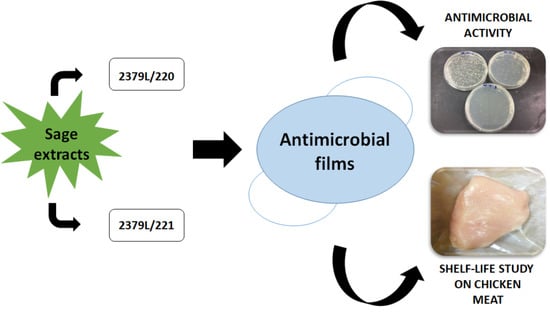

Antimicrobial Potential of Plastic Films Incorporated with Sage Extract on Chicken Meat

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Preparation of Extracts

2.3. Preparation of Coated Films

2.4. Determination of Antimicrobial Activity of Coated Films

2.4.1. Microbial Cultures Preparation

2.4.2. Modified ISO 22196 Method

2.5. Shelf Life

2.5.1. Determination of Microbiological Activity of Coated Films

Sampling and Storage

Total Plate Count (TPC)

2.5.2. Quality Assessment

Colour Analysis

Weight Change Analysis

Texture Analysis

pH Analysis

2.6. Statistical Analysis

3. Results and Discussion

3.1. Antimicrobial Activity of Coated Films

3.2. Shelf Life Study

3.2.1. Total Plate Count (TPC)

3.2.2. Colour Changes

3.2.3. Weight Loss Changes

3.2.4. Hardness Changes

3.2.5. pH Changes

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Petrou, S.; Tsiraki, M.; Giatrakou, V.; Savvaidis, I.N. Chitosan dipping or oregano oil treatments, singly or combined on modified atmosphere pack-aged chicken breast meat. Int. J. Food Microbiol. 2012, 156, 264–271. [Google Scholar] [CrossRef] [PubMed]

- Al-Jasser, M.S. Effect of cooling and freezing temperatures on microbial and chemical properties of chicken meat during storage. J. Food Agric. Environ. 2012, 10, 113–116. [Google Scholar]

- Stonehouse, G.G.; Evans, J.A. The use of supercooling for fresh foods: A review. J. Food Eng. 2015, 148, 74–79. [Google Scholar] [CrossRef] [Green Version]

- Garavito, J.; Moncayo-Martinez, D.; Castellanos, D.A. Evaluation of antimicrobial coatings on preservation and shelf life of fresh chicken breast fillets under cold storage. Foods 2020, 9, 1203. [Google Scholar] [CrossRef] [PubMed]

- Donado-Godoy, P.; Clavijo, V.; Leon, M.; Tafur, M.A.; Gonzales, S.; Hume, M.; Alali, W.; Walls, I.; Lo Fo Wong, D.M.A.; Doyle, M.P. Prevalence of Salmonella on retail broiler chicken meat carcasses in Colombia. J. Food Prot. 2012, 75, 1134–1138. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, I.; Lin, H.; Zou, L.; Brody, A.L.; Li, Z.; Qazi, I.M.; Pavase, T.R.; Lv, L. A comprehensive review on the application of active packaging technologies to muscle foods. Food Control 2017, 82, 163–178. [Google Scholar] [CrossRef]

- Bastarrachea, L.; Wong, D.; Roman, M.; Lin, Z.; Goddard, J. Active packaging coatings. Coatings 2015, 5, 771–791. [Google Scholar] [CrossRef]

- Gontard, N. Tailor made food packaging concept. In Proceedings of the IUFoST, 13th World Congress of Food Science and Technology: Food Is Life, Nantes, France, 2–17 September 2006. [Google Scholar]

- Camo, J.; Beltran, J.A.; Roncales, P. Extension of the display life of lamb with an antioxidant active packaging. Meat Sci. 2008, 80, 1086–1091. [Google Scholar] [CrossRef]

- Cegielska-Radziejewska, R.; Tycner, B.; Kijowski, J.; Zabielski, J.; Szablewski, T. Quality and shelf life of chilled, pretreated MAP poultry meat products. Bull. Vet. Inst. Pulawy 2008, 52, 603–609. [Google Scholar]

- Economou, T.; Pournis, N.; Ntzimani, A.; Savvaidis, I.N. Nisin–EDTA treatments and modified atmosphere packaging to increase fresh chicken meat shelf-life. Food Chem. 2009, 114, 1470–1476. [Google Scholar] [CrossRef]

