Radical Scavenging Activity and Physicochemical Properties of Aquafaba-Based Mayonnaises and Their Functional Ingredients

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Materials

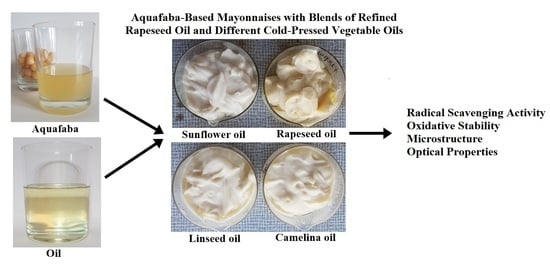

2.2. Preparation of Mayonnaise Samples

2.3. Characterization of Mayonnaise Ingredients

2.3.1. Determination of Emulsifying Properties

2.3.2. Determination of Protein Concentration

2.3.3. Determination of Fatty Acid Composition

2.3.4. Determination of Radical Scavenging Activity

2.4. Characterization of Mayonnaise Samples

2.4.1. Determination of Radical Scavenging Activity

2.4.2. Determination of Oxidative Stability

2.4.3. Microstructure

2.4.4. Color Parameters

2.5. Statistical Analysis

3. Results and Discussion

3.1. Characterization of Mayonnaise Ingredients

3.1.1. Emulsifying Properties and Protein Content

3.1.2. Fatty Acid Compositions of Vegetable Oils

3.1.3. Radical Scavenging Activity of Mayonnaise Ingredients

3.2. Characterization of Mayonnaise Samples

3.2.1. Radical Scavenging Activity

3.2.2. Oxidative Status

3.2.3. Microstructure

3.2.4. Color

3.3. Principal Component Analysis

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ghorbani Gorji, S.; Smyth, H.E.; Sharma, M.; Fitzgerald, M. Lipid oxidation in mayonnaise and the role of natural antioxidants: A review. Trends Food Sci. Technol. 2016, 56, 88–102. [Google Scholar] [CrossRef] [Green Version]

- Di Mattia, C.; Balestra, F.; Sacchetti, G.; Neri, L.; Mastrocola, D.; Pittia, P. Physical and structural properties of extra-virgin olive oil based mayonnaise. LWT-Food Sci. Technol. 2015, 62, 764–770. [Google Scholar] [CrossRef]

- Geng, M.; Hu, T.; Zhou, Q.; Taha, A.; Qin, L.; Lv, W.; Xu, X.; Pan, S.; Hu, H. Effects of different nut oils on the structures and properties of gel-like emulsions induced by ultrasound using soy protein as an emulsifier. Int. J. Food Sci. Technol. 2021, 56, 1649–1660. [Google Scholar] [CrossRef]

- Raudsepp, P.; Brüggemann, D.A.; Lenferink, A.; Otto, C.; Andersen, M.L. Oxidative stabilization of mixed mayonnaises made with linseed oil and saturated medium-chain triglyceride oil. Food Chem. 2014, 152, 378–385. [Google Scholar] [CrossRef]

- Eidhin, D.N.; O’Beirne, D. Oxidative stability of camelina oil in salad dressings, mayonnaises and during frying. Int. J. Food Sci. Technol. 2010, 45, 444–452. [Google Scholar] [CrossRef]

- Symoniuk, E.; Ratusz, K.; Krygier, K. Oxidative stability and the chemical composition of market cold-pressed linseed oil. Eur. J. Lipid Sci. Technol. 2017, 119, 1700055. [Google Scholar] [CrossRef]

- Ratusz, K.; Symoniuk, E.; Wroniak, M.; Rudzińska, M. Bioactive compounds, nutritional quality and oxidative stability of cold-pressed camelina (Camelina sativa L.) oils. Appl. Sci. 2018, 8, 2606. [Google Scholar] [CrossRef] [Green Version]

- Siger, A.; Nogala-Kalucka, M.; Lampart-Szczapa, E. The content and antioxidant activity of phenolic compounds in cold-pressed plant oils. J. Food Lipids 2008, 15, 137–149. [Google Scholar] [CrossRef]

