3D Printing of Textured Soft Hybrid Meat Analogues

Abstract

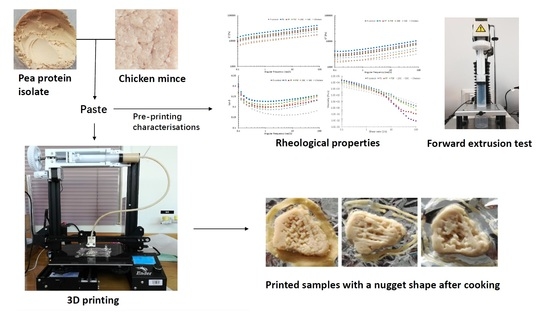

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Sample Preparation

2.3. Rheological Properties

2.3.1. Temperature Sweeps

2.3.2. Frequency Sweeps

2.3.3. Shear Flow Behaviour Tests

2.4. Forward Extrusion Testing of PPI and Chicken Pastes

2.5. 3D Printing Process

2.6. Statistical Analysis

3. Results and Discussion

3.1. Rheology

3.1.1. Temperature Sweeps

PPI Pastes

PPI-Chicken Paste

3.1.2. Frequency Sweeps

3.1.3. Shear Flow Behaviour

3.2. Forward Extrusion Test

3.3. Printing Performance

3.3.1. Appearance of Printed Meat Analogues in Different Formulations and Nozzle Sizes

3.3.2. Appearance and Macrostructure of Printed Meat Analogues after Cooking

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ortega, M.P.; Soto, R. Meat consumption and health. In Food and Beverage Consumption and Health; Nova Publishers: New York, NY, USA, 2013. [Google Scholar]

- FAO. Animal Production and Health Division: Meat & Meat Products. Available online: https://www.fao.org/ag/againfo/themes/en/meat/home.html (accessed on 17 November 2021).

- Ilea, R.C. Intensive livestock farming: Global trends, increased environmental concerns, and ethical solutions. J. Agric. Environ. Ethics 2009, 22, 153–167. [Google Scholar] [CrossRef]

- Stehfest, E.; Bouwman, L.; van Vuuren, D.P.; den Elzen, M.G.J.; Eickhout, B.; Kabat, P. Climate benefits of changing diet. Clim. Chang. 2009, 95, 83–102. [Google Scholar] [CrossRef]

- Sabaté, J.; Soret, S. Sustainability of plant-based diets: Back to the future. Am. J. Clin. Nutr. 2014, 100 (Suppl. 1), 476S–482S. [Google Scholar] [CrossRef] [PubMed]

- Aiking, H. Future protein supply. Trends Food Sci. Technol. 2011, 22, 112–120. [Google Scholar] [CrossRef]

- Tibbott, S. Food science and technology. In Handbook of Food and Beverage Fermentation; Marcel Dekker: New York, NY, USA, 2004. [Google Scholar]

- Riaz, M.N. Soy Applications in Food; Taylor and Francis: Boca Raton, FL, USA, 2006. [Google Scholar]

- Joshi, V.; Kumar, S. Meat analogues: Plant based alternatives to meat products—A review. Int. J. Food Ferment. Technol. 2015, 5, 107. [Google Scholar] [CrossRef]

- Nieuwland, M.; Geerdink, P.; Brier, P.; van den Eijnden, P.; Henket, J.T.M.M.; Langelaan, M.L.P.; Stroeks, N.; van Deventer, H.C.; Martin, A.H. Reprint of “Food-Grade Electrospinning of Proteins”. Innov. Food Sci. Emerg. Technol. 2014, 24, 138–144. [Google Scholar] [CrossRef]

- Yao, G.; Liu, K.S.; Hsieh, F. A new method for characterizing fiber formation in meat analogs during high-moisture extrusion. J. Food Sci. 2006, 69, 303–307. [Google Scholar] [CrossRef]

- Liu, K.; Hsieh, F.-H. Protein–Protein interactions during high-moisture extrusion for fibrous meat analogues and comparison of protein solubility methods using different solvent systems. J. Agric. Food Chem. 2008, 56, 2681–2687. [Google Scholar] [CrossRef]

- Beniwal, A.S.; Singh, J.; Kaur, L.; Hardacre, A.; Singh, H. Meat analogs: Protein restructuring during thermomechanical processing. Compr. Rev. Food Sci. Food Saf. 2021, 20, 1221–1249. [Google Scholar] [CrossRef]

