1. Introduction

Smoothies are considered a typical example of a “superfood”, which is defined as a natural food that could have beneficial effects on human health due to its nutrient composition [

1]. They usually consist of mixed fruits/vegetables with added milk, either animal or plant-based. Other studies confirm an association between a high intake of fruits and vegetables and the prevention of chronic diseases, obesity, diabetes, and cardiovascular diseases [

2,

3]. Smoothies also represent an excellent matrix for the addition of various functional ingredients, such as probiotics or plant extracts, thus offering great potential for the production of functional foods [

4,

5]. In line with this, smoothies also seem to play a positive role in nutrition, as they are potentially beneficial to health [

6,

7,

8] and can therefore provide increased fruit and vegetable consumption, especially in young age groups [

9].

Smoothies are usually prepared fresh without any preservation and therefore have a very short shelf life. Juices and drinks are usually preserved by thermal pasteurization at 84–88 °C for 15–45 min [

10]. The main objective of pasteurization is to deactivate thermolabile microorganisms responsible for food spoilage or food poisoning, such as yeasts, molds, and vegetative bacteria [

11,

12]. In addition to microbial inactivation, thermal pasteurization has also been successfully used to deactivate juice enzymes whose activities can cause oxidative changes during processing and storage [

13]. Therefore, thermally treated juices have an extended shelf life of up to several months at refrigerated or room temperature, without a significant loss of quality [

14]. However, the application of heat treatment in smoothies can lead to undesirable changes in the functional properties of thermally unstable bioactive compounds (BACs), as well as sensory properties, such as color, taste, and odor [

12,

15]. Therefore, the application of innovative non-thermal technologies, such as high-pressure processing (HP), has been increasingly explored as a substitute for heat treatment in the processing of fruit and vegetable juices [

16].

HP, by applying pressures between 100 and 1000 MPa for several seconds or minutes, effectively deactivates microbial growth and denatures enzymes, with minimal changes in the nutritional and sensory quality [

17]. However, the efficiency of this technology is strongly influenced by the operating conditions, such as the pressure level, temperature, and time, followed by the water activity, microbial species, and cell growth phase [

18,

19]. HP has been approved by the U.S. Food and Drug Administration (FDA) and the U.S. Department of Agriculture (USDA) as a complementary non-thermal pasteurization technique that can ensure microbial safety and significantly extend the shelf life of processed foods [

20]. Since smoothies are multi-component systems consisting of various biological macromolecules and BACs that promote microbial growth, the use of HP to extend shelf life and maintain fresh-like quality characteristics can be a major challenge for the food industry.

When consumers consider processed foods (e.g., smoothies), they try to choose products with a significant nutritional value, but also with attractive colors [

21]. In contrast to thermal treatment, HP was found to keep the visual color much closer to that of the untreated smoothie [

21]. While thermal pasteurization (P) could negatively affect the stability of the BACs in smoothies [

22], a recent study showed that HP could even increase the baseline levels of nutritional quality in vegetable smoothies during cold storage [

23]. Moreover, HP was found to be a less destructive treatment in terms of the vitamin C stability, compared to thermal processing, which could reduce vitamin C content by 35–44% [

24]. In addition, cold storage can negatively affect ascorbic acid content in smoothies over storage time [

25], but these changes were less pronounced, compared to thermally treated samples [

21].

Some studies suggest that the HP operating conditions (e.g., pressure level, processing time, and processing temperature) may also significantly affect the stability of the BACs in smoothies [

24]. Phenolic compounds were 15% higher in smoothies treated below 450 MPa than in those treated at 600 MPa. The authors explained that the longer time to reach final pressurization (400 MPa vs. 600 MPa) may cause this effect [

24]. Therefore, the HP processing conditions should be carefully considered to find an optimal HP regime that leads to satisfactory results.