- Ntzimani, A.G.; Giatrakou, V.I.; Savvaidis, I.N. Combined natural antimicrobial treatments (EDTA, lysozyme, rosemary and oregano oil) on semi cooked coated chicken meat stored in vacuum packages at 4 °C: Microbiological and sensory evaluation. Innov. Food Sci. Emerg. Tech. 2010, 11, 187–196. [Google Scholar] [CrossRef]

- Kanatt, S.R.; Rao, M.S.; Chawla, S.P.; Sharma, A. Effects of chitosan coating on shelf-life of ready-to-cook meat products during chilled storage. LWT Food Sci. Tech. 2013, 53, 321–326. [Google Scholar] [CrossRef]

- Stanojevic, D.; Comic, L.; Stefanovic, O.; Solujic-Sukdolak, S. In vitro synergistic antibacterial activity of Salvia officinalis and some preservatives. Arch. Biol. Sci. 2010, 62, 175–183. [Google Scholar] [CrossRef]

- Velickovic, D.T.; Randjelovic, N.V.; Ristic, M.S.; Velickovic, A.S.; Smelcerovic, A.A. Chemical constituents and antimicrobial activity of the ethanol extracts obtained from the flower, leaf and stem of Salvia officinalis L. J. Serb. Chem. Soc. 2003, 68, 17–24. [Google Scholar] [CrossRef]

- Mehdizadeh, T.; Tajik, H.; Jafarie, S.; Kaboudari, A. Effect of Salvia officinalis L. extract on chemical, microbial, sensory and shelf life of rainbow trout fillet. Food Sci. Biotechnol. 2019, 28, 1499–1506. [Google Scholar] [CrossRef] [PubMed]

- Horiuchi, K.; Shiota, S.; Hatano, T.; Yoshida, T.; Kuroda, T.; Tsuchiya, T. Antimicrobial activity of oleanolic acid from Salvia officinalis and related compounds on vancomycin-resistant enterococci (VRE). Biol. Pharm. Bull. 2007, 30, 1147–1149. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neagu, E.; Paun, G.; Radu, G.L. Chemical composition and antioxidant activity of Salvia officinalis concentrated by ultrafiltration. Rom. Biotechnol. Lett. 2019, 19, 9203–9211. [Google Scholar]

- Khalil, R.; Li, Z.G. Antimicrobial activity of essential oil of Salvia officinalis L. collected in Syria. Afr. J. Biotech. 2011, 10, 8397–8402. [Google Scholar]

- Alizadeh, A.; Shaabani, M. Essential oil composition, phenolic content, antioxidant and antimicrobial activity in Salvia officinalis L. cultivated in Iran. Adv. Environ. Biol. 2012, 6, 221–226. [Google Scholar]

- Generalic, I.; Skroza, D.; Surjak, J.; Mozina, S.S.; Ljubenkov, I.; Katalinic, A.; Simat, V.; Katalinic, V. Seasonal variations of phenolic compounds and biological properties in sage (Salvia officinalis L.). Chem. Biodivers. 2012, 9, 441–457. [Google Scholar]

- Salevic, A.; Prieto, C.; Cabedo, L.; Nedovi´c, V.; Lagaron, J.M. Physicochemical, antioxidant and antimicrobial properties of electrospun poly(ε-caprolactone) films containing a solid dispersion of sage (Salvia officinalis L.) extract. Nanomaterials 2019, 9, 270. [Google Scholar] [CrossRef] [Green Version]

- Javanmard, M. Application of edible coatings incorporated sage (Salvia officinalis) alcoholic extract for inhibition of Aspergillus flavus growth on pistachio kernel. Iran. J. Nutr. Sci. Food Technol. 2012, 9, 85–95. [Google Scholar]

- Fatma, E.K.; Ayse, A.; Caglar, K. Extraction and HPLC analysis of sage (Salvia officinalis) plant. Nat. Prod. Chem. Res. 2018, 5, 298. [Google Scholar]

- ISO 22196. International Standard, 1st ed.; Plastics—Measurement of Antibacterial Activity on Plastics Surfaces: Geneva, Switzerland, 2007. [Google Scholar]

- Chouliara, E.; Karatapanis, A.; Savvaidis, I.N.; Kontominas, M.G. Combined effect of oregano essential oil and modified atmosphere packaging on shelf-life extension of fresh chicken breast meat, stored at 4 °C. Food Microbiol. 2007, 24, 607–617. [Google Scholar] [CrossRef] [PubMed]

