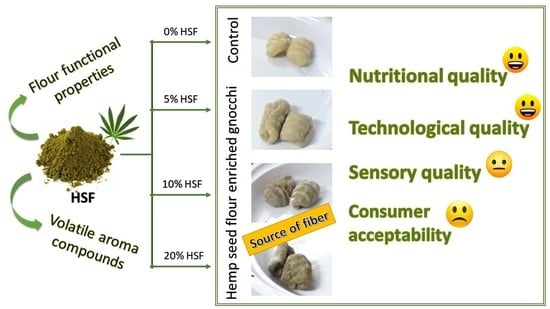

Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Functional Properties of HSF, Wheat Flour, and Composite Flours

2.2.1. Bulk Density

2.2.2. Water Holding Capacity

2.2.3. Swelling Index

2.3. Aroma Compounds of HSF

2.4. Dough and Gnocchi Preparation

2.5. Proximate Chemical Analysis of Gnocchi Samples

2.6. Pasta Cooking Conditions

2.7. Weight Increase and Solid Loss

2.8. Color

2.9. Texture Analyses

2.10. QDA Sensory Analysis

2.11. Consumer’s Acceptability Test

2.12. Statistical Analysis

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hussain, T.; Jeena, G.; Pitakbut, T.; Vasilev, N.; Kayser, O. Cannabis sativa research trends, challenges, and new-age perspectives. Iscience 2021, 24, 103391. [Google Scholar] [CrossRef] [PubMed]

- Odieka, A.E.; Obuzor, G.U.; Oyedeji, O.O.; Gondwe, M.; Hosu, Y.S.; Oyedeji, A.O. The medicinal natural products of Cannabis sativa Linn.: A review. Molecules 2022, 27, 1689. [Google Scholar] [CrossRef] [PubMed]

- European Parliament; Council of the European Union Regulation (EU). No 1307/2013 of the European Parliament and of the Council Establishing Rules for Direct Payments to Farmers under Support Schemes within the Framework of the Common Agricultural Policy and Repealing Council Regulation (EC) No 637/2008 and Council Regulation (EC) No 73/2009, Article 32 (6). Off. J. Eur. Union L 2013, 347, 608–670. Available online: http://data.europa.eu/eli/reg/2013/1307/oj (accessed on 8 August 2022).

- European Parliament; Council of the European Union Regulation (EU). No. 1308/2013 of the European Parliament and of the Council of 17 December 2013 Establishing a Common Organisation of the Markets in Agricultural Products and Repealing Council Regulations (EEC) No. 922/72, (EEC) No. 234/79, (EC) No. 1037/2001 and (EC) No. 1234/2007. (Consolidated Version 2021). Off. J. Eur. Union L 2013, 347, 671–854. Available online: https://data.europa.eu/eli/reg/2013/1308/oj (accessed on 8 August 2022).

- Farinon, B.; Molinari, R.; Costantini, L.; Merendino, N. The seed of industrial hemp (Cannabis sativa L.): Nutritional quality and potential functionality for human health and nutrition. Nutrients 2020, 12, 1935. [Google Scholar] [CrossRef]

- Leonard, W.; Zhang, P.; Ying, D.; Fang, Z. Hempseed in food industry: Nutritional value, health benefits, and industrial applications. Compr. Rev. Food Sci. Food Saf. 2020, 19, 282–308. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Norajit, K.; Kim, M.H.; Kim, Y.H.; Ryu, G.H. Influence of extrusion condition and hemp addition on wheat dough and bread properties. Food Sci. Biotechnol. 2013, 22, 89–97. [Google Scholar] [CrossRef]

- Radočaj, O.; Dimić, E.; Tsao, R. Effects of hemp (Cannabis sativa L.) seed oil press-cake and decaffeinated green tea leaves (Camellia sinensis) on functional characteristics of gluten-free crackers. J. Food Sci. 2014, 79, C318–C325. [Google Scholar] [CrossRef]

- Teterycz, D.; Sobota, A.; Przygodzka, D.; Łysakowska, P. Hemp seed (Cannabis sativa L.) enriched pasta: Physicochemical properties and quality evaluation. PLoS ONE 2021, 16, e0248790. [Google Scholar] [CrossRef]

- Korus, J.; Witczak, M.; Ziobro, R.; Juszczak, L. Hemp (Cannabis sativa ssp. sativa) flour and protein preparation as natural nutrients and structure forming agents in starch based gluten-free bread. LWT 2017, 84, 143–150. [Google Scholar] [CrossRef]