While smoothies are very popular among consumers, many cannot consume these products based on milk of animal origin due to lactose intolerance, allergies, or a trend towards vegetarian diets, so there is a need for more research on the use of non-dairy substitutes in fruit and vegetable smoothies [

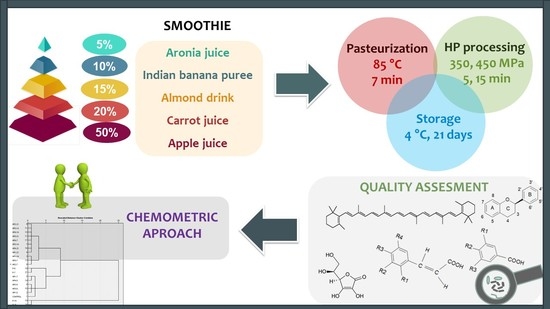

26]. Consequently, the aim of the present study was to evaluate the use of HP technology (350 and 450 MPa/5 and 15 min/room temperature) and conventional thermal processing (85 °C for 7 min) for almond milk-based smoothies in terms of nutritional value and color parameters during cold storage. A chemometric approach was used to evaluate the changes in the quality parameters of smoothies during storage in relation to the preservation technology applied.

2. Materials and Methods

2.1. Sample Preparation

Smoothies were prepared by mixing apple juice (50%, v/v), carrot juice (20%, v/v), chokeberry juice (5%, v/v), almond drink (15%, v/v), and Indian banana puree (10%, w/v). Apple (cv. Golden Delicious) and carrot juices were prepared from raw materials purchased from a local market. A cold-pressed juicer (300 W TEFAL Infinity Press Revolution ZC500H38, France), with a speed of 80 rpm and a filter diameter of 0.3 mm, was used to prepare cloudy apple juice, while a juicer (1000 W BOSCH MES 4000, Germany), with a filter diameter of 0.5 mm, was used to prepare carrot juice. Approximately 8.5 L of apple juice and 3.4 L of carrot juice were prepared, which required around 14 kg of apples and 7 kg of carrots. The chokeberry juice (cca 1 L) and Indian banana puree (cca 1.7 kg) were kept frozen and thawed at room temperature before the smoothie preparation. All ingredients were homogenized using a hand blender (170 W SIEMENS MQ 33001, Germany) and then filled into polyethylene terephthalate (PET) bottles, which were then subjected to a high pressure (HP). Two bottles of 200 mL for one HP and one storage time were filled with a smoothie, resulting in a total of 16 HP-bottles. For the pasteurization, three glass bottles (500 mL) were filled with the smoothies for each storage regime, i.e., a total of 4 P-bottles. Two glass bottles (500 mL) were filled with the control samples (untreated) and represented fresh smoothies.

2.2. High-Pressure Processing

The prepared smoothies were treated with a high pressure using an HP device from Stansted Fluid Power (UK). The samples in plastic bottles were previously vacuumed in the disposable plastic bags provided in a vacuum device (STATUS SV2000) and then placed in a high-pressure container filled with a pressurized liquid (propylene/glycol: water in a 50:50 ratio). The samples were subjected to a pressure of 350 MPa and 450 MPa for 5 and 15 min, respectively, at room temperature (≈20 °C), according to the experimental design given in

Table 1.

2.3. Thermal Pasteurization (P)

The thermal pasteurization (P) regime was selected from the literature for the smoothie with a similar composition [

27]. A batch laboratory pasteurizer (PS-100, Oprema Ludbreg d.o.o. Ludbreg, Croatia) was used for the P of smoothies at 85 °C for 7 min. Preliminary studies showed that the pasteurizer needs 19 min to reach the set temperature, so the total pasteurization time of the smoothie samples was 26 min. Pasteurized smoothies were subjected to standard storage regimes and used for analysis at the defined storage times (

Table 1).

2.4. Determination of Bioactive Compounds

All absorbance measurements were conducted with a UV/Vis spectrophotometer (VWR UV-1600PC Spectrophotometer, VWR International, Pennsylvania, PA, USA). For each sample duplicate measurements were performed.

2.4.1. Ultrasound-Assisted Extraction of Bioactive Compounds

The extraction was carried out in the ultrasonic processor, Bandelin Sonorex (Germany), operating at a 40 kHz frequency, with modified methods from previously published data [

28,

29]. Briefly, 5 g (±0.0001) of a smoothie, along with 20 mL of ethanol (96%), as an extraction solvent, was mixed in an Erlenmeyer flask, and the mixture was sonicated for 15 min at T = 50 °C. Afterwards, the extract was filtered through Whatman filter paper No. 40 (Whatman International Ltd., Kent, UK) and made up to 25 mL in a volumetric flask with extraction solvent. All extracts were prepared in duplicates. Prior to analysis, the extracts were stored at T = 4 °C in an inert gas atmosphere.

