Application of Ethyl Cellulose and Ethyl Cellulose + Polyethylene Glycol for the Development of Polymer-Based Formulations using Spray-Drying Technology for Retinoic Acid Encapsulation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

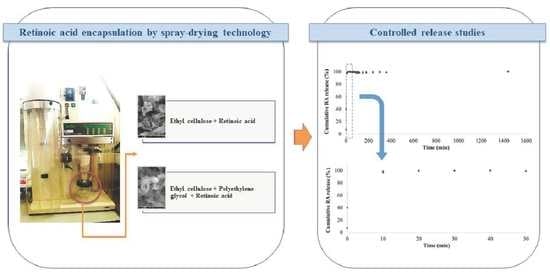

2.2. Formulation of RA Loaded-Polymer-Based Microparticles by Spray-Drying Technology

2.3. Microparticle Morphology

2.4. Particle Size Distribution

2.5. Encapsulation Efficiency and Loading Capacity

2.6. Controlled Release Experiments

2.7. Statistical Analysis

3. Results and Discussion

3.1. Surface Morphology of Microparticles

3.2. Microparticle Particle Size

3.3. Encapsulation Efficiency and Loading Capacity

3.4. Drug Controlled Release

3.5. Kinetic Models

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gonçalves, A.; Estevinho, B.N.; Rocha, F. Formulation approaches for improved retinoids delivery in the treatment of several pathologies. Eur. J. Pharm. Biopharm. 2019, 143, 80–90. [Google Scholar] [CrossRef] [PubMed]

- Bouterfa, H.; Picht, T.; Keß, D.; Herbold, C.; Noll, E.; Black, P.M.L.; Roosen, K.; Tonn, J.C. Retinoids inhibit human glioma cell proliferation and migration in primary cell cultures but not in established cell lines. Neurosurgery 2000, 46, 419–430. [Google Scholar] [CrossRef] [PubMed]

- Jeong, Y.I.; Chung, K.D.; Kim, D.H.; Kim, Y.H.; Lee, Y.S.; Choi, K.C. All-trans retinoic acid-incorporated nanoparticles of deoxycholic acid-conjugated dextran for treatment of CT26 colorectal carcinoma cells. Int. J. Nanomed. 2013, 8, 485–493. [Google Scholar] [CrossRef] [Green Version]

- Siddikuzzaman, C.; Guruvayoorappan, V.M.; Berlin, G. All trans retinoic acid and cancer. Immunopharmacol. Immunotoxicol. 2011, 33, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Lotan, R. Retinoids as modulators of tumor cell invasion and metastasis. Semin. Cancer Biol. 1991, 2, 197–208. [Google Scholar]

- Carneiro, G.; Silva, E.L.; Pacheco, L.A.; de Souza-Fagundes, E.M.; Corrêa, N.C.R.; de Goes, A.M.; de Oliveira, M.C.; Ferreira, L.A.M. Formation of ion pairing as an alternative to improve encapsulation and anticancer activity of all-trans retinoic acid loaded in solid lipid nanoparticles. Int. J. Nanomed. 2012, 7, 6011–6020. [Google Scholar] [CrossRef] [Green Version]

- Huang, P.; Chandra, V.; Rastinejad, F. Retinoic acid actions through mammalian nuclear receptors. Chem. Rev. 2014, 114, 233–254. [Google Scholar] [CrossRef] [Green Version]

- Adamson, P.C. All- Trans -Retinoic Acid Pharmacology and Its Impact on the Treatment of Acute Promyelocytic Leukemia. Oncologist 1996, 1, 305–314. [Google Scholar] [CrossRef] [Green Version]

- Achkar, C.C.; Bentel, J.M.; Boylan, J.F.; Scher, H.I.; Gudas, L.J.; Miller, W.H. Differences in the pharmacokinetic properties of orally administered all-trans-retinoic acid and 9-cis-retinoic acid in the plasma of nude mice. Drug Metab. Dispos. 1994, 22, 451–458. [Google Scholar]

- Hirota, T.; Fujimoto, T.; Konno, K.; Sakakibara, Y.N.K.; Tsurusawa, M.; Takitani, K.; Miyake, M. Pharmacokinetics studies of all-trans retinoic acid (ATRA) and pilot study of intermittent schedule of ATRA and chemotherapy in childhood acute promyelocytic leukemia. Children’s cancer and leukemia study group. Jpn. J. Clin. Hematol. 1997, 38, 1170–1176. [Google Scholar]