- Alessandrini, L.; Balestra, F.; Romani, S.; Rocculi, P.; Rosa, M.D. Physicochemical and sensory properties of fresh potato-based pasta (Gnocchi). J. Food Sci. 2010, 75, S542–S547. [Google Scholar] [CrossRef] [PubMed]

- Burgos, V.E.; López, E.P.; Goldner, M.C.; Del Castillo, V.C. Physicochemical characterization and consumer response to new Andean ingredients-based fresh pasta: Gnocchi. Int. J. Gastron. Food Sci. 2019, 16, 100142. [Google Scholar] [CrossRef]

- Budryn, G.; Nebesny, E.; Rachwal-Rosiak, D.; Oracz, J. Fatty acids, essential amino acids, and chlorogenic acids profiles, in vitro protein digestibility and antioxidant activity of food products containing green coffee extract. Int. Food Res. J. 2013, 20, 2133. [Google Scholar]

- Liu, T.; Hamid, N.; Yoo, M.J.; Kantono, K.; Pereira, L.; Farouk, M.M.; Knowles, S.O. Physicochemical and sensory characterization of gnocchi and the effects of novel formulation on in vitro digestibility. J. Food Sci. Technol. 2016, 53, 4033–4042. [Google Scholar] [CrossRef] [PubMed]

- Cappa, C.; Laureati, M.; Casiraghi, M.C.; Erba, D.; Vezzani, M.; Lucisano, M.; Alamprese, C. Effects of red rice or buckwheat addition on nutritional, technological, and sensory quality of potato-based pasta. Foods 2021, 10, 91. [Google Scholar] [CrossRef] [PubMed]

- Republic of Italy. DECRETO 4 Novembre 2019: Definizione di Livelli Massimi di Tetraidrocannabinolo (THC) Negli Alimenti (20A00016). Gazz. Uff. Della Repubb. Ital. 2019, 11, 3–6. Available online: https://www.gazzettaufficiale.it/eli/id/2020/01/15/20A00016/sg (accessed on 1 August 2022).

- Yellavila, S.B.; Agbenorhevi, J.K.; Asibuo, J.Y.; Sampson, G.O. Proximate composition, minerals content and functional properties of five lima bean accessions. J. Food Secur. 2015, 3, 69–74. [Google Scholar] [CrossRef]

- Giami, S.Y.; Okonkwo, V.I.; Akusu, M.O. Chemical composition and functional properties of raw, heat-treated and partially proteolysed wild mango (Irvingia gabonensis) seed flour. Food Chem. 1994, 49, 237–243. [Google Scholar] [CrossRef]

- Das, P.C.; Khan, M.J.; Rahman, M.S.; Majumder, S.; Islam, M.N. Comparison of the physico-chemical and functional properties of mango kernel flour with wheat flour and development of mango kernel flour based composite cakes. NFS J. 2019, 17, 1–7. [Google Scholar] [CrossRef]

- Condurso, C.; Mazzaglia, A.; Tripodi, G.; Cincotta, F.; Dima, G.; Lanza, M.C.; Verzera, A. Sensory analysis and head-space aroma volatiles for the characterization of capers from different geographic origin. J. Essent. Oil Res. 2016, 28, 185–192. [Google Scholar] [CrossRef]

- Horwitz, W.; Latimer, G.W. Official Methods of Analysis of AOAC International; AOAC International: Rockville, ML, USA, 2005. [Google Scholar]

- Mokrzycki, W.S.; Tatol, M. Color difference ∆E—A survey. Mach. Graph. Vis. 2011, 20, 383–411. [Google Scholar]

- ISO 13299:2003; Sensory Analysis—Methodology—General Guidance for Establishing a Sensory Profile. ISO: Geneva, Switzerland, 2003. Available online: https://www.iso.org/standard/37227.html (accessed on 9 August 2022).

- ISO 8586-1:1993; Sensory Analysis—General Guidance for the Selection, Training and Monitoring of Assessors. ISO: Geneva, Switzerland, 1993. Available online: https://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/01/58/15875.html (accessed on 5 August 2022).

- ISO 8589:2007; Sensory Analysis—General Guidance for the Design of Test Rooms. ISO: Geneva, Switzerland, 2007. Available online: https://www.iso.org/standard/36385.html (accessed on 30 July 2022).

