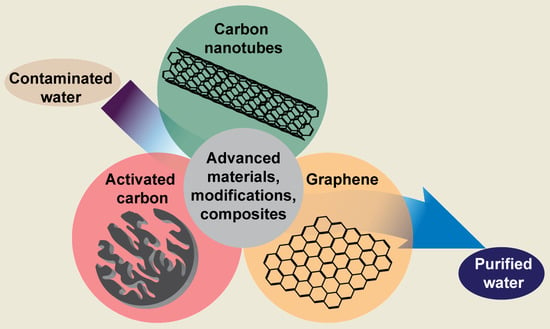

Activated Carbon, Carbon Nanotubes and Graphene: Materials and Composites for Advanced Water Purification

Abstract

:1. Introduction

2. Classifications of Water Contaminant Species

2.1. Naturally Occurring Water Contaminants

2.2. Artificially Derived Water Contaminant Species

3. Activated Carbon for Water Purification

3.1. Properties of Activated Carbon Relevant to Water Purification

3.2. Adsorption Mechanism of Activated Carbon

3.3. Chemical Modifications of Activated Carbon for Improved Contaminant Adsorption

3.4. Biologically Activated Carbon for Water Purification

3.5. Emerging Methods to Improve Water Purification Using Activated Carbon

4. Carbon Nanotube Based Water Purification Technology

4.1. Carbon Nanotube Adsorption Properties and Target Species

4.2. Chemical Modifications and Composite Materials of Carbon Nanotubes for Enhanced Water Contaminant Removal

4.3. Carbon Nanotube Materials for Antimicrobial and Antibiofouling Water Purification Applications

4.4. Point-of-Use Water Purification Devices Based on Carbon Nanotubes

5. Graphene-Based Materials for Water Purification

5.1. Properties of Graphene and Graphene Oxide

5.2. Water Purification Mechanisms Using Graphene and Specific Targeted Species

5.3. Emerging Composite Graphene Materials for Enhanced Water Purification

5.4. Graphene and Graphene Composites for Point-of-Use Devices

6. Conclusions and Future Perspectives

Conflicts of Interest

References

- Gavrilescu, M.; Demnerová, K.; Aamand, J.; Agathos, S.; Fava, F. Emerging pollutants in the environment: Present and future challenges in biomonitoring, ecological risks and bioremediation. New Biotechnol. 2015, 32, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Pal, A.; He, Y.; Jekel, M.; Reinhard, M.; Gin, K.Y.-H. Emerging contaminants of public health significance as water quality indicator compounds in the urban water cycle. Environ. Int. 2014, 71, 46–62. [Google Scholar] [CrossRef] [PubMed]

- Mostofa, K.M.G.; Liu, C.-Q.; Mottaleb, M.A.; Wan, G.; Ogawa, H.; Vione, D.; Yoshioka, T.; Wu, F. Dissolved Organic Matter in Natural Waters; Springer: Berlin/Heidelberg, Germany, 2013; pp. 1–137. [Google Scholar]

- Cabral, J.P.S. Water microbiology. Bacterial pathogens and water. Int. J. Environ. Res. Public Health 2010, 7. [Google Scholar] [CrossRef] [PubMed]

- Schwarzenbach, R.P.; Escher, B.I.; Fenner, K.; Hofstetter, T.B.; Johnson, C.A.; von Gunten, U.; Wehrli, B. The challenge of micropollutants in aquatic systems. Science 2006, 313, 1072. [Google Scholar] [CrossRef] [PubMed]

- Baghoth, S.A.; Sharma, S.K.; Amy, G.L. Tracking natural organic matter (NOM) in a drinking water treatment plant using fluorescence excitation–emission matrices and parafac. Water Res. 2011, 45, 797–809. [Google Scholar] [CrossRef] [PubMed]

- Richardson, S.D. Disinfection by-products and other emerging contaminants in drinking water. TrAC Trends Anal. Chem. 2003, 22, 666–684. [Google Scholar] [CrossRef]

- Frank, J.; Ruhl, A.S.; Jekel, M. Impacts of backwashing on granular activated carbon filters for advanced wastewater treatment. Water Res. 2015, 87, 166–174. [Google Scholar] [CrossRef] [PubMed]

- Gibert, O.; Lefèvre, B.; Fernández, M.; Bernat, X.; Paraira, M.; Pons, M. Fractionation and removal of dissolved organic carbon in a full-scale granular activated carbon filter used for drinking water production. Water Res. 2013, 47, 2821–2829. [Google Scholar] [CrossRef] [PubMed]

- Moreno-Castilla, C. Adsorption of organic molecules from aqueous solutions on carbon materials. Carbon 2004, 42, 83–94. [Google Scholar] [CrossRef]

- Smith, S.C.; Rodrigues, D.F. Carbon-based nanomaterials for removal of chemical and biological contaminants from water: A review of mechanisms and applications. Carbon 2015, 91, 122–143. [Google Scholar] [CrossRef]

- Bhatnagar, A.; Hogland, W.; Marques, M.; Sillanpää, M. An overview of the modification methods of activated carbon for its water treatment applications. Chem. Eng. J. 2013, 219, 499–511. [Google Scholar] [CrossRef]

- Sui, Z.; Meng, Q.; Zhang, X.; Ma, R.; Cao, B. Green synthesis of carbon nanotube-graphene hybrid aerogels and their use as versatile agents for water purification. J. Mater. Chem. 2012, 22, 8767–8771. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Z.; Gao, C. Ultrathin graphene nanofiltration membrane for water purification. Adv. Funct. Mater. 2013, 23, 3693–3700. [Google Scholar] [CrossRef]

- Karumuri, A.K.; Oswal, D.P.; Hostetler, H.A.; Mukhopadhyay, S.M. Silver nanoparticles attached to porous carbon substrates: Robust materials for chemical-free water disinfection. Mater. Lett. 2013, 109, 83–87. [Google Scholar] [CrossRef]

- Her, N.; Amy, G.; McKnight, D.; Sohn, J.; Yoon, Y. Characterization of DOM as a function of MW by fluorescence EEM and HPLC-SEC using UVA, DOC, and fluorescence detection. Water Res. 2003, 37, 4295–4303. [Google Scholar] [CrossRef]

- Lozovik, P.A.; Morozov, A.K.; Zobkov, M.B.; Dukhovicheva, T.A.; Osipova, L.A. Allochthonous and autochthonous organic matter in surface waters in Karelia. Water Resour. 2007, 34, 204–216. [Google Scholar] [CrossRef]

- Stedmon, C.A.; Markager, S. Tracing the production and degradation of autochthonous fractions of dissolved organic matter by fluorescence analysis. Limnol. Oceanogr. 2005, 50, 1415–1426. [Google Scholar] [CrossRef]

- King, D.N.; Donohue, M.J.; Vesper, S.J.; Villegas, E.N.; Ware, M.W.; Vogel, M.E.; Furlong, E.F.; Kolpin, D.W.; Glassmeyer, S.T.; Pfaller, S. Microbial pathogens in source and treated waters from drinking water treatment plants in the united states and implications for human health. Sci. Total Environ. 2016, 562, 987–995. [Google Scholar] [CrossRef] [PubMed]

- Richardson, S.D.; Kimura, S.Y. Water analysis: Emerging contaminants and current issues. Anal. Chem. 2016, 88, 546–582. [Google Scholar] [CrossRef] [PubMed]

- Kong, L.; Kadokami, K.; Wang, S.; Duong, H.T.; Chau, H.T.C. Monitoring of 1300 organic micro-pollutants in surface waters from Tianjin, north China. Chemosphere 2015, 122, 125–130. [Google Scholar] [CrossRef] [PubMed]

- Sebilo, M.; Mayer, B.; Nicolardot, B.; Pinay, G.; Mariotti, A. Long-term fate of nitrate fertilizer in agricultural soils. Proc. Natl. Acad. Sci. USA 2013, 110, 18185–18189. [Google Scholar] [CrossRef] [PubMed]

- Schoumans, O.F.; Chardon, W.J.; Bechmann, M.E.; Gascuel-Odoux, C.; Hofman, G.; Kronvang, B.; Rubæk, G.H.; Ulén, B.; Dorioz, J.M. Mitigation options to reduce phosphorus losses from the agricultural sector and improve surface water quality: A review. Sci. Total Environ. 2014, 468, 1255–1266. [Google Scholar] [CrossRef] [PubMed]

- Patrolecco, L.; Ademollo, N.; Grenni, P.; Tolomei, A.; Barra Caracciolo, A.; Capri, S. Simultaneous determination of human pharmaceuticals in water samples by solid phase extraction and HPLC with UV-fluorescence detection. Microchem. J. 2013, 107, 165–171. [Google Scholar] [CrossRef]

- Pruden, A. Balancing water sustainability and public health goals in the face of growing concerns about antibiotic resistance. Environ. Sci. Technol. 2014, 48, 5–14. [Google Scholar] [CrossRef] [PubMed]

- Gopal, K.; Tripathy, S.S.; Bersillon, J.L.; Dubey, S.P. Chlorination byproducts, their toxicodynamics and removal from drinking water. J. Hazard. Mater. 2007, 140, 1–6. [Google Scholar] [CrossRef] [PubMed]

