Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Used

2.2. Preparation of Composite Flours

2.3. Mixolab Measurements

2.4. Rheofermentometer Analysis

2.5. Bread-Making Procedure

2.6. Physical Characteristics of Bread

2.7. Sensory Evaluation

2.8. Color of the Breads

2.9. Statistical Analysis

3. Results and Discussion

3.1. Dough Properties

3.1.1. Dough Mixing and Pasting Properties Measured by a Mixolab

3.1.2. Rheofermentometer Evaluation

3.2. Bread Evaluation

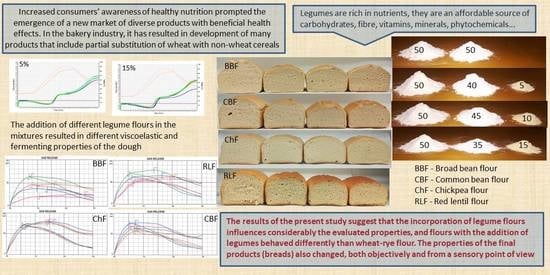

4. Conclusions

- -

- water absorption significantly increased with the addition of common bean flour (CBF) and broad bean flour (BBF), and an addition of red lentil flour (RLF) and chickpea flour (ChF) slightly reduced the binding of the composite flour; none of the additives (legume flours), replacing the proportion of rye flour (RF) in composite flours, had a potentiating effect on the stability of the dough;

- -

- the mixolab curve can distinguish different stages pertaining to the dough changes due to both the mixing force and the temperature, and the results showed a weakening of the protein network depending on the amount of legume flour added and on the specific legume flour. In terms of the interaction of mechanical processing and thermal procedure, the most stable (at the level of the control wheat–rye flour) was flour with the addition of CBF, in all applied proportions of this addition;

- -

- the addition of legume flours mainly influenced the dough behavior during the cooling phase, and in all samples with a higher proportion of legume flour there was an increase in resistance to starch retrogradation. From the evaluated samples, the additions of CBF had the biggest impact on increasing the resistance to retrogradation;

- -

- in comparison with the control flour, significant differences were found in the values of the slopes alpha, beta and gamma depending on the added legume flour and the amount of its addition. BBF addition most significantly affected the observed properties;

- -

- determining the ability to form fermenting gases is crucial in order to produce bread with a good volume, and the doughs with an addition of BBF clearly had the worst course of the rheofermentometer curves. The other three examined flour mixtures showed similar properties and overall the additives, with the exception of BBF, can be assessed as potentially suitable and applicable in bakery technology on the basis of the results of this analysis;

- -

- the bread volume depends on the dough expansion during fermentation and baking, and the ability of the matrix to stabilize the retained gas. In all our samples with additions of legume flour, the bread volume was significantly lower compared to wheat–rye breads. RLF proved to be the most suitable legume flour in terms of bread volume, even with the highest selected addition of 15%. The least suitable legume flour was BBF, in all additions;

- -

- the sensory evaluation confirmed that the addition of legume flour of 5% gives breads rated approximately the same or even better than the control bread; higher additions (15%) add extra typical legume flavors and aromas to breads, which have been assessed less positively, especially in the case of BBF;

- -

- the effect of individual additions on crust and crumb color was significant, which was also confirmed by the E-eye color spectrum; breads with the addition of ChF, CBF and BBF had a considerable proportion of darker colors compared to the control bread and bread with RLF.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bread: A Nutrition Staple. EUFIC. Available online: https://www.eufic.org/en/healthy-living/article/bread-a-nutritious-staple#:~:text=Bread%20has%20been%20part%20of,nutrients%2C%20dietary%20fibre%20and%20phytochemicals (accessed on 9 December 2014).

- Valavanidis, A. Bread, Oldest Man-made Staple Food in Human Diet Bread Intake Is Integral to Good Health and Whole Grain Cereals Beneficial against Chronic Diseases. Available online: www.chem-tox-ecotox.org/ScientificReviews (accessed on 15 November 2018).