- Clinical and Laboratory Standards Institute. Method for Antifungal Disk Diffusion Susceptibility Testing of Nondermatophyte Filamentous Fungi; Approved Guideline; CLSI document M51-A; Clinical and Laboratory Standards Institute: Wayne, PA, USA, 2010. [Google Scholar]

- Takma, D.K.; Korel, F. Active packaging films as a carrier of black cumin essential oil: Development and effect on quality and shelf-life of chicken breast meat. Food Packag. Shelf Life 2019, 19, 210–217. [Google Scholar] [CrossRef]

- Wang, J.; Zhuang, H.; Hinton, A.; Zhang, J. Influence of in-package cold plasma treatment on microbiological shelf life and appearance of fresh chicken breast fillets. Food Microbiol. 2016, 60, 142–146. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, H.; Kamkar, A.; Misaghi, A.; Zunabovic, M.; Fatehi, S. Nanocomposite films with CMC, okra mucilage, and ZnO nanoparticles: Extending the shelf-life of chicken breast meat. Food Packag. Shelf Life 2019, 21, 100330. [Google Scholar] [CrossRef]

- Masoumi, B.; Abbasi, A.; Mazloomi, S.M. The effect of saffron on microbial, physicochemical and texture profile of chicken (breast) meat stored in refrigerator. Int. J. Nutr. Sci. 2018, 3, 164–170. [Google Scholar]

- AOAC. Official Methods of Analysis, 16th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 1995. [Google Scholar]

- Niu, X.; Liu, Y.; Song, Y.; Han, J.; Pan, H. Rosin modified cellulose nanofiber as a reinforcing and co-antimicrobial agent in polylactic acid/chitosan composite film for food packaging. Carbohydr. Polym. 2018, 183, 102–109. [Google Scholar] [CrossRef] [PubMed]

- El Astal, Z.Y.; Ashour, A.E.R.A.; Kerrit, A.A.M. Antimicrobial activity of some medicinal plant extracts in Palestine. Pak. J. Med. Sci. 2005, 21, 187–193. [Google Scholar]

- Ali, M.R.; Aboud, A.S. Antimicrobial activities of aqueous and methanolic extracts from Salvia officinalis and Salix acmophylla used in the treatment of wound infection isolates. Ibn Al-Haitham J. Pure Appl. Sci. 2010, 23, 28–38. [Google Scholar]

- Poulios, E.; Giaginis, C.; Vasios, G.K. Current state of the art on the antioxidant activity of sage (Salvia spp.) and its bioactive components. Planta Med. 2020, 86, 224–238. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cushnie, T.P.; Lamb, A.J. Antimicrobial activity of flavonoids. Int. J. Antimicrob. Agents. 2005, 26, 343–356. [Google Scholar] [CrossRef] [PubMed]

- Zhang, L.; Kong, Y.; Wu, D.; Zhang, H.; Wu, J.; Chen, J.; Ding, J.; Hu, L.; Jiang, H.; Shen, X. Three flavonoids targeting the βhydroxyacyl-acyl carrier protein dehydratase from Helicobacter pylori: Crystal structure characterization with enzymatic inhibition assay. Protein Sci. 2008, 17, 1971–1978. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Moghimi, R.; Aliahmadi, A.; McClements, D.J.; Rafati, H. Investigations of the effectiveness of nanoemulsions from sage oil as antibacterial agents on some food borne pathogens. LWT Food Sci. Technol. 2016, 71, 69–76. [Google Scholar] [CrossRef]

- Aljuraifani, A.A. Antimicrobial activity of some medicinal plants used in Saudi Arabia. Can. J. Appl. Sci. 2011, 5, 1509–1512. [Google Scholar]

- Padgett, T.; Han, I.Y.; Dawson, P.L. Incorporation of food-grade antimicrobial compounds into biodegradable packaging films. J. Food Prot. 1998, 61, 1330–1335. [Google Scholar] [CrossRef] [PubMed]

- Corrales, M.; Han, J.H.; Tauscher, B. Antimicrobial properties of grape seed extracts and their effectiveness after incorporation into pea starch films. Int. J. Food Sci. Technol. 2009, 44, 425–433. [Google Scholar] [CrossRef]

- Kim, K.W.; Min, B.J.; Kim, Y.T.; Kimmel, R.M.; Cooksey, K.; Park, S.I. Antimicrobial activity against foodborne pathogens of chitosan biopolymer films of different molecular weights. LWT Food Sci. Tech. 2011, 44, 565–569. [Google Scholar] [CrossRef]