- Chen, D.; Jones, O.G.; Campanella, O.H. Plant protein-based fibers: Fabrication, characterization, and potential food applications. Crit. Rev. Food Sci. Nutr. 2021, 1–25. [Google Scholar] [CrossRef]

- Manski, J.M.; van der Goot, A.J.; Boom, R.M. Advances in structure formation of anisotropic protein-rich foods through novel processing concepts. Trends Food Sci. Technol. 2007, 18, 546–557. [Google Scholar] [CrossRef]

- Cornet, S.H.V.; Snel, S.J.E.; Schreuders, F.K.G.; van der Sman, R.G.M.; Beyrer, M.; van der Goot, A.J. Thermo-mechanical processing of plant proteins using shear cell and high-moisture extrusion cooking. Crit. Rev. Food Sci. Nutr. 2021, 1–18. [Google Scholar] [CrossRef] [PubMed]

- Ministry for Primary Industries of New Zealand. The Evolution of Plant Protein–Assessing Consumer Response; Ministry for Primary Industries of New Zealand: Wellington, New Zealeand, 2018.

- Kyriakopoulou, K.; Dekkers, B.; van der Goot, A.J. Plant-based meat analogues. In Sustainable Meat Production and Processing; Elsevier: Amsterdam, The Netherlands, 2019; pp. 103–126. [Google Scholar] [CrossRef]

- Cichero, J.A.Y. Adjustment of food textural properties for elderly patients. J. Texture Stud. 2016, 47, 277–283. [Google Scholar] [CrossRef] [Green Version]

- Kouzani, A.Z.; Adams, S.; Whyte, J.D.; Oliver, R.; Hemsley, B.; Palmer, S.; Balandin, S. 3D printing of food for people with swallowing difficulties. In Proceedings of the DesTech 2016: International Conference on Design and Technology, Geelong, Australia, 5–8 December 2016; KnE Engineering: Dubai, United Arab Emirates, 2017; Volume 2017, pp. 23–29. [Google Scholar] [CrossRef]

- Godoi, F.C.; Prakash, S.; Bhandari, B.R. 3d printing technologies applied for food design: Status and prospects. J. Food Eng. 2016, 179, 44–54. [Google Scholar] [CrossRef] [Green Version]

- Hitti, N. Novameat Develops 3D-Printed Vegan Steak from Plant-Based Proteins. Available online: https://www.dezeen.com/2018/11/30/novameat-3d-printed-meat-free-steak/ (accessed on 30 November 2018).

- Plant-Based Meat|NOVAMEAT|Barcelona. Available online: https://www.novameat.com/ (accessed on 17 November 2021).

- SavorEat. Available online: https://savoreat.com/ (accessed on 17 November 2021).

- Osen, R.; Toelstede, S.; Wild, F.; Eisner, P.; Schweiggert-Weisz, U. High moisture extrusion cooking of pea protein isolates: Raw Material characteristics, extruder responses, and texture properties. J. Food Eng. 2014, 127, 67–74. [Google Scholar] [CrossRef]

- Plant Based Nuggets|Raised & Rooted. Available online: https://www.raisedandrooted.com/products/plant-based-nuggets/ (accessed on 17 November 2021).

- Sunfed Bull Free Beef, Boar Free Bacon & Chicken Free Chicken. Available online: https://sunfed.world/ (accessed on 17 November 2021).

- Wang, L.; Zhang, M.; Bhandari, B.; Yang, C. Investigation on fish surimi gel as promising food material for 3D printing. J. Food Eng. 2018, 220, 101–108. [Google Scholar] [CrossRef]

- Kim, H.W.; Bae, H.; Park, H.J. Classification of the printability of selected food for 3D printing: Development of an assessment method using hydrocolloids as reference material. J. Food Eng. 2017, 215, 23–32. [Google Scholar] [CrossRef]

- Zhu, S.; Stieger, M.A.; van der Goot, A.J.; Schutyser, M.A.I. Extrusion-based 3D printing of food pastes: Correlating rheological properties with printing behaviour. Innov. Food Sci. Emerg. Technol. 2019, 58, 102214. [Google Scholar] [CrossRef]

- Pusch, K.; Hinton, T.J.; Feinberg, A.W. Large volume syringe pump extruder for desktop 3D printers. HardwareX 2018, 3, 49–61. [Google Scholar] [CrossRef]