- Dewettinck, K.; Van Bockstaele, F.; Kühne, B.; Van de Walle, D.; Courtens, T.; Gellynck, X. Nutritional value of bread: Influence of processing, food interaction and consumer perception. J. Cereal Sci. 2008, 48, 243–257. [Google Scholar] [CrossRef]

- Sabanis, D.; Tzia, C. Effect of Rice, Corn and Soy Flour Addition on Characteristics of Bread Produced from Different Wheat Cultivars. Food Bioprocess Technol. 2009, 2, 68–79. [Google Scholar] [CrossRef]

- Ocieczek, A.; Kostek, R. Sorptive properties of type 2000 wheat and rye flours. Acta Agrophys. 2009, 14, 393–402. [Google Scholar]

- Voicu, G.; Constantin, G.; Stefan, E.M.; Ipate, G. Variation of farinographic parameters of doughs obtained from wheat and rye flour mixtures during kneading. UPB Sci. Bull. Ser. D Mech. Eng. 2012, 74, 307–320. [Google Scholar]

- Stępniewska, S.; Hassoon, W.H.; Szafrańska, A.; Cacak-Pietrzak, G.; Dziki, D. Procedures for Breadmaking Quality Assessment of Rye Wholemeal Flour. Foods 2019, 8, 331. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Almeida, E.L.; Kil Chang, Y.; Steel, C.J. Dietary fibre sources in bread: Influence on technological quality. LWT Food Sci. Technol. 2013, 50, 545–553. [Google Scholar] [CrossRef] [Green Version]

- Tebben, L.; Shen, Y.; Li, Y. Improvers and functional ingredients in whole wheat bread: A review of their effects on dough properties and bread quality. Trends Food Sci. Technol. 2018, 81, 10–24. [Google Scholar] [CrossRef]

- Torbica, A.; Belović, M.; Tomić, J. Novel breads of non-wheat flours. Food Chem. 2019, 282, 134–140. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations. Pulses Nutritious Seeds for A Sustainable Future; Food and Agriculture Organization of the United Nations: Rome, Italy, 2016; p. 176. ISBN 978-92-5-109172-2. [Google Scholar]

- Fan, G.; Beta, T. Proximate Composition, Phenolic Profiles and Antioxidant Capacity of Three Common Bean Varieties (Phaseolus vulgaris L.). J. Food Chem. Nanotechnol. 2016, 2, 147–152. [Google Scholar] [CrossRef]

- Erbersdobler, H.F.; Barth, C.A.; Jahreis, G. Legumes in human nutrition. Nutrient content and protein quality of pulses. Ernahrungs Umschau 2017, 64, 140–144. [Google Scholar] [CrossRef]

- Turfani, V.; Narducci, V.; Durazzo, A.; Galli, V.; Carcea, M. Technological, nutritional and functional properties of wheat bread enriched with lentil or carob flours. LWT Food Sci. Technol. 2017, 78, 361–366. [Google Scholar] [CrossRef]

- Margier, M.; Georgé, S.; Hafnaoui, N.; Remond, D.; Nowicki, M.; Du Chaffaut, L.; Amiot, M.-J.; Reboul, E. Nutritional Composition and Bioactive Content of Legumes: Characterization of Pulses Frequently Consumed in France and Effect of the Cooking Method. Nutrients 2018, 10, 1668. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kumar, S.; Pandey, G. Biofortification of pulses and legumes to enhance nutrition. Heliyon 2020, 6, e03682. [Google Scholar] [CrossRef] [PubMed]

- Sońta, M.; Rekiel, A. Legumes—Use for nutritional and feeding purposes. J. Elementol. 2019, 25, 835–849. [Google Scholar] [CrossRef]

- Tirdiľova, I.; Vollmannova, A.; Siekel, P.; Zetochova, E.; Čeryova, S.; Trebichalsky, P. Selected legumes as a source of valuable substances in human nutrition. J. Food Nutr. Res. 2020, 59, 193–201. [Google Scholar]

- Boukid, F.; Zannini, E.; Carini, E.; Vittadini, E. Pulses for bread fortification: A necessity or a choice? Trends Food Sci. Technol. 2019, 88, 416–428. [Google Scholar] [CrossRef]

- Bresciani, A.; Marti, A. Using Pulses in Baked Products: Lights, Shadows, and Potential Solutions. Foods 2019, 8, 451. [Google Scholar] [CrossRef] [Green Version]

- Wyrwisz, M.K.J. The Application of Dietary Fiber in Bread Products. J. Food Process. Technol. 2015, 6, 447. [Google Scholar] [CrossRef]

- Fendri, L.B.; Chaari, F.; Maaloul, M.; Kallel, F.; Abdelkafi, L.; Chaabouni, S.E.; Ghribi-Aydi, D. Wheat bread enrichment by pea and broad bean pods fibers: Effect on dough rheology and bread quality. LWT Food Sci. Technol. 2016, 73, 584–591. [Google Scholar] [CrossRef]

