Enhancement Studies on Manufacturing and Properties of Novel Silica Aerogel Composites

Abstract

:1. Introduction

2. Results and Discussion

2.1. Influence of Mold Design

2.2. Hydrophobicity

2.3. Mechanical Properties of Silica Aerogel Composites

2.3.1. Cyclic Compression Loading Behaviour

2.3.2. Stress Relaxation Behaviour

2.3.3. Flexural Behaviour

3. Conclusions

4. Materials and Methods

4.1. Raw Materials

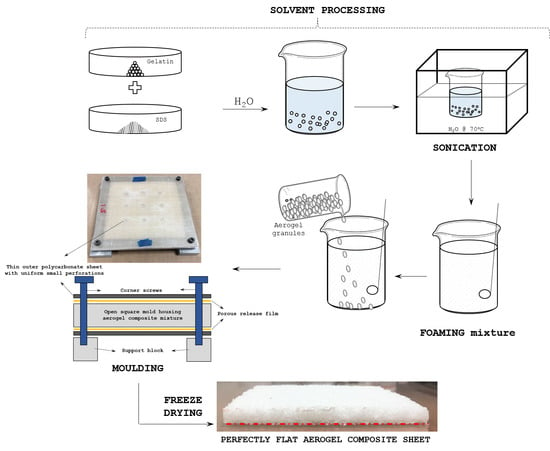

4.2. Manufacturing Process

4.3. Characterization Methods

Author Contributions

Conflicts of Interest

References

- Aegerter, M.A.; Leventis, N.; Koebel, M.M. Advances in Sol-Gel Derived Materials and Technologies. In Aerogels Handbook; Springer: New York, NY, USA, 2011. [Google Scholar]

- Maleki, H.; Durães, L.; Portugal, A. An overview on silica aerogels synthesis and different mechanical reinforcing strategies. J. Non Cryst. Solids 2014, 385, 55–74. [Google Scholar] [CrossRef]

- CABOT Corporation. Aerogel Blanket for Thermal Insulation Applications. Available online: http://www.Cabotcorp.Com/Solutions/Products-Plus/Aerogel/Blanket (accessed on 2 February 2014).

- Sachithanadam, M.; Joshi, S.C. Silica Aerogel Composites: Novel Fabrication Methods. In Engineering Materials; Springer: Singapore, 2016. [Google Scholar]

- Gurav, J.L.; Jung, I.K.; Park, H.H.; Kang, E.S.; Nadargi, D.Y. Silica Aerogel: Synthesis and Applications. J. Nanomater. 2010, 2010, 11. [Google Scholar] [CrossRef]

- Rao, A.V.; Bhagat, S.D.; Hirashima, H.; Pajonk, G.M. Synthesis of flexible silica aerogels using methyltrimethoxysilane (MTMS) precursor. J. Coll. Interface Sci. 2006, 300, 279–285. [Google Scholar]

- Rao, A.V.; Haranath, D. Effect of methyltrimethoxysilane as a synthesis component on the hydrophobicity and some physical properties of silica aerogels. Microporous Mesoporous Mater. 1999, 30, 267–273. [Google Scholar]

- Maghsoudi, K.; Motahari, S. Mechanical, thermal, and hydrophobic properties of silica aerogel–epoxy composites. J. Appl. Polym. Sci. 2018, 135. [Google Scholar] [CrossRef]

- Leventis, N.; Sadekar, A.; Chandrasekaran, N.; Sotiriou-Leventis, C. Click Synthesis of Monolithic Silicon Carbide Aerogels from Polyacrylonitrile-Coated 3D Silica Networks. Chem. Mater. 2010, 22, 2790–2803. [Google Scholar] [CrossRef]

- Leventis, N. Three-Dimensional Core-Shell Superstructures: Mechanically Strong Aerogels. Acc. Chem. Res. 2007, 40, 874–884. [Google Scholar] [CrossRef] [PubMed]

- Leventis, N.; Sotiriou-Leventis, C.; Zhang, G.; Rawashdeh, A.M.M. Nanoengineering Strong Silica Aerogels. Nano Lett. 2002, 2, 957–960. [Google Scholar] [CrossRef]

- He, S.; Sun, G.; Cheng, X.; Dai, H.; Chen, X. Nanoporous SiO2 grafted aramid fibers with low thermal conductivity. Compos. Sci. Technol. 2017, 146, 91–98. [Google Scholar] [CrossRef]

- Li, C.; Cheng, X.; Li, Z.; Pan, Y.; Huang, Y.; Gong, L. Mechanical, thermal and flammability properties of glass fiber film/silica aerogel composites. J. Non Cryst. Solids 2017, 457, 52–59. [Google Scholar] [CrossRef]

- Li, Z.; Cheng, X.; He, S.; Shi, X.; Gong, L.; Zhang, H. Aramid fibers reinforced silica aerogel composites with low thermal conductivity and improved mechanical performance. Compos. Part A Appl. Sci. Manuf. 2016, 84, 316–325. [Google Scholar] [CrossRef]

- Li, Z.; Gong, L.; Li, C.; Pan, Y.; Huang, Y.; Cheng, X. Silica aerogel/aramid pulp composites with improved mechanical and thermal properties. J. Non Cryst. Solids 2016, 454, 1–7. [Google Scholar] [CrossRef]

- Hu, Y.; Mackenzie, J.D. Rubber-like elasticity of organically modified silicates. J. Mater. Sci. 1992, 27, 4415–4420. [Google Scholar] [CrossRef]

- Vaitkus, S.; Granev, V.; Gnip, I.; Vėjelis, S.; Kairytė, A. Stress Relaxation in Expanded Polystyrene (EPS) Under Uniaxial Loading Conditions. Proc. Eng. 2013, 57, 1213–1222. [Google Scholar] [CrossRef]

- Timoshenko, S.; Gere, J.M. Mechanics of Materials; Van Nostrand Reinhold Co.: New York, NY, USA, 1972. [Google Scholar]

- Carlsson, L.A.; Kardomateas, G.A. Structural and Failure Mechanics of Sandwich Composites; Springer: Houten, The Netherlands, 2011. [Google Scholar]

- Lumira Translucent Aerogel. SDS LA1000. CABOT China Ltd.: Shangai, China. Available online: http://www.cabotcorp.com/solutions/products-plus/aerogel/particles (accessed on 20 June 2016).

