A Comparative Thermoacoustic Insulation Study of Silica Aerogels Reinforced with Reclaimed Textile Fibres: Cotton, Polyester and Wool

Abstract

:1. Introduction

2. Results and Discussion

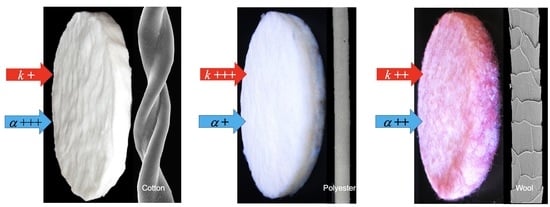

2.1. Characterization of Reclaimed Fibres

2.1.1. Length

2.1.2. Diameter and Damage Level of the Reclaimed Fibres

2.1.3. Identification by FTIR

Cotton

Polyester

Wool

2.2. Characterization of the Silica Aerogel Composites

2.2.1. Cotton-Reinforced Composites

- Aerogel composites: general presentation and key properties

- Insulation Results: Thermal and Acoustic

- Factors affecting thermal and acoustic insulation

2.2.2. Polyester-Reinforced Composites

- Aerogel composites: general presentation and key properties

- The Young’s modulus of the polyester-reinforced composites is comparatively higher than that of the cotton-reinforced composites. A plausible reason might be that the smallest non-hydrolysable branch of the VTMS co-precursor, when compared to the longer branch of the isoBTES precursor, imparted flexibility to the silica–cotton composites (see Table 1). But the main reason seems to be the regularity of the polyester fibres, because the absence of cavities (like the cotton fibres) or a crimped character (like the wool fibres) does not favour the dissipation of the stress load [63]. According to Lu and colleagues, straight fibres “provide a stronger reinforcement to the aerogel composites, compared with the curved ones” [63]. Among the TEOS-VTMS systems of polyester–silica composites, by increasing the fraction of fibres, the composites gain in terms of flexibility, as denoted by the lower value of the Young’s modulus presented in Table 3. The significant difference in dimensions between the fibres’ diameter and pore/secondary particles’ dimension creates unbalanced responses to the received stress loads, which can explain the high standard deviation of some composites. Insulation results: thermal and acoustic

- Factors affecting thermal and acoustic insulation

2.2.3. Wool-Reinforced Composites

- Aerogel composites: general presentation and key properties

- Insulation results: thermal and acoustic

- Factors affecting thermal and acoustic insulation

2.2.4. Final Remarks on the Reinforcement Matrices and Scaled-Up Composites

3. Conclusions

4. Materials and Methods

4.1. Materials

4.2. Preparation of the Composites

4.2.1. Cotton-Reinforced Composites

4.2.2. Polyester-Reinforced Composites

4.2.3. Wool-Reinforced Composites

4.2.4. Characterization Techniques

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A. Reclaimed Fibre Damage

Appendix B. Study of the Optimal Processing Conditions

- Polyester-Reinforced Silica Aerogel Composites

- Post-Synthesis Solvent

| Post-Synthesis Solvent | Polyester | Shrinkage (%) | Density (kg m−3) | k (mW m−1 K−1) | |||

|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Height | Volume | |||

| EtOAc | 0.16 ± 0.0 | 8.3 ± 0.3 | 24.4 ± 1.0 | 27.1 ± 1.8 | 58.3 ± 0.1 | 241 ± 8 | 51.2 ± 4.9 |

| Heptane | 0.16 ± 0.0 | 8.6 ± 0.2 | 18.1 ± 0.7 | 14.2 ± 3.8 | 42.5 ± 3.2 | 170 ± 9 | 47.6 ± 3.0 |

| Hexane | 0.16 ± 0.0 | 8.4 ± 0.1 | 15.7 ± 2.9 | 21.2 ± 3.1 | 44.1 ± 1.7 | 180 ± 7 | 50.1 ± 3.1 |

- Polyester Content

- Precursor System

| Precursor(s) System | Polyester | Shrinkage (%) | Density (kg m−3) | k (mW m−1 K−1) | |||

|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Height | Volume | |||

| TEOS | 0.23 ± 0.0 | 11.0 ± 0.4 | 10.1 ± 0.7 | 15.7 ± 2.8 | 31.9 ± 1.3 | 163 ± 3 | 32.4 ± 0.8 |

| TEOS-isoBTES | 0.23 ± 0.0 | 11.9 ± 0.7 | 14.0 ± 0.3 | 27.5 ± 0.7 | 46.4 ± 0.9 | 184 ± 8 | 47.4 ± 0.7 |

| TEOS-VTES | 0.23 ± 0.0 | 11.5 ± 0.0 | 8.5 ± 0.1 | 13.4 ± 0.6 | 27.6 ± 0.3 | 145 ± 3 | 34.6 ± 1.8 |

| TEOS-VTMS | 0.23 ± 0.0 | 10.5 ± 0.3 | 6.8 ± 0.6 | 5.6 ± 1.2 | 18.1 ± 2.0 | 141 ± 3 | 25.3 ± 0.3 |

- Molar Ratio of Precursor/Co-Precursor

- 2.