- Mudgil, D.; Barak, S.; Khatkar, B.S. Cookie texture, spread ratio and sensory acceptability of cookies as a function of soluble dietary fiber, baking time and different water levels. LWT 2017, 80, 537–542. [Google Scholar] [CrossRef]

- Laufenberg, G.; Schulze, N. A modular strategy for processing of fruit and vegetable wastes into value-added products. In Handbook of Waste Management and Co-Product Recovery in Food Processing; Keith Waldron, K., Ed.; Woodhead Publishing: Sawston, UK, 2009; pp. 286–353. [Google Scholar] [CrossRef]

- Dhankhar, J.; Vashistha, N.; Sharma, A. Development of biscuits by partial substitution of refined wheat flour with chickpea flour and date powder. J. Microbiol. Biotechnol. Food Sci. 2021, 8, 1093–1097. [Google Scholar] [CrossRef]

- Farooq, Z.; Boye, J.I. Novel food and industrial applications of pulse flours and fractions. In Pulse Foods: Processing, Quality and Nutraceutical Applications; Tiwari, B.K., Gowen, A., McKenna, B., Eds.; Academic Press: Oxford, UK, 2011; pp. 283–323. [Google Scholar] [CrossRef]

- European Parliament and Council. Regulation (EC) No. 1924/2006 of the European Parliament and of the Council of 20 December 2006 on Nutrition and Health Claims Made on Foods. Off. J. Eur. Union L 2006, 404, 9–25. [Google Scholar]

- Stephen, A.M.; Champ, M.M.J.; Cloran, S.J.; Fleith, M.; Van Lieshout, L.; Mejborn, H.; Burley, V.J. Dietary fibre in Europe: Current state of knowledge on definitions, sources, recommendations, intakes and relationships to health. Nutr. Res. Rev. 2017, 30, 149–190. [Google Scholar] [CrossRef] [PubMed]

- Mullin, W.J.; Smith, J.M. Dietary fiber in raw and cooked potatoes. J. Food Compos. Anal. 1991, 4, 100–106. [Google Scholar] [CrossRef]

- Hummel, C. Macaroni Products: Manufacture, Processing and Packing; Food Trade Press: London, UK, 1966. [Google Scholar]

- Malcolmson, L.J.; Matsuo, R.R. Effects of cooking water composition on stickiness and cooking loss of spaghetti. Cereal Chem. 1993, 70, 272–275. [Google Scholar]

- Rayas-Duarte, P.; Mock, C.M.; Satterlee, L.D. Quality of spaghetti containing buckwheat, amaranth, and lupin flours. Cereal Chem. 1996, 73, 381–387. [Google Scholar]

- Tudorica, C.M.; Kuri, V.; Brennan, C.S. Nutritional and physicochemical characteristics of dietary fiber enriched pasta. J. Agric. Food Chem. 2002, 50, 347–356. [Google Scholar] [CrossRef]

- Petitot, M.; Boyer, L.; Minier, C.; Micard, V. Fortification of pasta with split pea and faba bean flours: Pasta processing and quality evaluation. Food Res. Int. 2010, 43, 634–641. [Google Scholar] [CrossRef]

- Krishnan, J.G.; Menon, R.; Padmaja, G.; Sajeev, M.S.; Moorthy, S.N. Evaluation of nutritional and physico-mechanical characteristics of dietary fiber-enriched sweet potato pasta. Eur. Food Res. Technol. 2012, 234, 467–476. [Google Scholar] [CrossRef]

- Chillo, S.; Laverse, J.; Falcone, P.M.; Protopapa, A.; Del Nobile, M.A. Influence of the addition of buckwheat flour and durum wheat bran on spaghetti quality. J. Cereal Sci. 2008, 47, 144–152. [Google Scholar] [CrossRef]

- Lucisano, M.; Cappa, C.; Fongaro, L.; Mariotti, M. Characterisation of gluten-free pasta through conventional and innovative methods: Evaluation of the cooking behavior. J. Cereal Sci. 2012, 56, 667–675. [Google Scholar] [CrossRef]

- Del Nobile, M.A.; Baiano, A.; Conte, A.; Mocci, G. Influence of protein content on spaghetti cooking quality. J. Cereal Sci. 2005, 41, 347–356. [Google Scholar] [CrossRef]

