Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

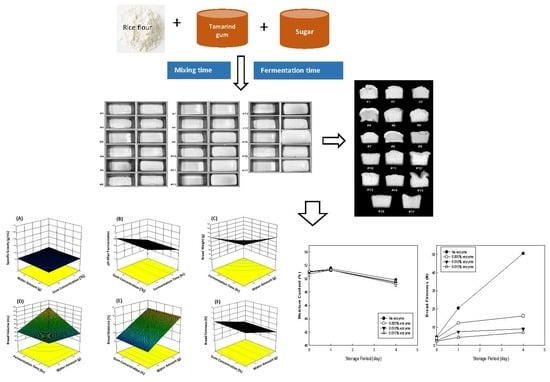

2.2. Preparation of Rice Bread

2.3. Analysis of Batter Property of Rice Bread

2.4. Evaluation of Rice Bread Quality

2.5. Evaluation of the Effect of an Anti-staling Enzyme on the Staling of Rice Bread during Storage

2.6. Statistical Analysis

3. Results and Discussion

3.1. Characteristics of the Batter of Rice Bread

3.2. Quality Characteristics of Rice Bread

3.3. Significant Factors Affecting the Quality Characteristics of Rice Bread

3.4. Effect of an Anti-staling Enzyme on the Quality of Rice Bread during Storage

4. Conclusions

Author Contributions

Acknowledgements

Conflicts of Interest

References

- Statistic Korea. Annual Trends of Food Grain Consumption in 2018. Available online: http://kostat.go.kr/portal/eng/pressReleases/1/index.board?bmode=read&aSeq=373404 (accessed on 1 December 2019).

- Green, P.H.R.; Jabri, B. Coeliac disease. Lancet 2003, 362, 383–391. [Google Scholar] [CrossRef]

- Kim, J.M. Characteristics of Rice Flours Prepared from Different Rice Varieties and Development of Gluten-Free Bakery Products Using Them. Ph.D. Thesis, Chonnam National University, Gwangju, Korea, February 2016. [Google Scholar]

- Han, H.M.; Cho, J.H.; Kang, H.W.; Koh, B.K. Rice varieties in relation to rice bread quality. J. Sci. Food Agric. 2012, 92, 1462–1467. [Google Scholar] [CrossRef]

- Mancebo, C.M.; Miguel, M.A.S.; Martinez, M.M.; Gomez, M. Optimisation of rheological properties of gluten-free doughs with HPMC, psyllium and different levels of water. J. Cereal Sci. 2015, 61, 8–15. [Google Scholar] [CrossRef]

- Mohammadi, M.; Sadeghnia, N.; Azizi, M.H.; Neyestani, T.R.; Mortazavian, A.M. Development of guten-free flat bread using hydrocolloids: Xanthan and CMC. J. Ind. Eng. Chem. 2014, 20, 1812–1818. [Google Scholar] [CrossRef]

- Masure, H.G.; Fierens, E.; Delcour, J.A. Current and forward looking experimental approaches in gluten-free bread making research. J. Cereal Sci. 2016, 67, 92–111. [Google Scholar] [CrossRef]

- Witczak, M.; Ziobro, R.; Juszczak, L.; Korus, J. Starch and starch derivatives in gluten-free systems—A review. J. Cereal Sci. 2016, 67, 46–57. [Google Scholar] [CrossRef]

- Anton, A.A.; Artifield, S.D. Hydrocolloids in gluten-free breads: A review. Inter. J. Food Sci. Nutr. 2008, 59, 11–23. [Google Scholar] [CrossRef] [PubMed]

- Lazaridou, A.; Duta, D.; Papageorgiou, M.; Belc, N.; Biliaderis, C.G. Effects of hydrocolloids on dough rheology and bread quality parameters in gluten-free formulations. J. Food Eng. 2007, 79, 1033–1047. [Google Scholar] [CrossRef]

- Mir, S.A.; Shah, M.A.; Naik, H.R.; Zargar, I.A. Influence of hydrocolloids on dough handling and technological properties of gluten-free breads. Trends Food Sci. Tech. 2016, 51, 49–57. [Google Scholar] [CrossRef]

- Nishita, K.D.; Roberts, R.L.; Bean, M.M. Development of a yeast-leavened rice-bread formula. Cereal Chem. 1976, 53, 626–635. [Google Scholar]