- Wool-Reinforced Silica Aerogel Composites

| Post-Synthesis Solvent | Wool | Shrinkage (%) | Density (kg m−3) | k (mW m−1 K−1) | |||

|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Height | Volume | |||

| EtOAc | 0.23 ± 0.0 | 10.6 ± 0.1 | 11.1 ± 1.1 | 24.6 ± 2.0 | 40.4 ± 1.6 | 175 ± 5 | 51.4 ± 0.2 |

| Heptane | 0.23 ± 0.0 | 10.4 ± 0.0 | 11.5 ± 0.8 | 23.1 ± 2.2 | 39.8 ± 1.7 | 169 ± 4 | 50.1 ± 1.0 |

- Precursor System

| Precursor(s) System | Wool | Shrinkage (%) | Density (kg m−3) | k (mW m−1 K−1) | |||

|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Height | Volume | |||

| TEOS-isoBTES | 0.24 ± 0.0 | 11.5 ± 0.1 | 8.7 ± 0.2 | 13.8 ± 2.5 | 28.1 ± 2.4 | 150 ± 3 | 48.5 ± 1.4 |

| TEOS-VTMS | 0.24 ± 0.0 | 10.7 ± 0.2 | 5.2 ± 1.1 | 7.3 ± 0.8 | 16.6 ± 2.7 | 136 ± 6 | 27.2 ± 0.5 |

- Wool Content

- 3.

- Conclusion of the Optimization Studies for Polyester–Silica and Wool–Silica Composites

- TEOS-VTMS system, with the molar ratios:

- Si:EtOH:H2O:CH3COOH:NH4OH = 0.82/0.18: 7.79:9.86:4.8 × 10−2:9.1 × 10−2.

- TEOS-VTMS System, with the Molar Ratios:

References

- Deshpande, R.; Smith, D.M.; Brinker, C.J. Preparation of High Porosity Xerogels by Chemical Surface Modification. U.S. Patent No. 5,565,142A, 15 October 1996. [Google Scholar]

- Pierre, A.C.; Rigacci, A. SiO2 Aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer Science+Business Media: New York, NY, USA, 2011; pp. 21–45. [Google Scholar]

- Sachithanadam, M.; Joshi, S.C. Silica Aerogel Composites Novel Fabrication Methods; Springer: Singapore, 2016; ISBN 978-981-10-0438-4. [Google Scholar]

- Linhares, T.; Amorim, M.T.P.; Durães, L. Silica Aerogel Composites with Embedded Fibres: A Review on Their Preparation, Properties and Applications. J. Mater. Chem. A 2019, 7, 22768–22802. [Google Scholar] [CrossRef]

- Textile Exchange. Preferred Fiber & Materials: Market Report 2022; Textile Exchange: Lamesa, TX, USA, 2022. [Google Scholar]

- Šajn, N. Textiles and the Environment; EPRS (European Parliamentary Research Service): Brussels, Belgium, 2022. [Google Scholar]

- Vadicherla, T.; Saravanan, D.; Muthu, S.S.K. Polyester Recycling—Technologies, Characterisation, and Applications. In Environmental Implications of Recycling and Recycled Products; Muthu, S.S.K., Ed.; Springer Science+Business Media: Singapore, 2015; pp. 149–165. [Google Scholar]

- Gulich, B. Development of Products Made of Reclaimed Fibres. In Recycling in Textiles; Wang, Y., Ed.; Woodhead Publishing: Cambridge, UK, 2006; pp. 117–136. [Google Scholar]

- Linhares, T.; Carneiro, V.H.; Merillas, B.; Pessoa de Amorim, M.T.; Durães, L. Textile Waste-Reinforced Cotton-Silica Aerogel Composites for Moisture Regulation and Thermal/Acoustic Barrier. J. Sol-Gel Sci. Technol. 2022, 102, 574–588. [Google Scholar] [CrossRef]

- Ba Thai, Q.; Le-Cao, K.; Nguyen, P.T.T.; Le, P.K.; Phan-Thien, N.; Duong, H.M. Fabrication and Optimization of Multifunctional Nanoporous Aerogels Using Recycled Textile Fibers from Car Tire Wastes for Oil-Spill Cleaning, Heat-Insulating and Sound Absorbing Applications. Colloids Surf. A Physicochem. Eng. Asp. 2021, 628, 127363. [Google Scholar] [CrossRef]

- Loh, J.W.; Goh, X.Y.; Nguyen, P.T.T.; Thai, Q.B.; Ong, Z.Y.; Duong, H.M. Advanced Aerogels from Wool Waste Fibers for Oil Spill Cleaning Applications. J. Polym. Environ. 2021, 30, 681–694. [Google Scholar] [CrossRef]

- Grand View Research. Acoustic Insulation Market Size, Share & Trends Analysis Report by Product, by End-Use, by Region (North America, Europe, APAC, Central & South America, MEA), and Segment Forecasts, 2016–2025. Available online: https://www.grandviewresearch.com/industry-analysis/acoustic-insulation-market# (accessed on 29 November 2022).

