Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

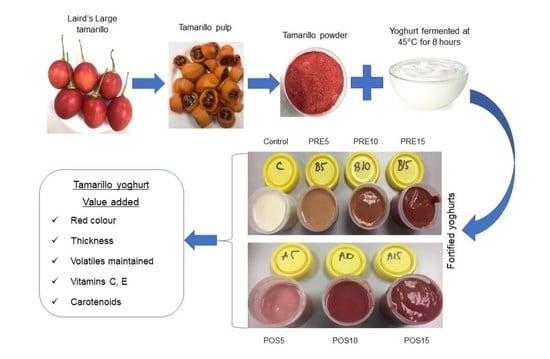

2.2. Yoghurt Preparation

2.3. Physicochemical Property Analysis of Yoghurt Samples

2.4. Rheological and Textural Analysis

2.5. Volatile Analysis

2.6. Fatty Acid Analysis

2.7. Reducing Sugar and Organic Acid Analysis

2.8. Analysis of α-Tocopherol, β-Carotene, and Ascorbic Acid

2.9. Statistical Analysis

3. Results and Discussion

3.1. Physical Properties and Proximate Compositions of Tamarillo Yoghurts

3.2. Rheological and Textural Analysis

3.3. Volatile Profile

3.4. Fatty Acid Profile

3.5. Reducing Sugar and Organic Acid Profile of Yoghurts

3.6. Determination of α-Tocopherol, β-Carotene, and Ascorbic Acid in Yoghurts

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Diep, T.; Pook, C.; Yoo, M. Phenolic and Anthocyanin Compounds and Antioxidant Activity of Tamarillo (Solanum betaceum Cav.). Antioxidants 2020, 9, 169. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Diep, T.T.; Pook, C.; Rush, E.C.; Yoo, M.J.Y. Quantification of Carotenoids, α-Tocopherol, and Ascorbic Acid in Amber, Mulligan, and Laird’s Large Cultivars of New Zealand Tamarillos (Solanum betaceum Cav.). Foods 2020, 9, 769. [Google Scholar] [CrossRef] [PubMed]

- Diep, T.T.; Pook, C.; Yoo, M.J.Y. Physicochemical properties and proximate composition of tamarillo (Solanum betaceum Cav.) fruits from New Zealand. J. Food Compost. Anal. 2020, 92, 103563. [Google Scholar] [CrossRef]

- Diep, T.T.; Rush, E.C.; Yoo, M.J.Y. Tamarillo (Solanum betaceum Cav.): A Review of Physicochemical and Bioactive Properties and Potential Applications. Food Rev. Int. 2020, 6, 1–25. [Google Scholar] [CrossRef]

- Schotsmans, W.; East, A.; Woolf, A. Tamarillo (Solanum betaceum (Cav.)). In Postharvest Biology and Technology of Tropical and Subtropical Fruits: Mangosteen to White Sapote; Elsevier: Amsterdam, The Netherlands, 2011; pp. 427–441, 442e. [Google Scholar]

- Salehi, F. Quality, physicochemical, and textural properties of dairy products containing fruits and vegetables: A review. Food Sci. Nutr. 2021, 9, 4666–4686. [Google Scholar] [CrossRef] [PubMed]

- Aryana, K.J.; Olson, D.W. A 100-Year Review: Yogurt and other cultured dairy products. J. Dairy Sci. 2017, 100, 9987–10013. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mittal, M.; Thakur, A.; Kaushik, R.; Chawla, P. Physicochemical properties of Ocimum sanctum enriched herbal fruit yoghurt. J. Food Process. Preserv. 2020, 44, e14976. [Google Scholar] [CrossRef]

- Najgebauer-Lejko, D.; Liszka, K.; Tabaszewska, M.; Domagała, J. Probiotic Yoghurts with Sea Buckthorn, Elderberry, and Sloe Fruit Purees. Molecules 2021, 26, 2345. [Google Scholar] [CrossRef] [PubMed]

