Dynamic Thermal Properties Estimation Using Sensitivity Coefficients for Rapid Heating Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Mathematical Model for Transient Heat Conduction in Cylindrical Coordinate for Constant Temperature Boundary Condition (R12B10T1) Experiment

2.3. Mathematical Model for Transient Heat Conduction in a Hollow Cylinder with Heat Flux on the Inside for Rapid Heating Condition (R22B10T1) Experiment

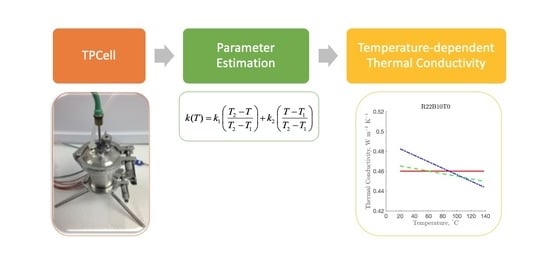

2.4. Parameter Estimation

2.5. Scaled Sensitivity Coefficient and Sequential Estimation

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Nomenclature

| R12B10T1 | transient heat conduction in cylindrical coordinate for constant temperature boundary condition |

| R22B10T1 | transient heat conduction in a hollow cylinder with heat flux on the inside and insulated on the outside for rapid heating condition |

| RMSE | root meat square error |

| a, b | parameters in linear model |

| parameter | |

| scaled sensitivity coefficient, °C | |

| prior information of parameter vector, , W m−1 K−1 | |

| volumetric capacity of heater, J m−3 K−1 | |

| volumetric capacity of thermocouple, J m−3 K−1 | |

| volumetric heat capacity of sample, J m−3 K−1 at | |

| volumetric heat capacity of sample, J m−3 K−1 at | |

| dimensionless thermal conductivity as a function of temperature | |

| dimensionless heat capacity as a function of temperature | |

| power, W m−3 | |

| thermal conductivity of sample, W m−1 K−1 | |

| thermal conductivity of heater, W m−1 K−1 | |

| thermal conductivity of thermocouple, W m−1 K−1 | |

| thermal conductivity in single parameter model, W m−1 K−1 | |

| parameters used in k model | |

| 95% lower confidence interval of parameters | |

| index | |

| number of responses | |

| radial position, m | |

| resistance of the heater, | |

| centerline of the cylinder, | |

| interface of heater and sample, m | |

| wall of the cup, m | |

| interface of thermocouple and sample, m | |

| wall of the cup, m | |

| RE | Relative error of parameter |

| temperature, °C | |

| temperature at °C | |

| initial temperature of sample, °C | |

| initial temperature for thermal properties, °C | |

| final temperature for thermal properties, °C | |

| time, s | |

| inverse covariance matrix of parameters | |

| 95% upper confidence interval of parameters | |

| inverse of covariance matrix of errors | |

| experimental response variable | |

| predicted response variable | |

| ZA | total height of cylinder for (R12B10T1) experiment, mm |

| Z1 | total height of cylinder for (R22B10T1) experiment, mm |

| axial position, m |

References

- Greiby, I.; Mishra, D.K.; Dolan, K.D. Inverse method to sequentially estimate temperature-dependent thermal conductivity of cherry pomace during nonisothermal heating. J. Food Eng. 2014, 127, 16–23. [Google Scholar] [CrossRef]

- Mishra, D.K.; Dolan, K.D.; Beck, J.V.; Ozadali, F. A novel instrument for rapid measurement of temperature-dependent thermal properties of conduction-heated food up to 140 °C. J. Food Eng. 2016, 191, 19–27. [Google Scholar] [CrossRef]

- Muramatsu, Y.; Greiby, I.; Mishra, D.K.; Dolan, K.D. Rapid Inverse Method to Measure Thermal Diffusivity of Low-Moisture Foods. J. Food Sci. 2017, 82, 420–428. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, I.O. Simultaneous estimation of thermal conductivity and volumetric heat capacity for solid foods using sequential parameter estimation technique. Food Res. Int. 2009, 42, 231–236. [Google Scholar] [CrossRef]