- Richardson, S.D.; Postigo, C. Drinking water disinfection by-products. In Emerging Organic Contaminants and Human Health; Barceló, D., Ed.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 93–137. [Google Scholar]

- De Melo, B.A.G.; Motta, F.L.; Santana, M.H.A. Humic acids: Structural properties and multiple functionalities for novel technological developments. Mater. Sci. Eng. C 2016, 62, 967–974. [Google Scholar] [CrossRef] [PubMed]

- Sharp, E.L.; Parsons, S.A.; Jefferson, B. Seasonal variations in natural organic matter and its impact on coagulation in water treatment. Sci. Total Environ. 2006, 363, 183–194. [Google Scholar] [CrossRef] [PubMed]

- Schreiber, B.; Brinkmann, T.; Schmalz, V.; Worch, E. Adsorption of dissolved organic matter onto activated carbon—Te influence of temperature, absorption wavelength, and molecular size. Water Res. 2005, 39, 3449–3456. [Google Scholar] [CrossRef] [PubMed]

- Holinger, E.P.; Ross, K.A.; Robertson, C.E.; Stevens, M.J.; Harris, J.K.; Pace, N.R. Molecular analysis of point-of-use municipal drinking water microbiology. Water Res. 2014, 49, 225–235. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Guan, S.; Sato, A.; Wang, X.; Wang, Z.; Yang, R.; Hsiao, B.S.; Chu, B. Nanofibrous microfiltration membranes capable of removing bacteria, viruses and heavy metal ions. J. Membr. Sci. 2013, 446, 376–382. [Google Scholar] [CrossRef]

- Srinivasan, N.R.; Shankar, P.A.; Bandyopadhyaya, R. Plasma treated activated carbon impregnated with silver nanoparticles for improved antibacterial effect in water disinfection. Carbon 2013, 57, 1–10. [Google Scholar] [CrossRef]

- National Health and Medical Research Concil. NRMMC (2011) Australian Drinking Water Guidelines Paper 6; Volume 2016 Update; Commonwealth of Australia: Canberra, Australia, 2011. [Google Scholar]

- Rasheed, S.; Campos, L.C.; Kim, J.K.; Zhou, Q.; Hashmi, I. Optimization of total trihalomethanes’ (TTHMS) and their precursors’ removal by granulated activated carbon (GAC) and sand dual media by response surface methodology (RSM). Water Sci. Technol: Water Supply 2016, 16, 783–793. [Google Scholar] [CrossRef]

- Fu, F.; Wang, Q. Removal of heavy metal ions from wastewaters: A review. J. Environ. Manag. 2011, 92, 407–418. [Google Scholar] [CrossRef] [PubMed]

- Reza, R.; Singh, G. Heavy metal contamination and its indexing approach for river water. Int. J. Environ. Sci. Technol. 2010, 7, 785–792. [Google Scholar] [CrossRef]

- Forgacs, E.; Cserháti, T.; Oros, G. Removal of synthetic dyes from wastewaters: A review. Environ. Int. 2004, 30, 953–971. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, M.B.; Zhou, J.L.; Ngo, H.H.; Guo, W. Adsorptive removal of antibiotics from water and wastewater: Progress and challenges. Sci. Total Environ. 2015, 532, 112–126. [Google Scholar] [CrossRef] [PubMed]

- Rivera-Utrilla, J.; Sánchez-Polo, M.; Ferro-García, M.Á.; Prados-Joya, G.; Ocampo-Pérez, R. Pharmaceuticals as emerging contaminants and their removal from water. A review. Chemosphere 2013, 93, 1268–1287. [Google Scholar] [CrossRef] [PubMed]

- Tepuš, B.; Simonič, M.; Petrinić, I. Comparison between nitrate and pesticide removal from ground water using adsorbents and NF and RO membranes. J. Hazard. Mater. 2009, 170, 1210–1217. [Google Scholar] [CrossRef] [PubMed]

- Chen, S.-S.; Taylor, J.S.; Mulford, L.A.; Norris, C.D. Influences of molecular weight, molecular size, flux, and recovery for aromatic pesticide removal by nanofiltration membranes. Desalination 2004, 160, 103–111. [Google Scholar] [CrossRef]

- Ando, N.; Matsui, Y.; Kurotobi, R.; Nakano, Y.; Matsushita, T.; Ohno, K. Comparison of natural organic matter adsorption capacities of super-powdered activated carbon and powdered activated carbon. Water Res. 2010, 44, 4127–4136. [Google Scholar] [CrossRef] [PubMed]

- Yahya, M.A.; Al-Qodah, Z.; Ngah, C.W.Z. Agricultural bio-waste materials as potential sustainable precursors used for activated carbon production: A review. Renew. Sustain. Energy Rev. 2015, 46, 218–235. [Google Scholar]

- Graese, S.L.; Snoeyink, V.L.; Lee, R.G. Granular activated carbon filter-adsorber systems. J. Am.Water Works Assoc. 1987, 79, 64–74. [Google Scholar]

- Han, S.; Kim, S.; Lim, H.; Choi, W.; Park, H.; Yoon, J.; Hyeon, T. New nanoporous carbon materials with high adsorption capacity and rapid adsorption kinetics for removing humic acids. Microporous Mesoporous Mater. 2003, 58, 131–135. [Google Scholar]

- Pezoti, O.; Cazetta, A.L.; Bedin, K.C.; Souza, L.S.; Martins, A.C.; Silva, T.L.; Santos Júnior, O.O.; Visentainer, J.V.; Almeida, V.C. NaOH-activated carbon of high surface area produced from guava seeds as a high-efficiency adsorbent for amoxicillin removal: Kinetic, isotherm and thermodynamic studies. Chem. Eng. J. 2016, 288, 778–788. [Google Scholar]

- Figueiredo, J.L. Functionalization of porous carbons for catalytic applications. J. Mater. Chem. A 2013, 1, 9351–9364. [Google Scholar]

- Dąbrowski, A.; Podkościelny, P.; Hubicki, Z.; Barczak, M. Adsorption of phenolic compounds by activated carbon—A critical review. Chemosphere 2005, 58, 1049–1070. [Google Scholar] [PubMed]

- Cheng, W.; Dastgheib, S.A.; Karanfil, T. Adsorption of dissolved natural organic matter by modified activated carbons. Water Res. 2005, 39, 2281–2290. [Google Scholar] [PubMed]

- Ebie, K.; Li, F.; Azuma, Y.; Yuasa, A.; Hagishita, T. Pore distribution effect of activated carbon in adsorbing organic micropollutants from natural water. Water Res. 2001, 35, 167–179. [Google Scholar] [PubMed]

- Pavoni, B.; Drusian, D.; Giacometti, A.; Zanette, M. Assessment of organic chlorinated compound removal from aqueous matrices by adsorption on activated carbon. Water Res. 2006, 40, 3571–3579. [Google Scholar] [PubMed]

- Li, Y.; Du, Q.; Liu, T.; Peng, X.; Wang, J.; Sun, J.; Wang, Y.; Wu, S.; Wang, Z.; Xia, Y.; et al. Comparative study of methylene blue dye adsorption onto activated carbon, graphene oxide, and carbon nanotubes. Chem. Eng. Res. Des. 2013, 91, 361–368. [Google Scholar]

- Li, L.; Quinlivan, P.A.; Knappe, D.R.U. Effects of activated carbon surface chemistry and pore structure on the adsorption of organic contaminants from aqueous solution. Carbon 2002, 40, 2085–2100. [Google Scholar] [CrossRef]

- Zhang, Y.-J.; Ou, J.-L.; Duan, Z.-K.; Xing, Z.-J.; Wang, Y. Adsorption of Cr(VI) on bamboo bark-based activated carbon in the absence and presence of humic acid. Colloids Surf. A 2015, 481, 108–116. [Google Scholar] [CrossRef]

- Nam, S.-W.; Choi, D.-J.; Kim, S.-K.; Her, N.; Zoh, K.-D. Adsorption characteristics of selected hydrophilic and hydrophobic micropollutants in water using activated carbon. J. Hazard. Mater. 2014, 270, 144–152. [Google Scholar] [CrossRef] [PubMed]

- Newcombe, G.; Hayes, R.; Drikas, M. Granular activated carbon: Importance of surface properties in the adsorption of naturally occurring organics. Colloids Surf. A 1993, 78, 65–71. [Google Scholar] [CrossRef]

- Prajapati, Y.N.; Bhaduri, B.; Joshi, H.C.; Srivastava, A.; Verma, N. Aqueous phase adsorption of different sized molecules on activated carbon fibers: Effect of textural properties. Chemosphere 2016, 155, 62–69. [Google Scholar] [CrossRef] [PubMed]

- Pelekani, C.; Snoeyink, V.L. Competitive adsorption in natural water: Role of activated carbon pore size. Water Res. 1999, 33, 1209–1219. [Google Scholar] [CrossRef]

- Mezohegyi, G.; van der Zee, F.P.; Font, J.; Fortuny, A.; Fabregat, A. Towards advanced aqueous dye removal processes: A short review on the versatile role of activated carbon. J. Environ. Manag. 2012, 102, 148–164. [Google Scholar] [CrossRef] [PubMed]