- Bianchini, C.B.; Vieira, M.P.; Arriola, N.D.; Dias, C.O.; Seraglio, S.K.; Costa, A.C.O.; Komatsu, R.A.; Machado, B.D.; Amboni, R.D.; Fritzen-Freire, C.B. Incorporation of uvaia (Eugenia pyriformis Cambess) pulp in yogurt: A promising application in the lactose-free dairy product market. J. Food Process. Preserv. 2020, 44, e14829. [Google Scholar] [CrossRef]

- Szołtysik, M.; Kucharska, A.Z.; Sokół-Łętowska, A.; Dąbrowska, A.; Bobak, Ł.; Chrzanowska, J. The effect of Rosa spinosissima fruits extract on lactic acid bacteria growth and other yoghurt parameters. Foods 2020, 9, 1167. [Google Scholar] [CrossRef]

- Sun-Waterhouse, D.; Zhou, J.; Wadhwa, S.S. Effects of adding apple polyphenols before and after fermentation on the properties of drinking yoghurt. Food Bioprocess Technol. 2012, 5, 2674–2686. [Google Scholar] [CrossRef]

- Wang, X.; Kristo, E.; LaPointe, G. Adding apple pomace as a functional ingredient in stirred-type yogurt and yogurt drinks. Food Hydrocoll. 2020, 100, 105453. [Google Scholar] [CrossRef]

- AOAC. Official Methods of Analysis, 18th ed.; Association of Official Analytical Chemists: Washington, DC, USA, 2005. [Google Scholar]

- Kristo, E.; Miao, Z.; Corredig, M. The role of exopolysaccharide produced by Lactococcus lactis subsp. cremoris in structure formation and recovery of acid milk gels. Int. Dairy J. 2011, 21, 656–662. [Google Scholar] [CrossRef]

- Diep, T.T.; Yoo, M.J.Y.; Pook, C.; Sadooghy-Saraby, S.; Gite, A.; Rush, E. Volatile Components and Preliminary Antibacterial Activity of Tamarillo (Solanum betaceum Cav.). Foods 2021, 10, 2212. [Google Scholar] [CrossRef]

- Sun, H.; Zhao, S. Determination of Fatty Acid Methyl Esters (FAMEs) in Milk Matrix Using an Agilent 5977E GC/MS; Agilent Technologies: Santa Clara, CA, USA, 2014. [Google Scholar]

- Ribeiro, T.B.; Bonifácio-Lopes, T.; Morais, P.; Miranda, A.; Nunes, J.; Vicente, A.A.; Pintado, M. Incorporation of olive pomace ingredients into yoghurts as a source of fibre and hydroxytyrosol: Antioxidant activity and stability throughout gastrointestinal digestion. J. Food Eng. 2021, 297, 110476. [Google Scholar] [CrossRef]

- Trigueros, L.; Sayas-Barberá, E.; Pérez-Álvarez, J.; Sendra, E. Use of date (Phoenix dactylifera L.) blanching water for reconstituting milk powder: Yogurt manufacture. Food Bioprod. Process. 2012, 90, 506–514. [Google Scholar] [CrossRef]

- Chong, J.; Yamamoto, M.; Xia, J. MetaboAnalystR 2.0: From raw spectra to biological insights. Metabolites 2019, 9, 57. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ścibisz, I.; Ziarno, M.; Mitek, M. Color stability of fruit yogurt during storage. J. Food Sci. Technol. 2019, 56, 1997–2009. [Google Scholar] [CrossRef] [Green Version]

- Harris, P.J.; Smith, B.G. Plant cell walls and cell-wall polysaccharides: Structures, properties and uses in food products. Int. J. Food Sci. Technol. 2006, 41, 129–143. [Google Scholar] [CrossRef]

- Liu, J.; Nakamura, A.; Corredig, M. Addition of pectin and soy soluble polysaccharide affects the particle size distribution of casein suspensions prepared from acidified skim milk. J. Agric. Food Chem. 2006, 54, 6241–6246. [Google Scholar] [CrossRef]

- Do Nascimento, G.E.; Simas-Tosin, F.F.; Iacomini, M.; Gorin, P.A.; Cordeiro, L.M. Rheological behavior of high methoxyl pectin from the pulp of tamarillo fruit (Solanum betaceum). Carbohydr. Polym. 2016, 139, 125–130. [Google Scholar] [CrossRef] [PubMed]