- Edwards, C.H.; Ryden, P.; Pinto, A.M.; Van Der Schoot, A.; Stocchi, C.; Perez-Moral, N.; Butterworth, P.J.; Bajka, B.; Berry, S.E.; Hill, S.E.; et al. Chemical, physical and glycaemic characterisation of PulseON®: A novel legume cell-powder ingredient for use in the design of functional foods. J. Funct. Foods 2020, 68, 103918. [Google Scholar] [CrossRef]

- Coda, R.; Varis, J.; Verni, M.; Rizzello, C.G.; Katina, K. Improvement of the protein quality of wheat bread through faba bean sourdough addition. LWT Food Sci. Technol. 2017, 82, 296–302. [Google Scholar] [CrossRef] [Green Version]

- Bojňanská, T.; Frančáková, H.; Líšková, M.; Tokár, M. Legumes—The alternative raw materials for bread production. J. Microbiol. Biotechnol. Food Sci. 2012, 1, 876–886. [Google Scholar]

- Švec, I.; Hrušková, M. The Mixolab parameters of composite wheat/hemp flour and their relation to quality features. LWT Food Sci. Technol. 2015, 60, 623–629. [Google Scholar] [CrossRef]

- Banu, I.; Stanojeska, I.; Stoenesci, G.; Ionescu, V.; Aprodu, I. Estimation of the baking quality of wheat flours based on rheological parameters of the mixolab curve. Czech J. Food Sci. 2011, 29, 35–44. [Google Scholar] [CrossRef] [Green Version]

- Schmiele, M.; Felisberto, M.H.F.; Clerici, M.T.P.S.; Kil Chang, Y. Mixolab™ for rheological evaluation of wheat flour partially replaced by soy protein hydrolysate and fructooligosaccharides for bread production. LWT Food Sci. Technol. 2017, 76, 259–269. [Google Scholar] [CrossRef]

- Gao, J.; Tay, S.L.; Koh, A.H.S.; Zhou, W. Dough and bread made from high- and low-protein flours by vacuum mixing: Part 2. Yeast activity, dough proofing and bread quality. J. Cereal Sci. 2017, 77, 275–283. [Google Scholar] [CrossRef]

- Bojňanská, T.; Šmitalová, J. The influence of additional fluors on the retention ability of dough and the technological quality of bakery products. Potravin. Slovak J. Food Sci. 2015, 9, 242–246. [Google Scholar] [CrossRef] [Green Version]

- Rosell, C.M.; Collar, C.; Haros, M. Assessment of hydrocolloid effects on the thermo-mechanical properties of wheat using the Mixolab. Food Hydrocoll. 2007, 21, 452–462. [Google Scholar] [CrossRef]

- ICC. Standard Methods of the International Association for Cereal Chemistry 173; International Association for Cereal Science and Technology: Vienna, Austria, 2010. [Google Scholar]

- AACC. Approved Methods of Analysis, 11th Edition—AACC Method 89-01.01. Cereals & Grains Association. Yeast Activity, Gas Production. 2000. Available online: https://methods.aaccnet.org/methods/89-01.pdf (accessed on 12 April 2016).

- Elía, M. A procedure for sensory evaluation of bread: Protocol developed by a trained panel. J. Sens. Stud. 2011, 26, 269–277. [Google Scholar] [CrossRef]

- Hadnađev, T.D.; Torbica, A.; Hadnađev, M. Rheological properties of wheat flour substitutes/alternative crops assessed by Mixolab. Procedia Food Sci. 2011, 1, 328–334. [Google Scholar] [CrossRef] [Green Version]

- Guzmán, C.; Posadas-Romano, G.; Hernández-Espinosa, N.; Morales-Dorantes, A.; Peña, R.J. A new standard water absorption criteria based on solvent retention capacity (SRC) to determine dough mixing properties, viscoelasticity, and bread-making quality. J. Cereal Sci. 2015, 66, 59–65. [Google Scholar] [CrossRef]

- Miyazaki, M.; Van Hung, P.; Maeda, T.; Morita, N. Recent advances in application of modified starches for breadmaking. Trends Food Sci. Technol. 2006, 17, 591–599. [Google Scholar] [CrossRef]

- Hadnađev, T.R.D.; Dokić, L.P.; Hadnađev, M.S.; Pojić, M.M.; Torbica, A.M. Rheological and Breadmaking Properties of Wheat Flours Supplemented with Octenyl Succinic Anhydride-Modified Waxy Maize Starches. Food Bioprocess Technol. 2013, 7, 235–247. [Google Scholar] [CrossRef]

- Kohajdová, Z.; Karovičová, J.; Magala, M. Effect of lentil and bean flours on rheological and baking properties of wheat dough. Chem. Pap. 2013, 67, 398–407. [Google Scholar] [CrossRef]