- Collins, J.; Ngo, T.; Qu, D.; Foster, M. Spectroscopic investigations of sequential nitric acid treatments on granulated activated carbon: Effects of surface oxygen groups on π density. Carbon 2013, 57, 174–183. [Google Scholar] [CrossRef]

- Guedidi, H.; Reinert, L.; Lévêque, J.-M.; Soneda, Y.; Bellakhal, N.; Duclaux, L. The effects of the surface oxidation of activated carbon, the solution pH and the temperature on adsorption of ibuprofen. Carbon 2013, 54, 432–443. [Google Scholar] [CrossRef]

- Yin, C.Y.; Aroua, M.K.; Daud, W.M.A.W. Review of modifications of activated carbon for enhancing contaminant uptakes from aqueous solutions. Sep. Purif. Technol. 2007, 52, 403–415. [Google Scholar] [CrossRef]

- Zhi, Y.; Liu, J. Surface modification of activated carbon for enhanced adsorption of perfluoroalkyl acids from aqueous solutions. Chemosphere 2016, 144, 1224–1232. [Google Scholar] [CrossRef] [PubMed]

- Reed, B.E.; Vaughan, R.; Jiang, L. As(III), As(V), Hg, and Pb removal by Fe-oxide impregnated activated carbon. J. Environ. Eng. 2000, 126, 869–873. [Google Scholar] [CrossRef]

- Jegadeesan, G.B.; Mondal, K.; Lalvani, S.B. Adsorption of Se (IV) and Se (VI) using copper-impregnated activated carbon and fly ash-extracted char carbon. Water Air Soil Pollut. 2015, 226, 1–12. [Google Scholar] [CrossRef]

- Yürüm, A.; Kocabaş-Ataklı, Z.Ö.; Sezen, M.; Semiat, R.; Yürüm, Y. Fast deposition of porous iron oxide on activated carbon by microwave heating and arsenic (V) removal from water. Chem. Eng. J. 2014, 242, 321–332. [Google Scholar] [CrossRef]

- Watson, K.; Farré, M.J.; Knight, N. Comparing a silver-impregnated activated carbon with an unmodified activated carbon for disinfection by-product minimisation and precursor removal. Sci. Total Environ. 2016, 542, 672–684. [Google Scholar] [CrossRef] [PubMed]

- Gonçalves, S.P.C.; Strauss, M.; Delite, F.S.; Clemente, Z.; Castro, V.L.; Martinez, D.S.T. Activated carbon from pyrolysed sugarcane bagasse: Silver nanoparticle modification and ecotoxicity assessment. Sci. Total Environ. 2016, 565, 833–840. [Google Scholar] [CrossRef] [PubMed]

- Biswas, P.; Bandyopadhyaya, R. Water disinfection using silver nanoparticle impregnated activated carbon: Escherichia coli cell-killing in batch and continuous packed column operation over a long duration. Water Res. 2016, 100, 105–115. [Google Scholar] [CrossRef] [PubMed]

- Alslaibi, T.M.; Abustan, I.; Ahmad, M.A.; Foul, A.A. A review: Production of activated carbon from agricultural byproducts via conventional and microwave heating. J. Chem. Technol. Biotechnol. 2013, 88, 1183–1190. [Google Scholar] [CrossRef]

- Saucier, C.; Adebayo, M.A.; Lima, E.C.; Cataluña, R.; Thue, P.S.; Prola, L.D.T.; Puchana-Rosero, M.J.; Machado, F.M.; Pavan, F.A.; Dotto, G.L. Microwave-assisted activated carbon from cocoa shell as adsorbent for removal of sodium diclofenac and nimesulide from aqueous effluents. J. Hazard. Mater. 2015, 289, 18–27. [Google Scholar] [CrossRef] [PubMed]

- Ge, X.; Tian, F.; Wu, Z.; Yan, Y.; Cravotto, G.; Wu, Z. Adsorption of naphthalene from aqueous solution on coal-based activated carbon modified by microwave induction: Microwave power effects. Chem. Eng. Process. Process Intensif. 2015, 91, 67–77. [Google Scholar] [CrossRef]

- Yao, S.; Zhang, J.; Shen, D.; Xiao, R.; Gu, S.; Zhao, M.; Liang, J. Removal of Pb(II) from water by the activated carbon modified by nitric acid under microwave heating. J. Colloid Interface Sci. 2016, 463, 118–127. [Google Scholar] [CrossRef] [PubMed]

- Ihsanullah; Al-Khaldi, F.A.; Abu-Sharkh, B.; Abulkibash, A.M.; Qureshi, M.I.; Laoui, T.; Atieh, M.A. Effect of acid modification on adsorption of hexavalent chromium (Cr(VI)) from aqueous solution by activated carbon and carbon nanotubes. Desalin. Water Treat. 2016, 57, 7232–7244. [Google Scholar] [CrossRef]

- Zhang, G.; Shi, L.; Zhang, Y.; Wei, D.; Yan, T.; Wei, Q.; Du, B. Aerobic granular sludge-derived activated carbon: Mineral acid modification and superior dye adsorption capacity. RSC Adv. 2015, 5, 25279–25286. [Google Scholar] [CrossRef]

- Ihsanullah; Al-Khaldi, F.A.; Abusharkh, B.; Khaled, M.; Atieh, M.A.; Nasser, M.S.; laoui, T.; Saleh, T.A.; Agarwal, S.; Tyagi, I.; et al. Adsorptive removal of cadmium(II) ions from liquid phase using acid modified carbon-based adsorbents. J. Mol. Liq. 2015, 204, 255–263. [Google Scholar] [CrossRef]

- Limousy, L.; Ghouma, I.; Ouederni, A.; Jeguirim, M. Amoxicillin removal from aqueous solution using activated carbon prepared by chemical activation of olive stone. Environ. Sci. Pollut. Res. 2016, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Mashhadi, S.; Javadian, H.; Ghasemi, M.; Saleh, T.A.; Gupta, V.K. Microwave-induced H2SO4 activation of activated carbon derived from rice agricultural wastes for sorption of methylene blue from aqueous solution. Desalin. Water Treat. 2016, 57, 21091–21104. [Google Scholar]

- Erdogan, T.; Oguz Erdogan, F. Characterization of the adsorption of disperse yellow 211 on activated carbon from cherry stones following microwave-assisted phosphoric acid treatment. Anal. Lett. 2016, 49, 917–928. [Google Scholar] [CrossRef]

- Thue, P.S.; dos Reis, G.S.; Lima, E.C.; Sieliechi, J.M.; Dotto, G.L.; Wamba, A.G.N.; Dias, S.L.P.; Pavan, F.A. Activated carbon obtained from sapelli wood sawdust by microwave heating for o-cresol adsorption. Res. Chem. Intermed. 2016, 1–25. [Google Scholar] [CrossRef]

- Ge, X.; Wu, Z.; Wu, Z.; Yan, Y.; Cravotto, G.; Ye, B.-C. Microwave-assisted modification of activated carbon with ammonia for efficient pyrene adsorption. J. Ind. Eng. Chem. 2016, 39, 27–36. [Google Scholar] [CrossRef]

- Martins, A.C.; Pezoti, O.; Cazetta, A.L.; Bedin, K.C.; Yamazaki, D.A.S.; Bandoch, G.F.G.; Asefa, T.; Visentainer, J.V.; Almeida, V.C. Removal of tetracycline by NaOH-activated carbon produced from macadamia nut shells: Kinetic and equilibrium studies. Chem. Eng. J. 2015, 260, 291–299. [Google Scholar] [CrossRef]

- Mestre, A.S.; Tyszko, E.; Andrade, M.A.; Galhetas, M.; Freire, C.; Carvalho, A.P. Sustainable activated carbons prepared from a sucrose-derived hydrochar: Remarkable adsorbents for pharmaceutical compounds. RSC Adv. 2015, 5, 19696–19707. [Google Scholar] [CrossRef]

- Niasar, H.S.; Li, H.; Kasanneni, T.V.R.; Ray, M.B.; Xu, C. Surface amination of activated carbon and petroleum coke for the removal of naphthenic acids and treatment of oil sands process-affected water (OSPW). Chem. Eng. J. 2016, 293, 189–199. [Google Scholar] [CrossRef]

- Njoku, V.O.; Foo, K.Y.; Asif, M.; Hameed, B.H. Preparation of activated carbons from rambutan (Nephelium lappaceum) peel by microwave-induced KOH activation for acid yellow 17 dye adsorption. Chem. Eng. J. 2014, 250, 198–204. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Karthiga Devi, G.; Arumugam, T. Synthesis and characterization of metallic nanoparticles impregnated onto activated carbon using leaf extract of mukia maderasapatna: Evaluation of antimicrobial activities. Microbial Pathogenesis 2016, 97, 198–203. [Google Scholar] [CrossRef] [PubMed]

- Abussaud, B.; Asmaly, H.A.; Ihsanullah; Saleh, T.A.; Gupta, V.K.; laoui, T.; Atieh, M.A. Sorption of phenol from waters on activated carbon impregnated with iron oxide, aluminum oxide and titanium oxide. J. Mol. Liq. 2016, 213, 351–359. [Google Scholar] [CrossRef]