- Elleuch, M.; Bedigian, D.; Roiseux, O.; Besbes, S.; Blecker, C.; Attia, H. Dietary fibre and fibre-rich by-products of food processing: Characterisation, technological functionality and commercial applications: A review. Food Chem. 2011, 124, 411–421. [Google Scholar] [CrossRef]

- Do Espírito Santo, A.P.; Cartolano, N.S.; Silva, T.F.; Soares, F.A.; Gioielli, L.A.; Perego, P.; Converti, A.; Oliveira, M.N. Fibers from fruit by-products enhance probiotic viability and fatty acid profile and increase CLA content in yoghurts. Int. J. Food Microbiol. 2012, 154, 135–144. [Google Scholar] [CrossRef]

- Sivakumaran, S.; Huffman, L.; Sivakumaran, S. The Concise New Zealand Food Composition Tables, 12th ed.; The New Zealand Institute for Plant & Food Research Limited and Ministry of Health: Palmerston North, New Zealand, 2017. [Google Scholar]

- Do Espírito Santo, A.; Perego, P.; Converti, A.; Oliveira, M.D. Influence of milk type and addition of passion fruit peel powder on fermentation kinetics, texture profile and bacterial viability in probiotic yoghurts. LWT 2012, 47, 393–399. [Google Scholar] [CrossRef]

- Acharjee, A.; Afrin, S.M.; Sit, N. Physicochemical, Textural and Rheological Properties of Yoghurt Enriched with Orange Pomace Powder. J. Food Process. Preserv. 2020, 45, e15193. [Google Scholar] [CrossRef]

- Cui, B.; Lu, Y.M.; Tan, C.P.; Wang, G.Q.; Li, G.H. Effect of cross-linked acetylated starch content on the structure and stability of set yoghurt. Food Hydrocoll. 2014, 35, 576–582. [Google Scholar] [CrossRef]

- Chetachukwu, A.S.; Thongraung, C.; Yupanqui, C.T. Effect of short-chain inulin on the rheological and sensory characteristics of reduced fat set coconut milk yoghurt. J. Texture Stud. 2018, 49, 434–447. [Google Scholar] [CrossRef]

- Staffolo, M.D.; Bertola, N.; Martino, M. Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int. Dairy J. 2004, 14, 263–268. [Google Scholar] [CrossRef]

- Walia, A.; Mishra, H.; Kumar, P. Effect of fermentation on physico-chemical, textural properties and yoghurt bacteria in mango soy fortified yoghurt. Afr. J. Food Sci. 2013, 7, 120–127. [Google Scholar] [CrossRef] [Green Version]

- Yuksel, Z.; Avci, E.; Erdem, Y.K. Characterization of binding interactions between green tea flavanoids and milk proteins. Food Chem. 2010, 121, 450–456. [Google Scholar] [CrossRef]

- Pan, L.H.; Liu, F.; Luo, S.Z.; Luo, J.P. Pomegranate juice powder as sugar replacer enhanced quality and function of set yogurts: Structure, rheological property, antioxidant activity and in vitro bioaccessibility. LWT 2019, 115, 108479. [Google Scholar] [CrossRef]

- Paseephol, T.; Small, D.M.; Sherkat, F. Rheology and texture of set yogurt as affected by inulin addition. J. Texture Stud. 2008, 39, 617–634. [Google Scholar] [CrossRef]

- Oliveira, M.; Sodini, I.; Remeuf, F.; Corrieu, G. Effect of milk supplementation and culture composition on acidification, textural properties and microbiological stability of fermented milks containing probiotic bacteria. Int. Dairy J. 2001, 11, 935–942. [Google Scholar] [CrossRef]

- Shihata, A.; Shah, N. Influence of addition of proteolytic strains of Lactobacillus delbrueckii subsp. bulgaricus to commercial ABT starter cultures on texture of yoghurt, exopolysaccharide production and survival of bacteria. Int. Dairy J. 2002, 12, 765–772. [Google Scholar] [CrossRef]

