Changes in Morphological and Physicochemical Properties of Waxy and Non-waxy Proso Millets during Cooking Process

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Cooking Conditions and Sample Preparation

2.3. Determination of Cooking Characteristics

2.4. Chemical Compositions

2.5. Morphological Properties of Proso Millet Grains

2.6. Morphological Characteristics of Proso Millet Flour

2.7. Crystalline Structure

2.8. Short-Range Ordered Structure

2.9. Thermal Properties

2.10. Pasting Properties

2.11. Statistical Analysis

3. Results and Discussion

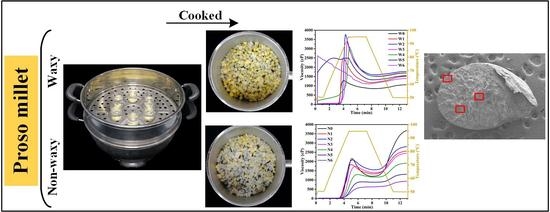

3.1. Proso Millet Grain Morphology during the Cooking Process

3.2. Characteristics of Cooked Proso Millet Grains

3.3. Chemical Compositions of Proso Millet Flour

3.4. SEM Images of Proso Millet Grains and Flours

3.5. Crystalline Structure

3.6. Ordered Structure

3.7. Thermal Properties of Proso Millet Flours

3.8. Pasting Properties of Proso Millet Flour

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Azad, M.O.K.; Jeong, D.I.; Adnan, M.; Salitxay, T.; Heo, J.W.; Naznin, M.T.; Lim, J.D.; Cho, D.H.; Park, B.J.; Park, C.H. Effect of Different Processing Methods on the Accumulation of the Phenolic Compounds and Antioxidant Profile of Broomcorn Millet (Panicum miliaceum L.) Flour. Foods 2019, 8, 7. [Google Scholar]

- Wiedemair, V.; Ramoner, R.; Huck, C.W. Investigations into the total antioxidant capacities of cultivars of gluten-free grains using near-infrared spectroscopy. Food Control 2019, 95, 189–195. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, P.; Qu, Y.; Gao, X.; Liang, J.; Yang, P.; Feng, B. Comparison of physicochemical properties and cooking edibility of waxy and non-waxy proso millet (Panicum miliaceum L.). Food Chem. 2018, 257, 271–278. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Panhwar, R.; Liu, J.; Gong, X.; Liang, J.; Liu, M.; Lu, P.; Gao, X.; Feng, B. Morphological diversity and correlation analysis of phenotypes and quality traits of proso millet (Panicum miliaceum L.) core collections. J. Integr. Agric. 2019, 18, 958–969. [Google Scholar] [CrossRef]

- Habiyaremye, C.; Matanguihan, J.B.; D’Alpoim Guedes, J.; Ganjyal, G.M.; Whiteman, M.R.; Kidwell, K.K.; Murphy, K.M. Proso millet (Panicum miliaceum L.) and its potential for cultivation in the pacific Northwest, U.S.: A review. Front. Plant Sci. 2016, 7, 1961. [Google Scholar] [CrossRef]

- Gong, X.-W.; Li, J.; Ma, H.-C.; Chen, G.-H.; Wang, M.; Yang, P.; Gao, J.-F.; Feng, B.-L. Field microclimate and yield for proso millet intercropping with mung bean in the dryland of Loess Plateau, Northwest China. Yingyong Shengtai Xuebao 2018, 29, 3256–3266. [Google Scholar]

- Annor, G.A.; Tyl, C.; Marcone, M.; Ragaee, S.; Marti, A. Why do millets have slower starch and protein digestibility than other cereals? Trends Food Sci. Tech. 2017, 66, 73–83. [Google Scholar] [CrossRef]

- Xu, D.; Hong, Y.; Gu, Z.; Cheng, L.; Li, Z.; Li, C. Effect of high pressure steam on the eating quality of cooked rice. LWT Food Sci. Technol. 2019, 104, 100–108. [Google Scholar] [CrossRef]

- Pan, T.; Zhao, L.; Lin, L.; Wang, J.; Liu, Q.; Wei, C. Changes in kernel morphology and starch properties of high-amylose brown rice during the cooking process. Food Hydrocoll. 2017, 66, 227–236. [Google Scholar] [CrossRef]

- Tian, J.; Cai, Y.; Qin, W.; Matsushita, Y.; Ye, X.; Ogawa, Y. Parboiling reduced the crystallinity and in vitro digestibility of non-waxy short grain rice. Food Chem. 2018, 257, 23–28. [Google Scholar] [CrossRef]