- El-Sohaimy, S.A.; Brennan, M.; Darwish, A.M.; Brennan, C. Physicochemical, texture and sensorial evaluation of pasta enriched with chickpea flour and protein isolate. Ann. Agric. Sci. 2020, 65, 28–34. [Google Scholar] [CrossRef]

- Larrosa, V.; Lorenzo, G.; Zaritzky, N.; Califano, A. Improvement of the texture and quality of cooked gluten-free pasta. LWT 2016, 70, 96–103. [Google Scholar] [CrossRef]

- Yildiz, O.; Meral, R.; Dogan, I.S. Determination of stickiness values of different flour combinations. Int. J. Food Eng. 2012, 8, 1–13. [Google Scholar] [CrossRef]

- Schwab, W.; Davidovich-Rikanati, R.; Lewinsohn, E. Biosynthesis of plant-derived flavor compounds. Plant J. 2008, 54, 712–732. [Google Scholar] [CrossRef]

- Condurso, C.; Cincotta, F.; Verzera, A. Determination of furan and furan derivatives in baby food. Food Chem. 2018, 250, 155–161. [Google Scholar] [CrossRef]

| Ingredients (g/100 g) | CG 1 | 5HG 2 | 10HG 3 | 20HG 4 |

|---|---|---|---|---|

| Water | 49.85 ± 0.01 | 49.85 ± 0.01 | 49.85 ± 0.01 | 49.85 ± 0.01 |

| Dehydrated potato | 29.91 ± 0.01 | 29.91 ± 0.01 | 29.91 ± 0.01 | 29.91 ± 0.01 |

| Wheat flour | 19.94 ± 0.01 | 18.94 ± 0.01 | 17.95 ± 0.01 | 15.95 ± 0.01 |

| HSF | - | 1.00 ± 0.01 | 1.99 ± 0.01 | 3.99 ± 0.01 |

| Salt | 0.29 ± 0.01 | 0.30 ± 0.01 | 0.30 ± 0.01 | 0.30 ± 0.01 |

| WF 1 | HSF 2 | 5HSF 3 | 10HSF 4 | 20HSF 5 | |

|---|---|---|---|---|---|

| Bulk density (g/mL) | 0.71 ± 0.01 a 6 | 0.60 ± 0.01 c | 0.71 ± 0.01 a | 0.69 ± 0.01 b | 0.67 ± 0.01 b |

| Water holding capacity (%) | 93.12 ± 0.009 c | 181.6 ± 0.007 a | 101.098 ± 0.007 b | 100.8 ± 0.009 b | 103.01 ± 0.005 b |

| Swelling index | 3.3 ± 0.11 b | 1.4 ± 0.05 c | 4.0 ± 0.10 a | 3.7 ± 0.08 a | 3.9 ± 0.08 a |

| CG 1 | 5HG 2 | 10HG 3 | 20HG 4 | |

|---|---|---|---|---|

| Moisture | 54.54 ± 0.63 | 54.55 ± 0.60 | 54.56 ± 0.61 | 54.57 ± 0.58 |

| Protein | 4.19 ± 0.03 d 5 | 4.36 ± 0.01 c | 4.53 ± 0.04 b | 4.87 ± 0.08 a |

| Carbohydrates | 38.58 ± 0.39 a | 37.89 ± 0.41 b | 37.19 ± 0.40 b | 35.80 ± 0.36 c |

| Fiber | 1.99 ± 0.01 d | 2.43 ± 0.02 c | 2.86 ± 0.02 b | 3.73 ± 0.02 a |

| Fat | 0.35 ± 0.00 d | 0.43 ± 0.00 c | 0.52 ± 0.00 b | 0.69 ± 0.00 a |

| Ash | 0.33 ± 0.00 b | 0.34 ± 0.00 a | 0.34 ± 0.00 a | 0.34 ± 0.00 a |

| Kcal | 174 ± 0.78 a | 173 ± 0.82 b | 172 ± 0.80 b | 169 ± 0.72 c |

| CG 1 | 5HG 2 | 10HG 3 | 20HG 4 | |

|---|---|---|---|---|

| OCT 5/s | 98 ± 4b 6 | 107 ± 8 b | 107 ± 7 b | 124 ± 5 a |

| Weight increase (% w/w) | 18.40 ± 1.71 c | 25.97 ± 3.05 a | 22.38 ± 2.98 b | 21.61 ± 2.84 b |