- Orha, C.; Pode, R.; Manea, F.; Lazau, C.; Bandas, C. Titanium dioxide-modified activated carbon for advanced drinking water treatment. Process Saf. Environ. Protect. 2016. [Google Scholar] [CrossRef]

- Hu, X.; Zhang, H.; Sun, Z. Adsorption of low concentration ceftazidime from aqueous solutions using impregnated activated carbon promoted by iron, copper and aluminum. Appl. Surf. Sci. 2016, 392, 332–341. [Google Scholar] [CrossRef]

- Mokhtari, P.; Ghaedi, M.; Dashtian, K.; Rahimi, M.R.; Purkait, M.K. Removal of methyl orange by copper sulfide nanoparticles loaded activated carbon: Kinetic and isotherm investigation. J. Mol. Liq. 2016, 219, 299–305. [Google Scholar] [CrossRef]

- Trang, V.N.; Dan, N.P.; Phuong, L.D.; Thanh, B.X. Pilot study on the removal of TOC, THMS, and HAAS in drinking water using ozone/UV–BAC. Desalin. Water Treat. 2014, 52, 990–998. [Google Scholar] [CrossRef]

- Lou, J.-C.; Yang, C.-Y.; Chang, C.-J.; Chen, W.-H.; Tseng, W.-B.; Han, J.-Y. Analysis and removal of assimilable organic carbon (AOC) from treated drinking water using a biological activated carbon filter system. J. Environ. Chem. Eng. 2014, 2, 1684–1690. [Google Scholar] [CrossRef]

- LaPara, T.M.; Hope Wilkinson, K.; Strait, J.M.; Hozalski, R.M.; Sadowksy, M.J.; Hamilton, M.J. The bacterial communities of full-scale biologically active, granular activated carbon filters are stable and diverse and potentially contain novel ammonia-oxidizing microorganisms. Appl. Environ. Microbiol. 2015, 81, 6864–6872. [Google Scholar] [CrossRef] [PubMed]

- Çeçen, F.; Aktaş, Ö. Activated Carbon for Water and Wastewater Treatment: Integration of Adsorption and Biological Treatment; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2011; p. 406. [Google Scholar]

- Chu, W.; Gao, N.; Yin, D.; Deng, Y.; Templeton, M.R. Ozone–biological activated carbon integrated treatment for removal of precursors of halogenated nitrogenous disinfection by-products. Chemosphere 2012, 86, 1087–1091. [Google Scholar] [CrossRef] [PubMed]

- Qin, W.; Li, W.-G.; Zhang, D.-Y.; Huang, X.-F.; Song, Y. Ammonium removal of drinking water at low temperature by activated carbon filter biologically enhanced with heterotrophic nitrifying bacteria. Environ. Sci. Pollut. Res. 2016, 23, 4650–4659. [Google Scholar] [CrossRef] [PubMed]

- Lou, J.-C.; Chang, C.-J.; Chen, W.-H.; Tseng, W.-B.; Han, J.-Y. Removal of trihalomethanes and haloacetic acids from treated drinking water by biological activated carbon filter. Water Air Soil Pollut. 2014, 225, 1–9. [Google Scholar] [CrossRef]

- Lou, J.-C.; Chan, H.-Y.; Han, J.-Y.; Yang, C.-Y. High removal of haloacetic acids from treated drinking water using bio-activated carbon method. Desalin. Water Treat. 2016, 1–12. [Google Scholar] [CrossRef]

- Liu, C.; Sun, Y.; Wang, D.; Sun, Z.; Chen, M.; Zhou, Z.; Chen, W. Performance and mechanism of low-frequency ultrasound to regenerate the biological activated carbon. Ultrason. Sonochem. 2017, 34, 142–153. [Google Scholar] [CrossRef] [PubMed]

- Rana, V.K.; Kissner, R.; Gaspard, S.; Levalois-Grützmacher, J. Cyclodextrin as a complexation agent in the removal of chlordecone from water. Chem. Eng. J. 2016, 293, 82–89. [Google Scholar] [CrossRef]

- Luo, X.; Lei, X.; Cai, N.; Xie, X.; Xue, Y.; Yu, F. Removal of heavy metal ions from water by magnetic cellulose-based beads with embedded chemically modified magnetite nanoparticles and activated carbon. ACS Sustainable Chem. Eng. 2016, 4, 3960–3969. [Google Scholar] [CrossRef]

- Jurado-Sánchez, B.; Sattayasamitsathit, S.; Gao, W.; Santos, L.; Fedorak, Y.; Singh, V.V.; Orozco, J.; Galarnyk, M.; Wang, J. Self-propelled activated carbon janus micromotors for efficient water purification. Small 2015, 11, 499–506. [Google Scholar] [CrossRef] [PubMed]

- Fornasiero, F.; Park, H.G.; Holt, J.K.; Stadermann, M.; Grigoropoulos, C.P.; Noy, A.; Bakajin, O. Ion exclusion by sub-2-nm carbon nanotube pores. Proc. Natl. Acad. Sci. USA 2008, 105, 17250–17255. [Google Scholar] [CrossRef] [PubMed]

- Kalra, A.; Garde, S.; Hummer, G. Osmotic water transport through carbon nanotube membranes. PNAS 2003, 100, 10175–10180. [Google Scholar] [CrossRef] [PubMed]

- Das, R.; Ali, M.E.; Hamid, S.B.A.; Ramakrishna, S.; Chowdhury, Z.Z. Carbon nanotube membranes for water purification: A bright future in water desalination. Desalination 2014, 336, 97–109. [Google Scholar] [CrossRef]

- Thomas, M.; Corry, B. A computational assessment of the permeability and salt rejection of carbon nanotube membranes and their application to water desalination. Philos. Trans. A Math. Phys. Eng. Sci. 2015, 374, 20150020. [Google Scholar] [CrossRef] [PubMed]

- Ren, X.; Chen, C.; Nagatsu, M.; Wang, X. Carbon nanotubes as adsorbents in environmental pollution management: A review. Chem. Eng. J. 2011, 170, 395–410. [Google Scholar] [CrossRef]

- Das, R.; Abd Hamid, S.B.; Ali, M.E.; Ismail, A.F.; Annuar, M.S.M.; Ramakrishna, S. Multifunctional carbon nanotubes in water treatment: The present, past and future. Desalination 2014, 354, 160–179. [Google Scholar] [CrossRef]

- Bui, N.; Meshot, E.R.; Kim, S.; Peña, J.; Gibson, P.W.; Wu, K.J.; Fornasiero, F. Ultrabreathable and protective membranes with sub-5 nm carbon nanotube pores. Adv. Mater. 2016, 28, 5871–5877. [Google Scholar] [CrossRef] [PubMed]

- Sharma, V.K.; McDonald, T.J.; Kim, H.; Garg, V.K. Magnetic graphene–carbon nanotube iron nanocomposites as adsorbents and antibacterial agents for water purification. Adv. Colloid Interface Sci. 2015, 225, 229–240. [Google Scholar] [CrossRef] [PubMed]

- Singh, G.; Rana, D.; Matsuura, T.; Ramakrishna, S.; Narbaitz, R.M.; Tabe, S. Removal of disinfection byproducts from water by carbonized electrospun nanofibrous membranes. Sep. Purif. Technol. 2010, 74, 202–212. [Google Scholar] [CrossRef]

- Wang, Y.; Ma, J.; Zhu, J.; Ye, N.; Zhang, X.; Huang, H. Multi-walled carbon nanotubes with selected properties for dynamic filtration of pharmaceuticals and personal care products. Water Res. 2016, 92, 104–112. [Google Scholar] [CrossRef] [PubMed]

- Lou, J.C.; Jung, M.J.; Yang, H.W.; Han, J.Y.; Huang, W.H. Removal of dissolved organic matter (DOM) from raw water by single-walled carbon nanotubes (SWCNTs). J. Environ. Sci. Health. Part A 2011, 46, 1357–1365. [Google Scholar] [CrossRef] [PubMed]

- Ji, L.; Chen, W.; Duan, L.; Zhu, D. Mechanisms for strong adsorption of tetracycline to carbon nanotubes: A comparative study using activated carbon and graphite as adsorbents. Environ. Sci. Technol. 2009, 43, 2322–2327. [Google Scholar] [CrossRef] [PubMed]

- Czech, B.; Oleszczuk, P. Sorption of diclofenac and naproxen onto MWCNT in model wastewater treated by H2O2 and/or UV. Chemosphere 2016, 149, 272–278. [Google Scholar] [CrossRef] [PubMed]

- Jadhav, A.H.; Mai, X.T.; Ofori, F.A.; Kim, H. Preparation, characterization, and kinetic study of end opened carbon nanotubes incorporated polyacrylonitrile electrospun nanofibers for the adsorption of pyrene from aqueous solution. Chem. Eng. J. 2015, 259, 348–356. [Google Scholar] [CrossRef]