- Grajzer, M.; Szmalcel, K.; Kuźmiński, Ł.; Witkowski, M.; Kulma, A.; Prescha, A. Characteristics and antioxidant potential of cold-pressed oils—Possible strategies to improve oil stability. Foods 2020, 9, 1630. [Google Scholar] [CrossRef]

- Ozdemir, N.; Kantekin-Erdogan, M.N.; Tat, T.; Tekin, A. Effect of black cumin oil on the oxidative stability and sensory characteristics of mayonnaise. J. Food Sci. Technol. 2018, 55, 1562–1568. [Google Scholar] [CrossRef]

- Thanonkaew, A.; Wongyai, S.; Decker, E.A.; McClements, D.J. Formation, antioxidant property and oxidative stability of cold pressed rice bran oil emulsion. J. Food Sci. Technol. 2015, 52, 6520–6528. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Rong, Y.; Chen, L.; Zhu, T.; Song, Y.; Yu, M.; Shan, Z.; Sands, A.; Hu, F.B.; Liu, L. Egg consumption and risk of coronary heart disease and stroke: Dose-response meta-analysis of prospective cohort studies. BMJ 2013, 346, e8539. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Y.; Zhou, C.; Zhou, X.; Li, L. Egg consumption and risk of cardiovascular diseases and diabetes: A meta-analysis. Atherosclerosis 2013, 229, 524–530. [Google Scholar] [CrossRef] [PubMed]

- Shin, J.Y.; Xun, P.; Nakamura, Y.; He, K. Egg consumption in relation to risk of cardiovascular disease and diabetes: A systematic review and meta-analysis. Am. J. Clin. Nutr. 2013, 98, 146–159. [Google Scholar] [CrossRef] [Green Version]

- Gibin, D.; Simonetto, A.; Zanini, B.; Gilioli, G. A framework assessing the footprints of food consumption. An application on water footprint in Europe. Environ. Impact Assess. Rev. 2022, 93, 106735. [Google Scholar] [CrossRef]

- Gonzales-González, V.A.; Díaz, A.M.; Fernández, K.; Rivera, M.F. Prevalence of food allergens sensitization and food allergies in a group of allergic Honduran children. Allergy Asthma Clin. Immunol. 2018, 14, 23. [Google Scholar] [CrossRef]

- Alu’datt, M.H.; Rababah, T.; Alhamad, M.N.; Ereifej, K.; Gammoh, S.; Kubow, S.; Tawalbeh, D. Preparation of mayonnaise from extracted plant protein isolates of chickpea, broad bean and lupin flour: Chemical, physiochemical, nutritional and therapeutic properties. J. Food Sci. Technol. 2017, 54, 1395–1405. [Google Scholar] [CrossRef] [Green Version]

- Aluko, R.E.; McIntosh, T. Limited enzymatic proteolysis increases the level of incorporation of canola proteins into mayonnaise. Innov. Food Sci. Emerg. Technol. 2005, 6, 195–202. [Google Scholar] [CrossRef]

- Sørensen, A.M.; Nielsen, N.S.; Hyldig, G.; Jacobsen, C. Influence of emulsifier type on lipid oxidation in fish oil-enriched light mayonnaise. Eur. J. Lipid Sci. Technol. 2010, 112, 1012–1023. [Google Scholar] [CrossRef]

- Rahmati, K.; Mazaheri Tehrani, M.; Daneshvar, K. Soy milk as an emulsifier in mayonnaise: Physico-chemical, stability and sensory evaluation. J. Food Sci. Technol. 2014, 51, 3341–3347. [Google Scholar] [CrossRef] [Green Version]

- Karshenas, M.; Goli, M.; Zamindar, N. Substitution of sesame and peanut defatted-meal milk with egg yolk and evaluation of the rheological and microstructural properties of low-cholesterol mayonnaise. Food Sci. Technol. Int. 2019, 25, 633–641. [Google Scholar] [CrossRef] [PubMed]

- Ali, M.R.; EL Said, R.M. Assessment of the potential of Arabic gum as an antimicrobial and antioxidant agent in developing vegan “egg-free” mayonnaise. J. Food Saf. 2020, 40, e12771. [Google Scholar] [CrossRef]