| Cooking loss (% w/w) | 5.58 ± 0.74 a | 3.10 ± 0.21 b | 2.92 ± 0.23 b | 2.82 ± 0.21 b |

| CG 1 | 5HG 2 | 10HG 3 | 20HG 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | |

| L* (D65) | 74.62 ± 1.72 a | 67.58 ± 2.75 A | ** 5 | 68.91 ± 3.38 b | 64.81 ± 3.64 B | ** | 69.19 ± 5.45 b | 60.78 ± 2.77 C | ** | 64.9 ± 4.09 c | 57.77 ± 2.9 D | ** |

| a* (D65) | −0.46 ± 0.14 a | −0.34 ± 0.41 A | ns 6 | −0.95 ± 0.19 b | −0.76 ± 0.33 B | ** | −1.24 ± 0.42 c | −1.97 ± 0.38 C | * | −1.33 ± 0.24 c | −2.71 ± 0.28 D | ** |

| b* (D65) | 15.74 ± 0.81 a | 10.17 ± 1.62 B | ** | 15.32 ± 1.82 a | 13.44 ± 1.95 A | ** | 14.21 ± 1.27 b | 12.85 ± 0.77 A | ** | 11.33 ± 1.06 c | 11.14 ± 1.33 B | ns |

| ΔELab | - | - | 5.75 ± 0.62 b | 4.31 ± 0.82 C | * | 5.70 ± 0.36 b | 7.49 ± 0.52 B | ** | 10.71 ± 0.98 a | 10.14 ± 0.81 A | ns | |

| CG 1 | 5HG 2 | 10HG 3 | 20HG 4 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | Raw | Cooked | Raw vs. Cooked | |

| Hardness/N | nd 5 b | 0.98 ± 0.16 B | ** 6 | 0.60 ± 0.06 a | 0.88 ± 0.18 B | ** | 0.65 ± 0.05 a | 1.41 ± 0.35 A | ** | 0.63 ± 0.09 a | 1.36 ± 0.26 A | ** |

| Adhesiveness/Ns | nd | −0.02 ± 0.02 | ns 7 | −0.01 ± 00 | −0.09 ± 0.07 | ** | n.d. | −0.05 ± 0.02 | ** | −0.01 ± 0.01 | −0.02 ± 0.02 | * |

| Springiness 8 | 0.98 ± 0.04 a | 1.11 ± 0.29 | ns | 0.95 ± 0.02 ab | 1 ± 0.05 | * | 0.93 ± 0.02 b | 0.89 ± 0.31 | ns | 0.92 ± 0.03 b | 0.98 ± 0.02 | ** |

| Cohesiveness 8 | 0.82 ± 0.06 | 0.89 ± 0.02 | ** | 0.81 ± 0.01 | 0.88 ± 0.03 | ** | 0.79 ± 0.02 | 0.80 ± 0.3 | ns | 0.79 ± 0.03 | 0.86 ± 0.02 | ** |

| Gumminess/N | nd b | 0.89 ± 0.15 B | ** | 0.52 ± 0.11 a | 0.77 ± 0.17 B | * | 0.53 ± 0.07 a | 1.27 ± 0.33 A | ** | 0.50 ± 0.08 a | 0.92 ± 0.23 A | ** |

| Chewiness/N | nd b | 0.74 ± 0.28 B | ** | 0.49 ± 0.11 a | 0.76 ± 0.18 B | * | 0.50 ± 0.08 a | 1.24 ± 0.32 A | ** | 0.46 ± 0.09 a | 0.90 ± 0.23 A | ** |

| Resilience 8 | 0.39 ± 0.03 | 0.01 ± 00 | ** | 0.40 ± 0.02 | 0.01 ± 00 | ** | 0.37 ± 0.04 | 0.01 ± 00 | ** | 0.40 ± 0.02 | 0.01 ± 00 | ** |

| CD 1 | 5HD 2 | 10HD 3 | 20HD 4 | |

|---|---|---|---|---|

| Stickiness (N) | 0.32 ± 0.02 a 5 | 0.26 ± 0.01 b | 0.26 ± 0.02 b | 0.26 ± 0.02 b |

| Work of Adhesion (Ns) | 0.03 ± 0.01 a | 0.02 ± 0.00 b | 0.02 ± 000 b | 0.01 ± 0.00 b |