- He, M.; Qiu, C.; Liao, Z.; Sui, Z.; Corke, H. Impact of cooking conditions on the properties of rice: Combined temperature and cooking time. Int. J. Biol. Macromol. 2018, 117, 87–94. [Google Scholar] [CrossRef] [PubMed]

- Guo, P.; Yu, J.; Wang, S.; Wang, S.; Copeland, L. Effects of particle size and water content during cooking on the physicochemical properties and in vitro starch digestibility of milled durum wheat grains. Food Hydrocoll. 2018, 77, 445–453. [Google Scholar] [CrossRef]

- Wang, R.; Wang, H.; Liu, X.; Ji, X.; Chen, L.; Lu, P.; Liu, M.; Teng, B.; Qiao, Z. Waxy allelic diversity in common millet (Panicum miliaceum L.) in China. Crop J. 2018, 6, 377–385. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, W.; Li, J.; Gong, X.; Feng, B. Physicochemical properties of starches in proso (Non-waxy and waxy) and foxtail millets (Non-waxy and waxy). Molecules 2019, 24, 1743. [Google Scholar] [CrossRef] [PubMed]

- Chao, G.; Gao, J.; Liu, R.; Wang, L.; Li, C.; Wang, Y.; Qu, Y.; Feng, B. Starch physicochemical properties of waxy proso millet (Panicum Miliaceum L.). Starch 2014, 66, 1005–1012. [Google Scholar] [CrossRef]

- Li, J.H.; Vasanthan, T.; Hoover, R.; Rossnagel, B.G. Starch from hull-less barley: IV. Morphological and structural changes in waxy, normal and high-amylose starch granules during heating. Food Res. Int. 2004, 37, 417–428. [Google Scholar] [CrossRef]

- Yang, Q.; Zhang, W.; Luo, Y.; Li, J.; Gao, J.; Yang, P.; Gao, X.; Feng, B. Comparison of structural and physicochemical properties of starches from five coarse grains. Food Chem. 2019, 288, 283–290. [Google Scholar] [CrossRef]

- Huang, J.; Zhao, L.; Man, J.; Wang, J.; Zhou, W.; Huai, H.; Wei, C. Comparison of physicochemical properties of B-type nontraditional starches from different sources. Int. J. Biol. Macromol. 2015, 78, 165–172. [Google Scholar] [CrossRef]

- Chen, M.H.; Bergman, C.J.; McClung, A.M.; Everette, J.D.; Tabien, R.E. Resistant starch: Variation among high amylose rice varieties and its relationship with apparent amylose content, pasting properties and cooking methods. Food Chem. 2017, 234, 180–189. [Google Scholar] [CrossRef]

- Batista, C.S.; Dos Santos, J.P.; Dittgen, C.L.; Colussi, R.; Bassinello, P.Z.; Elias, M.C.; Vanier, N.L. Impact of cooking temperature on the quality of quick cooking brown rice. Food Chem. 2019, 286, 98–105. [Google Scholar] [CrossRef]

- Fitzgerald, M.A.; McCouch, S.R.; Hall, R.D. Not just a grain of rice: The quest for quality. Trends Plant Sci. 2009, 14, 133–139. [Google Scholar] [CrossRef] [PubMed]

- Yadav, B.K.; Jindal, V.K. Dimensional changes in milled rice (Oryza sativa L.) kernel during cooking in relation to its physicochemical properties by image analysis. J. Food Eng. 2007, 81, 710–720. [Google Scholar] [CrossRef]

- Vermeylen, R.; Derycke, V.; Delcour, J.A.; Goderis, B.; Reynaers, H.; Koch, M.H.J. Gelatinization of starch in excess water: Beyond the melting of lamellar crystallites. A combined wide- and small-angle X-ray scattering study. Biomacromolecules 2006, 7, 2624–2630. [Google Scholar] [CrossRef] [PubMed]

- Tester, R.F.; Morrison, W.R. Swelling and gelatinization of cereal starches. I. Effects of amylopectin, amylose and lipids. Cereal Chem. 1990, 67, 551–557. [Google Scholar]

- Zhang, C.; Zhou, L.; Zhu, Z.; Lu, H.; Zhou, X.; Qian, Y.; Li, Q.; Lu, Y.; Gu, M.; Liu, Q. Characterization of grain quality and starch fine structure of two japonica rice (Oryza Sativa) cultivars with good sensory properties at different temperatures during the filling stage. J. Agric. Food Chem. 2016, 64, 4048–4057. [Google Scholar] [CrossRef]

- Wang, S.J.; Li, C.L.; Copeland, L.; Niu, Q.; Wang, S. Starch retrogradation: A comprehensive review. Compr. Rev. Food Sci. Food Saf. 2015, 14, 568–585. [Google Scholar] [CrossRef]

