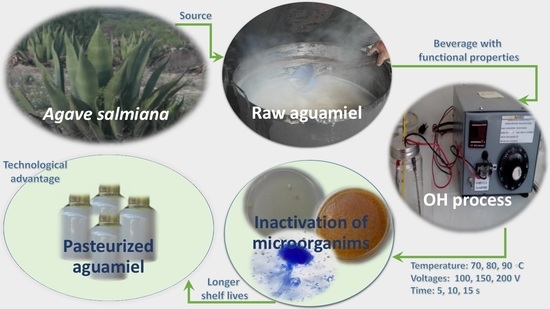

Effect of Ohmic Heating on Sensory, Physicochemical, and Microbiological Properties of “Aguamiel” of Agave salmiana

Abstract

:1. Introduction

2. Materials and Methods

2.1. Aguamiel Beverage

2.2. Ohmic Heating (OH) Equipment

2.3. Aguamiel Electric Conductivity

2.4. Ohmic and Conventional Heating

2.4.1. Conventional Heating (CH) Pasteurization Process

2.4.2. Ohmic Heating (OH) Pasteurization Process

2.5. Microbiological Analysis

2.6. Physicochemical Analysis: pH, Total Sugars and Soluble Solids

2.7. Color Analysis

2.8. Statistical Analysis

3. Results and Discussion

3.1. Evaluation of Electric Conductivity and Temperature of Aguamiel Samples

3.2. Microbiological Analysis

3.3. Analysis of Physicochemical Properties: pH, Total Sugars and Soluble Solids

3.4. Color Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Muñiz-Márquez, D.B.; Contreras, J.C.; Rodríguez, R.; Mussatto, S.I.; Wong-Paz, J.E.; Teixeira, J.A.; Aguilar, C.N. Influence of thermal effect on sugars composition of Mexican Agave syrup. CyTA J. Food 2015, 1, 1–6. [Google Scholar] [CrossRef]

- Escajeda, L.F.R.; Hernandez, M.C.; Jasso, R.M.R.; Rodriguez, A.V.C.; Olivo, A.R.; Esquivel, J.C.C.; Cerda, R.B. Discussion between alternative processing and preservation technologies and their application in beverages: A review. J. Food Process. Preserv. 2017, 42, e13322. [Google Scholar] [CrossRef]

- Evrendilek, G.A.; Baysal, T.; Icier, F.; Yildiz, H.; Demirdoven, A.; Bozkurt, H. Processing of Fruits and Fruit Juices by Novel Electrotechnologies. Food Eng. Rev. 2011, 4, 68–87. [Google Scholar] [CrossRef]

- Jin, T.Z.; Guo, M.; Yang, R. Combination of pulsed electric field processing and antimicrobial bottle for extending microbiological shelf-life of pomegranate juice. Innov. Food Sci. Emerg. Technol. 2014, 26, 153–158. [Google Scholar] [CrossRef]

- Timmermans, R.; Groot, M.N.; Nederhoff, A.; Van Boekel, M.; Matser, A.; Mastwijk, H. Pulsed electric field processing of different fruit juices: Impact of pH and temperature on inactivation of spoilage and pathogenic micro-organisms. Int. J. Food Microbiol. 2014, 173, 105–111. [Google Scholar] [CrossRef] [PubMed]

- Knirsch, M.C.; dos Santos, C.A.; de Oliveira Soares Vicent, A.A.M.; Penna, T.C.V. Ohmic heating—A review. Trends Food Sci. Technol. 2010, 21, 436–441. [Google Scholar] [CrossRef]

- Norma Oficial Mexicana. NOM-111-SSA1-1994. Available online: http://www.salud.gob.mx/unidades/cdi/nom/111ssa14.html#:~:text=1.1%20Esta%20Norma%20Oficial%20Mexicana,25%20%C2%B1%201%C2%B0C (accessed on 24 May 1995).