- Yildiz, E.; Ozcan, T. Functional and textural properties of vegetable-fibre enriched yoghurt. Int. J. Dairy Technol. 2019, 72, 199–207. [Google Scholar] [CrossRef]

- Peng, Y.; Serra, M.; Horne, D.; Lucey, J. Effect of fortification with various types of milk proteins on the rheological properties and permeability of nonfat set yogurt. J. Food Sci. 2009, 74, C666–C673. [Google Scholar] [CrossRef]

- Cheng, H. Volatile flavor compounds in yogurt: A review. Crit. Rev. Food Sci. Nutr. 2010, 50, 938–950. [Google Scholar] [CrossRef]

- Routray, W.; Mishra, H.N. Scientific and technical aspects of yogurt aroma and taste: A review. Compr. Rev. Food Sci. Food Saf. 2011, 10, 208–220. [Google Scholar] [CrossRef]

- Chen, C.; Zhao, S.; Hao, G.; Yu, H.; Tian, H.; Zhao, G. Role of lactic acid bacteria on the yogurt flavour: A review. Int. J. Food Prop. 2017, 20, S316–S330. [Google Scholar] [CrossRef] [Green Version]

- Durant, A.A.; Rodríguez, C.; Santana, A.I.; Herrero, C.; Rodríguez, J.C.; Gupta, M.P. Analysis of Volatile Compounds from Solanumbetaceum Cav. Fruits from Panama by Head-Space Micro Extraction. Rec. Nat. Prod. 2013, 7, 15. [Google Scholar]

- Torrado, A.; Suárez, M.; Duque, C.; Krajewski, D.; Neugebauer, W.; Schreier, P. Volatile constituents from tamarillo (Cyphomandra betacea Sendtn.) fruit. Flavour Fragr. J. 1995, 10, 349–354. [Google Scholar] [CrossRef]

- Wong, K.; Wong, S. Volatile constituents of Cyphomandra betacea Sendtn. fruit. J. Essent. Oil Res. 1997, 9, 357–359. [Google Scholar] [CrossRef]

- Marand, M.A.; Amjadi, S.; Marand, M.A.; Roufegarinejad, L.; Jafari, S.M. Fortification of yogurt with flaxseed powder and evaluation of its fatty acid profile, physicochemical, antioxidant, and sensory properties. Powder Technol. 2020, 359, 76–84. [Google Scholar] [CrossRef]

- Van Nieuwenhove, C.P.; Moyano, A.; Castro-Gómez, P.; Fontecha, J.; Sáez, G.; Zárate, G.; Pizarro, P.L. Comparative study of pomegranate and jacaranda seeds as functional components for the conjugated linolenic acid enrichment of yogurt. LWT 2019, 111, 401–407. [Google Scholar] [CrossRef]

- Achicanoy, D.D.; Benavides, A.H.; Martinez-Correa, H.A. Study of supercritical CO2 extraction of tamarillo (Cyphomandra Betacea) seed oil containing high added value compounds. Electrophoresis 2018, 39, 1917–1925. [Google Scholar] [CrossRef] [PubMed]

- Rybicka, I.; Gliszczyńska-Świgło, A. Sugars in dairy products of different flavours. Int. Dairy J. 2021, 114, 104933. [Google Scholar] [CrossRef]

- Gao, Q.-H.; Wu, C.-S.; Wang, M.; Xu, B.-N.; Du, L.-J. Effect of drying of jujubes (Ziziphus jujuba Mill.) on the contents of sugars, organic acids, α-tocopherol, β-carotene, and phenolic compounds. J. Agric. Food Chem. 2012, 60, 9642–9648. [Google Scholar] [CrossRef]

- Temiz, H.; Tarakci, Z.; Karadeniz, T.; Bak, T. The effect of loquat fruit (Eriobotrya japonica) marmalade addition and storage time on phsico-chemical and sensory properties of yogurt. J. Agric. Sci. 2012, 18, 329–338. [Google Scholar]