- Sigmaaldrich.com. Gelatin from Porcine Skin. Available online: https://www.sigmaaldrich.com/catalog/product/sial/48724?lang=en®ion=SG (accessed on 28 March 2017).

- Sigmaaldrich.com. Sodium Dodecyl Sulphate. Available online: https://www.sigmaaldrich.com/catalog/product/sigma/l4390?lang=en®ion=SG (accessed on 03 April 2017).

- Sigmaaldrich.com. Silica Fumed, 0.007 μm. Available online: https://www.sigmaaldrich.com/catalog/product/aldrich/s5130?lang=en®ion=SG (accessed on 21 June 2017).

- Wang, Y.-T.; Zhao, H.B.; Degracia, K.C.; Han, L.X.; Sun, H.; Sun, M.; Wang, Y.Z.; Schiraldi, D.A. Green Approach to Improving the Strength and Flame Retardancy of Poly(vinyl alcohol)/Clay Aerogels: Incorporating Biobased Gelatin. ACS Appl. Mater. Interfaces 2017, 9, 42258–42265. [Google Scholar] [CrossRef] [PubMed]

| Sample | θ (Degrees) | Remarks | |

|---|---|---|---|

| S1 | S2 | ||

| SAC | 110.1 ± 4 | 98.2 ± 6 | All variants are hydrophobic. |

| FSC-20MG | 108.0 ± 8 | 98.0 ± 5 | |

| FSC-80MG | 104.2 ± 3 | 103.2 ± 2 | |

| CAC | 117.5 ± 3 | 114.2 ± 1 | |

| Sample | Peak Load in Each Cycle (N) | % Peak Load Change | Young’s Modulus (kPa) | |||

|---|---|---|---|---|---|---|

| PL,1 | PL,2 | PL,3 | ΔP2 | ΔP3 | ||

| SAC | 1820 ± 280 | 3155 ± 510 | 4495 ± 600 | 73.3 | 42.5 | 750 |

| FSC-20MG | 1820 ± 230 | 3267 ± 405 | 4796 ± 620 | 79.5 | 46.8 | 774 |

| FSC-80MG | 1677 ± 160 | 3034 ± 325 | 4587 ± 95 | 80.9 | 51.2 | 691 |

| CAC | 1692 ± 80 | 2979 ± 450 | 4336 ± 235 | 76.1 | 45.6 | 690 |

| Sample | Recovered Compressive Displacement, mm | ||

|---|---|---|---|

| Δδ1 | Δδ2 | Δδ3 | |

| SAC | 64 ± 4 | 49 ± 4 | 42 ± 4 |

| FSC-20MG | 66 ± 10 | 50 ± 11 | 42 ± 10 |

| FSC-80MG | 63 ± 7 | 52 ± 7 | 44 ± 1 |

| CAC | 64 + 14 | 49 ± 12 | 41 ± 14 |

| Sample | δ (mm) (±6%) | P (N) (±5%) | σf (kPa) | εf (%) |

|---|---|---|---|---|

| SAC | 9.37 | 11.72 | 210.6 | 18 |

| FSC-20MG | 5.52 | 9.34 | 167.4 | 9 |

| FSC-80MG | 4.78 | 10.48 | 189.0 | 8 |

| CAC | 10.30 | 9.91 | 178.2 | 17 |

| HSC | 9.14 | 22.36 | 401.4 | 34 |

| Sample * | Planar Dimension (mm2) | Thickness (mm) | Weight (g) | Density (kg/m3) |

|---|---|---|---|---|

| SAC | 101.7 × 101.6 | 9.8 | 10.63 | 104.97 |

| FSC-20MG | 101.8 × 101.9 | 9.9 | 12.16 | 97.99 |

| FSC-80MG | 101.8 × 101.9 | 9.9 | 10.99 | 107.01 |

| CAC | 102.4 × 102.5 | 9.8 | 10.6 | 103.05 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joshi, S.C.; Manikandan, P.; Jothi, Y. Enhancement Studies on Manufacturing and Properties of Novel Silica Aerogel Composites. Gels 2018, 4, 5. https://doi.org/10.3390/gels4010005

Joshi SC, Manikandan P, Jothi Y. Enhancement Studies on Manufacturing and Properties of Novel Silica Aerogel Composites. Gels. 2018; 4(1):5. https://doi.org/10.3390/gels4010005

Chicago/Turabian StyleJoshi, Sunil Chandrakant, Periyasamy Manikandan, and Yogeswari Jothi. 2018. "Enhancement Studies on Manufacturing and Properties of Novel Silica Aerogel Composites" Gels 4, no. 1: 5. https://doi.org/10.3390/gels4010005

APA StyleJoshi, S. C., Manikandan, P., & Jothi, Y. (2018). Enhancement Studies on Manufacturing and Properties of Novel Silica Aerogel Composites. Gels, 4(1), 5. https://doi.org/10.3390/gels4010005