2.4.2. Determination of the Total Phenolic Content (TPC)

The total phenolic contents were determined according to a modified method from the literature [

19]. The reaction mixture contained: 0.4 mL of extract, 0.4 mL of Folin-Ciocalteu reagent, and 4 mL of sodium carbonate solution (75 g L

−1). After 1 h of incubation at room temperature in the dark, the absorbance was measured at 725 nm using a spectrophotometer. A blank sample was prepared with distilled water, instead of extract. A calibration curve was prepared using a standard solution of gallic acid (10–250 mg L

−1), and the results were expressed as mg of gallic acid equivalent (GAE) per 100 mL of the sample.

2.4.3. Determination of the Total Flavonoids (TFL)

The total flavonoids were determined according to Chang et al. [

30]. First, 0.5 mL of extract was mixed with 1.5 mL of 96% ethanol, 0.1 mL of 10% Al(NO

3)

3, 0.1 mL of 1 M potassium acetate, and 2.8 mL of distilled water. After 30 min of incubation at room temperature, the absorbance of the reaction mixture was measured at 415 nm using a spectrophotometer. A calibration curve was prepared using a standard solution of quercetin (10–100 mg L

−1), and the results were expressed as mg of quercetin equivalent (QE) per 100 mL of the sample.

2.4.4. Determination of the Total Hydroxycinnamic Acids (HCA)

To determine the content of total hydroxycinnamic acids, the procedure proposed by Howard et al. [

31] was applied, with slight modifications. In a test tube, 0.25 mL of extract was mixed with 0.25 mL of 1 g L

−1 HCl (in 96% ethanol) and 4.55 mL of 2 g L

−1 HCl (in distilled water) and stirred in a vortex for 10 s, then allowed to react in the dark for 30 min at room temperature. After this time, the solution absorbance was measured at 320 nm in a spectrophotometer. As a blank sample extraction, solvent, instead of extract, was used. A standard solution of chlorogenic acid (10–100 mg L

−1) was used for the calibration curve preparation, and the results were expressed as mg of chlorogenic acid equivalent (CAE) per 100 mL of the sample.

2.4.5. Determination of the Total Carotenoids (CAR)

The total carotenoids were determined using the method of Lichtenthaler and Buschmann [

32]. The absorbance maxima of the smoothie extracts in contrast to the blank (96% ethanol) were read at 470 nm and 649 nm for Chl a and at 664 nm for Chl b using the UV/Vis spectrophotometer, and the total carotenoids C(x + c) [xanthophylls and carotenes] were calculated from the following equations:

The results were expressed as mg per 100 mL of the sample.

2.4.6. HPLC-DAD Determination of Vitamin C (Ascorbic Acid)

Separations and quantifications of vitamin C were performed using HPLC equipment (Thermo Scientific Accela HPLC system, Thermo Fisher Scientific, Waltham, MA, USA) on Nucleosil 100-5C18, 5 µm (250 mm × 4.6 mm I.D.) column (Phenomenex, Los Angeles, CA, USA). The separation was performed using a standard method (HRN EN 14130:2005—Determination of vitamin C by HPLC). The LOD (limit of detection) and LOQ (limit of quantitation) values were as follows: 0.2 mg and 100 mL−1 and 1.6 mg and 100 mL−1, respectively. The content of vitamin C was expressed in mg of ascorbic acid (the sum of ascorbic acid and its oxidative form of dehydroascorbic acid) per 100 mL of the sample.

2.5. Instrumental Color Measurement

Color measurements were made using diffuse reflectance spectrophotometry on a colorimeter (CM-3500d, Konica-Minolta, Tokyo, Japan). A pulsed xenon lamp was used for the standard D 65 illumination. All necessary measurement settings were made using the Spectramagic NX program (Konica-Minolta, Tokyo, Japan). The geometry d/8 was chosen, where the surface of the sample is viewed at an angle of 8° to its normal. L* (lightness), a* (green to red), and b* (yellow to blue) were measured, and the values of C (chroma), H (hue), and ∆E

ab (colour difference) were calculated (1, 2, 3). The values obtained represent the average of 4 replicates.