- Norma Oficial Mexicana. NOM-210-SSA1-2014. Available online: http://dof.gob.mx/nota_detalle.php?codigo=5398468&fecha=26/06/2015#:~:text=NORMA%20Oficial%20Mexicana%20NOM%2D210,Determinaci%C3%B3n%20de%20microorganismos%20pat%C3%B3genos (accessed on 26 June 2015).

- Norma Oficial Mexicana. NOM-218-SSA1-2011. Available online: http://dof.gob.mx/normasOficiales/4643/salud/salud.htm#:~:text=1.1%20Esta%20norma%20establece%20las,las%20bebidas%20adicionadas%20con%20cafe%C3%ADna (accessed on 10 February 2012).

- Lee, J.Y.; Kim, S.-S.; Kang, D.-H. Effect of pH for inactivation of Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice by ohmic heating. LWT 2015, 62, 83–88. [Google Scholar] [CrossRef]

- Srivastav, S.; Srishti, R. Changes in electrical conductivity of liquid foods during ohmic heating. Int. J. Agric. Biol. Eng. 2014, 7, 133–138. [Google Scholar]

- Izaguirre, J.; Belmares, R.; Cruz, M. Uso de tecnologías emergentes para la elaboración de bebidas funcionales (Aloe vera). Acta Química Mex. 2013, 5, 12–15. [Google Scholar]

- Darvishi, H.; Khostaghaza, M.H.; Najafi, G. Ohmic heating of pomegranate juice: Electrical conductivity and pH change. J. Saudi Soc. Agric. Sci. 2013, 12, 101–108. [Google Scholar] [CrossRef] [Green Version]

- Sakr, M.; Liu, S. A comprehensive review on applications of ohmic heating (OH). Renew. Sustain. Energy Rev. 2014, 39, 262–269. [Google Scholar] [CrossRef]

- Sarang, S.; Sastry, S.K.; Knipe, L. Electrical conductivity of fruits and meats during ohmic heating. J. Food Eng. 2008, 87, 351–356. [Google Scholar] [CrossRef]

- Kim, S.-S.; Kang, D.-H. Comparison of pH effects on ohmic heating and conventional heating for inactivation of Escherichia coli O157:H7, Salmonella enterica Serovar Typhimurium and Listeria monocytogene s in orange juice. LWT 2015, 64, 860–866. [Google Scholar] [CrossRef]

- Santos-Zea, L.; Leal-Díaz, A.M.; Cortés-Ceballos, E.; Gutiérrez-Uribe, J.A. Agave (Agave spp.) and its Traditional Products as a Source of Bioactive Compounds. Curr. Bioact. Compd. 2012, 8, 218–231. [Google Scholar] [CrossRef]

- Enríquez-Salazar, M.I.; Veana, F.; Aguilar, C.N.; De La Garza-Rodríguez, I.M.; López, M.G.; Rutiaga-Quiñones, O.M.; Morlett-Chávez, J.A.; Rodríguez-Herrera, R. Microbial diversity and biochemical profile of aguamiel collected from Agave salmiana and A. atrovirens during different seasons of year. Food Sci. Biotechnol. 2017, 26, 1003–1011. [Google Scholar] [CrossRef] [PubMed]

- Alcántara-Zavala, A.E.; Figueroa-Cárdenas, J.; Morales-Sánchez, E.; Aldrete-Tapia, J.A.; Arvizu-Medrano, S.M.; Martínez-Flores, H.E. Application of ohmic heating to extend shelf life and retain the physicochemical, microbiological, and sensory properties of pulque. Food Bioprod. Process. 2019, 118, 139–148. [Google Scholar] [CrossRef]

- Park, I.-K.; Kang, D.H. Effect of Electropermeabilization by Ohmic Heating for Inactivation of Escherichia coli O157:H7, Salmonella enterica Serovar Typhimurium, and Listeria monocytogenes in Buffered Peptone Water and Apple Juice. Appl. Environ. Microbiol. 2013, 79, 7122–7129. [Google Scholar] [CrossRef] [Green Version]