- Gouda, A.A.; Al Ghannam, S.M. Impregnated multiwalled carbon nanotubes as efficient sorbent for the solid phase extraction of trace amounts of heavy metal ions in food and water samples. Food Chem. 2016, 202, 409–416. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Huang, Q.; Liu, M.; Tian, J.; Zeng, G.; Li, Z.; Wang, K.; Zhang, Q.; Wan, Q.; Deng, F.; et al. Preparation of amine functionalized carbon nanotubes via a bioinspired strategy and their application in Cu2+ removal. Appl. Surf. Sci. 2015, 343, 19–27. [Google Scholar] [CrossRef]

- Mubarak, N.M.; Sahu, J.N.; Abdullah, E.C.; Jayakumar, N.S. Rapid adsorption of toxic Pb(II) ions from aqueous solution using multiwall carbon nanotubes synthesized by microwave chemical vapor deposition technique. J. Environ. Sci. 2016, 45, 143–155. [Google Scholar] [CrossRef] [PubMed]

- Gupta, V.K.; Moradi, O.; Tyagi, I.; Agarwal, S.; Sadegh, H.; Shahryari-Ghoshekandi, R.; Makhlouf, A.S.H.; Goodarzi, M.; Garshasbi, A. Study on the removal of heavy metal ions from industry waste by carbon nanotubes: Effect of the surface modification: A review. Critical Reviews in Environ. Sci. Technol. 2016, 46, 93–118. [Google Scholar] [CrossRef]

- Ihsanullah; Abbas, A.; Al-Amer, A.M.; Laoui, T.; Al-Marri, M.J.; Nasser, M.S.; Khraisheh, M.; Atieh, M.A. Heavy metal removal from aqueous solution by advanced carbon nanotubes: Critical review of adsorption applications. Sep. Purif. Technol. 2016, 157, 141–161. [Google Scholar] [CrossRef]

- Liu, Y.; Cui, G.; Luo, C.; Zhang, L.; Guo, Y.; Yan, S. Synthesis, characterization and application of amino-functionalized multi-walled carbon nanotubes for effective fast removal of methyl orange from aqueous solution. RSC Adv. 2014, 4, 55162–55172. [Google Scholar] [CrossRef]

- Naghizadeh, A.; Nasseri, S.; Rashidi, A.M.; Rezaei Kalantary, R.; Nabizadeh, R.; Mahvi, A.H. Adsorption kinetics and thermodynamics of hydrophobic natural organic matter (NOM) removal from aqueous solution by multi-wall carbon nanotubes. Water Sci. Technol. Water Supply 2013, 13, 273. [Google Scholar] [CrossRef]

- Liu, F.-F.; Fan, J.-L.; Wang, S.-G.; Ma, G.-H. Adsorption of natural organic matter analogues by multi-walled carbon nanotubes: Comparison with powdered activated carbon. Chem. Eng. J. 2013, 219, 450–458. [Google Scholar] [CrossRef]

- Datsyuk, V.; Kalyva, M.; Papagelis, K.; Parthenios, J.; Tasis, D.; Siokou, A.; Kallitsis, I.; Galiotis, C. Chemical oxidation of multiwalled carbon nanotubes. Carbon 2008, 46, 833–840. [Google Scholar] [CrossRef]

- Ziegler, K.J.; Gu, Z.; Peng, H.; Flor, E.L.; Hauge, R.H.; Smalley, R.E. Controlled oxidative cutting of single-walled carbon nanotubes. J. Am. Chem. Soc. 2005, 127, 1541–1547. [Google Scholar] [CrossRef] [PubMed]

- Marshall, M.W.; Popa-Nita, S.; Shapter, J.G. Measurement of functionalised carbon nanotube carboxylic acid groups using a simple chemical process. Carbon 2006, 44, 1137–1141. [Google Scholar] [CrossRef]

- Krishna Kumar, A.S.; Jiang, S.-J.; Tseng, W.-L. Effective adsorption of chromium(VI)/Cr(III) from aqueous solution using ionic liquid functionalized multiwalled carbon nanotubes as a super sorbent. J. Mater. Chem. A 2015, 3, 7044–7057. [Google Scholar] [CrossRef]

- Gong, J.-L.; Wang, B.; Zeng, G.-M.; Yang, C.-P.; Niu, C.-G.; Niu, Q.-Y.; Zhou, W.-J.; Liang, Y. Removal of cationic dyes from aqueous solution using magnetic multi-wall carbon nanotube nanocomposite as adsorbent. J. Hazard. Mater. 2009, 164, 1517–1522. [Google Scholar] [CrossRef] [PubMed]

- Yu, F.; Ma, J.; Han, S. Adsorption of tetracycline from aqueous solutions onto multi-walled carbon nanotubes with different oxygen contents. Sci. Rep. 2014, 4, 5326. [Google Scholar] [CrossRef] [PubMed]

- Ma, C.-Y.; Huang, S.-C.; Chou, P.-H.; Den, W.; Hou, C.-H. Application of a multiwalled carbon nanotube-chitosan composite as an electrode in the electrosorption process for water purification. Chemosphere 2016, 146, 113–120. [Google Scholar] [CrossRef] [PubMed]

- Esfahani, M.R.; Tyler, J.L.; Stretz, H.A.; Wells, M.J.M. Effects of a dual nanofiller, nano-TiO2 and MWCNT, for polysulfone-based nanocomposite membranes for water purification. Desalination 2015, 372, 47–56. [Google Scholar] [CrossRef]

- Yang, S.; Hu, J.; Chen, C.; Shao, D.; Wang, X. Mutual effects of Pb(II) and humic acid adsorption on multiwalled carbon nanotubes/polyacrylamide composites from aqueous solutions. Environ. Sci. Technol. 2011, 45, 3621–3627. [Google Scholar] [CrossRef] [PubMed]

- Lee, J.; Ye, Y.; Ward, A.J.; Zhou, C.; Chen, V.; Minett, A.I.; Lee, S.; Liu, Z.; Chae, S.-R.; Shi, J. High flux and high selectivity carbon nanotube composite membranes for natural organic matter removal. Sep. Purif. Technol. 2016, 163, 109–119. [Google Scholar] [CrossRef]

- Siddiqa, A.; Shahid, A.; Gill, R. Silica decorated cnts sponge for selective removal of toxic contaminants and oil spills from water. J. Environ. Chem. Eng. 2015, 3, 892–897. [Google Scholar] [CrossRef]

- Chen, X.; Qiu, M.; Ding, H.; Fu, K.; Fan, Y. A reduced graphene oxide nanofiltration membrane intercalated by well-dispersed carbon nanotubes for drinking water purification. Nanoscale 2016, 8, 5696–5705. [Google Scholar] [CrossRef] [PubMed]

- Oulton, R.; Haase, J.P.; Kaalberg, S.; Redmond, C.T.; Nalbandian, M.J.; Cwiertny, D.M. Hydroxyl radical formation during ozonation of multiwalled carbon nanotubes: Performance optimization and demonstration of a reactive CNT filter. Environ. Sci. Technol. 2015, 49, 3687–3697. [Google Scholar] [CrossRef] [PubMed]

- Duman, O.; Tunç, S.; Polat, T.G.; Bozoğlan, B.K. Synthesis of magnetic oxidized multiwalled carbon nanotube-κ-carrageenan-Fe3O4 nanocomposite adsorbent and its application in cationic methylene blue dye adsorption. Carbohydr. Polym. 2016, 147, 79–88. [Google Scholar] [CrossRef] [PubMed]

- Alsabagh, A.M.; Fathy, M.; Morsi, R.E. Preparation and characterization of chitosan/silver nanoparticle/copper nanoparticle/carbon nanotube multifunctional nano-composite for water treatment: Heavy metals removal; kinetics, isotherms and competitive studies. RSC Adv. 2015, 5, 55774–55783. [Google Scholar] [CrossRef]

- Mattia, D.; Lee, K.P.; Calabrò, F. Water permeation in carbon nanotube membranes. Curr. Opin. Chem. Eng. 2014, 4, 32–37. [Google Scholar] [CrossRef]

- Lee, K.-J.; Park, H.-D. The most densified vertically-aligned carbon nanotube membranes and their normalized water permeability and high pressure durability. J. Membr. Sci. 2016, 501, 144–151. [Google Scholar] [CrossRef]

- Lee, B.; Baek, Y.; Lee, M.; Jeong, D.H.; Lee, H.H.; Yoon, J.; Kim, Y.H. A carbon nanotube wall membrane for water treatment. Nat. Commun. 2015, 6. [Google Scholar] [CrossRef] [PubMed]

- Trivedi, S.; Alameh, K. Effect of vertically aligned carbon nanotube density on the water flux and salt rejection in desalination membranes. SpringerPlus 2016, 5, 1158. [Google Scholar] [CrossRef] [PubMed]

- Jafari, A.; Mahvi, A.H.; Nasseri, S.; Rashidi, A.; Nabizadeh, R.; Rezaee, R. Ultrafiltration of natural organic matter from water by vertically aligned carbon nanotube membrane. J. Environ. Health Sci. Eng. 2015, 13, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Jame Sadia, A.; Zhou, Z. Electrochemical carbon nanotube filters for water and wastewater treatment. Nanotechnol. Rev. 2016, 5, 41–50. [Google Scholar]