- Sciarini, L.S.; Ribotta, P.D.; León, A.E.; Pérez, G.T. Effect of hydrocolloids on gluten- free batter properties and bread quality. Int. J. Food Sci. Tech. 2010, 45, 2306–2312. [Google Scholar] [CrossRef]

- Jang, K.J.; Hong, Y.E.; Moon, Y.J.; Jeon, S.J.; Angalat, S.; Kweon, M. Exploring the applicability of tamarind gum for making gluten-free rice bread. Food Sci. Biotechnol. 2018, 27, 1639–1648. [Google Scholar] [CrossRef] [PubMed]

- Maeda, T.; Yamashita, H.; Morita, N. Application of xyloglucan to improve the gluten membrane on breadmaking. Carbohydr. Polym. 2007, 68, 658–664. [Google Scholar] [CrossRef]

- Hera, E.; Martinez, M.; Gomez, M. Influence of flour particle size on quality of gluten-free rice bread. LWT—Food Sci. Technol. 2013, 54, 199–206. [Google Scholar] [CrossRef]

- Jang, K.J. Effect of Tamarind Gum on Gluten-Free Rice Batter Properties and Bread Quality. Master’s Thesis, Pusan National University, Busan, Korea, February 2018. [Google Scholar]

- AACC. Method 44-15.02, Method 74-09.01.2010. In Approved Methods of Analysis, 11th ed.; American Association of Cereal Chemists: St. Paul, MN, USA.

- Martinez, M.M.; Gomez, M. Rheological and microstructural evolution of the most common gluten-free flours and starches during bread fermentation and baking. J. Food Eng. 2017, 197, 78–86. [Google Scholar] [CrossRef]

- Cappa, C.; Lucisano, M.; Mariotti, M. Influence of Psyllium, sugar beet fibre and water on gluten-free dough properties and bread quality. Carbohydr. Polym. 2013, 98, 1657–1666. [Google Scholar] [CrossRef]

- Blanco, C.A.; Ronda, F.; Pérez, B.; Pando, V. Improving gluten-free bread quality by enrichment with acidic food additives. Food Chem. 2011, 127, 1204–1209. [Google Scholar] [CrossRef]

- Tsatsaragkou, K.; Gounaropoulos, G.; Mandala, I. Development of gluten free bread containing carob flour and resistant starch. LWT—Food Sci. Technol. 2014, 58, 124–129. [Google Scholar] [CrossRef]

- Bollain, C.; Collar, C. Dough viscoelastic response of hydrocolloid/ enzyme/surfactant blends assessed by uni- and bi-axial extension measurements. Food Hydrocoll. 2004, 18, 499–507. [Google Scholar] [CrossRef]

- Gujral, H.S.; Rosell, C.M. Improvement of the breadmaking quality of rice flour by glucose oxidase. Food Res. Int. 2004, 37, 75–81. [Google Scholar] [CrossRef]

- Ribotta, P.D.; Perez, G.T.; Leon, A.E.; Anon, M.C. Effect of emulsifier and guar gum on micro structural, rheological and baking performance on frozen bread dough. Food Hydrocoll. 2004, 18, 305–313. [Google Scholar] [CrossRef]

- Zeleznak, K.J.; Hoseney, R.C. The role of water in the retrogradation of wheat starch gels and bread crumb. Cereal Chem. 1986, 63, 407–411. [Google Scholar]

- Collar, C.; Bollain, C.; Angioloni, A. Significance of microbial transglutaminase on the sensory, mechanical and crumb grain pattern of enzyme supplemented fresh pan breads. J. Food Eng. 2005, 70, 479–488. [Google Scholar] [CrossRef]

| Std Order | Run Order | Gum (%) | Water (g) | Mixing Time (min) | Fermentation Time (min) |