- Tao, P.; McCafferty, D.J. Bioinspired Thermal Insulation and Storage Materials. In Bioinspired Engineering of Thermal Materials; Deng, T., Ed.; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2018; pp. 201–223. [Google Scholar]

- Stojanovic, A.; Koebel, M.M. Low Cost Silica Aerogel Production. In Proceedings of the CISBAT 2015 International Conference on Future Buildings and Districts—Sustainability from Nano to Urban Scale, Lausanne, Switzerland, 9–11 September 2015; Scartezzini, J.-L., Ed.; EPFL Solar Energy and Building Physics Laboratory: Lausanne, Switzerland, 2015; Volume 1, pp. 27–32. [Google Scholar]

- Vajó, B.; Lakatos, Á. Super Insulation Materials—An Application to Historical Buildings. Buildings 2021, 11, 525. [Google Scholar] [CrossRef]

- Ananthan, Y.; Sanghamitra, K.K.; Hebalkar, N. Silica Aerogels for Energy Conservation and Saving. In Nanotechnology for Energy Sustainability; Raj, B., Van de Voorde, M., Mahajan, Y., Eds.; Wiley-VHC: Weinheim, Germany, 2017; pp. 939–966. [Google Scholar]

- Mazrouei-Sebdani, Z.; Begum, H.; Schoenwald, S.; Horoshenkov, K.V.; Malfait, W.J. A Review on Silica Aerogel-Based Materials for Acoustic Applications. J. Non. Cryst. Solids 2021, 562, 120770. [Google Scholar] [CrossRef]

- Ferreira-Gonçalves, T.; Iglesias-Mejuto, A.; Linhares, T.; Coelho, M.P.; Vieira, P.; Faísca, P.; Catarino, J.; Pinto, P.; Ferreira, D.; Ferreira, H.A.; et al. Biological Thermal Performance of Organic and Inorganic Aerogels as Patches for Photothermal Therapy. Gels 2022, 8, 485. [Google Scholar] [CrossRef]

- Amares, S.; Sujatmika, E.; Hong, T.W.; Durairaj, R.; Hamid, H.S.H.B. A Review: Characteristics of Noise Absorption Material. J. Phys. Conf. Ser. 2017, 908, 012005. [Google Scholar] [CrossRef] [Green Version]

- Talebi, Z.; Soltani, P.; Habibi, N.; Latifi, F. Silica Aerogel/Polyester Blankets for Efficient Sound Absorption in Buildings. Constr. Build. Mater. 2019, 220, 76–89. [Google Scholar] [CrossRef]

- Arenas, J.P.; Crocker, M.J. Recent Trends in Porous Sound-Absorbing Materials. Sound Vib. 2009, 44, 12–17. [Google Scholar]

- European Commission. DG ENV Sustainable Natural Materials Can Be Used for Noise Insulation; Science for Environment Policy; European Commission: Bristol, UK, 2011. [Google Scholar]

- Oldham, D.J.; Egan, C.A.; Cookson, R.D. Sustainable Acoustic Absorbers from the Biomass. Appl. Acoust. 2011, 72, 350–363. [Google Scholar] [CrossRef]

- Gliścińska, E.; Krucińska, I.; Michalak, M.; Puchalski, M.; Ciechańska, D.; Kazimierczak, J.; Bloda, A. Bio-Based Composites for Sound Absorption. In Composites from Renewable and Sustainable Materials; Poletto, M., Ed.; ExLi4EvA: London, UK, 2016; pp. 217–239. [Google Scholar]

- Gordon, S. Cotton Fibre Quality. In Cotton: Science and Technology; Gordon, S., Hsieh, Y.-L., Eds.; Woodhead Publishing: Boca Raton, FL, USA, 2007; pp. 68–100. [Google Scholar]

- Harwood, J.; Harwood, R. Testing of Natural Textile Fibres. In Handbook of Natural Fibres Volume 1: Types, Properties and Factors Affecting Breeding and Cultivation; Kozłowski, R.M., Ed.; Woodhead Publishing: Cambridge, UK, 2012; pp. 345–390. [Google Scholar]

- Choudhury, A.K.R. Textile Preparation and Dyeing; Science Publishers: Durham, NH, USA, 2006. [Google Scholar]

- Bradow, J.M.; Wartelle, L.H.; Bauer, P.J.; Sassenrath-Cole, G.F. Small-Sample Cotton Fiber Quality Quantitation. J. Cotton Sci. 1997, 1, 48–60. [Google Scholar]