- Farooq, A.M.; Li, C.; Chen, S.; Fu, X.; Zhang, B.; Huang, Q. Particle size affects structural and in vitro digestion properties of cooked rice flours. Int. J. Biol. Macromol. 2018, 118 Pt A, 160–167. [Google Scholar] [CrossRef]

- Cheetham, N.W.H.; Tao, L. Variation in crystalline type with amylose content in maize starch granules: An X-ray powder diffraction study. Carbohyd. Polym. 1998, 36, 277–284. [Google Scholar] [CrossRef]

- Rewthong, O.; Soponronnarit, S.; Taechapairoj, C.; Tungtrakul, P.; Prachayawarakorn, S. Effects of cooking, drying and pretreatment methods on texture and starch digestibility of instant rice. J. Food Eng. 2011, 103, 258–264. [Google Scholar] [CrossRef]

- Chanvrier, H.; Uthayakumaran, S.; Appelqvist, I.A.M.; Gidley, M.J.; Gilbert, E.P.; Lopez-Rubio, A. Influence of storage conditions on the structure, thermal behavior, and formation of enzyme-resistant starch in extruded starches. J. Agric. Food Chem. 2007, 55, 9883–9890. [Google Scholar] [CrossRef]

- Wang, M.; Shen, Q.; Hu, L.; Hu, Y.; Ye, X.; Liu, D.; Chen, J. Physicochemical properties, structure and in vitro digestibility on complex of starch with lotus (Nelumbo nucifera Gaertn.) leaf flavonoids. Food Hydrocoll. 2018, 81, 191–199. [Google Scholar] [CrossRef]

- Sevenou, O.; Hill, S.E.; Farhat, I.A.; Mitchell, J.R. Organisation of the external region of the starch granule as determined by infrared spectroscopy. Int. J. Biol. Macromol. 2002, 31, 79–85. [Google Scholar] [CrossRef]

- Zhang, L.; Zhao, L.L.; Bian, X.F.; Guo, K.; Zhou, L.; Wei, C.X. Characterization and comparative study of starches from seven purple sweet potatoes. Food Hydrocoll. 2018, 80, 168–176. [Google Scholar] [CrossRef]

- Guo, K.; Lin, L.S.; Fan, X.X.; Zhang, L.; Wei, C.X. Comparison of structural and functional properties of starches from five fruit kernels. Food Chem. 2018, 257, 75–82. [Google Scholar] [CrossRef] [PubMed]

- Gao, J.F.; Kreft, I.; Chao, G.M.; Wang, Y.; Liu, X.J.; Wang, L.; Wang, P.K.; Gao, X.L.; Feng, B.L. Tartary buckwheat (Fagopyrum tataricum Gaertn.) starch, a side product in functional food production, as a potential source of retrograded starch. Food Chem. 2016, 190, 552–558. [Google Scholar] [CrossRef]

- Shim, J.; Mulvaney, S.J. Effect of heating temperature, pH, concentration and starch/whey protein ratio on the viscoelastic properties of corn starch/whey protein mixed gels. J. Sci. Food Agric. 2001, 81, 706–717. [Google Scholar] [CrossRef]

- Wang, S.; Li, C.; Zhang, X.; Copeland, L.; Wang, S. Retrogradation enthalpy does not always reflect the retrogradation behavior of gelatinized starch. Sci. Rep. 2016, 6, 20965. [Google Scholar] [CrossRef]

- Bagley, E.B.; Christianson, D.D. Swelling capacity of starch and its relationship to suspension viscosity-effect of cooking time, temperature and concentration. J. Texture Stud. 1982, 13, 115–126. [Google Scholar] [CrossRef]

- Tester, R.F.; Karkalas, J.; Qi, X. Starch—Composition, fine structure and architecture. J. Cereal Sci. 2004, 39, 151–165. [Google Scholar] [CrossRef]

| Samples | Chemical Compositions Content (%) | IR Ratio | ||||

|---|---|---|---|---|---|---|

| Fat | Protein | Amylose | Total Starch | 1045/1022 (cm−1) | 1022/995 (cm−1) | |

| W0 | 3.91 ± 0.13 a | 16.85 ± 0.09 cd | 4.27 ± 0.11 f | 64.41 ± 1.46 ab | 0.420 ± 0.010 a | 0.735 ± 0.003 f |

| W1 | 3.82 ± 0.13 ab | 16.72 ± 0.05 d | 4.34 ± 0.21 f | 64.00 ± 1.07 b | 0.404 ± 0.007 a | 0.800 ± 0.009 d |