- Trigueros, L.; Pérez-Alvarez, J.; Viuda-Martos, M.; Sendra, E. Production of low-fat yogurt with quince (Cydonia oblonga Mill.) scalding water. LWT-Food Sci. Technol. 2011, 44, 1388–1395. [Google Scholar] [CrossRef]

- da Costa, M.P.; da Silva Frasao, B.; da Costa Lima, B.R.C.; Rodrigues, B.L.; Junior, C.A.C. Simultaneous analysis of carbohydrates and organic acids by HPLC-DAD-RI for monitoring goat’s milk yogurts fermentation. Talanta 2016, 152, 162–170. [Google Scholar] [CrossRef]

- Raybaudi-Massilia, R.M.; Mosqueda-Melgar, J.; Martín-Belloso, O. Antimicrobial activity of malic acid against Listeria monocytogenes, Salmonella Enteritidis and Escherichia coli O157: H7 in apple, pear and melon juices. Food Control 2009, 20, 105–112. [Google Scholar] [CrossRef]

- Etienne, A.; Génard, M.; Lobit, P.; Mbeguié-A-Mbéguié, D.; Bugaud, C. What controls fleshy fruit acidity? A review of malate and citrate accumulation in fruit cells. J. Exp. Bot. 2013, 64, 1451–1469. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Delgado, T.; Ramalhosa, E.; Pereira, J.A.; Casal, S. Organic acid profile of chestnut (Castanea sativa Mill.) as affected by hot air convective drying: Drying influence on chestnut organic acids. Int. J. Food Prop. 2018, 21, 557–565. [Google Scholar] [CrossRef] [Green Version]

- Naujoks, J.; Tabeling, C.; Dill, B.D.; Hoffmann, C.; Brown, A.S.; Kunze, M.; Kempa, S.; Peter, A.; Mollenkopf, H.-J.; Dorhoi, A. IFNs modify the proteome of Legionella-containing vacuoles and restrict infection via IRG1-derived itaconic acid. PLoS Path. 2016, 12, e1005408. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Srinivasulu, C.; Ramgopal, M.; Ramanjaneyulu, G.; Anuradha, C.; Kumar, C.S. Syringic acid (SA)—A review of its occurrence, biosynthesis, pharmacological and industrial importance. Biomed. Pharmacother. 2018, 108, 547–557. [Google Scholar] [CrossRef]

- Sarkar, T.; Salauddin, M.; Hazra, S.K.; Chakraborty, R. The impact of raw and differently dried pineapple (Ananas comosus) fortification on the vitamins, organic acid and carotene profile of dairy rasgulla (sweetened cheese ball). Heliyon 2020, 6, e05233. [Google Scholar] [CrossRef]

| Parameters | Tamarillo Powder (%/Dry Weight) | Control | POS5 | POS10 | POS15 | PRE5 | PRE10 | PRE15 |

|---|---|---|---|---|---|---|---|---|

| Lightness (L*) | - | 76.53 ± 0.87 a | 52.98 ± 0.26 b | 40.07 ± 0.36 c | 35.23 ± 0.24 d | 69.8 ± 0.93 e | 50.05 ± 0.62 f | 39.92 ± 0.12 c |

| Redness (a*) | - | −0.33 ± 0.10 a | 29.13 ± 0.23 b | 31.12 ± 0.25 c | 32.58 ± 0.39 d | 9.53 ± 0.40 e | 24.13 ± 0.28 f | 28.05 ± 0.19 g |

| Yellowness (b*) | - | 11.63 ± 0.43 a | 8.13 ± 0.29 b | 9.82 ± 0.10 c | 10.05 ± 0.15 c | 20.07 ± 0.56 d | 12.37 ± 0.23 e | 9.78 ± 0.13 c |

| Syneresis (%) | - | 30.19 ± 0.90 a | 22.88 ± 1.84 b | 18.21 ± 1.62 c | 11.18 ± 1.19 d | 20.65 ± 1.48 b | 15.78 ± 1.07 e | 9.59 ± 1.25 d |