- Singh, S.P.; Soni, B.; Bajpai, S.K. Chemically Modified Cotton Fibers for Antimicrobial Applications. In Cellulose-Based Graft Copolymers Structure and Chemistry; Thakur, V.K., Ed.; CRC Press: Boca Raton, FL, USA, 2015; pp. 235–269. [Google Scholar]

- Chakraborty, S.; Agarwal, S.; Dandge, S.S. Analysis of Cotton Fibre Properties: A Data Mining Approach. J. Inst. Eng. Ser. E 2018, 99, 163–176. [Google Scholar] [CrossRef]

- Negm, M.; Sanad, S. Cotton Fibres, Picking, Ginning, Spinning and Weaving. In Handbook of Natural Fibres Volume 2: Processing and Applications; Kozłowski, R.M., Mackiewicz-Talarczyk, M., Eds.; Woodhead Publishing: Cambridge, UK, 2020; pp. 3–48. [Google Scholar]

- Grishanov, S. Structure and Properties of Textile Materials. In Handbook of Textile and Industrial Dyeing; Volume 1: Principles Processes and Types of Dye; Clark, M., Ed.; Woodhead Publishing Limited: Cambridge, UK, 2011; pp. 28–63. [Google Scholar]

- Alagirusamy, R.; Das, A. Property Enhancement through Blending. In Polyesters and Polyamides; Deopura, B.L., Alagirusamy, R., Joshi, M., Gupta, B., Eds.; Woodhead Publishing: Boca Raton, FL, USA, 2008; pp. 219–252. [Google Scholar]

- Malik, S.A.; Tanwari, A.; Syed, U.; Qureshi, R.F.; Mengal, N. Blended Yarn Analysis: Part I-Influence of Blend Ratio and Break Draft on Mass Variation, Hairiness, and Physical Properties of 15 Tex PES/CO Blended Ring-Spun Yarn. J. Nat. Fibers 2012, 9, 197–206. [Google Scholar] [CrossRef]

- Lang, C.; Wu, M.; Pan, X.; Jin, J.; Wang, F.; Xu, B.; Qiu, Y. Algorithm for Measuring Fiber Length Distributions of Raw Cotton and Combed Wool Using Dual-Beard Image Method. Text. Res. J. 2020, 90, 2149–2160. [Google Scholar] [CrossRef]

- Lawrence, C.A. Fundamentals of Spun Yarn Technology; CRC Press LLC: Boca Raton, FL, USA, 2003. [Google Scholar]

- D’Arcy, J.B. Sheep Management and Wool Technology, 3rd ed.; New South Wales University Press: Kensington, Australia, 1990. [Google Scholar]

- Peets, P.; Kaupmees, K.; Vahur, S.; Leito, I. Reflectance FT-IR Spectroscopy as a Viable Option for Textile Fiber Identification. Herit. Sci. 2019, 7, 15–20. [Google Scholar] [CrossRef]

- Poletto, M.; Pistor, V.; Zattera, A.J. Structural Characteristics and Thermal Properties of Native Cellulose. In Cellulose—Fundamental Aspects; van de Ven, T., Godbout, L., Eds.; InTech: Rijeka, Croatia, 2013; pp. 56–68. [Google Scholar]

- Parker, F.S. Applications of Infrared Spectroscopy in Biochemistry, Biology, and Medicine; Plenum Press: New York, NY, USA, 1971. [Google Scholar]

- Abidi, N.; Hequet, E.; Cabrales, L. Applications of Fourier Transform Infrared Spectroscopy to Study Cotton Fibers. In Fourier Transforms—New Analytical Approaches and FTIR Strategies; Nikolić, G.S., Ed.; InTech: Rijeka, Croatia, 2011; pp. 89–114. [Google Scholar]

- Fan, M.; Dai, D.; Huang, B. Fourier Transform Infrared Spectroscopy for Natural Fibres. In Fourier Transform—Materials Analysis; Salih, S., Ed.; IntechOpen: Rijeka, Croatia, 2012; pp. 45–68. [Google Scholar]

- El-Sakhawy, M.; Kamel, S.; Salama, A.; Tohamy, H.A.S. Preparation and Infrared Study of Cellulose Based Amphiphilic Materials. Cellul. Chem. Technol. 2018, 52, 193–200. [Google Scholar]

- Liu, Y.; Kokot, S.; Sambi, T.J. Vibrational Spectroscopic Investigation of Australian Cotton Cellulose Fibres: Part 1. A Fourier Transform Raman Study. Analyst 1998, 123, 633–636. [Google Scholar] [CrossRef]

- Garside, P.; Wyeth, P. Identification of Cellulosic Fibres by FTIR Spectroscopy: Thread and Single Fibre Analysis by Attenuated Total Reflectance. Stud. Conserv. 2004, 48, 269–275. [Google Scholar] [CrossRef] [Green Version]

- Zhbankov, R.G.; Andrianov, V.M.; Marchewka, M.K. Fourier Transform IR and Raman Spectroscopy and Structure of Carbohydrates. J. Mol. Struct. 1997, 436, 637–654. [Google Scholar] [CrossRef]