- Shand, P.J.; Ya, H.; Pietrasik, Z.; Wanasundara, P.K.J.P.D. Physicochemical and textural properties of heat-induced pea protein isolate gels. Food Chem. 2007, 102, 1119–1130. [Google Scholar] [CrossRef]

- Aryee, A.N.A.; Agyei, D.; Udenigwe, C.C. Impact of processing on the chemistry and functionality of food proteins. In Proteins in Food Processing; Elsevier: Amsterdam, The Netherlands, 2018; pp. 27–45. [Google Scholar] [CrossRef]

- Moreno, H.M.; Domínguez-Timón, F.; Díaz, M.T.; Pedrosa, M.M.; Borderías, A.J.; Tovar, C.A. Evaluation of gels made with different commercial pea protein isolate: Rheological, structural and functional properties. Food Hydrocoll. 2020, 99, 105375. [Google Scholar] [CrossRef]

- Jiang, H.; Zheng, L.; Zou, Y.; Tong, Z.; Han, S.; Wang, S. 3D food printing: Main components selection by considering rheological properties. Crit. Rev. Food Sci. Nutr. 2019, 59, 2335–2347. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.D.; Arntfield, S.D. Gelation properties of salt-extracted pea protein isolate induced by heat treatment: Effect of heating and cooling rate. Food Chem. 2011, 124, 1011–1016. [Google Scholar] [CrossRef]

- Oyinloye, T.M.; Yoon, W.B. Stability of 3D printing using a mixture of pea protein and alginate: Precision and application of additive layer manufacturing simulation approach for stress distribution. J. Food Eng. 2021, 288, 110127. [Google Scholar] [CrossRef]

- Uruakpa, F.O.; Arntfield, S.D. Impact of urea on the microstructure of commercial canola protein–carrageenan network: A research note. Int. J. Biol. Macromol. 2006, 38, 115–119. [Google Scholar] [CrossRef]

- Rabeler, F.; Feyissa, A.H. Kinetic modeling of texture and color changes during thermal treatment of chicken breast meat. Food Bioprocess Technol. 2018, 11, 1495–1504. [Google Scholar] [CrossRef] [Green Version]

- Lesiów, T.; Xiong, Y.L. Mechanism of rheological changes in poultry myofibrillar proteins during gelation. Avian Poult. Biol. Rev. 2001, 12, 137–149. [Google Scholar] [CrossRef]

- Tornberg, E. Effects of heat on meat proteins–Implications on structure and quality of meat products. Meat Sci. 2005, 70, 493–508. [Google Scholar] [CrossRef]

- Graça, C.; Raymundo, A.; de Sousa, I. Rheology changes in oil-in-water emulsions stabilized by a complex system of animal and vegetable proteins induced by thermal processing. LWT 2016, 74, 263–270. [Google Scholar] [CrossRef]

- Lopes da Silva, J.A.; Rao, M.A. Rheological behavior of food gels. In Rheology of Fluid and Semisolid Foods; Barbosa-Cánovas, G.V., Ed.; Food Engineering Series; Springer US: Boston, MA, USA, 2007; pp. 339–401. [Google Scholar] [CrossRef]

- Sim, S.Y.J.; Moraru, C.I. High-pressure processing of pea protein–starch mixed systems: Effect of starch on structure formation. J. Food Process. Eng. 2020, 43, 13352. [Google Scholar] [CrossRef]

- Lille, M.; Nurmela, A.; Nordlund, E.; Metsä-Kortelainen, S.; Sozer, N. Applicability of protein and fiber-rich food materials in extrusion-based 3D printing. J. Food Eng. 2018, 220, 20–27. [Google Scholar] [CrossRef]

- Savadkoohi, S.; Shamsi, K.; Hoogenkamp, H.; Javadi, A.; Farahnaky, A. Mechanical and gelling properties of comminuted sausages containing chicken MDM. J. Food Eng. 2013, 117, 255–262. [Google Scholar] [CrossRef]

- Lipton, J.I. Printable food: The technology and its application in human health. Curr. Opin. Biotechnol. 2017, 44, 198–201. [Google Scholar] [CrossRef]

- Schirmer, M.; Jekle, M.; Becker, T. Starch gelatinization and its complexity for analysis. Starch 2015, 67, 30–41. [Google Scholar] [CrossRef]

- Liu, Z.; Zhang, M.; Bhandari, B.; Yang, C. Impact of rheological properties of mashed potatoes on 3D printing. J. Food Eng. 2018, 220, 76–82. [Google Scholar] [CrossRef] [Green Version]