- Raikos, V.; Hayes, H.; Ni, H. Aquafaba from commercially canned chickpeas as potential egg replacer for the development of vegan mayonnaise: Recipe optimisation and storage stability. Int. J. Food Sci. Technol. 2020, 55, 1935–1942. [Google Scholar] [CrossRef]

- He, Y.; Shim, Y.Y.; Mustafa, R.; Meda, V.; Reaney, M.J.T. Chickpea cultivar selection to produce aquafaba with superior emulsion properties. Foods 2019, 8, 685. [Google Scholar] [CrossRef] [Green Version]

- Damian, J.J.; Huo, S.; Serventi, L. Phytochemical content and emulsifying ability of pulses cooking water. Eur. Food Res. Technol. 2018, 244, 1647–1655. [Google Scholar] [CrossRef]

- He, Y.; Meda, V.; Reaney, M.J.T.; Mustafa, R. Aquafaba, a new plant-based rheological additive for food applications. Trends Food Sci. Technol. 2021, 111, 27–42. [Google Scholar] [CrossRef]

- Muehlbauer, F.J.; Sarker, A. Economic importance of chickpea: Production, value, and world Trade. In The Chickpea Genome; Varshney, R.K., Thudi, M., Muehlbauer, F., Eds.; Compendium of Plant Genomes; Springer International Publishing: Cham, Switzerland, 2017; pp. 5–12. [Google Scholar] [CrossRef]

- Buhl, T.F.; Christensen, C.H.; Hammershøj, M. Aquafaba as an egg white substitute in food foams and emulsions: Protein composition and functional behavior. Food Hydrocoll. 2019, 96, 354–364. [Google Scholar] [CrossRef]

- Meurer, M.C.; de Souza, D.; Ferreira Marczak, L.D. Effects of ultrasound on technological properties of chickpea cooking water (aquafaba). J. Food Eng. 2020, 265, 109688. [Google Scholar] [CrossRef]

- He, Y.; Purdy, S.K.; Tse, T.J.; Tar’an, B.; Meda, V.; Reaney, M.J.T.; Mustafa, R. Standardization of aquafaba production and application in vegan mayonnaise analogs. Foods 2021, 10, 1978. [Google Scholar] [CrossRef]

- Cheung, L.; Wanasundara, J.; Nickerson, M.T. The effect of pH and nacl levels on the physicochemical and emulsifying properties of a cruciferin protein isolate. Food Biophys. 2014, 9, 105–113. [Google Scholar] [CrossRef]

- Pearce, K.N.; Kinsella, J.E. Emulsifying properties of proteins: Evaluation of a turbidimetric technique. J. Agric. Food Chem. 1978, 26, 716–723. [Google Scholar] [CrossRef]

- PN-75-A-04018:1975/Az3:2002; Agri-Food Products—Determination of Nitrogen Content by the Kjeldahl Method and the Conversion of Protein. Polish Committee for Standardization: Warszawa, Poland, 2002.

- ISO 5508; Animal and Vegetable Fats and Oils—Analysis by Gas Chromatography of Methyl Esters of Fatty Acid. International Organization for Standardization: Geneva, Switzerland, 1996.

- ISO 5509; Animal and Vegetable Fats and Oils—Preparation of Methyl Esters of Fatty Acids. International Organization for Standardization: Geneva, Switzerland, 2000.

- Szydłowska-Czerniak, A.; Tułodziecka, A.; Momot, M.; Stawicka, B. Physicochemical, antioxidative, and sensory properties of refined rapeseed oils. J. Am. Oil Chem. Soc. 2019, 96, 405–419. [Google Scholar] [CrossRef]

- Alizadeh, L.; Abdolmaleki, K.; Nayebzadeh, K.; Shahin, R. Effects of tocopherol, rosemary essential oil and ferulago angulata extract on oxidative stability of mayonnaise during its shelf life: A comparative study. Food Chem. 2019, 285, 46–52. [Google Scholar] [CrossRef] [PubMed]

- ISO 3960; Animal and Vegetable Fats and Oils—Determination of Peroxide Value–Iodometric (Visual) Endpoint Determination. International Organization for Standardization: Geneva, Switzerland, 2017.

