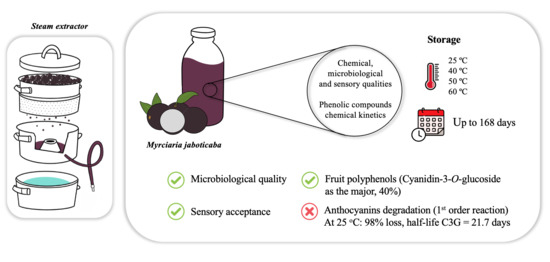

Chemical, Microbiological and Sensory Stability of Steam Extracted Jaboticaba (Myrciaria jaboticaba) Juice

Abstract

:1. Introduction

2. Materials and Methods

2.1. Standards and Chemicals

2.2. Jaboticaba Juice Processing and Storage

2.3. Sugar Analysis by HPLC-ELSD

2.4. Organic Acids Analysis by HPLC-DAD

2.5. Phenolic Compounds Analysis by HPLC-DAD-MS

2.6. Instrumental Color

2.7. Kinetics of Degradation and Formation of Phenolic Compounds

2.8. Microbiological Analyses

2.9. Sensory Analysis

2.10. Statistical Analysis

3. Results and Discussion

3.1. Sugars, Organic Acids and Phenolic Compounds Profiles and Sensory Acceptance of Steam Extracted Jaboticaba Juice

3.2. Sugars and Organic Acid Stabilities, Phenolic Compounds Degradation and Instrumental Color Modification during Storage of Unsweetened Jaboticaba Juice

3.3. Sensory Acceptance and Microbiological Quality of Sweetened and Unsweetened Jaboticaba Juices after Six Months of Storage

3.4. Degradation and Formation of Phenolic Compounds of Jaboticaba Juice during Storage

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Danner, M.A.; Citadin, I.; Fernanes Junior, A.d.A.; Assmann, A.P.; Mazaro, S.M.; Sasso, S.A.Z. Formação de mudas de jabuticabeira (Plinia sp.) em diferentes substrates e tamanhos de recipients. Rev. Bras. Frutic. 2007, 29, 179–182. [Google Scholar] [CrossRef] [Green Version]

- Inada, K.O.P.; Oliveira, A.A.; Revorêdo, T.B.; Martins, A.B.N.; Lacerda, E.C.Q.; Freire, A.S.; Braz, B.F.; Santelli, R.E.; Torres, A.G.; Perrone, D.; et al. Screening of the chemical composition and occurring antioxidants in jabuticaba (Myrciaria jaboticaba) and jussara (Euterpe edulis) fruits and their fractions. J. Funct. Foods 2015, 17, 422–433. [Google Scholar] [CrossRef] [Green Version]

- Inada, K.O.P.; Duarte, P.A.; Lapa, J.; Miguel, M.A.L.; Monteiro, M. Jabuticaba (Myrciaria jaboticaba) juice obtained by steam-extraction: Phenolic compound profile, antioxidant capacity, microbiological stability, and sensory acceptability. J. Food Sci. Technol. 2018, 55, 52–61. [Google Scholar] [CrossRef] [PubMed]

- Inada, K.O.P.; Torres, A.G.; Perrone, D.; Monteiro, M. High hydrostatic pressure processing affects the phenolic profile, preserves sensory attributes and ensures microbial quality of jabuticaba (Myrciaria jaboticaba) juice. J. Sci. Food Agric. 2018, 98, 231–239. [Google Scholar] [CrossRef] [PubMed]

- Duarte, W.F.; Dias, D.R.; Oliveira, J.M.; Teixeira, J.A.; de Almeida e Silva, J.B.; Schwan, R.F. Characterization of different fruit wines made from cacao, cupuassu, gabiroba, jaboticaba and umbu. LWT Food Sci. Technol. 2010, 43, 1564–1572. [Google Scholar] [CrossRef]

- Duarte, W.F.; Amorim, J.C.; Lago, L.d.A.; Dias, D.R.; Schwan, R.F. Optimization of fermentation conditions for production of the jabuticaba (Myrciaria cauliflora) spirit using the response surface methodology. J. Food Sci. 2011, 76, 782–790. [Google Scholar] [CrossRef]