- Higueras, L.; Lopez-Carballo, G.; Hernandez-Munoz, P.; Gavara, R.; Rollini, M. Development of a novel antimicrobial film based on chitosan with LAE (ethyl-Nα-dodecanoyl-l-arginate) and its application to fresh chicken. Int. J. Food Microbiol. 2013, 165, 339–345. [Google Scholar] [CrossRef]

- Bazargani-Gilani, B.; Aliakbarlu, J.; Tajik, H. Effect of pomegranate juice dipping and chitosan coating enriched with Zataria multiflora Boiss essential oil on the shelf-life of chicken meat during refrigerated storage. Inno. Food Sci. Emerg. Tech. 2015, 29, 280–287. [Google Scholar] [CrossRef]

- Swanson, K.; Buchanan, R.; Cole, M.; Cordier, J.L.; Flowers, R.; Gorris, L.; Taniwaki, M.; Tompkin, R.; Zwietering, M. Microorganisms in Foods 8: Use of Data for Assessing Process Control and Product Acceptance; Springer Science: Berlin/Heidelberg, Germany, 2011. [Google Scholar]

- Katiyo, W.; Kock, H.L.; Coorey, R.; Buys, E.M. Sensory implications of chicken meat spoilage in relation to microbial and physicochemical characteristics during refrigerated storage. LWT Food Sci. Tech. 2020, 128, 109468. [Google Scholar] [CrossRef]

- Demirhan, B.; Candogan, K. Active packaging of chicken meats with modified atmosphere including oxygen scavengers. Poult. Sci. 2017, 96, 1394–1401. [Google Scholar] [CrossRef]

- Karimnezhad, F.; Razavilar, V.; Anvar, A.A.; Eskandari, S. Study the antimicrobial effects of chitosan-based edible film containing the Trachyspermum ammi essential oil on shelf-life of chicken meat. Microbiol. Res. 2017, 8, 84–87. [Google Scholar] [CrossRef] [Green Version]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Morris, M.A.; Cummins, E.; Kerry, J.P. Effects of a combination of antimicrobial silver low density polyethylene nanocomposite films and modified atmosphere packaging on the shelf life of chicken breast fillets. Food Packag. Shelf Life 2015, 4, 26–35. [Google Scholar] [CrossRef]

- Ripoche, A.C.; Chollet, E.; Peyrol, E.; Sebti, I. Evaluation of nisin diffusion in a polysaccharide gel: Influence of agarose and fatty content. Innov. Food Sci. Emerg. Technol. 2006, 7, 107–111. [Google Scholar] [CrossRef]

- Diblan, S.; Kaya, S. Antimicrobials used in active packaging films. Food Health 2018, 4, 63–79. [Google Scholar] [CrossRef]

- Corrales, M.; Fernandez, A.; Han, J.H. Antimicrobial packaging systems. In Innovations in Food Packaging, 2nd ed.; Han., J.H., Ed.; Elsevier: Cambridge, MA, USA, 2013; pp. 133–170. [Google Scholar]

- Shen, S.; Jiang, Y.; Liu, X.; Luo, Y.; Gao, L. Quality assessment of rainbow trout (Oncorhynchus mykiss) fillets during super chilling and chilled storage. J. Food Sci. Tech. 2015, 52, 5204–5211. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Azlin-Hasim, S.; Cruz-Romero, M.C.; Morris, M.A.; Padmanabhan, S.C.; Cummins, E.; Kerry, J.P. The potential application of antimicrobial silver polyvinyl chloride nanocomposite films to extend the shelf-life of chicken breast fillets. Food Bioproc. Tech. 2016, 9, 1661–1673. [Google Scholar] [CrossRef]

- Jouki, M.; Khazaei, N. Lipid oxidation and color changes of fresh camel meat stored under different atmosphere packaging systems. J. Food Process. Tech. 2012, 3, 1000189. [Google Scholar]

- Saucier, L.; Gendron, C.; Gariepy, C. Shelf life of ground poultry meat stored under modified atmosphere. Poult. Sci. 2000, 79, 1851–1856. [Google Scholar] [CrossRef]

- Badee, A.Z.M.; Moawad, R.K.; EINoketi, M.M.; Gouda, M.M. Improving the quality and shelf-life of refrigerated chicken meat by marjoram essential oil. J. Appl. Sci. Res. 2013, 9, 5718–5729. [Google Scholar]

- Lee, Y.S.; Saha, A.; Xiong, R.; Owens, C.M.; Meullenet, J.F. Changes in broiler breast fillet tenderness, water-holding capacity, and color attributes during long-term frozen storage. J. Food Sci. 2008, 73, E162–E168. [Google Scholar] [CrossRef] [PubMed]