- Mohamed, I.O. Development of a simple and robust inverse method for determination of thermal diffusivity of solid foods. J. Food Eng. 2010, 101, 1–7. [Google Scholar] [CrossRef]

- Martins, R.C.; Silva, C.L.M. Inverse problem methodology for thermal-physical properties estimation of frozen green beans. J. Food Eng. 2004, 63, 383–392. [Google Scholar] [CrossRef]

- Zueco, J.; Alhama, F.; Gonazález Fernández, C.F. Inverse determination of the specific heat of foods. J. Food Eng. 2004, 64, 347–353. [Google Scholar] [CrossRef]

- Da Silva, W.P.; E Silva, C.M.D.P.S.; De Souto, L.M.; Moreira, I.D.S.; Da Silva, E.C.O. Mathematical model for determining thermal properties of whole bananas with peel during the cooling process. J. Food Eng. 2018, 227, 11–17. [Google Scholar] [CrossRef]

- Monteau, J.-Y. Estimation of thermal conductivity of sandwich bread using an inverse method. J. Food Eng. 2008, 85, 132–140. [Google Scholar] [CrossRef]

- Ebrahimifakhar, A.; Yuill, D. Inverse estimation of thermophysical properties and initial moisture content of cereal grains during deep-bed grain drying. Biosyst. Eng. 2020, 196, 97–111. [Google Scholar] [CrossRef]

- Mariani, V.C.; Barbosa De Lima, A.G.; Dos Santos Coelho, L. Apparent thermal diffusivity estimation of the banana during drying using inverse method. J. Food Eng. 2008, 85, 569–579. [Google Scholar] [CrossRef]

- Gulati, T.; Datta, A. Enabling computer-aided food process engineering: Property estimation equations for transport phenomena-based models. J. Food Eng. 2013, 116, 483–504. [Google Scholar] [CrossRef]

- Mariani, V.C.; Do Amarante Álvaro, C.C.D.; Dos Santos Coelho, L.D.S. Estimation of apparent thermal conductivity of carrot purée during freezing using inverse problem. Int. J. Food Sci. Technol. 2009, 44, 1292–1303. [Google Scholar] [CrossRef]

- Mariani, V.C.; Dos Santos Coelho, L. Estimation of the apparent thermal diffusivity coefficient using an inverse technique. Inverse Probl. Sci. Eng. 2009, 17, 569–589. [Google Scholar] [CrossRef]

- Ramsaroop, R.; Persad, P. Determination of the heat transfer coefficient and thermal conductivity for coconut kernels using an inverse method with a developed hemispherical shell model. J. Food Eng. 2012, 110, 141–157. [Google Scholar] [CrossRef]

- Vidyarthi, S.K.; Mishra, D.K.; Dolan, K.D.; Muramatsu, Y. Inverse estimation of fluid-to-particle heat transfer coefficient in aseptic processing of particulate foods. Biosyst. Eng. 2020, 198, 210–222. [Google Scholar] [CrossRef]

- Reddy, R.S.; Arepally, D.; Datta, A.K. Estimation of heat flux in bread baking by inverse problem. J. Food Eng. 2019, 271, 109774. [Google Scholar] [CrossRef]

- Da Silva, W.P.; De Medeiros, M.S.; Gomes, J.P.; E Silva, C.M.D.P.S. Improvement of methodology for determining local thermal diffusivity and heating time of green coconut pulp during its pasteurization. J. Food Eng. 2020, 285, 110104. [Google Scholar] [CrossRef]

- Beck, J.V.; Arnold, K.J. Parameter Estimation in Engineering and Science; John Wiley & Sons: New York, NY, USA, 1977. [Google Scholar]

- Dolan, K.D.; Mishra, D.K. Parameter Estimation in Food Science. Annu. Rev. Food Sci. Technol. 2013, 4, 401–422. [Google Scholar] [CrossRef]

- Beck, J.V.; Litkouhi, B. Heat conduction numbering system for basic geometries. Int. J. Heat Mass Transf. 1988, 31, 505–515. [Google Scholar] [CrossRef]