- Du, S.-K.; Jiang, H.; Yu, X.; Jane, J.-L. Physicochemical and functional properties of whole legume flour. LWT Food Sci. Technol. 2014, 55, 308–313. [Google Scholar] [CrossRef]

- Bucsella, B.; Molnár, D.; Harasztos, A.H.; Tömösközi, S. Comparison of the rheological and end-product properties of an industrial aleurone-rich wheat flour, whole grain wheat and rye flour. J. Cereal Sci. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Rosell, C.M.; Santos, E.; Collar, C. Physical characterization of fiber-enriched bread doughs by dual mixing and temperature constraint using the Mixolab®. Eur. Food Res. Technol. 2010, 231, 535–544. [Google Scholar] [CrossRef] [Green Version]

- Rojas, J.; Rosell, C.; de Barber, C.B. Pasting properties of different wheat flour-hydrocolloid systems. Food Hydrocoll. 1999, 13, 27–33. [Google Scholar] [CrossRef]

- Stępniewska, S.; Słowik, E.; Cacak-Pietrzak, G.; Romankiewicz, D.; Szafrańska, A.; Dziki, D. Prediction of rye flour baking quality based on parameters of swelling curve. Eur. Food Res. Technol. 2017, 244, 989–997. [Google Scholar] [CrossRef] [Green Version]

- Stanojeska, M.; Sokoloski, B. Creating the correlation model at flour T-400 among Amylograph unit and γ slope of Mixolab curve. J. Hyg. Eng. Des. 2012, 1, 247–250. [Google Scholar]

- Barrera, G.N.; Pérez, G.T.; Ribotta, P.D.; León, A.E. Influence of damaged starch on cookie and bread-making quality. Eur. Food Res. Technol. 2007, 225, 1–7. [Google Scholar] [CrossRef]

- Barrera, G.N.; Bustos, M.C.; Iturriaga, L.; Flores, S.K.; León, A.E.; Ribotta, P.D. Effect of damaged starch on the rheological properties of wheat starch suspensions. J. Food Eng. 2013, 116, 233–239. [Google Scholar] [CrossRef]

- Miyazaki, M.; Maeda, T.; Morita, N. Effect of various dextrin substitutions for wheat flour on dough properties and bread qualities. Food Res. Int. 2004, 37, 59–65. [Google Scholar] [CrossRef]

- Blandino, M.; Marinaccio, F.; Ingegno, B.L.; Pansa, M.G.; Vaccino, P.; Tavella, L.; Reyneri, A. Evaluation of common and durum wheat rheological quality through Mixolab® analysis after field damage by cereal bugs. Field Crop. Res. 2015, 179, 95–102. [Google Scholar] [CrossRef]

- Moreira, R.; Chenlo, F.; Torres, M.; Prieto, D. Influence of the particle size on the rheological behaviour of chestnut flour doughs. J. Food Eng. 2010, 100, 270–277. [Google Scholar] [CrossRef]

- Dapcevic-Hadnađev, T.; Pojić, M.; Hadnađev, M.; Torbica, A. The Role of Empirical Rheology in Flour Quality Control. In Wide Spectra of Quality Control; Akyar, I., Ed.; IntechOpen: London, UK, 2011; pp. 335–360. ISBN 978-953-51-6072-1. [Google Scholar]

- Verheyen, C.; Albrecht, A.; Elgeti, D.; Jekle, M.; Becker, T. Impact of gas formation kinetics on dough development and bread quality. Food Res. Int. 2015, 76, 860–866. [Google Scholar] [CrossRef]

- Bojňanská, T.; Vollmannová, A.; Musilová, J. Milk thistle flour effect on dough rheological properties. Potravin. Slovak J. Food Sci. 2020, 14, 788–797. [Google Scholar] [CrossRef]

- Rubel, I.A.; Pérez, E.E.; Manrique, G.D.; Genovese, D.B. Fibre enrichment of wheat bread with Jerusalem artichoke inulin: Effect on dough rheology and bread quality. Food Struct. 2015, 3, 21–29. [Google Scholar] [CrossRef]

- Poinot, P.; Arvisenet, G.; Grua-Priol, J.; Fillonneau, C.; Le-Bail, A.; Prost, C. Influence of inulin on bread: Kinetics and physico-chemical indicators of the formation of volatile compounds during baking. Food Chem. 2010, 119, 1474–1484. [Google Scholar] [CrossRef]