- Mir, N.A.; Rafiq, A.; Kumar, F.; Singh, V.; Shukla, V. Determinants of broiler chicken meat quality and factors affecting them: A Review. J. Food Sci. Tech. 2017, 54, 2997–3009. [Google Scholar] [CrossRef] [PubMed]

- Cheng, Q.; Sun, D.W. Factors affecting the water holding capacity of red meat products: A review of recent research advances. Crit. Rev. Food Sci. Nutr. 2008, 48, 137–159. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Wu, J.; Guo, X. Effects of antimicrobial and antioxidant activities of spice extracts on raw chicken meat quality. Food Sci. Hum. Wellness 2016, 5, 39–48. [Google Scholar] [CrossRef] [Green Version]

- Koohmaraie, M.; Kent, M.P.; Shackelford, S.D.; Veiseth, E.; Tommy, L.; Wheeler, T.L. Meat tenderness and muscle growth: Is there any relationship? Meat Sci. 2002, 62, 345–352. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Ghoshal, G.; Goyal, M. Biodegradable composite films/coatings of modified corn starch/gelatin for shelf life improvement of cucumber. J. Food Sci. Tech. 2020, 58, 1227–1237. [Google Scholar] [CrossRef] [PubMed]

- Dave, D.; Ghaly, A.E. Meat spoilage mechanisms and preservation techniques: A critical review. Am. J. Agric. Biol. Sci. 2011, 6, 486–510. [Google Scholar]

- Salem, F.M.; Ibrahim, H.M. Dry fermented buffalo sausage with sage oil extract: Safety and quality. Grasas Y Aceites 2010, 61, 76–85. [Google Scholar]

- Abandansarie, S.S.R.; Ariaii, P.; Langerodi, M.C. Effects of encapsulated rosemary extract on oxidative and microbiological stability of beef meat during refrigerated storage. Food Sci. Nutr. 2019, 7, 3969–3978. [Google Scholar] [CrossRef] [PubMed]

| The Basic Properties of Formulated Coatings (Adhesives) | |||

|---|---|---|---|

| Grade | Total Solids Content (%) | Sage Solids Content (%) | Viscosity (mPa.s @ Brookfield RV, sp1, 50 rpm, 20 °C) |

| 2379L/220 | 32.31 | 2.5 | 195 |

| 2379L/221 | 32.55 | 2.5 | 360 |

| Six Formulations of Coated Films | |

|---|---|

| No | Film Code |

| 1 | Film 1—2379L/220 coated at 6 g/m2 wet on 12 µm PET |

| 2 | Film 2—2379L/220 coated at 6 g/m2 wet on 35 µm Biopolymer TP302 |

| 3 | Film 3—2379L/221 coated at 6 g/m2 wet on 52 µm HCFD2 compostable laminate |

| 4 | Film 4—2379L/221 coated at 6 g/m2 wet on 12 µm PET |

| 5 | Film 5—2379L/221 coated at 6 g/m2 wet on 35 µm Biopolymer TP302 |

| 6 | Film 6—2379L/221 coated at 6 g/m2 wet on 23 µm Natureflex NVR |

| Property | Sample | Day | |||

|---|---|---|---|---|---|

| 1 | 3 | 5 | 7 | ||

| Weight loss (%) | Control | 3.69 ± 0.03 Ad | 5.09 ± 0.04 Ac | 5.55 ± 0.04 Ab | 6.83 ± 0.02 Aa |

| Film 1 | 3.16 ± 0.02 Ed | 4.63 ± 0.02 Cc | 5.25 ± 0.02 CDb | 6.34 ± 0.02 Da | |

| Film 2 | 3.23 ± 0.02 Dd | 4.49 ± 0.03 Dc | 5.11 ± 0.03 Eb | 6.19 ± 0.04 Ea | |

| Film 3 | 3.43 ± 0.02 Bd | 4.59 ± 0.04 Cc | 5.21 ± 0.03 Db | 6.55 ± 0.02 Ca | |

| Film 4 | 3.43 ± 0.02 BCd | 3.75 ± 0.02 Bc | 5.40 ± 0.03 Bb | 6.63 ± 0.02 Ba | |

| Film 5 | 3.37 ± 0.03 Cd | 4.43 ± 0.02 Dc | 5.28 ± 0.04 CDb | 6.55 ± 0.02 Ca | |