| pH | - | 4.47 ± 0.03 a | 4.03 ± 0.01 b | 4.01 ± 0.02 c | 3.93 ± 0.01 d | 4.35 ± 0.00 e | 4.29 ± 0.02 f | 4.06 ± 0.01 g |

| Acidity (%) | - | 0.91 ± 0.02 a | 1.18 ± 0.04 b | 1.26 ± 0.03 c | 1.33 ± 0.03 d | 1.05 ± 0.02 e | 1.21 ± 0.03 b | 1.3 ± 0.01 d |

| TSS (°Brix) | - | 7.32 ± 0.19 a | 9.05 ± 0.14 b | 9.57 ± 0.08 c | 10.12 ± 0.13 d | 8.81 ± 0.06 e | 9.33 ± 0.06 f | 9.71 ± 0.07 c |

| Moisture (%) | - | 89.72 ± 0.02 a | 85.11 ± 0.05 b | 81.92 ± 0.08 c | 78.78 ± 0.01 d | 85.79 ± 0.16 e | 81.94 ± 0.11 c | 79.2 ± 0.13 f |

| Ash (%) | 8.26 | 0.53 ± 0.10 a | 0.61 ± 0.09 a | 0.67 ± 0.13 a | 0.7 ± 0.08 a | 0.58 ± 0.11 a | 0.64 ± 0.17 a | 0.68 ± 0.12 a |

| Protein (%) | 9.69 | 1.84 ± 0.08 a | 2.43 ± 0.11 b | 3.06 ± 0.05 c | 3.41 ± 0.08 d | 2.19 ± 0.10 e | 2.76 ± 0.07 f | 3.18 ± 0.09 c |

| Fat (%) | 2.36 | 2.93 ± 0.18 a | 1.54 ± 0.15 b | 1.92 ± 0.34 bc | 2.59 ± 0.22 ad | 1.72 ± 0.25 b | 2.28 ± 0.27 cd | 2.85 ± 0.21 a |

| Carbohydrate (%) | 31.7 | 2.37 ± 0.16 a | 5.05 ± 0.41 b | 6.5 ± 0.40 c | 8.06 ± 0.78 d | 4.81 ± 0.24 b | 8.15 ± 0.33 d | 8.89 ± 0.68 d |

| Dietary Fibre (%) | 15.2 | 0.00 ± 0.00 | 0.36 ± 0.09 a | 0.72 ± 0.10 b | 1.05 ± 0.05 c | 0.31 ± 0.06 a | 0.68 ± 0.10 b | 0.96 ± 0.05 c |

| Parameters | Control | POS5 | POS10 | POS15 | PRE5 | PRE10 | PRE15 |

|---|---|---|---|---|---|---|---|

| Rheology | |||||||

| Consistency coefficient (K, Pa·s) | <0.005 | 0.30 ± 0.03 | 2.22 ± 0.07 | 13.1 ± 0.37 | 0.28 ± 0.02 | 2.25 ± 0.07 | 10.54 ± 0.82 |

| Flow behaviour index (n) | 0.88 ± 0.12 | 0.68 ± 0.02 | 0.57 ± 0.01 | 0.40 ± 0.00 | 0.65 ± 0.01 | 0.52 ± 0.00 | 0.42 ± 0.01 |

| Viscosity at 350 s−1 (Pa·s) | 0.01 ± 0.00 a | 0.05 ± 0.00 b | 0.18 ± 0.01 c | 0.40 ± 0.01 d | 0.04 ± 0.00 b | 0.14 ± 0.01 e | 0.35 ± 0.01 f |

| Elastic modulus (Pa) | N/A | 0.16 ± 0.00 a | 0.57 ± 0.01 b | 1.05 ± 0.03 c | 0.12 ± 0.00 d | 0.45 ± 0.005 e | 0.93 ± 0.02 f |

| Texture | |||||||

| Firmness (N) | 1.05 ± 0.00 a | 1.15 ± 0.01 b | 1.60 ± 0.02 c | 1.83 ± 0.08 d | 1.13 ± 0.02 b | 1.55 ± 0.02 c | 2.21 ± 0.04 e |