- Leonarski, E.; dos Santos, D.F.; Kuasnei, M.; Lenhani, G.C.; Quast, L.B.; Pinto, V.Z. Development, chemical, and sensory characterization of liqueurs from Brazilian native fruits. J. Culin. Sci. Technol. 2020, 1–14. [Google Scholar] [CrossRef]

- Dias, D.R.; Silva, M.S.; de Souza, A.C.; Magalhães-Guedes, K.T.; Ribeiro, F.S.d.R.; Schwan, R.F. Vinegar production from jabuticaba fruits (Myrciaria jaboticaba) using immobilized acetic acid bacteria. Food Technol. Biotechnol. 2016, 54, 351–359. [Google Scholar] [CrossRef]

- Priyadarshini, A.; Priyadarshini, A. Market dimensions of the fruit juice industry. In Fruit Juices: Extraction, Composition, Quality and Analysis, 1st ed.; Rajauria, G., Tiwari, B.K., Eds.; Academic Press: London, UK, 2018; pp. 15–32. ISBN 978-0-12-802230-6. [Google Scholar]

- Bates, R.P.; Morris, J.R.; Crandall, P.G. General juice manufacture principles. In Principles and Practices of Small- and Medium-Scale Fruit Juice Processing; Food and Agricultural Organization: Rome, Italy, 2001; pp. 37–58. ISBN 92-5-104661-1. [Google Scholar]

- Lopes, M.L.M.; Miguel, M.A.L.; Fialho, E.; Valente-Mesquita, V.L. Grape juice obtained using steam extraction and other small-scale extraction methods: Phenolic content, antioxidant capacity and stability during storage. Int. J. Food Sci. Technol. 2016, 51, 1696–1702. [Google Scholar] [CrossRef]

- Hellström, J.; Mattila, P.; Karjalainen, R. Stability of anthocyanins in berry juices stored at different temperatures. J. Food Compos. Anal. 2013, 31, 12–19. [Google Scholar] [CrossRef]

- Ma, C.; Sun, Z.; Chen, C.; Zhang, L.; Zhu, S. Simultaneous separation and determination of fructose, sorbitol, glucose and sucrose in fruits by HPLC-ELSD. Food Chem. 2014, 145, 784–788. [Google Scholar] [CrossRef]

- Scherer, R.; Rybka, A.C.P.; Ballus, C.A.; Meinhart, A.D.; Teixeira Filho, J.; Godoy, H.T. Validation of a HPLC method for simultaneous determination of main organic acids in fruits and juices. Food Chem. 2012, 135, 150–154. [Google Scholar] [CrossRef] [Green Version]

- Van Boekel, M.A.J.S. Kinetic modeling of food quality: A critical review. Compr. Rev. Food Sci. Food Saf. 2008, 7, 144–158. [Google Scholar] [CrossRef]

- Downes, F.P.; Ito, K. Compendium of Methods for the Microbiological Examination of Foods, 4th ed.; American Public Health Association: Washington, DC, USA, 2001; ISBN 978-0875531755. [Google Scholar]

- Geraldi, M.V.; Cazarin, C.B.B.; Dias-Audibert, F.L.; Pereira, G.A.; Carvalho, G.G.; Kabuki, D.Y.; Catharino, R.R.; Pastore, G.M.; Behrens, J.H.; Cristianini, M.; et al. Influence of high isostatic pressure and thermal pasteurization on chemical composition, color, antioxidant properties and sensory evaluation of jabuticaba juice. LWT Food Sci. Technol. 2021, 139, 110548. [Google Scholar] [CrossRef]

- Pereira, L.D.; Barbosa, J.M.G.; da Silva, A.J.R.; Ferri, P.H.; Santos, S.C. Polyphenol and ellagitannin constituents of jabuticaba (Myrciaria cauliflora) and chemical variability at different stages of fruit development. J. Agric. Food Chem. 2017, 65, 1209–1219. [Google Scholar] [CrossRef] [PubMed]