- Hölzl, K.; Lin, S.; Tytgat, L.; Van Vlierberghe, S.; Gu, L.; Ovsianikov, A. Bioink properties before, during and after 3D bioprinting. Biofabrication 2016, 8, 032002. [Google Scholar] [CrossRef]

- Faes, M.; Valkenaers, H.; Vogeler, F.; Vleugels, J.; Ferraris, E. Extrusion-based 3D printing of ceramic components. Procedia CIRP 2015, 28, 76–81. [Google Scholar] [CrossRef] [Green Version]

- Kern, C.; Weiss, J.; Hinrichs, J. Additive layer manufacturing of semi-hard model cheese: Effect of calcium levels on thermo-rheological properties and shear behavior. J. Food Eng. 2018, 235, 89–97. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, M.; Prakash, S.; Liu, Y. Physical properties of 3D printed baking dough as affected by different compositions. Innov. Food Sci. Emerg. Technol. 2018, 49, 202–210. [Google Scholar] [CrossRef]

- Dick, A.; Bhandari, B.; Prakash, S. 3D printing of meat. Meat Sci. 2019, 153, 35–44. [Google Scholar] [CrossRef]

- Lipton, J.; Arnold, D.; Nigl, F.; Lopez, N.; Cohen, D.; Norén, N.; Lipson, H. Multi-Material Food Printing with Complex Internal Structure Suitable for Conventional Post-Processing; University of Texas Library: Austin, TX, USA, 2010. [Google Scholar] [CrossRef]

- Schreuders, F.K.G.; Dekkers, B.L.; Bodnár, I.; Erni, P.; Boom, R.M.; van der Goot, A.J. Comparing structuring potential of pea and soy protein with gluten for meat analogue preparation. J. Food Eng. 2019, 261, 32–39. [Google Scholar] [CrossRef]

| Ingredients | Percentage (% w/w, Wet Basis) | |||||

|---|---|---|---|---|---|---|

| P Control 1 | PS 1 | PF 1 | PSF 1 | 20CHK 1 | 50CHK 1 | |

| PPI | 30 | 26.4 | 27.6 | 24 | 19.2 | 12 |

| Starch | 0 | 3.6 | 0 | 3.6 | 3.6 | 3.6 |

| Fat | 0 | 0 | 2.4 | 2.4 | 2.4 | 2.4 |

| Chicken paste | 0 | 0 | 0 | 0 | 19.2 | 48 |

| Soy lecithin | 1 | 1 | 1 | 1 | 1 | 1 |

| Water | 69 | 69 | 69 | 69 | 54.6 2 | 33 2 |

| Samples 3 | Extrusion Force (N) 1,2 | |

|---|---|---|

| Nozzle Size | ||

| 1.54 mm | 2.16 mm | |

| P control | 57.74 ± 1.86 a | 49.91 ± 1.98 a |

| PS | 73.47 ± 4.30 b | 83.64 ± 2.18 d |

| PF | 141.10 ± 9.43 e | 98.80 ± 2.13 e |

| PSF | 87.88 ± 3.63 c | 62.13 ± 2.85 b |

| 20CHK | 106.31 ± 3.06 d | 83.22 ± 2.50 d |

| 50CHK | 84.27 ± 0.85 b,c | 74.07 ± 0.54 c |

| Chicken | N/A | 67.73 ± 1.78 b |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, T.; Kaur, L.; Furuhata, Y.; Aoyama, H.; Singh, J. 3D Printing of Textured Soft Hybrid Meat Analogues. Foods 2022, 11, 478. https://doi.org/10.3390/foods11030478

Wang T, Kaur L, Furuhata Y, Aoyama H, Singh J. 3D Printing of Textured Soft Hybrid Meat Analogues. Foods. 2022; 11(3):478. https://doi.org/10.3390/foods11030478

Chicago/Turabian StyleWang, Tianxiao, Lovedeep Kaur, Yasufumi Furuhata, Hiroaki Aoyama, and Jaspreet Singh. 2022. "3D Printing of Textured Soft Hybrid Meat Analogues" Foods 11, no. 3: 478. https://doi.org/10.3390/foods11030478

APA StyleWang, T., Kaur, L., Furuhata, Y., Aoyama, H., & Singh, J. (2022). 3D Printing of Textured Soft Hybrid Meat Analogues. Foods, 11(3), 478. https://doi.org/10.3390/foods11030478