| Consistency (N·s) | 15.80 ± 0.04 a | 16.61 ± 0.05 a | 21.92 ± 0.46 b | 24.19 ± 0.87 c | 16.19 ± 0.10 a | 21.19 ± 0.37 b | 30.83 ± 1.07 d |

| Cohesiveness (N) | <−0.005 a | −0.14 ± 0.01 b | −0.34 ± 0.00 c | −0.5 ± 0.02 d | −0.14 ± 0.01 b | −0.28 ± 0.02 e | −0.73 ± 0.05 f |

| Analytes | Concentration (mg/100 g Yoghurt) | ||||||

|---|---|---|---|---|---|---|---|

| Control | POS5 | POS10 | POS15 | PRE5 | PRE10 | PRE15 | |

| Reducing sugars | |||||||

| Fructose | 22.5 ± 3.08 a | 482 ± 120 b | 1066 ± 318 cd | 1161 ± 269 d | 365 ± 49.1 b | 909 ± 346 cd | 895 ± 156 c |

| Lactose | 1019 ± 86.4 a | 1483 ± 45.6 b | 1376 ± 91.4 c | 1263 ± 50.4 d | 2277 ± 31.2 e | 1938 ± 121 f | 1702 ± 25.4 g |

| Galactose | 283 ± 41.8 a | 387 ± 16.5 b | 372 ± 31.9 b | 318 ± 9.93 c | 46.8 ± 3.6 d | 44.5 ± 4.98 d | 36.4 ± 3.72 d |

| Glucose | 79.2 ± 11.5 a | 248 ± 11.1 b | 427 ± 30.8 c | 491 ± 26.9 d | 214 ± 9.99 e | 385 ± 30.3 f | 495 ± 22.7 d |

| Mannose | 1.72 ± 0.05 a | 3.49 ± 0.15 b | 4.21 ± 0.38 c | 4.54 ± 0.28 c | 4.66 ± 0.18 c | 5.79 ± 0.53 d | 6.12 ± 0.76 d |

| Ribose | 0.17 ± 0.01 a | 0.52 ± 0.08 b | 0.57 ± 0.06 b | 0.81 ± 0.13 c | 1.94 ± 0.3 d | 1.8 ± 0.4 de | 1.64 ± 0.27 e |

| Rhamnose | n.d | <0.005 ab | 0.01 ± 0.01 ab | 0.05 ± 0.03 cd | 0.02 ± 0.02 abc | 0.03 ± 0.04 bc | 0.07 ± 0.04 d |

| Maltose | 739 ± 55.4 a | 1117 ± 131 b | 1070 ± 69 b | 1051 ± 73.3 b | 1643 ± 161 c | 1428 ± 163 d | 1340 ± 105 d |

| Glucuronic acid | 0.75 ± 0.05 a | 1.2 ± 0.08 b | 1.25 ± 0.16 b | 1.23 ± 0.17 b | 1.46 ± 0.2 c | 1.31 ± 0.27 bc | 1.31 ± 0.23 bc |

| Arabinose | 0.07 ± 0.03 a | 0.27 ± 0.04 b | 0.33 ± 0.06 b | 0.61 ± 0.09 c | 0.42 ± 0.05 d | 0.47 ± 0.1 de | 0.51 ± 0.1 e |

| Xylose | 0.04 ± 0.04 a | 1.95 ± 0.29 b | 3.46 ± 0.54 c | 3.91 ± 0.59 cd | 1.83 ± 0.31 b | 2.73 ± 0.32 e | 3.98 ± 0.53 d |

| Fucose | 0.24 ± 0.03 a | 0.31 ± 0.05 b | 0.31 ± 0.07 ab | 0.39 ± 0.06 c | 0.34 ± 0.05 bc | 0.34 ± 0.06 bc | 0.32 ± 0.05 b |

| Total reducing sugars | 2145 ± 198 | 3725 ± 325 | 4321 ± 543 | 4296 ± 431 | 4558 ± 256 | 4717 ± 668 | 4483 ± 315 |

| Organic acids | |||||||

| Malic acid | 0.57 ± 0.09 a | 20.7 ± 0.57 b | 22.5 ± 0.18 c | 43.4 ± 0.13 d | 19.6 ± 0.33 b | 34.1 ± 0.72 e | 44.7 ± 1.09 f |