| W2 | 3.65 ± 0.10 ab | 16.77 ± 0.10 cd | 4.51 ± 0.16 f | 64.23 ± 1.51 ab | 0.381 ± 0.002 b | 0.818 ± 0.011 c |

| W3 | 3.23 ± 0.18 cd | 16.70 ± 0.06 d | 4.42 ± 0.19 f | 64.43 ± 1.14 ab | 0.378 ± 0.008 b | 0.844 ± 0.009 b |

| W4 | 3.14 ± 0.20 d | 16.95 ± 0.18 c | 4.26 ± 0.17 f | 63.83 ± 1.20 b | n.d. | n.d. |

| W5 | 3.18 ± 0.20 d | 17.21 ± 0.06 b | 3.97 ± 0.09 f | 63.63 ± 1.43 b | n.d. | n.d. |

| W6 | 2.92 ± 0.13 de | 17.67 ± 0.01 a | 3.90 ± 0.13 f | 63.13 ± 1.73 b | n.d. | n.d. |

| N0 | 3.58 ± 0.10 b | 14.74 ± 0.10 h | 28.85 ± 1.27 cd | 66.48 ± 1.00 ab | 0.387 ± 0.005 b | 0.776 ± 0.006 e |

| N1 | 3.54 ± 0.09 bc | 14.67 ± 0.13 h | 26.84 ± 0.59 d | 66.29 ± 1.24 ab | 0412 ± 0.007 a | 0.783 ± 0.008 de |

| N2 | 3.25 ± 0.16 cd | 14.86 ± 0.06g h | 32.74 ± 1.52 b | 66.53 ± 1.88 ab | 0.372 ± 0.004 b | 0.824 ± 0.008 c |

| N3 | 2.93 ± 0.12 de | 14.86 ± 0.13g h | 37.93 ± 0.95 a | 67.89 ± 1.82 a | 0.345 ± 0.006 c | 0.889 ± 0.003 a |

| N4 | 2.76 ± 0.12 ef | 15.04 ± 0.06 g | 24.38 ± 1.34 e | 65.49 ± 2.16 ab | n.d. | n.d. |

| N5 | 2.51 ± 0.14 fg | 15.39 ± 0.04 f | 29.22 ± 1.64 c | 66.19 ± 1.78 ab | n.d. | n.d. |

| N6 | 2.36 ± 0.10 g | 15.61 ± 0.07 e | 32.25 ± 1.76 b | 64.81 ± 1.18 ab | n.d. | n.d. |

| Samples | To (°C) | Tp (°C) | Tc (°C) | ΔH (J/g) | Tc-To (°C) |

|---|---|---|---|---|---|

| W0 | 71.1 ± 0.1 d | 77.1 ± 0.1 d | 83.1 ± 0.8 b | 7.5 ± 0.7 a | 12.0 ± 0.1 a |

| W1 | 72.8 ± 0.2 c | 76.6 ± 0.2 e | 82.6 ± 0.0 b | 6.3 ± 0.3 b | 9.8 ± 0.2 b |

| W2 | 74.9 ± 0.1 b | 80.1 ± 0.1 a | 85.5 ± 0.4 a | 5.3 ± 0.1 c | 10.6 ± 0.3 b |

| W3 | 75.6 ± 0.0 a | 78.9 ± 0.2 b | 84.3 ± 0.1 a | 0.6 ± 0.0 h | 8.7 ± 0.0 c |

| W4 | n.d. | n.d. | n.d. | n.d. | n.d. |

| W5 | n.d. | n.d. | n.d. | n.d. | n.d. |

| W6 | n.d. | n.d. | n.d. | n.d. | n.d. |

| N0 | 72.2 ± 0.3 c | 75.6 ± 0.2 f | 80.9 ± 0.7 c | 4.3 ± 0.1 d | 8.6 ± 1.0 c |

| N1 | 70.8 ± 0.8 d | 74.4 ± 0.3 g | 78.6 ± 0.8 d | 3.8 ± 0.2 e | 7.8 ± 0.1 cd |

| N2 | 72.6 ± 0.4 c | 75.4 ± 0.1 f | 80.8 ± 0.2 c | 4.0 ± 0.1 e | 8.2 ± 0.1 cd |

| N3 | 74.7 ± 0.3 b | 77.9 ± 0.2 c | 82.2 ± 0.3 b | 2.8 ± 0.1 f | 7.6 ± 0.0 d |

| N4 | 76.2 ± 0.1 a | 79.4 ± 0.1 b | 85.0 ± 0.2 a | 1.9 ± 0.1 g | 8.7 ± 0.1 c |

| N5 | n.d. | n.d. | n.d. | n.d. | n.d. |

| N6 | n.d. | n.d. | n.d. | n.d. | n.d. |

| Samples | PV (cP) | TV (cP) | BD (cP) | FV (cP) | SB (cP) | PT (min) | PTM (°C) |