- Mishra, D.K.; Dolan, K.D.; Beck, J.V.; Ozadali, F. Use of Scaled Sensitivity Coefficient Relations for Intrinsic Verification of Numerical Codes and Parameter Estimation for Heat Conduction. J. Verif. Valid. Uncertain. Quantif. 2017, 2, 031005. [Google Scholar] [CrossRef]

- Mishra, D.K.; Dolan, K.D.; Beck, J.V.; Ozadali, F. Temperature-Dependent Dielectric and Thermal Properties of Whey Protein Gel and Mashed Potato. Trans. ASABE 2013, 56, 1457–1467. [Google Scholar] [CrossRef] [Green Version]

- Krishna Kumar, P.K.; Bhunia, K.; Tang, J.; Rasco, B.A.; Takhar, P.S.; Sablani, S.S. Thermal transition and thermo-physical properties of potato (Solanum tuberosum L.) var. Russet brown. J. Food Meas. Charact. 2018, 12, 1572–1580. [Google Scholar] [CrossRef]

- Marcotte, M.; Taherian, A.R.; Karimi, Y. Thermophysical properties of processed meat and poultry products. J. Food Eng. 2008, 88, 315–322. [Google Scholar] [CrossRef]

- Tavman, I.H.; Tavman, S. Measurement of thermal conductivity of dairy products. J. Food Eng. 1999, 41, 109–114. [Google Scholar] [CrossRef]

- Choi, Y.; Okos, M.R. Effect of temperature and composition on the thermal properties of food. In Food Engineering and Process Applications 1; Maguer, M.L., Jelen, P., Eds.; Elsevier: London, UK; New York, NY, USA, 1986; Volume 1, pp. 93–101. [Google Scholar]

- Muniandy, A. Application of Temperature-Dependent Thermal Properties in Food Thermal Process Simulation and Selection of Product Formulation; Purdue University: West Lafayette, IN, USA, 2019. [Google Scholar]