|---|---|---|---|---|---|

| 1 | 12 | 1 | 80 | 5 | 30 |

| 2 | 14 | 2 | 80 | 5 | 30 |

| 3 | 9 | 1 | 100 | 5 | 30 |

| 4 | 16 | 2 | 100 | 5 | 30 |

| 5 | 3 | 1 | 80 | 10 | 30 |

| 6 | 5 | 2 | 80 | 10 | 30 |

| 7 | 10 | 1 | 100 | 10 | 30 |

| 8 | 17 | 2 | 100 | 10 | 30 |

| 9 | 13 | 1 | 80 | 5 | 60 |

| 10 | 7 | 2 | 80 | 5 | 60 |

| 11 | 11 | 1 | 100 | 5 | 60 |

| 12 | 2 | 2 | 100 | 5 | 60 |

| 13 | 1 | 1 | 80 | 10 | 60 |

| 14 | 6 | 2 | 80 | 10 | 60 |

| 15 | 4 | 1 | 100 | 10 | 60 |

| 16 | 15 | 2 | 100 | 10 | 60 |

| 17 | 8 | 1.5 | 90 | 7.5 | 45 |

| Std Order | Batter | Bread | ||||

|---|---|---|---|---|---|---|

| pH before Fermentation | pH after Fermentation | Weight (g) | Volume (mL) | Moisture Content (%) | Firmness (N) | |

| 1 | 6.2 ± 0.1 a,* | 5.9 ± 0.1 a | 153.8 ± 0.2 b,c | 289.8 ± 11.5 b | 46.2 ± 0.0 a | 9.8 ± 1.1 e,f |

| 2 | 6.3 ± 0.2 a | 5.9 ± 0.2 a | 154.1 ± 0.5 b,c | 300.1 ± 0.9 b | 45.3 ± 0.3 a | 8.9 ± 0.1 d,e,f |

| 3 | 6.2 ± 0.0 a | 5.9 ± 0.1 a | 150.7 ± 0.2 b,c | 273.2 ± 5.0 a,b | 50.0 ± 0.6 c | 7.0 ± 1.2 b,c,d,e |

| 4 | 6.3 ± 0.2 a | 5.9 ± 0.2 a | 153.2 ± 0.7 b,c | 370.1 ± 6.0 d,e | 49.9 ± 0.5 c | 6.8 ± 1.2 b,c,d,e |

| 5 | 6.0 ± 0.1 a | 5.7 ± 0.1 a | 152.9 ± 0.9 b,c | 295.2 ± 5.0 b | 45.6 ± 0.7 a | 8.5 ± 0.9 c,d,e |

| 6 | 6.0 ± 0.1 a | 5.7 ± 0.2 a | 154.6 ± 1.1 c | 276.2 ± 14.1 a,b | 44.4 ± 0.3 a | 8.8 ± 1.0 d,e,f |

| 7 | 6.2 ± 0.0 a | 5.8 ± 0.0 a | 152.3 ± 0.8 b,c | 258.3 ± 4.5 a | 51.3 ± 0.1 c | 7.0 ± 0.6 b,c,d,e |

| 8 | 6.3 ± 0.3 a | 5.8 ± 0.2 a | 152.2 ± 1.4 b,c | 274.3 ± 8.8 a,b | 50.6 ± 0.8 c | 7.0 ± 0.2 b,c,d,e |

| 9 | 6.2 ± 0.0 a | 5.5 ± 0.0 a | 151.1 ± 0.3 b,c | 282.7 ± 3.5 a,b | 46.3 ± 0.3 a | 7.9 ± 1.0 c,d,e |

| 10 | 6.1 ± 0.2 a | 5.5 ± 0.2 a | 152.0 ± 0.1 b,c | 270.6 ± 6.2 a,b | 44.4 ± 0.2 a | 9.9 ± 1.1 e,f |

| 11 | 6.2 ± 0.1 a | 5.6 ± 0.0 a | 145.3 ± 1.1 a | 338.3 ± 3.8 c | 50.6 ± 0.7 c | 4.0 ± 0.1 a,b |

| 12 | 6.1 ± 0.2 a | 5.5 ± 0.1 a | 145.2 ± 0.6 a | 360.0 ± 12.4 c,d,e | 50.4 ± 1.0 c | 5.5 ± 0.4 a,b,c |

| 13 | 6.0 ± 0.1 a | 5.5 ± 0.1 a | 153.2 ± 4.1 b,c | 293.5 ± 12.8 b | 45.2 ± 1.3 a | 12.0 ± 2.0 f |

| 14 | 6.0 ± 0.1 a | 5.4 ± 0.2 a | 150.3 ± 0.6 b | 275.3 ± 0.8 a,b | 44.4 ± 0.2 a | 8.5 ± 0.9 c,d,e |