- Nikonenko, N.A.; Buslov, D.K.; Sushko, N.I.; Zhbankov, R.G. Investigation of Stretching Vibrations of Glycosidic Linkages in Disaccharides and Polysaccarides with Use of IR Spectra Deconvolution. Biopolym. Biospectrosc. Sect. 2000, 57, 257–262. [Google Scholar] [CrossRef]

- Smith, B.C. Infrared Spectral Interpretation—A Systematic Approach; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Ma, Y.; Jiang, Y.; Liang, Y.; Zhang, W.; Zhang, H.; Zhang, R. Preparation and Biocompatibility of Polyester Films Grafted with Functional MPEG Copolymers. Chem. Res. Chin. Univ. 2017, 33, 847–852. [Google Scholar] [CrossRef]

- Bellamy, L.J. The Infra-Red Spectra of Complex Molecules, 3rd ed.; Chapman & Hall: London, UK, 1971. [Google Scholar]

- Moore, K.E.; Mangos, D.N.; Slattery, A.D.; Raston, C.L.; Boulos, R.A. Wool Deconstruction Using a Benign Eutectic Melt. RSC Adv. 2016, 6, 20095–20101. [Google Scholar] [CrossRef] [Green Version]

- McGregor, B.A.; Liu, X.; Wang, X.G. Comparisons of the Fourier Transform Infrared Spectra of Cashmere, Guard Hair, Wool and Other Animal Fibres. J. Text. Inst. 2018, 109, 813–822. [Google Scholar] [CrossRef]

- Patil, N.V.; Netravali, A.N. Enhancing Strength of Wool Fiber Using a Soy Flour Sugar-Based “Green” Cross-Linker. ACS Omega 2019, 4, 5392–5401. [Google Scholar] [CrossRef]

- Kawabata, S.; Rengasamy, R.S. Thermal Conductivity of Unidirectional Fibre Composites Made from Yarns and Computation of Thermal Conductivity of Yarns. Indian J. Fibre Text. Res. 2002, 27, 217–223. [Google Scholar]

- Paul, P.; Ahirwar, M.; Behera, B.K. Acoustic Behaviour of Needle Punched Nonwoven Structures Produced from Various Natural and Synthetic Fibers. Appl. Acoust. 2022, 199, 109043. [Google Scholar] [CrossRef]

- Szymanski, J. Acoustical Treatment for Indoor Areas. In Handbook for Sound Engineers; Ballou, G.M., Ed.; Focal Press: Oxford, UK, 2008; pp. 95–125. [Google Scholar]

- Horvat, G.; Pantić, M.; Knez, Ž.; Novak, Z. A Brief Evaluation of Pore Structure Determination for Bioaerogels. Gels 2022, 8, 438. [Google Scholar] [CrossRef]

- Van Der Voort, P.; Leus, K.; De Canck, E. Introduction to Porous Materials; John Wiley & Sons Ltd.: Chichester, UK, 2019. [Google Scholar]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Are and Porosity (Recomendations 1984). Handb. Heterog. Catal. 2008, 3, 1503–1516. [Google Scholar] [CrossRef]

- Reichenauer, G. Structural Characterization of Aerogels. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer Science+Business Media: New York, NY, USA, 2011; pp. 449–498. [Google Scholar]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of Gases, with Special Reference to the Evaluation of Surface Area and Pore Size Distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Begum, H.; Horoshenkov, K.V.; Conte, M.; Malfait, W.J.; Zhao, S.; Koebel, M.M.; Bonfiglio, P.; Venegas, R. The Acoustical Properties of Tetraethyl Orthosilicate Based Granular Silica Aerogels. J. Acoust. Soc. Am. 2021, 149, 4149–4158. [Google Scholar] [CrossRef]

- Lu, Z.; Yuan, Z.; Liu, Q.; Hu, Z.; Xie, F.; Zhu, M. Multi-Scale Simulation of the Tensile Properties of Fiber-Reinforced Silica Aerogel Composites. Mater. Sci. Eng. A 2015, 625, 278–287. [Google Scholar] [CrossRef]

- Narang, P.P. Material Parameter Selection in Polyester Fibre Insulation for Sound Transmission and Absorption. Appl. Acoust. 1995, 45, 335–358. [Google Scholar] [CrossRef]

- Tascan, M.; Vaughn, E.A.; Stevens, K.A.; Brown, P.J. Effects of Total Surface Area and Fabric Density on the Acoustical Behavior of Traditional Thermal-Bonded Highloft Nonwoven Fabrics. J. Text. Inst. 2011, 102, 746–751. [Google Scholar] [CrossRef]

- Utell, M.J.; Maxim, L.D. Refractory Ceramic Fibers: Fiber Characteristics, Potential Health Effects and Clinical Observations. Toxicol. Appl. Pharmacol. 2018, 361, 113–117. [Google Scholar] [CrossRef]

