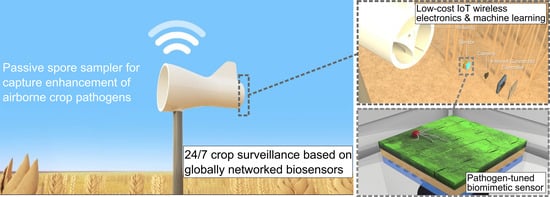

Development of a Passive Spore Sampler for Capture Enhancement of Airborne Crop Pathogens

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sampler Configuration

2.2. Numerical Simulation

2.3. Experimental Testing

2.4. Spore Capture Assessment

3. Results and Discussion

3.1. Sampler Geometry

3.2. Comparison between Simulation and Experimental Results

3.3. Spore Capture Performance

3.4. Weathervaning Performance

4. Concluding Remarks

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Aslanov, R.; El Jarroudi, M.; Gollier, M.; Pallez-Barthel, M.; Beyer, M. Yellow rust does not like cold winters. But how to find out which temperature and time frames could be decisive in vivo? J. Plant Pathol. 2019, 101, 539–546. [Google Scholar] [CrossRef]

- Central Intelligence Agency. The World Factbook. Available online: https://www.cia.gov/library/publications/the-world-factbook/geos/et.html (accessed on 8 May 2020).

- Wellings, C. Global status of stripe rust: A review of historical and current threats. Euphytica 2011, 179, 129–141. [Google Scholar] [CrossRef]

- Meyer, M.; Cox, J.A.; Hitchings, M.D.T.; Burgin, L.; Hort, M.C.; Hodson, D.P.; Gilligan, C.A. Quantifying airborne dispersal routes of pathogens over continents to safeguard global wheat supply. Nat. Plants 2017, 3, 780–786. [Google Scholar] [CrossRef] [PubMed]

- Jørgensen, L.N.; Matzen, N.; Hansen, J.G.; Semaskiene, R.; Korbas, M.; Danielewicz, J.; Głazek, M.; Maumene, C.; Rodemann, B.; Weigand, S.; et al. Four azoles’ profile in the control of Septoria, yellow rust and brown rust in wheat across Europe. Crop. Prot. 2018, 105, 16–27. [Google Scholar] [CrossRef]

- Allen-Sader, C.; Thurston, W.; Meyer, M.; Nure, E.; Bacha, N.; Alemayehu, Y.; Stutt, R.O.J.H.; Safka, D.; Craig, A.P.; Derso, E.; et al. An early warning system to predict and mitigate wheat rust diseases in Ethiopia. Environ. Res. Lett. 2019, 14, 115004. [Google Scholar] [CrossRef]

- Sporando. Early Alert System for Crop Disease. Available online: https://spornadosampler.com/ (accessed on 5 June 2020).

- Lacey, M.E.; West, J.S. The Air Spora: A Manual for Catching and Identifying Airborne Biological Particles, Chapter 4: Using a Burkard Trap; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Hirst, J.M. An Automatic Volumetric Spore Trap. Ann. Appl. Boil. 1952, 39, 257–265. [Google Scholar] [CrossRef]

- Ward-Smith, A.J. Internal Fluid Flow-The Fluid Dynamics of Flow in Pipes and Ducts; Oxford University Press: Oxford, UK, 1980. [Google Scholar]

- Wheadr Speak. Available online: https://weatherspark.com/y/100668/Average-Weather-in-Addis-Ababa-Ethiopia-Year-Round (accessed on 8 May 2020).

- Vince, J. Mathematics for Computer Graphics; Springer Science and Business Media LLC: Berlin/Heidelberg, Germany, 2010. [Google Scholar]

- Nabawy, M.R.A.; Elnomrossy, M.M.; Abdelrahman, M.M.; Elbayoumi, G.M. Aerodynamic shape optimisation, wind tunnel measurements and CFD analysis of a MAV wing. Aeronaut. J. 2012, 116, 685–708. [Google Scholar] [CrossRef] [Green Version]

- Wilcox, D.C. Turbulence Modeling for CFD, 2nd ed.; DCW Industries, Inc.: La Canada, CA, USA, 1998. [Google Scholar]

- Rowell, J.B.; Roelfs, A.P. Evidence for an unrecognized source of overwintering wheat stem rust in the United States. Plant Dis. Rep. 1971, 55, 990–992. [Google Scholar]

- Meyer, M. Modelling Atmospheric Dispersal of Fungal Pathogens on Continental Scales to Safeguard Global Wheat Production. Ph.D. Thesis, University of Cambridge, Cambridge, UK, 2018. [Google Scholar] [CrossRef]

- Bojdo, N.; Ellis, M.; Filippone, A.; Jones, M.; Pawley, A. Particle-Vane Interaction Probability in Gas Turbine Engines. J. Turbomach. 2019, 141, 091010. [Google Scholar] [CrossRef] [Green Version]

- Belyaev, S.; Levin, L. Techniques for collection of representative aerosol samples. J. Aerosol Sci. 1974, 5, 325–338. [Google Scholar] [CrossRef]

- Kim, S.; Park, H.; Gruszewski, H.A.; Schmale, D.G.; Jung, S. Vortex-induced dispersal of a plant pathogen by raindrop impact. Proc. Natl. Acad. Sci. USA 2019, 116, 4917–4922. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ranz, W.E.; Wong, J.B. Impaction of Dust and Smoke Particles on Surface and Body Collectors. Ind. Eng. Chem. 1952, 44, 1371–1381. [Google Scholar] [CrossRef]

- Rama-Rao, B.V.; Tien, C. Aerosol deposition in two-dimensional laminar stagnation flow. J. Aerosol Sci. 1989, 20, 775–785. [Google Scholar] [CrossRef]

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blackall, J.L.; Wang, J.; Nabawy, M.R.A.; Quinn, M.K.; Grieve, B.D. Development of a Passive Spore Sampler for Capture Enhancement of Airborne Crop Pathogens. Fluids 2020, 5, 97. https://doi.org/10.3390/fluids5020097

Blackall JL, Wang J, Nabawy MRA, Quinn MK, Grieve BD. Development of a Passive Spore Sampler for Capture Enhancement of Airborne Crop Pathogens. Fluids. 2020; 5(2):97. https://doi.org/10.3390/fluids5020097

Chicago/Turabian StyleBlackall, James L., Jie Wang, Mostafa R. A. Nabawy, Mark K. Quinn, and Bruce D. Grieve. 2020. "Development of a Passive Spore Sampler for Capture Enhancement of Airborne Crop Pathogens" Fluids 5, no. 2: 97. https://doi.org/10.3390/fluids5020097

APA StyleBlackall, J. L., Wang, J., Nabawy, M. R. A., Quinn, M. K., & Grieve, B. D. (2020). Development of a Passive Spore Sampler for Capture Enhancement of Airborne Crop Pathogens. Fluids, 5(2), 97. https://doi.org/10.3390/fluids5020097