- Vecitis, C.D.; Gao, G.; Liu, H. Electrochemical carbon nanotube filter for adsorption, desorption, and oxidation of aqueous dyes and anions. J. Phys. Chem. C 2011, 115, 3621–3629. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, H.; Zhou, Z.; Wang, T.; Ong, C.N.; Vecitis, C.D. Degradation of the common aqueous antibiotic tetracycline using a carbon nanotube electrochemical filter. Environ. Sci. Technol. 2015, 49, 7974–7980. [Google Scholar] [CrossRef] [PubMed]

- Rahaman, M.S.; Vecitis, C.D.; Elimelech, M. Electrochemical carbon-nanotube filter performance toward virus removal and inactivation in the presence of natural organic matter. Environ. Sci. Technol. 2012, 46, 1556–1564. [Google Scholar] [CrossRef] [PubMed]

- Brady-Estévez, A.S.; Kang, S.; Elimelech, M. A single-walled-carbon-nanotube filter for removal of viral and bacterial pathogens. Small 2008, 4, 481–484. [Google Scholar] [CrossRef] [PubMed]

- Baek, Y.; Kim, C.; Seo, D.K.; Kim, T.; Lee, J.S.; Kim, Y.H.; Ahn, K.H.; Bae, S.S.; Lee, S.C.; Lim, J.; et al. High performance and antifouling vertically aligned carbon nanotube membrane for water purification. J. Membr. Sci. 2014, 460, 171–177. [Google Scholar] [CrossRef]

- Dong, X.; Yang, L. Dual functional nisin-multi-walled carbon nanotubes coated filters for bacterial capture and inactivation. J. Biol. Eng. 2015, 9, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Wang, L.; Wang, X.; Zhou, J.-B.; Zhao, R.-S. Carbon nanotube sponges as a solid-phase extraction adsorbent for the enrichment and determination of polychlorinated biphenyls at trace levels in environmental water samples. Talanta 2016, 160, 79–85. [Google Scholar] [CrossRef] [PubMed]

- Luan, J.; Hou, P.-X.; Liu, C.; Shi, C.; Li, G.-X.; Cheng, H.-M. Efficient adsorption of organic dyes on a flexible single-wall carbon nanotube film. J. Mater. Chem. A 2016, 4, 1191–1194. [Google Scholar] [CrossRef]

- Dehghani, M.H.; Mohammadi, M.; Mohammadi, M.A.; Mahvi, A.H.; Yetilmezsoy, K.; Bhatnagar, A.; Heibati, B.; McKay, G. Equilibrium and kinetic studies of trihalomethanes adsorption onto multi-walled carbon nanotubes. Water Air Soil Pollut. 2016, 227, 1–17. [Google Scholar] [CrossRef]

- Babaei, A.A.; Lima, E.C.; Takdastan, A.; Alavi, N.; Goudarzi, G.; Vosoughi, M.; Hassani, G.; Shirmardi, M. Removal of tetracycline antibiotic from contaminated water media by multi-walled carbon nanotubes: Operational variables, kinetics, and equilibrium studies. Water Sci. Technol. 2016, 74, 1202–1216. [Google Scholar] [CrossRef] [PubMed]

- Patiño, Y.; Díaz, E.; Ordóñez, S.; Gallegos-Suarez, E.; Guerrero-Ruiz, A.; Rodríguez-Ramos, I. Adsorption of emerging pollutants on functionalized multiwall carbon nanotubes. Chemosphere 2015, 136, 174–180. [Google Scholar] [CrossRef] [PubMed]

- Nie, C.; Peng, Z.; Yang, Y.; Cheng, C.; Ma, L.; Zhao, C. Kevlar based nanofibrous particles as robust, effective and recyclable absorbents for water purification. J. Hazard. Mater. 2016, 318, 255–265. [Google Scholar] [CrossRef] [PubMed]

- Zouzelka, R.; Kusumawati, Y.; Remzova, M.; Rathousky, J.; Pauporté, T. Photocatalytic activity of porous multiwalled carbon nanotube-TiO2 composite layers for pollutant degradation. J. Hazard. Mater. 2016, 317, 52–59. [Google Scholar] [CrossRef] [PubMed]

- Park, W.K.; Yoon, Y.; Kim, S.; Yoo, S.; Do, Y.; Kang, J.-W.; Yoon, D.H.; Yang, W.S. Feasible water flow filter with facilely functionalized Fe3O4-non-oxidative graphene/CNT composites for arsenic removal. J. Environ. Chem. Eng. 2016, 4, 3246–3252. [Google Scholar] [CrossRef]

- Bakr, A.R.; Rahaman, M.S. Electrochemical efficacy of a carboxylated multiwalled carbon nanotube filter for the removal of ibuprofen from aqueous solutions under acidic conditions. Chemosphere 2016, 153, 508–520. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lang, W.-Z.; Xu, H.-P.; Zhang, X.; Guo, Y.-J. Improved poly(vinyl butyral) hollow fiber membranes by embedding multi-walled carbon nanotube for the ultrafiltrations of bovine serum albumin and humic acid. Chem. Eng. J. 2015, 260, 90–98. [Google Scholar] [CrossRef]

- Peter, K.T.; Vargo, J.D.; Rupasinghe, T.P.; De Jesus, A.; Tivanski, A.V.; Sander, E.A.; Myung, N.V.; Cwiertny, D.M. Synthesis, optimization, and performance demonstration of electrospun carbon nanofiber–carbon nanotube composite sorbents for point-of-use water treatment. ACS Appl. Mater. Interfaces 2016, 8, 11431–11440. [Google Scholar] [CrossRef] [PubMed]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. Nat. Mater. 2007, 6, 183–191. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Ang, P.K.; Wang, Z.; Tang, A.L.L.; Thong, J.T.L.; Loh, K.P. High mobility, printable, and solution-processed graphene electronics. Nano Lett. 2010, 10, 92–98. [Google Scholar] [CrossRef] [PubMed]

- Miao, X.; Tongay, S.; Petterson, M.K.; Berke, K.; Rinzler, A.G.; Appleton, B.R.; Hebard, A.F. High efficiency graphene solar cells by chemical doping. Nano Lett. 2012, 12, 2745–2750. [Google Scholar] [CrossRef] [PubMed]

- Dreyer, D.R.; Park, S.; Bielawski, C.W.; Ruoff, R.S. The chemistry of graphene oxide. Chem. Soc. Rev. 2010, 39, 228–240. [Google Scholar] [CrossRef] [PubMed]

- Cohen-Tanugi, D.; Grossman, J.C. Water desalination across nanoporous graphene. Nano Lett. 2012, 12, 3602–3608. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; McCarthy, D.T.; Deletic, A.; Zhang, X. Silver/reduced graphene oxide hydrogel as novel bactericidal filter for point-of-use water disinfection. Adv. Funct. Mater. 2015, 25, 4344–4351. [Google Scholar] [CrossRef]

- Kyzas, G.Z.; Deliyanni, E.A.; Matis, K.A. Graphene oxide and its application as an adsorbent for wastewater treatment. J. Chem. Technol. Biotechnol. 2014, 89, 196–205. [Google Scholar] [CrossRef]

- Gao, W.; Majumder, M.; Alemany, L.B.; Narayanan, T.N.; Ibarra, M.A.; Pradhan, B.K.; Ajayan, P.M. Engineered graphite oxide materials for application in water purification. ACS Appl. Mater. Interfaces 2011, 3, 1821–1826. [Google Scholar] [CrossRef] [PubMed]

- Hu, M.; Mi, B. Enabling graphene oxide nanosheets as water separation membranes. Environ. Sci. Technol. 2013, 47, 3715–3723. [Google Scholar] [CrossRef] [PubMed]

- Nair, R.R.; Wu, H.A.; Jayaram, P.N.; Grigorieva, I.V.; Geim, A.K. Unimpeded permeation of water through helium-leak–tight graphene-based membranes. Science 2012, 335, 442. [Google Scholar] [CrossRef] [PubMed]

- Liang, B.; Zhang, P.; Wang, J.; Qu, J.; Wang, L.; Wang, X.; Guan, C.; Pan, K. Membranes with selective laminar nanochannels of modified reduced graphene oxide for water purification. Carbon 2016, 103, 94–100. [Google Scholar] [CrossRef]

- Xia, S.; Ni, M.; Zhu, T.; Zhao, Y.; Li, N. Ultrathin graphene oxide nanosheet membranes with various d-spacing assembled using the pressure-assisted filtration method for removing natural organic matter. Desalination 2015, 371, 78–87. [Google Scholar] [CrossRef]

- Carmalin Sophia, A.; Lima, E.C.; Allaudeen, N.; Rajan, S. Application of graphene based materials for adsorption of pharmaceutical traces from water and wastewater- a review. Desalin. Water Treat. 2016, 1–14. [Google Scholar] [CrossRef]

- Hu, W.; Peng, C.; Luo, W.; Lv, M.; Li, X.; Li, D.; Huang, Q.; Fan, C. Graphene-based antibacterial paper. ACS Nano 2010, 4, 4317–4323. [Google Scholar] [CrossRef] [PubMed]