- Hasan, M.A.; Sangashetty, R.; Esther, A.C.M.; Patil, S.B.; Sherikar, B.N.; Dey, A. Prospect of Thermal Insulation by Silica Aerogel: A Brief Review. J. Inst. Eng. Ser. D 2017, 98, 297–304. [Google Scholar] [CrossRef]

- Li, L.; Yalcin, B.; Nguyen, B.N.; Meador, M.A.B.; Cakmak, M. Flexible Nanofiber-Reinforced Aerogel (Xerogel) Synthesis, Manufacture, and Characterization. ACS Appl. Mater. Interfaces 2009, 1, 2491–2501. [Google Scholar] [CrossRef]

- Carneiro, V.H.P. Development of Lightweight Auxetic Composites for Noise Reduction and Vibration Damping. Ph.D. Thesis, University of Minho, Braga, Portugal, 2020. [Google Scholar]

- D 2495-01; Standard Test Method for Moisture in Cotton by Oven-Drying. ASTM International: West Conshohocken, PA, USA, 2001; pp. 1–6.

- Hearle, J.W.S. Physical Structure and Properties of Cotton. In Cotton: Science and Technology; Gordon, S., Hsieh, Y.-L., Eds.; Woodhead Publishing: Boca Raton, FL, USA, 2007; pp. 35–67. [Google Scholar]

- Gauthier, B.M.; Bakrania, S.D.; Anderson, A.M.; Carroll, M.K. A Fast Supercritical Extraction Technique for Aerogel Fabrication. J. Non. Cryst. Solids 2004, 350, 238–243. [Google Scholar] [CrossRef]

- Deopura, B.L.; Padaki, N.V. Synthetic Textile Fibres: Polyamide, Polyester and Aramid Fibres. In Textiles and Fashion: Materials, Design and Technology; Sinclair, R., Ed.; Elsevier Ltd.: Kidlington, UK, 2015; pp. 97–114. [Google Scholar]

- Hearle, J.W.S.; Morton, W.E. Physical Properties of Textile Fibres; Woodhead Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Wong, J.C.H.; Kaymak, H.; Brunner, S.; Koebel, M.M. Mechanical Properties of Monolithic Silica Aerogels Made from Polyethoxydisiloxanes. Microporous Mesoporous Mater. 2014, 183, 23–29. [Google Scholar] [CrossRef]

- Prat, D.; Hayler, J.; Wells, A. A Survey of Solvent Selection Guides. Green Chem. 2014, 16, 4546–4551. [Google Scholar] [CrossRef]

- Mal, P.; Ganguly, D. Dyeing and Recent Developments. In Fibres to Smart Textiles Advances in Manufacturing, Technologies, and Applications; Patnaik, A., Patnaik, S., Eds.; Taylor & Francis Group, LLC: Boca Raton, FL, USA, 2020; pp. 169–186. [Google Scholar]

- Pedersen-Bjergaard, S.; Gjelstad, A.; Halvorsen, T.G. Sample Preparation. In Bioanalysis of Pharmaceuticals: Sample Preparation, Separation Techniques and Mass Spectrometry; Hansen, S.H., Pedersen-Bjergaard, S., Eds.; John Wiley & Sons, Ltd.: Chichester, UK, 2015; pp. 73–121. [Google Scholar]

- Kondo, T. Hydrogen Bonds in Cellulose and Cellulose Derivatives. In Polysaccharides: Structural Diversity and Functional Versatility; Dumitriu, S., Ed.; Marcel Dekker: New York, NY, USA, 2005; pp. 69–98. [Google Scholar]

- Wei, W.; Li, C.W.; Xie, J.M.; Zhu, J.J.; Lü, X.M.; Yan, C.H. Application of Hydrophobic Silica/Fiber Composite Aerogels in Organic Absorption. Mater. Sci. Forum 2011, 675, 1035–1039. [Google Scholar]

- Boonrawd, C.; Yodyingyong, S.; Benyahia, L.; Triampo, D. Novel Solvent–Latex Mixing: Thermal Insulation Performance of Silica Aerogel/Natural Rubber Composite. Gels 2022, 8, 7. [Google Scholar] [CrossRef] [PubMed]

- Campbell, G.S.; Norman, J.M. An Introduction to Environmental Biophysics, 2nd ed.; Springer: New York, NY, USA, 1998. [Google Scholar]

- Torres, R.B.; Vareda, J.P.; Lamy-Mendes, A.; Durães, L. Effect of Different Silylation Agents on the Properties of Ambient Pressure Dried and Supercritically Dried Vinyl-Modified Silica Aerogels. J. Supercrit. Fluids 2019, 147, 81–89. [Google Scholar] [CrossRef]

- Jones, S.M.; Sakamoto, J. Applications of Aerogels in Space Exploration. In Aerogels Handbook; Aegerter, M.A., Koebel, M.M., Eds.; Springer Science+Business Media: New York, NY, USA, 2011; pp. 721–746. [Google Scholar]