- Lee, S.-Y.; Sagong, H.-G.; Ryu, S.; Kang, D.-H. Effect of continuous ohmic heating to inactivate Escherichia coli O157:H7, Salmonella Typhimurium and Listeria monocytogenes in orange juice and tomato juice. J. Appl. Microbiol. 2012, 112, 723–731. [Google Scholar] [CrossRef]

- Saberian, H.; Hamidi, E.Z.; Abbasi, S. Effect of conventional and ohmic pasteurization on some Bioactive components of Aloe vera gel juice. Iran. J. Chem. Eng. 2015, 34, 99–108. [Google Scholar]

- Jaeger, H.; Roth, A.; Toepfl, S.; Holzhauser, T.; Engel, K.-H.; Knorr, D.; Vogel, R.F.; Bandick, N.; Kulling, S.; Heinz, V.; et al. Opinion on the use of ohmic heating for the treatment of foods. Trends Food Sci. Technol. 2016, 55, 84–97. [Google Scholar] [CrossRef]

- Kumar, M.; Jyoti; Hausain, A. Effect of ohmic heating of buffalo milk on microbial quality and tesure of paneer. Asian J. Dairy Food Res. 2014, 33, 9–13. [Google Scholar] [CrossRef]

- Saxena, J.; Makroo, H.A.; Srivastava, B. Optimization of time-electric field combination for PPO inactivation in sugarcane juice by ohmic heating and its shelf life assessment. LWT 2016, 71, 329–338. [Google Scholar] [CrossRef]

- Gomathy, K.; Thangavel, K.; Balakrishnan, M.; Kasthuri, R. Effect of Ohmic Heating on the Electrical Conductivity, Biochemical and Rheological Properties of Papaya Pulp. J. Food Process. Eng. 2015, 38, 405–413. [Google Scholar] [CrossRef]

- Leizerson, S.; Shimoni, E. Effect of Ultrahigh-Temperature Continuous Ohmic Heating Treatment on Fresh Orange Juice. J. Agric. Food Chem. 2005, 53, 3519–3524. [Google Scholar] [CrossRef] [PubMed]

- Darvishi, H.; Hosainpour, A.; Nargesi, F. Ohmic Heating Behaviour and Electrical Conductivity of Tomato Paste. J. Nutr. Food Sci. 2012, 2, 1–6. [Google Scholar] [CrossRef] [Green Version]

- Pereira, R.N.C.; Teixeira, J.A.; Vicente, A.A. Comparison of chemical properties of food products processed by conventional and ohmic heating. Chem. Pap. 2007, 61, 30–35. [Google Scholar] [CrossRef] [Green Version]

- Kim, S.; Choi, W.; Kang, D.-H. Application of low frequency pulsed ohmic heating for inactivation of foodborne pathogens and MS-2 phage in buffered peptone water and tomato juice. Food Microbiol. 2017, 63, 22–27. [Google Scholar] [CrossRef]

- Mercali, G.D.; Schwartz, S.J.; Marczak, L.D.F.; Tessaro, I.C.; Sastry, S. Ascorbic acid degradation and color changes in acerola pulp during ohmic heating: Effect of electric field frequency. J. Food Eng. 2014, 123, 1–7. [Google Scholar] [CrossRef]

- Tumpanuvatr, T.; Jittanit, W. The temperature prediction of some botanical beverages, concentrated juices and purees of orange and pineapple during ohmic heating. J. Food Eng. 2012, 113, 226–233. [Google Scholar] [CrossRef]

- Demirdöven, A.; Baysal, T. Optimization of ohmic heating applications for pectin methylesterase inactivation in orange juice. J. Food Sci. Technol. 2012, 51, 1817–1826. [Google Scholar] [CrossRef] [Green Version]