- ISO 6885; Animal and Vegetable Fats and Oils—Determination of Anisidine Value. International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 660; Animal and Vegetable Fats and Oils—Determination of Acid Value and Acidity. International Organization for Standardization: Geneva, Switzerland, 2020.

- Yan, W.; Qiao, L.; Gu, X.; Li, J.; Xu, R.; Wang, M.; Reuhs, B.; Yang, Y. Effect of high pressure treatment on the physicochemical and functional properties of egg yolk. Eur. Food Res. Technol. 2010, 231, 371–377. [Google Scholar] [CrossRef]

- Suhag, R.; Dhiman, A.; Thakur, D.; Kumar, A.; Upadhyay, A. Physico-chemical and functional properties of microfluidized egg yolk. J. Food Eng. 2020, 294, 110416. [Google Scholar] [CrossRef]

- Karaca, A.C.; Low, N.; Nickerson, M. Emulsifying properties of chickpea, faba bean, lentil and pea proteins produced by isoelectric precipitation and salt extraction. Food Res. Int. 2011, 44, 2742–2750. [Google Scholar] [CrossRef]

- Mustafa, R.; He, Y.; Shim, Y.Y.; Reaney, M.J.T. Aquafaba, wastewater from chickpea canning, functions as an egg replacer in sponge cake. Int. J. Food Sci. Technol. 2018, 53, 2247–2255. [Google Scholar] [CrossRef]

- Xu, Y.; Obielodan, M.; Sismour, E.; Arnett, A.; Alzahrani, S.; Zhang, B. Physicochemical, functional, thermal and structural properties of isolated kabuli chickpea proteins as affected by processing approaches. Int. J. Food Sci. Technol. 2017, 52, 1147–1154. [Google Scholar] [CrossRef]

- Bouyer, E.; Mekhloufi, G.; Rosilio, V.; Grossiord, J.-L.; Agnely, F. Proteins, polysaccharides, and their complexes used as stabilizers for emulsions: Alternatives to synthetic surfactants in the pharmaceutical field? Int. J. Pharm. 2012, 436, 359–378. [Google Scholar] [CrossRef]

- Günal-Köroğlu, D.; Turan, S.; Capanoglu, E. Interaction of lentil protein and onion skin phenolics: Effects on functional properties of proteins and in vitro gastrointestinal digestibility. Food Chem. 2022, 372, 130892. [Google Scholar] [CrossRef]

- Chung, C.; Sher, A.; Rousset, P.; Decker, E.A.; McClements, D.J. Formulation of food emulsions using natural emulsifiers: Utilization of quillaja saponin and soy lecithin to fabricate liquid coffee whiteners. J. Food Eng. 2017, 209, 1–11. [Google Scholar] [CrossRef]

- Bors, M.D.; Semeniuc, C.A.; Socaci, S.; Vlaic, R.; Moldovan, O.P.; Pop, A.V.; Tofa, M. The influence of variety and processing on the total phenolic content and antioxidant activity of mustard. Rom. Biotechnol. Lett. 2017, 22, 12827–12833. [Google Scholar]

- Xu, B.; Chang, S.K.C. Effect of soaking, boiling, and steaming on total phenolic contentand antioxidant activities of cool season food legumes. Food Chem. 2008, 110, 1–13. [Google Scholar] [CrossRef] [PubMed]

- Rabiej-Kozioł, D.; Krzemiński, M.P.; Szydłowska-Czerniak, A. Synthesis of steryl hydroxycinnamates to enhance antioxidant activity of rapeseed oil and emulsions. Materials 2020, 13, 4536. [Google Scholar] [CrossRef]

- De Bruno, A.; Romeo, R.; Gattuso, A.; Piscopo, A.; Poiana, M. Functionalization of a vegan mayonnaise with high value ingredient derived from the agro-industrial sector. Foods 2021, 10, 2684. [Google Scholar] [CrossRef]

- Bolarin, F.M.; Oke, M.O. Effect of addition of moringa (Moringa oleifera L.) seed flour on the quality characteristics of mayonnaise. IJMRAP 2018, 1, 11–17. [Google Scholar] [CrossRef]