| Dough Strength/Cohesiveness (mm) | 1.48 ± 0.26 | 1.26 ± 0.14 | 1.12 ± 0.16 | 1.20 ± 0.76 |

| Volatile Compounds | LRI 1 | Percentage 2 | Volatile Compounds | LRI 1 | Percentage 2 |

|---|---|---|---|---|---|

| Acids | Esters | ||||

| Acetic acid | 1450 | 3.30 ± 0.29 | Ethyl acetate | 883 | 0.33 ± 0.02 |

| Propanoic acid | 1536 | 0.11 ± 0.00 | Propyl acetate | 971 | 0.15 ± 0.01 |

| 3-Methylbutanoic acid | 1666 | 0.35 ± 0.02 | 3-Methylbutyl acetate | 1117 | 0.30 ± 0.02 |

| Pentanoic acid | 1733 | 0.21 ± 0.02 | Hexyl acetate | 1266 | 0.07 ± 0.00 |

| (E)-2-Butenoic acid | 1772 | 0.19 ± 0.01 | γ-Butyrolactone | 1629 | 0.41 ± 0.03 |

| Hexanoic acid | 1839 | 2.52 ± 0.19 | γ-Hexalactone | 1699 | 0.40 ± 0.03 |

| Heptanoic acid | 1945 | 0.12 ± 0.00 | γ-Nonalactone | 2020 | 0.12 ± 0.01 |

| Octanoic acid | 2051 | 0.19 ± 0.01 | All | 1.78 ± 0.05 | |

| Nonanoic acid | 2156 | 0.28 ± 0.01 | Ketones | ||

| 2-Octenoic acid | 2175 | 0.12 ± 0.00 | Acetone | 811 | 0.44 ± 0.03 |

| Decanoic acid | 2262 | 0.20 ± 0.01 | 2-Butanone | 900 | 0.38 ± 0.02 |

| All | 7.59 ± 0.35 | Heptan-2-one | 1178 | 2.88 ± 0.19 | |

| Aldehydes | 3-Octanone | 1249 | 0.36 ± 0.02 | ||

| 2-Methylbutanal | 911 | 1.50 ± 0.10 | 2-Octanone | 1281 | 1.48 ± 0.09 |

| 3-Methylbutanal | 915 | 5.94 ± 0.32 | 2-Methyl-1-hepten-6-one | 1328 | 0.11 ± 0.00 |

| Pentanal | 976 | 2.24 ± 0.12 | 6-Methyl-5-hepten-2-one | 1333 | 0.29 ± 0.01 |

| Hexanal | 1078 | 10.67 ± 0.96 | 3-Octen-2-one | 1405 | 0.35 ± 0.02 |

| 2-Methyl-2-butenal | 1094 | 0.17 ± 0.01 | 3,5-Octadien-2-one | 1516 | 0.38 ± 0.02 |

| Heptanal | 1182 | 0.21 ± 0.02 | All | 6.68 ± 0.22 | |

| (E)-2-Hexenal | 1217 | 0.59 ± 0.04 | Terpenoids | ||

| Octanal | 1286 | 0.08 ± 0.00 | α-Pinene | 1014 | 1.50 ± 0.08 |

| (Z)-2-Heptenal | 1323 | 1.47 ± 0.09 | Camphene | 1058 | 0.12 ± 0.01 |

| (E)-2-Octenal | 1427 | 0.30 ± 0.02 | β-Pinene | 1103 | 0.42 ± 0.03 |

| (E,E)-2,4-Heptadienal | 1492 | 0.47 ± 0.02 | 3-Carene | 1144 | 0.68 ± 0.04 |

| Benzaldehyde | 1523 | 1.30 ± 0.09 | β-Myrcene | 1157 | 0.41 ± 0.03 |

| (E)-2-Nonenal | 1532 | 0.50 ± 0.02 | Eucalyptol | 1206 | 0.26 ± 0.02 |

| All | 25.45 ± 1.03 | p-Cymene | 1268 | 0.37 ± 0.02 | |

| Alcohols | p-Cymenene | 1435 | 0.46 ± 0.03 | ||

| 2-Methyl-1-propanol | 1082 | 1.69 ± 0.10 | Linalool | 1539 | 0.08 ± 0.00 |

| 2-Pentanol | 1110 | 0.10 ± 0.00 | (Z)-Pinocamphone | 1543 | 0.15 ± 0.01 |

| 1-Butanol | 1133 | 0.23 ± 0.01 | Fenchyl alcohol | 1576 | 0.12 ± 0.01 |

| 1-Penten-3-ol | 1149 | 0.87 ± 0.06 | (E)-α-Bergamotene | 1580 | 0.27 ± 0.02 |

| 3-Methyl-1-butanol | 1198 | 10.11 ± 0.99 | Caryophyllene | 1592 | 2.00 ± 0.11 |