| Treatments | Temperature (°C) | Voltage (V) | Time (s) |

|---|---|---|---|

| POH-1 | 70 | 100 | 5 |

| POH-2 | 70 | 150 | 10 |

| POH-3 | 70 | 200 | 15 |

| POH-4 | 80 | 100 | 5 |

| POH-5 | 80 | 150 | 10 |

| POH-6 | 80 | 200 | 15 |

| POH-7 | 90 | 100 | 5 |

| POH-8 | 90 | 150 | 10 |

| POH-9 | 90 | 200 | 15 |

| Treatment | CFU/mL | ||

|---|---|---|---|

| E. coli | Yeasts | Lactobacillus | |

| Raw aguamiel | 3.0 × 105 | 2.86 × 105 | 5.4 × 104 |

| 95 °C 5 s | n.a* | - | - |

| 70 °C 30 min | n.a* | 2100 | 960 |

| POH-1 | 200 | - | - |

| POH-2 | n.a* | - | - |

| POH-3 | n.a* | - | - |

| POH-4 | n.a* | - | - |

| POH-5 | n.a* | - | - |

| POH-6 | n.a* | - | - |

| POH-7 | n.a* | - | - |

| POH-8 | n.a* | - | - |

| POH-9 | n.a* | - | - |

| pH | Soluble Solids (°Brix) | Total Sugars | |

|---|---|---|---|

| Raw aguamiel | 6.2 ± 0.1 b | 9.3 ± 0.5 a | 147.67 ± 1.1 abc |

| 70 °C 30 min | 6.2 ± 0.2 a | 8.8 ± 0.1 a | 95.59 ± 1.9 h |

| 95 °C 5 s | 6.1 ± 0.1 a | 10 ± 0.1 b | 164.60 ± 7.8 a |

| POH-1 | 6.1 ± 0.1 a | 11 ± 0.2 c | 105.94 ± 1.1 fg |

| POH-2 | 6.5 ± 0.2 c | 11 ± 0.1 c | 104.24 ± 2.8 fg |

| POH-3 | 6.5 ± 0.2 c | 10 ± 0.2 c | 121.50 ± 1.3 ef |

| POH-4 | 6.2 ± 0.1 b | 11 ± 0.1 c | 158.02 ± 3.3 ab |

| POH-5 | 6.2 ± 0.2 b | 11 ± 0.5 c | 125.63 ± 2.7 cdef |

| POH-6 | 6.1 ± 0.2 a | 11 ± 0.5 c | 122.50 ± 2.7 def |

| POH-7 | 6.2 ± 0.2 b | 11 ± 0.5 c | 150.49 ± 4.2 ab |

| POH-8 | 6.2 ± 0.1 b | 11 ± 0.6 c | 144.54 ± 1.5 abcd |

| POH-9 | 6.2 ± 0.2 b | 12 ± 0.5 d | 137.85 ± 1.8 bcde |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rascón, L.; Cruz, M.; Rodríguez-Jasso, R.M.; Neira-Vielma, A.A.; Ramírez-Barrón, S.N.; Belmares, R. Effect of Ohmic Heating on Sensory, Physicochemical, and Microbiological Properties of “Aguamiel” of Agave salmiana. Foods 2020, 9, 1834. https://doi.org/10.3390/foods9121834

Rascón L, Cruz M, Rodríguez-Jasso RM, Neira-Vielma AA, Ramírez-Barrón SN, Belmares R. Effect of Ohmic Heating on Sensory, Physicochemical, and Microbiological Properties of “Aguamiel” of Agave salmiana. Foods. 2020; 9(12):1834. https://doi.org/10.3390/foods9121834

Chicago/Turabian StyleRascón, Luis, Mario Cruz, Rosa M. Rodríguez-Jasso, Alberto A. Neira-Vielma, Sonia N. Ramírez-Barrón, and Ruth Belmares. 2020. "Effect of Ohmic Heating on Sensory, Physicochemical, and Microbiological Properties of “Aguamiel” of Agave salmiana" Foods 9, no. 12: 1834. https://doi.org/10.3390/foods9121834

APA StyleRascón, L., Cruz, M., Rodríguez-Jasso, R. M., Neira-Vielma, A. A., Ramírez-Barrón, S. N., & Belmares, R. (2020). Effect of Ohmic Heating on Sensory, Physicochemical, and Microbiological Properties of “Aguamiel” of Agave salmiana. Foods, 9(12), 1834. https://doi.org/10.3390/foods9121834