- Wagh, P.B.; Begag, R.; Pajonk, G.M.; Rao, A.V.; Haranath, D. Comparison of Some Physical Properties of Silica Aerogel Monoliths Synthesized by Different Precursors. Mater. Chem. Phys. 1999, 57, 214–218. [Google Scholar] [CrossRef]

- Tan, B.; Rankin, S.E. Effects of Progressive Changes in Organoalkoxysilane Structure on the Gelation and Pore Structure of Templated and Non-Templated Sol-Gel Materials. J. Non. Cryst. Solids 2006, 352, 5453–5462. [Google Scholar] [CrossRef]

- Zeng, S.Q.; Hunt, A.; Greif, R. Transport Properties of Gas in Silica Aerogel. J. Non. Cryst. Solids 1995, 186, 264–270. [Google Scholar] [CrossRef]

- Anderson, A.M.; Wattley, C.W.; Carroll, M.K. Silica Aerogels Prepared via Rapid Supercritical Extraction: Effect of Process Variables on Aerogel Properties. J. Non. Cryst. Solids 2009, 355, 101–108. [Google Scholar] [CrossRef]

- Rao, A.V.; Pajonk, G.M.; Bangi, U.K.H.; Rao, A.P.; Koebel, M.M. Sodium Silicate Based Aerogels via Ambient Pressure Drying. In Aerogels Handbook; Aegerter, M.A., Leventis, N., Koebel, M.M., Eds.; Springer Science+Business Media: New York, NY, USA, 2011; pp. 103–124. [Google Scholar]

- Notario, B.; Pinto, J.; Rodriguez-perez, M.A. Nanoporous Polymeric Materials: A New Class of Materials with Enhanced Properties. Prog. Mater. Sci. 2016, 78, 93–139. [Google Scholar] [CrossRef] [Green Version]

- Vareda, J.P.; Matias, T.; Durães, L. Facile Preparation of Ambient Pressure Dried Aerogel-like Monoliths with Reduced Shrinkage Based on Vinyl-Modified Silica Networks. Ceram. Int. 2018, 44, 17453–17458. [Google Scholar] [CrossRef]

| Composites | Cotton | Shrinkage (%) | Thickness (mm) | Density (kg m−3) | E (kPa) | k (mW m−1 K−1) | a (∑ 100–2000 Hz) | ||

|---|---|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Volume | ||||||

| (a) convent. mat | 2.4 | 8.5 | 8.9 ± 0.7 | 52.3 ± 1.5 | 8.2 ± 0.3 | 214 ± 9 | 64 ± 4 | 49.7 ± 0.3 | 146 |

| (b) convent. mat | 4.1 | 13.5 | 4.2 ± 0.5 | 43.6 ± 0.8 | 10.2 ± 0.4 | 197 ± 3 | 65 ± 17 | 59.2 ± 0.3 | 181 |

| (c) comp. mat | 4.1 | 12.4 | 3.3 ± 0.1 | 41.1 ± 2.1 | 10.4 ± 0.2 | 204 ± 5 | 58 ± 4 | 51.1 ± 0.2 | 167 |

| Composites | Skeletal Density (kg m−3) | Porosity (%) | ABET (m2 g−1) | Vp, BJH (cm3 g−1) | Dp, BJH (nm) | Vpore (cm3 g−1) | Dpore (nm) |

|---|---|---|---|---|---|---|---|

| (b) convent. mat | 1319 ± 20 | 85.3 ± 0.3 | 555.5 ± 4.6 | 0.82 ± 0.02 | 3.8 ± 1.1 | 4.33 ± 0.07 | 31.2 ± 0.5 |

| (c) comp. mat | 1227 ± 13 | 83.4 ± 0.4 | 691.9 ± 6.7 | 1.04 ± 0.02 | 3.5 ± 1.2 | 4.09 ± 0.10 | 23.6 ± 0.6 |

| Composites | Polyester | Shrinkage (%) | Thickness (mm) | Density (kg m−3) | E (kPa) | k (mW m−1 K−1) | α (∑ 100–2000 Hz) | ||

|---|---|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Volume | ||||||

| 73-27 molar ratio % | 3.5 | 10.9 | 2.4 ± 0.3 | 18.5 ± 0.5 | 9.6 ± 0.2 | 133 ± 4 | 245 ± 30 | 24.4 ± 0.5 | 62 |

| 5.1 | 16.0 | 3.5 ± 0.0 | 16.4 ± 1.0 | 14.8 ± 0.5 | 141 ± 6 | 215 ± 20 | 26.6 ± 1.5 | 73 | |

| 82-18 molar ratio % | 3.5 | 13.0 | 1.4 ± 0.1 | 10.6 ± 0.1 | 14.9 ± 0.1 | 115 ± 3 | 247 ± 15 | 24.4 ± 0.5 | 64 |