- McClements, D.J. Food Emulsions: Principles, Practices, and Techniques, 3rd ed.; CRC Press: Boca Raton, FL, USA, 2015. [Google Scholar] [CrossRef]

- Yildirim, M.; Sumnu, G.; Sahin, S. Rheology, particle-size distribution, and stability of low-fat mayonnaise produced via double emulsions. Food Sci. Biotechnol. 2016, 25, 1613–1618. [Google Scholar] [CrossRef]

- Armaforte, E.; Hopper, L.; Stevenson, G. Preliminary investigation on the effect of proteins of different leguminous species (cicer arietinum, vicia faba and lens culinarius) on the texture and sensory properties of egg-free mayonnaise. LWT-Food Sci. Technol. 2021, 136, 110341. [Google Scholar] [CrossRef]

| Ingredient | MRO (g/100 g) | MSO (g/100 g) | MLO (g/100 g) | MCO (g/100 g) |

|---|---|---|---|---|

| Aquafaba | 23.70 | 23.70 | 23.70 | 23.70 |

| Mustard | 1.25 | 1.25 | 1.25 | 1.25 |

| Nutritional yeast | 0.10 | 0.10 | 0.10 | 0.10 |

| Vinegar | 0.65 | 0.65 | 0.65 | 0.65 |

| Sugar | 0.15 | 0.15 | 0.15 | 0.15 |

| Salt | 0.15 | 0.15 | 0.15 | 0.15 |

| RRO | 67.00 | 67.00 | 67.00 | 67.00 |

| CPRO | 7.00 | – | – | – |

| CPSO | – | 7.00 | – | – |

| CPLO | – | – | 7.00 | – |

| CPCO | – | – | – | 7.00 |

| Emulsifier Type | EAI ± SD (m2/g) | ESI ± SD (min) | Protein ± SD (%) |

|---|---|---|---|

| Aquafaba | 13.75 ± 0.69 b | 20.92 ± 0.61 a | 1.26 ± 0.05 a |

| Egg yolk | 1.78 ± 0.07 a | 2385 ± 103 b | 16.12 ± 0.47 b |

| Oil Type | C16:0 ± SD (%) | C18:0 ± SD (%) | C18:1 ± SD (%) | C18:2 ± SD (%) | C18:3 ± SD (%) | C20:0 ± SD (%) | C20:1 ± SD (%) | ΣSAFA (%) | ΣMUFA (%) | ΣPUFA (%) |

|---|---|---|---|---|---|---|---|---|---|---|

| RRO | 4.4 ± 0.1 a | 1.8 ± 0.1 a | 62.2 ± 0.2 d | 19.3 ± 0.1 b,c | 9.2 ± 0.1 c | 0.7 ± 0.0 c | 1.4 ± 0.0 c | 6.9 | 63.6 | 28.5 |

| CPRO | 4.8 ± 0.0 b | 1.6 ± 0.0 a | 63.4 ± 0.1 e | 19.4 ± 0.0 c | 8.0 ± 0.1 b | 0.6 ± 0.0 c | 1.2 ± 0.0 b | 7.0 | 64.6 | 27.4 |

| CPSO | 6.6 ± 0.1 e | 3.7 ± 0.1c | 29.0 ± 0.0 c | 58.9 ± 0.1 d | 0.1 ± 0.0 a | 0.3 ± 0.0 b | 0.1 ± 0.0 a | 10.6 | 29.1 | 59.0 |

| CPLO | 5.3 ± 0.0 c | 2.5 ± 0.0 b | 18.8 ± 0.1 b | 19.2 ± 0.0 b | 30.5 ± 0.1 d | 1.7 ± 0.1 d | 15.0 ± 0.1 d | 9.5 | 33.8 | 49.7 |

| CPCO | 5.5 ± 0.0 d | 4.1 ± 0.1 d | 15.6 ± 0.0 a | 16.3 ± 0.0 a | 57.5 ± 0.1 e | 0.1 ± 0.0 a | 0.1 ± 0.0 a | 9.7 | 15.7 | 73.8 |