| 1-Pentanol | 1239 | 1.81 ± 0.11 | Terpinen-4-ol | 1596 | 0.10 ± 0.00 |

| (Z)-2-Penten-1-ol | 1305 | 0.08 ± 0.00 | (E)-Pinocarveol | 1648 | 0.19 ± 0.02 |

| 2-Heptanol | 1309 | 0.52 ± 0.03 | (E)-β-Farnesene | 1658 | 0.13 ± 0.00 |

| (E)-2-Penten-1-ol | 1312 | 0.07 ± 0.00 | α-Humulene | 1663 | 0.56 ± 0.03 |

| 1-Hexanol | 1343 | 9.98 ± 0.75 | Neral | 1680 | 0.92 ± 0.06 |

| (Z)-2-Hexen-1-ol | 1399 | 0.05 ± 0.00 | α-Terpineol | 1689 | 0.09 ± 0.00 |

| 2-Octanol | 1410 | 0.12 ± 0.00 | endo-Borneol | 1693 | 0.06 ± 0.00 |

| 1-Octen-3-ol | 1440 | 0.55 ± 0.03 | β-Selinene | 1711 | 0.17 ± 0.01 |

| 1-Heptanol | 1446 | 0.29 ± 0.01 | α-Selinene | 1717 | 0.07 ± 0.00 |

| (Z)-2-Octen-1-ol | 1608 | 0.13 ± 0.01 | Caryophyllene oxide | 1971 | 0.17 ± 0.01 |

| 1-Nonanol | 1651 | 0.06 ± 0.00 | All | 9.30 ± 0.17 | |

| Benzyl alcohol | 1869 | 0.05 ± 0.00 | Nitriles | ||

| Phenyl ethyl alcohol | 1903 | 0.12 ± 0.00 | Hexanenitrile | 1298 | 0.60 ± 0.03 |

| 1-Dodecanol | 1956 | 0.08 ± 0.00 | All | 0.60 ± 0.03 | |

| 1-Tetradecanol | 2160 | 0.13 ± 0.01 | Furanic compounds | ||

| All | 27.05 ± 1.39 | 2-Methylfuran | 864 | 0.59 ± 0.04 | |

| Hydrocarbons | 2-Ethylfuran | 950 | 4.13 ± 0.29 | ||

| 3-Methylnonane | 957 | 0.22 ± 0.01 | 2-Propylfuran | 1027 | 0.35 ± 0.02 |

| Decane | 991 | 0.93 ± 0.06 | 2- Butylfuran | 1128 | 1.12 ± 0.09 |

| Dodecane | 1190 | 0.55 ± 0.03 | 2-Pentylfuran | 1226 | 13.34 ± 1.01 |

| Tridecane | 1290 | 0.32 ± 0.02 | All | 19.53 ± 1.06 | |

| All | 2.02 ± 0.07 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Merlino, M.; Tripodi, G.; Cincotta, F.; Prestia, O.; Miller, A.; Gattuso, A.; Verzera, A.; Condurso, C. Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour. Foods 2022, 11, 2783. https://doi.org/10.3390/foods11182783

Merlino M, Tripodi G, Cincotta F, Prestia O, Miller A, Gattuso A, Verzera A, Condurso C. Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour. Foods. 2022; 11(18):2783. https://doi.org/10.3390/foods11182783

Chicago/Turabian StyleMerlino, Maria, Gianluca Tripodi, Fabrizio Cincotta, Ottavia Prestia, Anthea Miller, Antonio Gattuso, Antonella Verzera, and Concetta Condurso. 2022. "Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour" Foods 11, no. 18: 2783. https://doi.org/10.3390/foods11182783

APA StyleMerlino, M., Tripodi, G., Cincotta, F., Prestia, O., Miller, A., Gattuso, A., Verzera, A., & Condurso, C. (2022). Technological, Nutritional, and Sensory Characteristics of Gnocchi Enriched with Hemp Seed Flour. Foods, 11(18), 2783. https://doi.org/10.3390/foods11182783