- Suemitsu, L.; Inada, K.O.P.; Fernandes, P.d.O.; Perrone, D.; Monteiro, M.; Melo, L. Development, sensory profile and physicochemical properties of jabuticaba nectar with lyophilized jussara pulp. Rev. Ciência Agronômica 2020, 51, e20196633. [Google Scholar] [CrossRef]

- Laaksonen, O.; Mäkilä, L.; Tahvonen, R.; Kallio, H.; Yang, B. Sensory quality and compositional characteristics of blackcurrant juices produced by different processes. Food Chem. 2013, 138, 2421–2429. [Google Scholar] [CrossRef]

- Drewnowski, A.; Mennella, J.A.; Johnson, S.L.; Bellisle, F. Sweetness and food preference. J. Nutr. 2012, 142, 1142–1148. [Google Scholar] [CrossRef] [Green Version]

- Cavalcanti, R.N.; Santos, D.T.; Meireles, M.A.A. Non-thermal stabilization mechanisms of anthocyanins in model and food systems—An overview. Food Res. Int. 2011, 44, 499–509. [Google Scholar] [CrossRef]

- Inada, K.O.P.; Nunes, S.; Martínez-Blázquez, J.A.; Tomás-Barberán, F.A.; Perrone, D.; Monteiro, M. Effect of high hydrostatic pressure and drying methods on phenolic compounds profile of jabuticaba (Myrciaria jaboticaba) peel and seed. Food Chem. 2020, 309, 125794. [Google Scholar] [CrossRef]

- Quatrin, A.; Pauletto, R.; Maurer, L.H.; Minuzzi, N.; Nichelle, S.M.; Carvalho, J.F.C.; Maróstica Junior, M.R.; Rodrigues, E.; Bochi, V.C.; Emanuelli, T. Characterization and quantification of tannins, flavonols, anthocyanins and matrix-bound polyphenols from jaboticaba fruit peel: A comparison between Myrciaria trunciflora and M. jaboticaba. J. Food Compos. Anal. 2019, 78, 59–74. [Google Scholar] [CrossRef]

- Obón, J.M.; Castellar, M.R.; Alacid, M.; Fernández-López, J.A. Production of a red–purple food colorant from Opuntia stricta fruits by spray drying and its application in food model systems. J. Food Eng. 2009, 90, 471–479. [Google Scholar] [CrossRef]

- Qian, B.-J.; Liu, J.-H.; Zhao, S.-J.; Cai, J.-X.; Jing, P. The effects of gallic/ferulic/caffeic acids on colour intensification and anthocyanin stability. Food Chem. 2017, 228, 526–532. [Google Scholar] [CrossRef]

- Peron, D.V.; Fraga, S.; Antelo, F. Thermal degradation kinetics of anthocyanins extracted from juçara (Euterpe edulis Martius) and “Italia” grapes (Vitis vinifera L.), and the effect of heating on the antioxidant capacity. Food Chem. 2017, 232, 836–840. [Google Scholar] [CrossRef]

- Sinela, A.; Rawat, N.; Mertz, C.; Achir, N.; Fulcrand, H.; Dornier, M. Anthocyanins degradation during storage of Hibiscus sabdariffa extract and evolution of its degradation products. Food Chem. 2017, 214, 234–241. [Google Scholar] [CrossRef]

- Hrazdina, G.; Borzell, A.J.; Robinson, W.B. Studies on the stability of the anthocyanidin-3,5-digucosides. Am. J. Enol. Vitic. 1970, 21, 201–204. [Google Scholar]

- Kirca, A.; Özkan, M.; Cemeroǧlu, B. Effects of temperature, solid content and pH on the stability of black carrot anthocyanins. Food Chem. 2007, 101, 212–218. [Google Scholar] [CrossRef]

- González, M.J.; Torres, J.L.; Medina, I. Impact of thermal processing on the activity of gallotannins and condensed tannins from Hamamelis virginiana used as functional ingredients in seafood. J. Agric. Food Chem. 2010, 58, 4274–4283. [Google Scholar] [CrossRef]