| Lactic acid | 674 ± 26.5 a | 920 ± 20.3 b | 1479 ± 124 c | 1683 ± 62.1 d | 846 ± 5.91 b | 1428 ± 20.6 c | 1833 ± 37.5 e |

| Malonic acid | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| Citric acid | 116 ± 13.2 a | 838 ± 12.5 b | 887 ± 27.6 c | 931 ± 62.9 c | 751 ± 16.9 d | 911 ± 32.6 c | 885 ± 23.5 c |

| Succinic acid | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| Fumaric acid | n.d | n.d | n.d | n.d | n.d | n.d | 0.72 ± 0.05 a |

| Itaconic acid | n.d | 0.28 ± 0.09 a | 0.81 ± 0.1 b | 0.91 ± 0.13 bc | 0.31 ± 0.03 a | 0.83 ± 0.11 b | 1.14 ± 0.1 c |

| Vanillic acid | n.d | n.d | n.d | n.d | n.d | n.d | n.d |

| Syringic acid | n.d | 1.9 ± 0.02 a | 2.28 ± 0.02 b | 2.74 ± 0.07 c | 1.2 ± 1.04 d | 2.27 ± 0.02 b | 2.63 ± 0.04 c |

| Cinnamic acid | 0.43 ± 0.01 a | 0.6 ± 0.05 b | 0.76 ± 0.06 c | 0.9 ± 0.06 d | 0.66 ± 0.08 b | 0.71 ± 0.02 c | 0.84 ± 0.05 d |

| Total organic acid | 791 ± 39.8 | 1782 ± 33.5 | 2392 ± 152 | 2662 ± 125 | 1619 ± 24.3 | 2377 ± 54.1 | 2768 ± 62.4 |

| Yoghurt Samples | α-Tocopherol (mg/100 g Yoghurt) | %AI of α-Tocopherol | β-Carotene (mg/100 g Yoghurt) | %RDI of β-Carotene | Ascorbic Acid (mg/100 g Yoghurt) | %RDI of Ascorbic Acid |

|---|---|---|---|---|---|---|

| Control | 0.09 ± 0 a | 1% | 0.03 ± 0 a | 1% | 0.57 ± 0.01 a | 2% |

| POS5 | 0.46 ± 0.02 b | 7% | 0.17 ± 0.03 b | 5% | 7.77 ± 0.33 b | 26% |

| POS10 | 0.62 ± 0.01 c | 9% | 0.26 ± 0.01 c | 7% | 11.57 ± 0.25 c | 39% |

| POS15 | 0.89 ± 0.02 d | 13% | 0.35 ± 0.01 d | 10% | 15.85 ± 0.35 d | 53% |

| PRE5 | 0.41 ± 0.01 e | 6% | 0.15 ± 0.02 b | 4% | 2.49 ± 0.02 e | 8% |

| PRE10 | 0.72 ± 0.01 f | 11% | 0.24 ± 0.01 e | 7% | 6.27 ± 0.17 f | 21% |

| PRE15 | 0.97 ± 0.04 g | 15% | 0.34 ± 0.03 d | 9% | 7.77 ± 0.05 b | 26% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Diep, T.T.; Yoo, M.J.Y.; Rush, E. Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt. Foods 2022, 11, 79. https://doi.org/10.3390/foods11010079

Diep TT, Yoo MJY, Rush E. Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt. Foods. 2022; 11(1):79. https://doi.org/10.3390/foods11010079

Chicago/Turabian StyleDiep, Tung Thanh, Michelle Ji Yeon Yoo, and Elaine Rush. 2022. "Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt" Foods 11, no. 1: 79. https://doi.org/10.3390/foods11010079

APA StyleDiep, T. T., Yoo, M. J. Y., & Rush, E. (2022). Effect of Tamarillo Fortification and Fermentation Process on Physicochemical Properties and Nutrient and Volatiles Content of Yoghurt. Foods, 11(1), 79. https://doi.org/10.3390/foods11010079