | 0–100 mm | [42] |

| Michelson interferometer | 8.44 pm/mm | 0–100 mm | [43] |

| Mach-Zehnder interferometer (MZI) based on thin core fiber | 288 pm/mm | 0–65 mm | [44] |

| S-bend plastic optical fiber | 0.04 dB/mm | 0–100 mm | [45] |

| Etched chirped fiber Bragg grating (FBG) | 1214 pm/mm | 0–7 mm | [46] |

| Multimode-Single mode-Multimode (MSM) | 264.6 pm/mm | 0–26 mm | [47] |

| Curved modulation of refractive index (RI) | 712 pm/mm | 0–24mm | [30] |

| MMI based on NCF | 352.5 pm/mm | 0–45 mm | This work |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Li, S.; Yan, X.; Zhang, X.; Wang, F.; Suzuki, T.; Ohishi, Y.; Cheng, T. A Refractive Index Sensitive Liquid Level Monitoring Sensor Based on Multimode Interference. Photonics 2020, 7, 89. https://doi.org/10.3390/photonics7040089

Zhang F, Li S, Yan X, Zhang X, Wang F, Suzuki T, Ohishi Y, Cheng T. A Refractive Index Sensitive Liquid Level Monitoring Sensor Based on Multimode Interference. Photonics. 2020; 7(4):89. https://doi.org/10.3390/photonics7040089

Chicago/Turabian StyleZhang, Fan, Shuguang Li, Xin Yan, Xuenan Zhang, Fang Wang, Takenobu Suzuki, Yasutake Ohishi, and Tonglei Cheng. 2020. "A Refractive Index Sensitive Liquid Level Monitoring Sensor Based on Multimode Interference" Photonics 7, no. 4: 89. https://doi.org/10.3390/photonics7040089

APA StyleZhang, F., Li, S., Yan, X., Zhang, X., Wang, F., Suzuki, T., Ohishi, Y., & Cheng, T. (2020). A Refractive Index Sensitive Liquid Level Monitoring Sensor Based on Multimode Interference. Photonics, 7(4), 89. https://doi.org/10.3390/photonics7040089