| Film 6 | 3.25 ± 0.01 Dd | 4.65 ± 0.02 Cc | 5.30 ± 0.02 Cb | 6.40 ± 0.02 Da | |

| Hardness (N) | Control | 123.55 ± 0.01 Ad | 130.14 ± 0.27 Ac | 138.68 ± 0.14 Ab | 144.02 ± 0.14 Aa |

| Film 1 | 119.58 ± 0.05 Ed | 122.25 ± 0.08 Ec | 130.59 ± 0.05 Eb | 140.42 ± 0.11 Da | |

| Film 2 | 118.80 ± 0.05 Fd | 121.41 ± 0.05 Fc | 130.22 ± 0.03 Fb | 137.69 ± 0.04 Ea | |

| Film 3 | 120.91 ± 0.06 Cd | 125.79 ± 0.04 Cc | 133.49 ± 0.07 Cb | 141.50 ± 0.07 Ca | |

| Film 4 | 121.38 ± 0.04 Bd | 125.88 ± 0.04 BCc | 133.97 ± 0.10 Bb | 142.51 ± 0.07 Ba | |

| Film 5 | 121.00 ± 0.16 Cd | 126.19 ± 0.05 Bc | 134.11 ± 0.05 Bb | 142.43 ± 0.06 Ba | |

| Film 6 | 120.23 ± 0.04 Dd | 122.72 ± 0.05 Dc | 132.43 ± 0.03 Db | 140.64 ± 0.15 Da | |

| pH | Control | 6.22 ± 0.07 Ad | 6.40 ± 0.05 Ac | 6.81 ± 0.06 Ab | 7.09 ± 0.03 Aa |

| Film 1 | 6.21 ± 0.02 Ad | 6.28 ± 0.02 BCc | 6.50 ± 0.04 Cb | 6.75 ± 0.02 Ca | |

| Film 2 | 6.22 ± 0.02 Ad | 6.33 ± 0.02 Bc | 6.45 ± 0.03 Cb | 6.72 ± 0.02 Ca | |

| Film 3 | 6.28 ± 0.02 Ad | 6.34 ± 0.02 ABc | 6.53 ± 0.03 BCb | 6.83 ± 0.02 Ba | |

| Film 4 | 6.24 ± 0.01 Ad | 6.35 ± 0.02 ABc | 6.63 ± 0.03 Bb | 6.86 ± 0.02 Ba | |

| Film 5 | 6.20 ± 0.02 Ac | 6.26 ± 0.02 Cc | 6.50 ± 0.04 Cb | 6.76 ± 0.02 Ca | |

| Film 6 | 6.25 ± 0.02 Ac | 6.31 ± 0.02 BCc | 6.52 ± 0.04 BCd | 6.85 ± 0.02 Ba | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aziman, N.; Jawaid, M.; Mutalib, N.A.A.; Yusof, N.L.; Nadrah, A.H.; Nazatul, U.K.; Tverezovskiy, V.V.; Tverezovskaya, O.A.; Fouad, H.; Braganca, R.M.; et al. Antimicrobial Potential of Plastic Films Incorporated with Sage Extract on Chicken Meat. Foods 2021, 10, 2812. https://doi.org/10.3390/foods10112812

Aziman N, Jawaid M, Mutalib NAA, Yusof NL, Nadrah AH, Nazatul UK, Tverezovskiy VV, Tverezovskaya OA, Fouad H, Braganca RM, et al. Antimicrobial Potential of Plastic Films Incorporated with Sage Extract on Chicken Meat. Foods. 2021; 10(11):2812. https://doi.org/10.3390/foods10112812

Chicago/Turabian StyleAziman, N., M. Jawaid, N. A. Abdul Mutalib, N. L. Yusof, A. H. Nadrah, U. K. Nazatul, V. V. Tverezovskiy, O. A. Tverezovskaya, H. Fouad, R. M. Braganca, and et al. 2021. "Antimicrobial Potential of Plastic Films Incorporated with Sage Extract on Chicken Meat" Foods 10, no. 11: 2812. https://doi.org/10.3390/foods10112812

APA StyleAziman, N., Jawaid, M., Mutalib, N. A. A., Yusof, N. L., Nadrah, A. H., Nazatul, U. K., Tverezovskiy, V. V., Tverezovskaya, O. A., Fouad, H., Braganca, R. M., Baker, P. W., Selbie, S., & Ali, A. (2021). Antimicrobial Potential of Plastic Films Incorporated with Sage Extract on Chicken Meat. Foods, 10(11), 2812. https://doi.org/10.3390/foods10112812