L1, a1, and b1 are the color parameters for the control samples, and L2, a2, and b2 are the color parameters of the treated samples.

2.6. Microbial Analyses

Classical microbiological methods were used to monitor the microbiological quality of the smoothies stored for 21 days at 4 °C. The tested microorganisms were selected according to the prescribed regulations for the microbiological criteria for foodstuffs (EC, 2073/2005) [

33].

A volume of 1 mL of each sample was homogenized in 9 mL of sterile water and serially diluted before plating (pour plate method for total aerobic mesophilic bacteria and spread plate method for other bacteria) on selective media. All analyses were made in triplicates. The total aerobic mesophilic bacteria were counted after incubation on nutrient agar (Merck, Darmstadt, Germany) at 37 °C for 48 h, Enterobacteriaceae after incubation on Violet Red Bile Glucose (VRBG) agar (Biolife, Milan, Italy) at 37 °C for 48 h, and mold and yeasts after incubation on potato dextrose agar (Biolife) at 25 °C for 96 h. Salmonella sp. was grown in a Rappaport-Vassiliadis (RV) Salmonella enrichment broth (Merck), followed by subculturing on xylose lysine deoxycholate (XLD) agar (Biolife) at 37 °C for 24–48 h. Listeria monocytogenes was detected using a two-step selective enrichment procedure in Fraser broth, followed by subculturing on PALCAM agar (Merck) at 37 °C for 24 h. The microbial growth was determined using traditional plate counting, and the results were expressed as the colony forming units per milliliter of juice (CFU mL−1).

2.7. Statistical Analysis

Descriptive statistics were used for the characterization of the sample. Discrete variables and factor scores were tested by MANOVA. Exploratory hierarchical Ward’s cluster analysis was used for measuring standardized similarities in samples. For nonparametric analysis, a Kruskal Wallis test was employed. In order to check the structure of specific variables, factor analysis (Principal Component Analysis; PCA) was performed on selected variables to estimate the overall changes in the nutritive value of samples for various combinations of independent variables. The appropriateness of factor analysis was tested by a Kaiser-Mayer-Olkin test (KMO) and Bartlett’s Test of Sphericity. The factor analysis score was calculated by the linear regression method. The level of significance for all tests was α ≤ 0.05, and the results were analyzed using SPSS software (v.22).

4. Conclusions

The chemometric approach can be useful for future applications in the food industry involving the differentiation of foodstuff, comparison of their classification according to applied technology, and quality prediction, allowing for fast and accurate characterizations of food. In this work, the conventional thermal pasteurization (85 °C/7 min) and high-pressure processing (350 and 450 MPa/5 and 15 min/room temperature) of smoothies during 21 days of cold storage were studied in terms of nutritional and microbial quality. An increased pressure did not affect TPC and HCA but decreased the levels of TFL, CAR, and vitamin C in the smoothie samples. A prolonged treatment time negatively affected the content of TPC, CAR, and vitamin C. In HP-smoothies, TFL showed the best stability, while vitamin C was found to be the most unstable during storage.

All the investigated phenolic compounds were observed in higher concentrations in the P samples, as compared to the HP-ones, while significantly lower contents of vitamin C and CAR were found in the P samples in comparison to the HP samples. The storage of the pasteurized smoothies, however, led to significantly higher losses of all the investigated compounds, compared to the HP samples, indicating that although pasteurization favored a better stability of some bioactive compounds, a greater stability was found for the HP samples during storage.

This research showed that high-pressure processing can be a viable choice for the preservation of smoothies’ quality during storage. This conclusion is based on the data, which strongly show that the high-pressure technology is able either to outperform or achieve the same results as conventional thermal pasteurization.

Since smoothies are complex food matrices, the stability of various bioactive compounds and the quality of the rest of the food should be tested prior to mass manufacturing them. Hence, more research on other successful applications of the technology in this part of food market is recommended.