| Ingredient | DPPH ± SD (μmol TE/100 g) | ABTS ± SD (μmol TE/100 g) |

|---|---|---|

| Aquafaba | 437 ± 22 b | 2097 ± 22 b |

| Nutritional yeast | 1687 ± 60 d | 9192 ± 238 d |

| Mustard | 1129 ± 16 c | 4985 ± 107 c |

| RRO | 387 ± 8.3 b | 669 ± 29 a |

| CPRO | 391 ± 19 b | 738 ± 25 a |

| CPSO | 290 ± 13 a | 588 ± 15 a |

| CPLO | 272 ± 4.5 a | 602 ± 27 a |

| CPCO | 387 ± 4.5 b | 706 ± 34 a |

| Mayonnaise Type | PV ± SD (mEq O2/kg) | AnV ± SD | TOTOX Index | AV ± SD (mg KOH/g) |

|---|---|---|---|---|

| MRO | 1.43 ± 0.06 c | 1.39 ± 0.08 c | 4.25 | 0.14 ± 0.01 a,b |

| MSO | 1.90 ± 0.06 d | 1.12 ± 0.06 b | 4.92 | 0.26 ± 0.01 c |

| MLO | 2.27 ± 0.10 f | 2.95 ± 0.06 d | 7.49 | 0.11 ± 0.01 a |

| MCO | 1.19 ± 0.01 b | 1.55 ± 0.09 c | 3.93 | 0.17 ± 0.01 b |

| MT1 | 2.09 ± 0.07 e | 1.19 ± 0.08 b,c | 5.37 | 0.49 ± 0.01 d |

| MT2 | 0.82 ± 0.01 a | 0.76 ± 0.05 a | 2.40 | 0.49 ± 0.02 d |

| MV | 4.61 ± 0.08 g | 3.07 ± 0.12 d | 12.29 | 0.52 ± 0.03 d |

| Mayonnaise Type | L* ± SD | a* ± SD | b* ± SD |

|---|---|---|---|

| MRO | 48.7 ± 0.2 e | 0.9 ± 0.2 c | 10.9 ± 0.4 c |

| MSO | 44.5 ± 0.1 b | −0.3 ± 0.1 a | 7.1 ± 0.3 a |

| MLO | 41.5 ± 0.3 a | 0.2 ± 0.1 b | 9.2 ± 0.2 b |

| MCO | 47.1 ± 0.5 c | 0.5 ± 0.1 b | 6.7 ± 0.1 a |

| MT1 | 47.9 ± 0.1 d | 3.4 ± 0.1 f | 11.2 ± 0.1 c |

| MT2 | 47.7 ± 0.2 d | 2.2 ± 0.2 d | 9.0 ± 0.4 b |

| MV | 41.4 ± 0.2 a | 2.6 ± 0.2 e | 11.3 ± 0.4 c |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Włodarczyk, K.; Zienkiewicz, A.; Szydłowska-Czerniak, A. Radical Scavenging Activity and Physicochemical Properties of Aquafaba-Based Mayonnaises and Their Functional Ingredients. Foods 2022, 11, 1129. https://doi.org/10.3390/foods11081129

Włodarczyk K, Zienkiewicz A, Szydłowska-Czerniak A. Radical Scavenging Activity and Physicochemical Properties of Aquafaba-Based Mayonnaises and Their Functional Ingredients. Foods. 2022; 11(8):1129. https://doi.org/10.3390/foods11081129

Chicago/Turabian StyleWłodarczyk, Katarzyna, Agnieszka Zienkiewicz, and Aleksandra Szydłowska-Czerniak. 2022. "Radical Scavenging Activity and Physicochemical Properties of Aquafaba-Based Mayonnaises and Their Functional Ingredients" Foods 11, no. 8: 1129. https://doi.org/10.3390/foods11081129

APA StyleWłodarczyk, K., Zienkiewicz, A., & Szydłowska-Czerniak, A. (2022). Radical Scavenging Activity and Physicochemical Properties of Aquafaba-Based Mayonnaises and Their Functional Ingredients. Foods, 11(8), 1129. https://doi.org/10.3390/foods11081129