| Model | R12B10T1 | R22B10T1 | |||||

|---|---|---|---|---|---|---|---|

| Rep 1 | Rep 2 | Rep 3 | Rep 1 | Rep 2 | Rep 3 | ||

| Single parameter model | kc | 0.457 | 0.490 | 0.504 | 0.464 | 0.459 | 0.458 |

| RMSE | 0.582 | 0.663 | 0.838 | 1.400 | 1.540 | 1.485 | |

| 0.456 | 0.490 | 0.503 | 0.462 | 0.458 | 0.457 | ||

| 0.457 | 0.491 | 0.505 | 0.465 | 0.460 | 0.459 | ||

| Linear model | a | 0.421 | 0.435 | 0.435 | 0.505 | 0.478 | 0.485 |

| b × 10−3 | 0.438 | 0.685 | 0.873 | −0.515 | −0.239 | −0.224 | |

| RMSE | 0.485 | 0.436 | 0.525 | 1.285 | 1.538 | 2.275 | |

| REa % | 0.174 | 0.165 | 0.157 | 1.179 | 0.915 | 0.783 | |

| REb % | 2.008 | 1.292 | 0.985 | −14.331 | −22.417 | −21.015 | |

| LCIa | 0.419 | 0.433 | 0.433 | 0.491 | 0.467 | 0.471 | |

| UCIa | 0.423 | 0.437 | 0.437 | 0.519 | 0.489 | 0.499 | |

| LCIb × 10−3 | 0.415 | 0.663 | 0.847 | −0.692 | −0.379 | −0.394 | |

| UCIb × 10−3 | 0.463 | 0.706 | 0.898 | −0.338 | −0.099 | −0.053 | |

| k model | k1 | 0.430 | 0.449 | 0.452 | 0.484 | 0.469 | 0.450 |

| k2 | 0.474 | 0.517 | 0.540 | 0.437 | 0.445 | 0.468 | |

| RMSE | 0.485 | 0.436 | 0.525 | 1.285 | 1.538 | 1.499 | |

| REk1 % | 0.129 | 0.122 | 0.114 | 0.616 | 0.508 | 0.495 | |

| REk2 % | 0.075 | 0.073 | 0.071 | 0.889 | 0.679 | 0.603 | |

| 0.428 | 0.447 | 0.451 | 0.477 | 0.463 | 0.444 | ||

| 0.431 | 0.450 | 0.454 | 0.491 | 0.475 | 0.456 | ||

| 0.473 | 0.516 | 0.538 | 0.427 | 0.437 | 0.461 | ||

| 0.475 | 0.518 | 0.541 | 0.446 | 0.453 | 0.475 | ||

| Rep 1 | Rep 2 | Rep 3 | ||||||

|---|---|---|---|---|---|---|---|---|

| R12B10T2 | a | b | a | b | a | b | ||

| Linear model | Covariance × 10−7 | a | 10.258 | −0.122 | 8.014 | −0.097 | 10.512 | −0.130 |

| b | −0.122 | 0.002 | −0.097 | 0.001 | −0.130 | 0.002 | ||

| Correlation | a | 1.000 | −0.988 | 1.000 | −0.985 | 1.000 | −0.983 | |

| b | −0.988 | 1.000 | −0.985 | 1.000 | −0.983 | 1.000 | ||

| k1 | k2 | k1 | k2 | k1 | k2 | |||

| k model | Covariance × 10−7 | k1 | 5.964 | −3.288 | 4.612 | −2.686 | 5.979 | −3.698 |

| k2 | −3.288 | 2.412 | −2.686 | 2.189 | −3.698 | 3.279 | ||

| Correlation | k1 | 1.000 | −0.867 | 1.000 | −0.845 | 1.000 | −0.835 | |

| k2 | −0.867 | 1.000 | −0.845 | 1.000 | −0.835 | 1.000 | ||

| R22B10T2 | a | b | a | b | a | b | ||

| Linear model | Covariance × 10−5 | a | 4.782 | −0.059 | 3.697 | −0.045 | 6.105 | −0.075 |

| b | −0.059 | 0.001 | −0.045 | 0.001 | −0.075 | 0.001 | ||

| Correlation | a | 1.000 | −0.996 | 1.000 | −0.996 | 1.000 | −0.996 | |

| b | −0.996 | 1.000 | −0.996 | 1.000 | −0.996 | 1.000 | ||

| k1 | k2 | k1 | k2 | k1 | k2 | |||

| k model | Covariance × 10−5 | k1 | 1.200 | −1.493 | 1.096 | −1.329 | 0.911 | −1.102 |

| k2 | −1.493 | 2.037 | −1.329 | 1.769 | −1.102 | 1.464 | ||

| Correlation | k1 | 1.000 | −0.955 | 1.000 | −0.955 | 1.000 | −0.955 | |

| k2 | −0.955 | 1.000 | −0.955 | 1.000 | −0.955 | 1.000 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muniandy, A.; Benyathiar, P.; Mishra, D.K.; Ozadali, F. Dynamic Thermal Properties Estimation Using Sensitivity Coefficients for Rapid Heating Process. Foods 2021, 10, 1954. https://doi.org/10.3390/foods10081954

Muniandy A, Benyathiar P, Mishra DK, Ozadali F. Dynamic Thermal Properties Estimation Using Sensitivity Coefficients for Rapid Heating Process. Foods. 2021; 10(8):1954. https://doi.org/10.3390/foods10081954

Chicago/Turabian StyleMuniandy, Anbuhkani, Patnarin Benyathiar, Dharmendra K. Mishra, and Ferhan Ozadali. 2021. "Dynamic Thermal Properties Estimation Using Sensitivity Coefficients for Rapid Heating Process" Foods 10, no. 8: 1954. https://doi.org/10.3390/foods10081954

APA StyleMuniandy, A., Benyathiar, P., Mishra, D. K., & Ozadali, F. (2021). Dynamic Thermal Properties Estimation Using Sensitivity Coefficients for Rapid Heating Process. Foods, 10(8), 1954. https://doi.org/10.3390/foods10081954