- Muindi, J.; Frankel, S.R.; Miller, W.H.; Jakubowski, A.; Scheinberg, D.A.; Young, C.W.; Dmitrovsky, E.; Warrell, R.P., Jr. Continuous treatment with all-trans retinoic acid causes a progressive reduction in plasma drug concentrations: Implications for relapse and retinoid “resistance” in patients with acute promyelocytic leukemia. Blood 1992, 79, 299–303. [Google Scholar] [CrossRef] [Green Version]

- Muindi, J.R.F.; Frankel, S.R.; Huselton, C.; DeGrazia, F.; Garland, W.A.; Young, C.W.; Warrell, R.P. Clinical Pharmacology of Oral All-trans Retinoic Acid in Patients with Acute Promyelocytic Leukemia. Cancer Res. 1992, 52, 2138–2142. [Google Scholar]

- Byun, Y.-R.; Kim, S.-Y.; Kim, S.-H.; Choi, Y.-D.; Han, I.-S.; Lee, K.-S.; Kim, C.-H. Controlled Drug Release System of Retinoic Acid. U.S. Patent US6764698B1, 20 July 2004. [Google Scholar]

- Lu, L.; Du, Y.; Ismail, M.; Ling, L.; Yao, C.; Fu, Z.; Li, X. Liposomes assembled from dimeric retinoic acid phospholipid with improved pharmacokinetic properties. Eur. J. Pharm. Sci. 2018, 112, 186–194. [Google Scholar] [CrossRef]

- Gonçalves, A.; Estevinho, B.N.; Rocha, F. Characterization of biopolymer-based systems obtained by spray-drying for retinoic acid controlled delivery. Powder Technol. 2019, 345, 758–765. [Google Scholar] [CrossRef]

- Gonçalves, A.; Estevinho, B.N.; Rocha, F. Spray-drying of oil-in-water emulsions for encapsulation of retinoic acid: Polysaccharide- and protein-based microparticles characterization and controlled release studies. Food Hydrocoll. 2022, 124, 107193. [Google Scholar] [CrossRef]

- Gonçalves, A.; Estevinho, B.N.; Rocha, F. Microencapsulation of retinoic acid by atomization into biopolymeric matrices: Binary and ternary blends of alginic acid sodium, xanthan gum and modified chitosan. Food Hydrocoll. 2022, 124, 107310. [Google Scholar] [CrossRef]

- Assadpour, E.; Jafari, S.M. Advances in Spray-Drying Encapsulation of Food Bioactive Ingredients: From Microcapsules to Nanocapsules. Annu. Rev. Food Sci. Technol. 2019, 10, 103–131. [Google Scholar] [CrossRef]

- Wasilewska, K.; Winnicka, K. Ethylcellulose-a pharmaceutical excipient with multidirectional application in drug dosage forms development. Materials 2019, 12, 3386. [Google Scholar] [CrossRef] [Green Version]

- Prasertmanakit, S.; Praphairaksit, N.; Chiangthong, W.; Muangsin, N. Ethyl cellulose microcapsules for protecting and controlled release of folic acid. AAPS Pharm. Sci. Tech. 2009, 10, 1104–1112. [Google Scholar] [CrossRef] [Green Version]

- Malipeddi, V.R.; Awasthi, R.; Dua, K. Formulation and evaluation of controlled release ethylcellulose and polyethylene glycol microspheres containing metoprolol tartrate. Interv. Med. Appl. Sci. 2016, 8, 60–67. [Google Scholar] [CrossRef]

- Corrêa-Filho, L.C.; Lourenço, M.M.; Moldão-Martins, M.; Alves, V.D. Microencapsulation of β-Carotene by Spray Drying: Effect of Wall Material Concentration and Drying Inlet Temperature. Int. J. Food Sci. 2019, 2019, 1–12. [Google Scholar] [CrossRef] [Green Version]

- Siontorou, C.; Nikoleli, G.-P.; Nikolelis, D.; Karapetis, S. Artificial Lipid Membranes: Past, Present, and Future. Membranes 2017, 7, 38. [Google Scholar] [CrossRef]

- Klopman, G.; Zhu, H. Recent Methodologies for the Estimation of N-Octanol/Water Partition Coefficients and their Use in the Prediction of Membrane Transport Properties of Drugs. Mini-Rev. Med. Chem. 2005, 5, 127–133. [Google Scholar] [CrossRef]

- Bahmani, A.; Saaidpour, S.; Rostami, A. A Simple, Robust and Efficient Computational Method for n-Octanol/Water Partition Coefficients of Substituted Aromatic Drugs. Sci. Rep. 2017, 7, 5760. [Google Scholar] [CrossRef]