| 5.0 | 17.1 | 2.5 ± 0.2 | 10.2 ± 0.4 | 15.6 ± 0.4 | 117 ± 4 | 174 ± 5 | 26.0 ± 0.9 | 71 | |

| Composites | Skeletal Density (kg m−3) | Porosity (%) | ABET (m2 g−1) | Vp, BJH (cm3 g−1) | Dp, BJH (nm) | Vpore (cm3 g−1) | Dpore (nm) |

|---|---|---|---|---|---|---|---|

| 82-18 molar ratio %; Polyester 17 wt% | 1119 ± 87 | 89.5 ± 0.8 | 577.2 ± 5.4 | 1.45 ± 0.05 | 9.3 ± 0.8 | 7.66 ± 0.26 | 53.1 ± 1.6 |

| Composites | Wool | Shrinkage (%) | Thickness (mm) | Density (kg m−3) | E (kPa) | k (mW m−1 K−1) | α (∑ 100–2000 Hz) | ||

|---|---|---|---|---|---|---|---|---|---|

| (g) | (wt%) | Diameter | Volume | ||||||

| 73-27 molar ratio % | 2.7 | 10.2 | 0.3 ± 0.2 | 10.0 ± 3.9 | 13.1 ± 0.5 | 121 ± 5 | 91 ± 11 | 24.0 ± 0.5 | 94 |

| 3.3 | 13.6 | 2.4 ± 0.5 | 11.4 ± 1.8 | 13.4 ± 0.4 | 120 ± 6 | 83 ± 7 | 26.0 ± 1.9 | 144 | |

| 82-18 molar ratio % | 2.6 | 11.3 | 0.2 ± 0.2 | 5.7 ± 3.5 | 13.5 ± 0.5 | 113 ± 5 | 65 ± 5 | 24.3 ± 3.1 | 92 |

| 3.6 | 14.8 | 0.1 ± 0.1 | 2.9 ± 1.0 | 13.8 ± 0.2 | 110 ± 3 | 56 ± 10 | 27.3 ± 2.2 | 104 | |

| Composites | Skeletal Density (kg m−3) | Porosity (%) | ABET (m2 g−1) | Vp, BJH (cm3 g−1) | Dp, BJH (nm) | Vpore (cm3 g−1) | Dpore (nm) |

|---|---|---|---|---|---|---|---|

| 73-27 molar ratio %; Wool 14 wt% | 1128 ± 40 | 89.4 ± 0.6 | 531.4 ± 5.9 | 1.39 ± 0.05 | 7.57 ± 1.45 | 7.46 ± 2.43 | 56.15 ± 2.43 |

| 82-18 molar ratio %; Wool 15 wt% | 1062 ± 13 | 89.6 ± 0.3 | 619.7 ± 6.2 | 1.80 ± 0.06 | 10.01 ± 1.03 | 8.15 ± 0.22 | 52.64 ± 1.29 |

| Reinforcement Matrices | Best Performing Aerogel Composites | ||||||

|---|---|---|---|---|---|---|---|

| Fibres | Thickness (mm) | Density (kg m−3) | α (100–2000 Hz) | k (mW m−1 K−1) | α (100–2000 Hz) | ||

| Sum | Peak | Sum | Peak | ||||

| Cotton | 9 | 68 | 180 | 0.89 | 59.2 | 179 | 0.86 |

| Polyester | 14 | 37 | 171 | 0.81 | 24.4 | 64 | 0.53 |

| Wool | 13 | 42 | 126 | 0.63 | 26.0 | 144 | 0.85 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Linhares, T.; Carneiro, V.H.; Pessoa de Amorim, M.T.; Durães, L. A Comparative Thermoacoustic Insulation Study of Silica Aerogels Reinforced with Reclaimed Textile Fibres: Cotton, Polyester and Wool. Gels 2023, 9, 548. https://doi.org/10.3390/gels9070548

Linhares T, Carneiro VH, Pessoa de Amorim MT, Durães L. A Comparative Thermoacoustic Insulation Study of Silica Aerogels Reinforced with Reclaimed Textile Fibres: Cotton, Polyester and Wool. Gels. 2023; 9(7):548. https://doi.org/10.3390/gels9070548

Chicago/Turabian StyleLinhares, Teresa, Vitor H. Carneiro, Maria T. Pessoa de Amorim, and Luisa Durães. 2023. "A Comparative Thermoacoustic Insulation Study of Silica Aerogels Reinforced with Reclaimed Textile Fibres: Cotton, Polyester and Wool" Gels 9, no. 7: 548. https://doi.org/10.3390/gels9070548

APA StyleLinhares, T., Carneiro, V. H., Pessoa de Amorim, M. T., & Durães, L. (2023). A Comparative Thermoacoustic Insulation Study of Silica Aerogels Reinforced with Reclaimed Textile Fibres: Cotton, Polyester and Wool. Gels, 9(7), 548. https://doi.org/10.3390/gels9070548