- Cabrita, L.; Petrov, V.; Pina, F. On the thermal degradation of anthocyanidins: Cyanidin. RSC Adv. 2014, 4, 18939–18944. [Google Scholar] [CrossRef]

- Hager, T.J.; Howard, L.R.; Prior, R.L. Processing and storage effects on the ellagitannin composition of processed blackberry products. J. Agric. Food Chem. 2010, 58, 11749–11754. [Google Scholar] [CrossRef]

| Storage Time (Days) | |||

|---|---|---|---|

| 0 | 56 | 112 | |

| Fructose (g/100 mL) | 1.79 ± 0.11 | 1.74 ± 0.08 | 1.80 ± 0.09 |

| Glucose (g/100 mL) | 1.10 ± 0.11 | 1.02 ± 0.05 | 1.15 ± 0.07 |

| Sucrose (g/100 mL) | 0.2017 ± 0.0344 | 0.1732 ± 0.005 | 0.1267 ± 0.0001 * |

| Total sugars (g/100 mL) | 3.09 ± 0.13 | 2.93 ± 0.09 | 3.08 ± 0.15 |

| Oxalic acid (mg/100 mL) | 22.30 ± 2.43 | 22.49 ± 2.54 | 23.00 ± 2.32 |

| Tartaric acid (mg/100 mL) | 20.87 ± 0.62 | 19.98 ± 0.73 | 17.94 ± 0.64 * |

| Malic acid (mg/100 mL) | 92.53 ± 7.22 | 93.31 ± 3.80 | 93.76 ± 4.78 |

| Citric acid (g/100 mL) | 1.31 ± 0.07 | 1.32 ± 0.05 | 1.39 ± 0.04 |

| Total organic acids (g/100 mL) | 1.44 ± 0.08 | 1.46 ± 0.05 | 1.53 ± 0.04 |

| Phenolic Compound | Unsweetened | Sweetened |

|---|---|---|

| Cyanidin-3-O-glucoside | 8.06 ± 0.15 | 7.91 ± 0.43 |

| Delphinidin-3-O-glucoside | 1.13 ± 0.03 | 1.10 ±0.06 |

| Gallic acid | 5.59 ± 0.61 | 5.24 ± 0.13 |

| Myricetin-3-O-rhamnoside | 0.48 ± 0.10 | 0.51 ± 0.03 |

| Quercetin-3-O-rutinoside | 0.71 ± 0.07 | 0.60 ± 0.01 |

| Ellagic acid | 3.91 ± 0.26 | 3.40 ± 0.12 * |

| Quercetin | traces | traces |

| Trans-cinnamic acid | 0.132 ± 0.025 | 0.115 ± 0.003 |

| Total | 20.03 ± 1.13 | 18.89 ± 0.44 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Martins, A.B.N.; Canto, M.; Perrone, D.; Monteiro, M. Chemical, Microbiological and Sensory Stability of Steam Extracted Jaboticaba (Myrciaria jaboticaba) Juice. Foods 2021, 10, 732. https://doi.org/10.3390/foods10040732

Martins ABN, Canto M, Perrone D, Monteiro M. Chemical, Microbiological and Sensory Stability of Steam Extracted Jaboticaba (Myrciaria jaboticaba) Juice. Foods. 2021; 10(4):732. https://doi.org/10.3390/foods10040732

Chicago/Turabian StyleMartins, Ana Beatriz Neves, Mariana Canto, Daniel Perrone, and Mariana Monteiro. 2021. "Chemical, Microbiological and Sensory Stability of Steam Extracted Jaboticaba (Myrciaria jaboticaba) Juice" Foods 10, no. 4: 732. https://doi.org/10.3390/foods10040732

APA StyleMartins, A. B. N., Canto, M., Perrone, D., & Monteiro, M. (2021). Chemical, Microbiological and Sensory Stability of Steam Extracted Jaboticaba (Myrciaria jaboticaba) Juice. Foods, 10(4), 732. https://doi.org/10.3390/foods10040732