- Liu, X.; Testa, B.; Fahr, A. Lipophilicity and Its Relationship with Passive Drug Permeation. Pharm. Res. 2011, 28, 962–977. [Google Scholar] [CrossRef]

- Dash, S.; Murthy, P.N.; Nath, L.; Chowdhury, P. Kinetic modeling on drug release from controlled drug delivery systems. Acta Pol. Pharm. 2010, 67, 217–223. [Google Scholar] [CrossRef]

- Liu, C.; Desai, K.G.; Tang, X.; Chen, X. Drug Release Kinetics of Spray-Dried Chitosan Microspheres. Dry. Technol. 2006, 24, 769–776. [Google Scholar] [CrossRef]

- Estevinho, B.N.; Rocha, F. Kinetic models applied to soluble vitamins delivery systems prepared by spray drying. Dry. Technol. 2017, 35, 1249–1257. [Google Scholar] [CrossRef]

- Antal, I.; Zelkó, R.; Röczey, N.; Plachy, J.; Rácz, I. Dissolution and diffuse reflectance characteristics of coated theophylline particles. Int. J. Pharm. 1997, 155, 83–89. [Google Scholar] [CrossRef]

- Coelho, S.C.; Laget, S.; Benaut, P.; Rocha, F.; Estevinho, B.N. A new approach to the production of zein microstructures with vitamin B12, by electrospinning and spray drying techniques. Powder Technol. 2021, 392, 47–57. [Google Scholar] [CrossRef]

- Goëlo, V.; Chaumun, M.; Gonçalves, A.; Estevinho, B.N.; Rocha, F. Polysaccharide-based delivery systems for curcumin and turmeric powder encapsulation using a spray-drying process. Powder Technol. 2020, 370, 137–146. [Google Scholar] [CrossRef]

- Belščak-Cvitanović, A.; Lević, S.; Kalušević, A.; Špoljarić, I.; Đorđević, V.; Komes, D.; Mršić, G.; Nedović, V. Efficiency Assessment of Natural Biopolymers as Encapsulants of Green Tea (Camellia sinensis L.) Bioactive Compounds by Spray Drying. Food Bioprocess Technol. 2015, 8, 2444–2460. [Google Scholar] [CrossRef]

- Corrêa-Filho, L.; Lourenço, S.; Duarte, D.; Moldão-Martins, M.; Alves, V. Microencapsulation of Tomato (Solanum lycopersicum L.) Pomace Ethanolic Extract by Spray Drying: Optimization of Process Conditions. Appl. Sci. 2019, 9, 612. [Google Scholar] [CrossRef] [Green Version]

- Waghulde, M.; Naik, J. Comparative study of encapsulated vildagliptin microparticles produced by spray drying and solvent evaporation technique. Dry. Technol. 2017, 35, 1645–1655. [Google Scholar] [CrossRef]

- Stocker, M.W.; Healy, A.M.; Ferguson, S. Spray Encapsulation as a Formulation Strategy for Drug-Based Room Temperature Ionic Liquids: Exploiting Drug-Polymer Immiscibility to Enable Processing for Solid Dosage Forms. Mol. Pharm. 2020, 17, 3412–3424. [Google Scholar] [CrossRef]

- Tsolaki, E.; Stocker, M.W.; Healy, A.M.; Ferguson, S. Formulation of ionic liquid APIs via spray drying processes to enable conversion into single and two-phase solid forms. Int. J. Pharm. 2021, 603, 120669. [Google Scholar] [CrossRef]

- Wagh, P.; Mujumdar, A.; Naik, J.B. Preparation and characterization of ketorolac tromethamine-loaded ethyl cellulose micro-/nanospheres using different techniques. Part. Sci. Technol. 2019, 37, 347–357. [Google Scholar] [CrossRef]

- Lucas, J.; Ralaivao, M.; Estevinho, B.N.; Rocha, F. A new approach for the microencapsulation of curcumin by a spray drying method, in order to value food products. Powder Technol. 2020, 362, 428–435. [Google Scholar] [CrossRef]

- Ribeiro, A.M.; Shahgol, M.; Estevinho, B.N.; Rocha, F. Microencapsulation of Vitamin A by spray-drying, using binary and ternary blends of gum arabic, starch and maltodextrin. Food Hydrocoll. 2020, 108, 106029. [Google Scholar] [CrossRef]

- Gharsallaoui, A.; Roudaut, G.; Chambin, O.; Voilley, A.; Saurel, R. Applications of spray-drying in microencapsulation of food ingredients: An overview. Food Res. Int. 2007, 40, 1107–1121. [Google Scholar] [CrossRef]