|---|---|---|---|---|---|---|---|

| W0 | 1300 ± 26 j | 848 ± 4 j | 452 ± 30 i | 1067 ± 13 l | 220 ± 16h i | 4.0 ± 0.0 l | 77.9 ± 0.7 h |

| W1 | 2508 ± 28 e | 1193 ± 25 f | 1315 ± 3 e | 1527 ± 16 i | 334 ± 10 f | 4.0 ± 0.0 l | 78.7 ± 0.6 g |

| W2 | 3775 ± 15 a | 1585 ± 11 a | 2190 ± 26 a | 1792 ± 24 f | 207 ± 35 hi | 4.3 ± 0.0 k | 81.7 ± 0.0 e |

| W3 | 3443 ± 44 b | 1520 ± 0 c | 1923 ± 44 b | 1723 ± 28 g | 203 ± 28 hi | 4.6 ± 0.0 j | 81.5 ± 0.0 e |

| W4 | 3073 ± 24 c | 1506 ± 6 c | 1578 ± 14 c | 1694 ± 6 h | 191 ± 4 j | 4.9 ± 0.0 h | 79.1 ± 0.0 g |

| W5 | 2522 ± 16 e | 1320 ± 9 e | 1189 ± 6 f | 1551 ± 6 i | 231 ± 13 h | 4.7 ± 0.0 i | 50.1 ± 0.0 i |

| W6 | 2618 ± 6 d | 1115 ± 13 h | 1513 ± 6 d | 1392 ± 4 j | 286 ± 3 g | 1.1 ± 0.0 m | 50.3 ± 0.2 i |

| N0 | 2175 ± 13 f | 1211 ± 9 f | 968 ± 9 g | 3675 ± 4 a | 2473 ± 6 a | 5.1 ± 0.0 f | 79.9 ± 0.0 f |

| N1 | 1842 ± 15 h | 1340 ± 11 e | 502 ± 4 h | 2568 ± 5 c | 1237 ± 6 b | 5.1 ± 0.0 g | 79.2 ± 0.1 g |

| N2 | 2096 ± 9 g | 1558 ± 6 b | 538 ± 4 h | 2813 ± 8 b | 1260 ± 9 b | 5.3 ± 0.0 e | 81.6 ± 0.0 e |

| N3 | 1749 ± 9 i | 1415 ± 11 d | 348 ± 18 j | 2454 ± 5 d | 1047 ± 6 c | 5.6 ± 0.0 d | 83.2 ± 0.0 d |

| N4 | 1306 ± 8 j | 1158 ± 4 g | 147 ± 3 k | 1914 ± 5 e | 758 ± 4 d | 5.9 ± 0.0 c | 84.7 ± 0.1 c |

| N5 | 912 ± 8 k | 887 ± 6 i | 24 ± 1 l | 1316 ± 4 k | 438 ± 1 e | 6.6 ± 0.0 b | 88.0 ± 0.0 b |

| N6 | 618 ± 4 l | 579 ± 5 k | 47 ± 1 l | 938 ± 9 m | 359 ± 4 f | 7.0 ± 0.0 a | 92.2 ± 0.3 a |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Q.; Liu, L.; Zhang, W.; Li, J.; Gao, X.; Feng, B. Changes in Morphological and Physicochemical Properties of Waxy and Non-waxy Proso Millets during Cooking Process. Foods 2019, 8, 583. https://doi.org/10.3390/foods8110583

Yang Q, Liu L, Zhang W, Li J, Gao X, Feng B. Changes in Morphological and Physicochemical Properties of Waxy and Non-waxy Proso Millets during Cooking Process. Foods. 2019; 8(11):583. https://doi.org/10.3390/foods8110583

Chicago/Turabian StyleYang, Qinghua, Long Liu, Weili Zhang, Jing Li, Xiaoli Gao, and Baili Feng. 2019. "Changes in Morphological and Physicochemical Properties of Waxy and Non-waxy Proso Millets during Cooking Process" Foods 8, no. 11: 583. https://doi.org/10.3390/foods8110583

APA StyleYang, Q., Liu, L., Zhang, W., Li, J., Gao, X., & Feng, B. (2019). Changes in Morphological and Physicochemical Properties of Waxy and Non-waxy Proso Millets during Cooking Process. Foods, 8(11), 583. https://doi.org/10.3390/foods8110583