- Babin, P.; Della Valle, G.; Dendievel, R.; Lassoued, N.; Salvo, L. Mechanical properties of bread crumbs from tomography based Finite Element simulations. J. Mater. Sci. 2005, 40, 5867–5873. [Google Scholar] [CrossRef]

- Codină, G.; Mironeasa, S.; Voica, D.; Mironeasa, C. Multivariate analysis of wheat flour dough sugars, gas production, and dough development at different fermentation times. Czech J. Food Sci. 2013, 31, 222–229. [Google Scholar] [CrossRef] [Green Version]

| WF | RF | ChF | BBF | CBF | RLF | |

|---|---|---|---|---|---|---|

| Energy value (kJ) | 1464 | 1396 | 1322 | 1300 | 1354 | 1263 |

| Carbohydrate content (g/100 g) | 71 | 68 | 59 | 49.7 | 49 | 54 |

| of which sugars | 1.59 | 3 | - | 3.3 | 3.2 | 2 |

| Fiber content (g/100 g) | 3.3 | 11 | - | - | - | - |

| Protein content (g/100 g) | 11 | 7.5 | 16.7 | 28 | 25 | 17 |

| Fat content (g/100 g) | 1.3 | 1.1 | 4.8 | 2.5 | 1.2 | 1.5 |

| of which saturated | 0.3 | 0.2 | 0.5 | 0.4 | 0.5 | 0.5 |

| Salt (g/100 g) | 0.01 | 0.01 | 0.07 | 0.01 | 0.01 | 0.01 |

| Chickpea Flour | Broad Bean Flour | Common Bean Flour | Red Lentil Flour |

|---|---|---|---|

| WF(50) + RF(50) | WF(50) + RF(50) | WF(50) + RF(50) | WF(50) + RF(50) |

| WF(50) + RF(45) + ChF(5) | WF(50) + RF(45) + BBF(5) | WF(50) + RF(45) + CBF(5) | WF(50) + RF(45) + RLF(5) |

| WF(50) + RF(40) + ChF(10) | WF(50) + RF(40) + BBF(10) | WF(50) + RF(40) + CBF(10) | WF(50) + RF(40) + RLF(10) |

| WF(50) + RF(35) + ChF(15) | WF(50) + RF(35) + BBF(15) | WF(50) + RF(35) + CBF(15) | WF(50) + RF(35) + RLF(15) |

| Mixing Speed | 80 rpm |

|---|---|

| Target torque | 1.10 Nm |

| Dough weight | 75 g |

| Tank temperature | 30 °C |

| Temperature 1st step | 30 °C |

| Duration 1st step | 8 min |

| 1st temperature gradient | 4 °C/min |

| Temperature 2nd step | 90 °C |

| Duration 2nd step | 7 min |

| 2st temperature gradient | −4 °C/min |

| Temperature 3rd step | 50 °C |

| Duration 3rd step | 5 min |

| Total analysis time | 45 min |

| Legume Flour Level (%) | WA (%) | Legume Flour Level (%) | WA (%) |

|---|---|---|---|

| 0 | 62.4 ± 0.40 b | 0 | 58.9 ± 0.28 b |

| Chickpea flour | Red lentil flour | ||

| 5 | 61.0 ± 0.39 a | 5 | 58.7 ± 0.28 b |

| 10 | 61.1 ± 0.48 ab | 10 | 58.8 ± 0.28 b |

| 15 | 61.6 ± 0.39 ab | 15 | 57.4 ± 0.35 a |

| Common bean flour | Broad bean flour | ||

| 5 | 63.6 ± 0.42 c | 5 | 60.1 ± 0.28 c |

| 10 | 64.7 ± 0.35 c | 10 | 60.2 ± 0.35 c |

| 15 | 66.2 ± 0.39 d | 15 | 60.1 ± 0.39 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bojňanská, T.; Musilová, J.; Vollmannová, A. Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough. Foods 2021, 10, 1087. https://doi.org/10.3390/foods10051087

Bojňanská T, Musilová J, Vollmannová A. Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough. Foods. 2021; 10(5):1087. https://doi.org/10.3390/foods10051087

Chicago/Turabian StyleBojňanská, Tatiana, Janette Musilová, and Alena Vollmannová. 2021. "Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough" Foods 10, no. 5: 1087. https://doi.org/10.3390/foods10051087

APA StyleBojňanská, T., Musilová, J., & Vollmannová, A. (2021). Effects of Adding Legume Flours on the Rheological and Breadmaking Properties of Dough. Foods, 10(5), 1087. https://doi.org/10.3390/foods10051087