- de Francisco, L.M.B.; Cerquetani, J.A.; Bruschi, M.L. Development and characterization of gelatin and ethylcellulose microparticles designed as platforms to delivery fluoride. Drug Dev. Ind. Pharm. 2013, 39, 1644–1650. [Google Scholar] [CrossRef]

- Estevinho, B.N.; Rocha, F.; Santos, L.; Alves, A. Microencapsulation with chitosan by spray drying for industry applications—A review. Trends Food Sci. Technol. 2013, 31, 138–155. [Google Scholar] [CrossRef]

| Microparticles Content | Product Yield (%) | Particle Mean Diameter | Encapsulation Efficiency (%) | Loading Capacity (%) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Formulation | Encapsulating Agent | Differential Volume Distribution (µm) | Differential Number Distribution (µm) | D (4,3) (µm) | D (3,2) (µm) | Span (µm) | |||

| MpPE | EC | 19 | 22 ± 2 bc | 0.090 ± 0.002 c | 22 ± 2 bc | 1.97 ± 0.03 d | 3.5 ± 0.2 a | - | - |

| EC + PEG | 21 | 6.0 ± 0.1 c | 0.54 ± 0.02 a | 6.0 ± 0.1 c | 3.0 ± 0.3 c | 3.0 ± 0.3 a | - | - | |

| MpPRA | EC | 12 | 44 ± 8 a | 0.13 ± 0.01 b | 44 ± 8 a | 5.2 ± 0.3 b | 6.1 ± 0.5 a | 107 ± 23 a | 10 ± 2 a |

| EC + PEG | 28 | 31 ± 13 ab | 0.0987 ± 0.0004 c | 31 ± 13 ab | 6.1 ± 0.4 a | 7 ± 3 a | 109 ± 19 a | 10 ± 2 a | |

| Parameters | Encapsulating Agents | |||

|---|---|---|---|---|

| EC | EC + PEG | |||

| Kinetic models | Zero-order | K0 (mg∙min−1) | 7.1 × 10−3 ± 4.6 × 10−4 | 7.2 × 10−3 ± 4.7 × 10−4 |

| Q0 (mg) | 2.2 × 10−2 ± 1.4 × 10−4 | 2.4 × 10−2 ± 1.6 × 10−3 | ||

| R2 | 0.774 | 0.751 | ||

| Higuchi | KH (mg∙min−0.5) | 3.6 × 10−2 ± 2.3 × 10−3 | 3.7 × 10−2 ± 2.4 × 10−3 | |

| R2 | 0.977 | 0.972 | ||

| Korsmeyer-Peppas | Kk (min−n) | 9.1 × 10−1 ± 6.0 × 10−2 | 9.8 × 10−1 ± 6.4 × 10−2 | |

| n | 0.024 ± 0.002 | 0.0040 ± 0.0003 | ||

| R2 | 0.809 | 0.875 | ||

| Weibull | τd (min) | 2 × 10−1 ± 1 × 10−2 | 4 × 10−4 ± 2.6 × 10−5 | |

| β | 3 × 10−1 ± 2 × 10−2 | 2 × 10−1 ± 1 × 10−2 | ||

| R2 | 0.841 | 0.768 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gonçalves, A.; Rocha, F.; Estevinho, B.N. Application of Ethyl Cellulose and Ethyl Cellulose + Polyethylene Glycol for the Development of Polymer-Based Formulations using Spray-Drying Technology for Retinoic Acid Encapsulation. Foods 2022, 11, 2533. https://doi.org/10.3390/foods11162533

Gonçalves A, Rocha F, Estevinho BN. Application of Ethyl Cellulose and Ethyl Cellulose + Polyethylene Glycol for the Development of Polymer-Based Formulations using Spray-Drying Technology for Retinoic Acid Encapsulation. Foods. 2022; 11(16):2533. https://doi.org/10.3390/foods11162533

Chicago/Turabian StyleGonçalves, Antónia, Fernando Rocha, and Berta N. Estevinho. 2022. "Application of Ethyl Cellulose and Ethyl Cellulose + Polyethylene Glycol for the Development of Polymer-Based Formulations using Spray-Drying Technology for Retinoic Acid Encapsulation" Foods 11, no. 16: 2533. https://doi.org/10.3390/foods11162533

APA StyleGonçalves, A., Rocha, F., & Estevinho, B. N. (2022). Application of Ethyl Cellulose and Ethyl Cellulose + Polyethylene Glycol for the Development of Polymer-Based Formulations using Spray-Drying Technology for Retinoic Acid Encapsulation. Foods, 11(16), 2533. https://doi.org/10.3390/foods11162533