| 15 | 6.1 ± 0.1 a | 5.4 ± 0.2 a | 144.1 ± 0.2 a | 349.1 ± 8.0 c,d | 49.3 ± 0.3 b,c | 3.1 ± 0.3 a |

| 16 | 6.3 ± 0.3 a | 5.6 ± 0.2 a | 145.6 ± 1.0 a | 380.0 ± 10.9 e | 50.6 ± 0.3 c | 4.0 ± 1.2 a,b |

| 17 | 6.0 ± 0.2 a | 5.5 ± 0.2 a | 149.9 ± 0.5 b | 365.6 ± 18.8 c,d,e | 47.0 ± 2.4a,b | 5.8 ± 1.1 a,b,c,d |

| Sample | Response | Significant Factor | p-Value | Significance |

|---|---|---|---|---|

| Batter | Specific gravity | - | - | - |

| pH before fermentation | - | - | - | |

| pH after fermentation | Fermentation time (FT) | 0.0002 | Negative | |

| Bread | Weight | Fermentation time | <0.0001 | Negative |

| Water amount (WA) | <0.0001 | Positive | ||

| WA × FT | 0.0024 | Positive | ||

| Volume | Fermentation time | 0.0207 | Positive | |

| WA × FT | 0.0097 | Positive | ||

| Moisture content | Water amount | 0.0002 | Positive | |

| Firmness | Water amount | <0.0001 | Negative |

| Enzyme Concentration (%) | Storage Time (day) | Tonset (°C) | Tpeak (°C) | Tend (°C) | Heat of Transition (ΔQ, J/g) |

|---|---|---|---|---|---|

| 0 | 0 | 40.1 ± 0.1 a,* | 48.1 ± 0.1 a | 66.9 ± 1.1 c,d,e,f | 0.35 ± 0.0 a |

| 1 | 40.0 ± 0.0 a | 53.4 ± 0.1 b | 64.8 ± 0.2 b,c,d,e | 0.82 ± 0.0 c | |

| 4 | 40.8 ± 0.9 a | 52.8 ± 0.4 b | 65.1 ± 0.6 b,c,d,e | 1.43 ± 0.1 e | |

| 0.005 | 0 | 40.0 ± 0.0 a | 48.0 ± 0.1 a | 67.8 ± 0.9 e,f | 0.28 ± 0.0 a |

| 1 | 40.0 ± 0.0 a | 52.8 ± 0.6 b | 64.6 ± 0.0 b,c,d | 0.60 ± 0.0 b | |

| 4 | 40.7 ± 0.3 a | 52.8 ± 0.6 b | 64.6 ± 0.7 b,c,d | 1.11 ± 0.1 d | |

| 0.010 | 0 | 40.18 ± 0.1 a | 48.7 ± 0.1 a | 68.4 ± 0.3 f | 0.37 ± 0.0 a |

| 1 | 40.0 ± 0.0 a | 52.7 ± 0.2 b | 61.0 ± 0.8 a | 0.40 ± 0.1 a | |

| 4 | 40.47 ± 0.1 a | 51.4 ± 2.1 b | 64.6 ± 0.6 b,c,d | 1.02 ± 0.1 d | |

| 0.015 | 0 | 40.0 ± 0.0 a | 48.5 ± 1.2 a | 67.6 ± 2.4 d,e,f | 0.25 ± 0.0 a |

| 1 | 40.0 ± 0.0 a | 53.0 ± 0.5 b | 63.8 ± 0.7 a,b,c | 0.36 ± 0.1 a | |

| 4 | 40.79 ± 0.7 a | 52.7 ± 0.8 b | 63.5 ± 0.0 a,b | 0.73 ± 0.0 b,c |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hong, Y.-E.; Kweon, M. Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum. Foods 2020, 9, 145. https://doi.org/10.3390/foods9020145

Hong Y-E, Kweon M. Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum. Foods. 2020; 9(2):145. https://doi.org/10.3390/foods9020145

Chicago/Turabian StyleHong, Ye-Eun, and Meera Kweon. 2020. "Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum" Foods 9, no. 2: 145. https://doi.org/10.3390/foods9020145

APA StyleHong, Y. -E., & Kweon, M. (2020). Optimization of the Formula and Processing Factors for Gluten-Free Rice Bread with Tamarind Gum. Foods, 9(2), 145. https://doi.org/10.3390/foods9020145