- Yan, H.; Wu, H.; Li, K.; Wang, Y.; Tao, X.; Yang, H.; Li, A.; Cheng, R. Influence of the surface structure of graphene oxide on the adsorption of aromatic organic compounds from water. ACS Appl. Mater. Interfaces 2015, 7, 6690–6697. [Google Scholar] [CrossRef] [PubMed]

- Sen Gupta, S.; Chakraborty, I.; Maliyekkal, S.M.; Adit Mark, T.; Pandey, D.K.; Das, S.K.; Pradeep, T. Simultaneous dehalogenation and removal of persistent halocarbon pesticides from water using graphene nanocomposites: A case study of lindane. ACS Sustain. Chem. Eng. 2015, 3, 1155–1163. [Google Scholar] [CrossRef]

- Azamat, J.; Khataee, A.; Joo, S.W. Molecular dynamics simulation of trihalomethanes separation from water by functionalized nanoporous graphene under induced pressure. Chem. Eng. Sci. 2015, 127, 285–292. [Google Scholar] [CrossRef]

- Abraham, J.; Vasu, K.S.; Williams, C.D.; Gopinadhan, K.; Su, Y.; Cherian, C.T.; Dix, J.; Prestat, E.; Haigh, S.J.; Grigorieva, I.V.; et al. Tunable sieving of ions using graphene oxide membranes. Nat. Nano 2017. [Google Scholar] [CrossRef] [PubMed]

- Liu, S.; Zeng, T.H.; Hofmann, M.; Burcombe, E.; Wei, J.; Jiang, R.; Kong, J.; Chen, Y. Antibacterial activity of graphite, graphite oxide, graphene oxide, and reduced graphene oxide: Membrane and oxidative stress. ACS Nano 2011, 5, 6971–6980. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Peng, H.; Wang, X.; Shao, F.; Yuan, Z.; Han, H. Graphene oxide exhibits broad-spectrum antimicrobial activity against bacterial phytopathogens and fungal conidia by intertwining and membrane perturbation. Nanoscale 2014, 6, 1879–1889. [Google Scholar] [CrossRef] [PubMed]

- Sun, X.-F.; Qin, J.; Xia, P.-F.; Guo, B.-B.; Yang, C.-M.; Song, C.; Wang, S.-G. Graphene oxide–silver nanoparticle membrane for biofouling control and water purification. Chem. Eng. J. 2015, 281, 53–59. [Google Scholar] [CrossRef]

- Rao, G.; Zhang, Q.; Zhao, H.; Chen, J.; Li, Y. Novel titanium dioxide/iron (III) oxide/graphene oxide photocatalytic membrane for enhanced humic acid removal from water. Chem. Eng. J. 2016, 302, 633–640. [Google Scholar] [CrossRef]

- Bao, Q.; Zhang, D.; Qi, P. Synthesis and characterization of silver nanoparticle and graphene oxide nanosheet composites as a bactericidal agent for water disinfection. J. Colloid Interface Sci. 2011, 360, 463–470. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Chen, L.; Bai, H.; Li, L. Graphene oxide-chitosan composite hydrogels as broad-spectrum adsorbents for water purification. J. Mater. Chem. A 2013, 1, 1992–2001. [Google Scholar] [CrossRef]

- Wang, Y.; Li, L.; Luo, C.; Wang, X.; Duan, H. Removal of Pb2+ from water environment using a novel magnetic chitosan/graphene oxide imprinted Pb2+. Int. J. Biol. Macromol. 2016, 86, 505–511. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.; Sun, Y.; Zhou, J.; Xu, R.; Duan, H. Mussel-inspired synthesis of polydopamine-functionalized graphene hydrogel as reusable adsorbents for water purification. ACS Appl. Mater. Interfaces 2013, 5, 425–432. [Google Scholar] [CrossRef] [PubMed]

- Ai, L.; Jiang, J. Removal of methylene blue from aqueous solution with self-assembled cylindrical graphene–carbon nanotube hybrid. Chem. Eng. J. 2012, 192, 156–163. [Google Scholar] [CrossRef]

- Giménez-Pérez, A.; Bikkarolla, S.K.; Benson, J.; Bengoa, C.; Stüber, F.; Fortuny, A.; Fabregat, A.; Font, J.; Papakonstantinou, P. Synthesis of N-doped and non-doped partially oxidised graphene membranes supported over ceramic materials. J. Mater. Sci. 2016, 51, 8346–8360. [Google Scholar] [CrossRef]

- Viraka Nellore, B.P.; Kanchanapally, R.; Pedraza, F.; Sinha, S.S.; Pramanik, A.; Hamme, A.T.; Arslan, Z.; Sardar, D.; Ray, P.C. Bio-conjugated CNT-bridged 3D porous graphene oxide membrane for highly efficient disinfection of pathogenic bacteria and removal of toxic metals from water. ACS Appl. Mater. Interfaces 2015, 7, 19210–19218. [Google Scholar] [CrossRef] [PubMed]

- Kabiri, S.; Tran, D.N.H.; Azari, S.; Losic, D. Graphene-diatom silica aerogels for efficient removal of mercury ions from water. ACS Appl. Mater. Interfaces 2015, 7, 11815–11823. [Google Scholar] [CrossRef] [PubMed]

- Vilela, D.; Parmar, J.; Zeng, Y.; Zhao, Y.; Sánchez, S. Graphene-based microbots for toxic heavy metal removal and recovery from water. Nano Lett. 2016, 16, 2860–2866. [Google Scholar] [CrossRef] [PubMed]

- Yusuf, M.; Khan, M.A.; Abdullah, E.C.; Elfghi, M.; Hosomi, M.; Terada, A.; Riya, S.; Ahmad, A. Dodecyl sulfate chain anchored mesoporous graphene: Synthesis and application to sequester heavy metal ions from aqueous phase. Chem. Eng. J. 2016, 304, 431–439. [Google Scholar] [CrossRef]

- Wan, S.; He, F.; Wu, J.; Wan, W.; Gu, Y.; Gao, B. Rapid and highly selective removal of lead from water using graphene oxide-hydrated manganese oxide nanocomposites. J. Hazard. Mater. 2016, 314, 32–40. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Zhang, S.; Gao, J.; Chung, T.-S. Layer-by-layer construction of graphene oxide (GO) framework composite membranes for highly efficient heavy metal removal. J. Membr. Sci. 2016, 515, 230–237. [Google Scholar] [CrossRef]

- Tiwari, J.N.; Mahesh, K.; Le, N.H.; Kemp, K.C.; Timilsina, R.; Tiwari, R.N.; Kim, K.S. Reduced graphene oxide-based hydrogels for the efficient capture of dye pollutants from aqueous solutions. Carbon 2013, 56, 173–182. [Google Scholar] [CrossRef]

- Cai, N.; Larese-Casanova, P. Application of positively-charged ethylenediamine-functionalized graphene for the sorption of anionic organic contaminants from water. J. Environ. Chem. Eng. 2016, 4, 2941–2951. [Google Scholar] [CrossRef]

| Contaminant Class | Example Species | Removal Methods | Removal Challenges | References |

|---|---|---|---|---|

| Natural organic matter | Humic acids Fulvic acids Proteins | Flocculation/sedimentation Filtration Adsorption | Wide range of functionalities, sizes Different mixture of compounds for each water source, with seasonal variations Adsorption affected by environmental factors and other contaminant species (pH, temperature) | [28,29,30] |

| Microorganism | Bacteria Viruses Protozoa | Chlorine disinfection Size exclusion filtration Neutralization by nanomaterials | Chlorine disinfection leads to DBPs Neutralization must meet regulation requirements Size exclusion does not capture all microorganisms Potential release of nanoparticles/nanomaterials into ecosystem | [31,32,33] |

| Disinfectant by-products | Trihalomethanes Haloacetic acids Halonitromethanes Haloamides Nitrosamines | Adsorption | Too small for ultrafiltration Regulatory guidelines for maximum concentrations apply | [26,27,34,35] |

| Heavy metals | Arsenic Mercury Lead Cadmium Chromium | Ion-exchange Adsorption Filtration Reverse osmosis Flocculation/sedimentation | Both cation and anions present Range of adsorption affinities Adsorptions effected by other contaminant species | [36,37] |

| Synthetic organics | Dyes Plasticizers Solvents Perfluorinated compounds | Adsorption Filtration Degradation | Wide range of chemistries and molecular weights Properties can be affected by environmental factors (pH, temperature, ionic concentration) | [38] |

| Pharmaceuticals | Hormones Steroids Analgesics Antibiotics Cosmetics | Adsorption Filtration Degradation | Both hydrophilic and hydrophobic compounds are present Some species have low affinity to adsorbents | [39,40] |

| Agriculturally derived | Pesticides Fertiliser Animal waste | Adsorption Filtration Flocculation/sedimentation Reverse osmosis | Wide range of chemistries and molecular weights | [41,42] |

| Modification Method | Modification Conditions | Carbon Source Material | Effect on Native Activated Carbon | Target Species | Adsorption Capacity (mg/g) | Ref. | |

|---|---|---|---|---|---|---|---|

| Native AC | Modified AC | ||||||

| Acid treatment | HNO3 + MW (130 °C, 800 W) | Rice husk | Increase oxide content Reduction in total surface area, small increase in micropore area | Pb(II) | 66.23 | 95.24 | [74] |

| HNO3 (120 °C, 48 h) | Not specified | Increased surface area Increased carboxylic acid groups | Cr(VI) | 3.46 | 18.519 | [75] | |

| (i) HNO3 (60 °C, 3 h + 300 °C, 3 h) (ii) H2SO4 (60 °C, 3 h + 300 °C, 3 h) | Aerobic granular sludge | Increased surface acid groups Decrease in surface area (reduction in micropores) | Malachite Green | 269.54 | (i) 303.03 (ii) 284.90 | [76] | |

| HNO3 (120 °C, 48 h) | Not specified | Increased surface area Increased carboxylic acid groups | Cd(II) | N/A | 1.98 | [77] | |

| H3PO4 (110 °C, 9 h) + 380 °C | Olive stone | Narrow microporosity range High number of acidic surface groups | Amoxicillin | N/A | 57.0 | [78] | |

| H2SO4 + MW (450 °C, 700 W, 20 min) | Rice straw | Increased AC surface roughness Increased overall porosity | MB | N/A | 62.5 | [79] | |

| H2SO4/ H3PO4 + MW (24 h RT, 300 W, 3 min) | Cherry stone | Increase in micropore volume from 767 m2/g to 1998 m2/g Significantly shorter activation time | Disperse yellow 211 | N/A | 283.3 | [80] | |

| Lime, ZnCl2, FeCl3, + MW (320 s, 1200 W) | Sapelli wood sawdust | High degree of microporosity Surface area of 914.08 m2/g | o-cresol | N/A | 239.2 | [81] | |

| Base treatment | NH3 (35 °C, 12 h) MW (500 W, 8 min) | Coal | Increased basicity (higher PZC) Increased surface area and pore volume | Polyaromatic hydrocarbons (pyrene) | 142.86 | 250.00 | [82] |

| 1000 °C under Ar 700 °C under NH3 | (i) Coal (ii) Coconut shell (iii) Wood (iv) Phenolic AC fiber | Reduction of oxygen content (70%) Increased PZC (>7) Increase in surface basicity through nitrogen functionality incorporation Variations observed for different source AC | Perfluorooctane sulfonic acid | (i) 1.11 (ii) 1.72 (iii) 2.70 (iv) 3.54 | (i) 2.16 (ii) 17.0 (iii) 85.2 (iv) 85.6 | [64] | |

| NaOH (2 h) 700 °C (90 min) | Macadamia nut shells | High surface area AC Large percentage of micropores PZC > 8 | Tetracycline | 58.82 * | 455.8 | [83] | |

| MW (8 min) (i) 300 W (ii) 500 W (iii) 700 W | Coal | Removal of oxide groups (increased basicity) Increased surface area and pore volume | Naphthalene | 111.79 | (i) 125.22 (ii) 131.20 (iii) 129.05 | [73] | |

| (i) KOH (ii) K2CO3 | Sucrose | (i) KOH treatment leads to very high surface area (2400 m2/g) and wide micropore distribution (ii) K2CO3 treatment results in 1400 m2/g surface area and ultramicropore sizes | Ibuprofen, paracetamol, clofibric acid, caffeine, iopamidol | 255 (Paracetamol) 147 (Iopamidol) | 514 (Paracetamol) 1050 (Iopamidol) | [84] | |

| Vapor and solution-based amination | Petroleum coke | Decrease in specific surface area from both treatments Increase in PZC | 2-Naphthoic acid | 189 | 214 (vapour) 298 (solution) | [85] | |

| KOH + MW (12 min, 600 W) | Rambutan peel | High surface area AC Short preparation time | Acid yellow 17 | 133.3 | 215.05 | [86] | |

| Impregnation | Reduction of Cu, Pb, Zn, Ag salts | Fishtail palm seeds | Incorporation of metal nanoparticles Antibacterial effects observed | Bacteria (gram +/−) | N/A | N/A | [87] |

| Mixing with AgNP | Sugarcane bagasse | Incorporation of 35 nm AgNP Retained adsorption capacity for small organics Antibacterial effects observed | Escherichia coli | N/A | N/A | [69] | |

| Calcination of metal salts (350 °C, 3 h) (i) Al2O3 (ii) TiO2 (iii) Fe2O3 | Not specified | Incorporation of metal oxide nanoparticles (Al2O3, TiO2, Fe2O3) | Phenol | 1.51 | (i) 3.546 (ii) 3.153 (iii) 3.288 | [88] | |

| O2 plasma treatment Mixing with AgNP | Not specified | Increased hydrophilicity of AC by O2 plasma treatment Incorporation of 28 nm AgNP Antibacterial effects observed | E. coli | N/A | N/A | [70] | |

| MW synthesis and impregnation of TiO2 nanoparticles | Not specified | TiO2 impregnation enabled UV photocatalyzed degradation of humic acid, resulting in higher adsorption capacity | Humic acid | 6.24 | 9.06 | [89] | |

| Reduction of metal salts (i) Fe (ii) Cu (iii) Al | Not specified | Decrease in specific surface area for modified ACs | Ceftazidime | N/A | (i) 161.3 (ii) 200 (iii) 172.4 | [90] | |

| Fe2O3 NP impregnation via MW hydrothermal | Charcoal | Decrease in overall surface area Small increase in mesopore volume | Ar(V) | N/A | 27.78 | [67] | |

| CuS NP impregnated AC | Not specified | Composite adsorbent exhibits high surface area and high porosity | Methyl orange | N/A | 122 | [91] | |

| CNT | Materials and Modification to CNT | Method | Target Species | Performance | Ref. |

|---|---|---|---|---|---|

| Native | MWCNT/SWCNT sponges | Flow Adsorption | Polychlorinated biphenyls | 81–119% recovery from real sample | [153] |

| SWCNT membrane | Batch Photodegradation induced adsorption | Rhodamine B | 190 mg/g adsorption (1.3 times higher than best performing carbon materials | [154] | |

| MWCNTs | Batch Adsorption | THMs | Adsorption capacities of 10.98, 6.85, 6.57, and 5.95 mg/g for CHCl3, CHCl2Br, CHClBr2, and CHBr3 respectively | [155] | |

| Acid treated MWCNTs | Batch Adsorption | Tetracycline | 253.38 mg/g adsorption | [156] | |

| (i) Pristine MWCNTs (ii) COOH-MWCNTs (iii) NH2-MWCNTs | Batch Adsorption | 1,8-Dichlorooctane, quinolone, alkylphenoletoxilate | Adsorption of target species affected by CNT functional groups and relative hydrophobicity of each | [157] | |

| HNO3 treated CNTs | Batch Adsorption | Cd(II) | Acid treated CNTs showed higher adsorption capacity than acid treated AC, carbon nanofibers and fly ash Greater than 95% removal of Cd(II) by CNTs | [77] | |

| Polymer composite | Acid treated MWCNTs + chitosan | Electrosorption | Aniline | 26.4 mg/g adsorption | [132] |

| Hydroxylated MWCNTs + PANI + PES | Flow Size exclusion Adsorption | Humic acid | 80% removal of humic acid High water flux | [135] | |

| SWCNTs + parylene membrane | Flow Size exclusion | Direct Blue 71, AuNP, Dengue virus | High water flux Rejection of ≥5 nm species | [110] | |

| SWCNTs + Kevlar nanofibers | Batch Adsorption | Phenylic compounds, heavy metals, dyes | Composite material displayed higher adsorption capacity for all compounds, when compared to polyethersulfone and polysulfone adsorbents | [158] | |

| CNT/silica nanoparticle sponges | Batch Adsorption | Oils, organic solvents | High adsorption capacity to oils and solvents, up to 1885 weight % | [136] | |

| MWCNT/TiO2/polysulfone | Flow Adsorption Exclusion | Humic acid | Composite outperformed native polysulfone material in terms of both adsorption/rejection of humic acid and water permeability Composite was flexible for different concentrations of humic acid | [133] | |

| Metal nanoparticle composite | Acid activated MWCNTs + TiO2 nanoparticles | Batch Photocatalyzed degradation | 4-Chlorophenol | Two fold increase in photocatalyzed degradation with MWCNTs | [159] |

| MWCNTs + Graphene + Fe3O4 nanoparticles | Batch Flow Adsorption | Ar(III) and (V) | Flow outperformed batch adsorption for removal of Ar(III) and Ar(V), 100% and 74% removal respectively | [160] | |

| Carrageenan modified acid treated MWCNTs + Fe3O4 nanoparticles | Batch Adsorption | Methylene blue | Carrageenan modified MWCNT composites outperformed non-carrageenan Composite could be magnetically separated | [139] | |

| Filter membrane infused | PVDF membrane + (i) Native MWCNTs (ii) Hydroxylated MWCNTs (iii) Animated MWCNTs (iv) Large inner diameter MWCNTs | Flow Adsorption | Triclosan, prometryn, 4-acetylamino-antipyrine, carbendazim, caffeine, ibuprofen, acetaminophen | Highest adsorption performance observed for hydroxylated MWCNTs High specific surface area improved performance | [113] |

| PTFE membrane + (i) Pristine MWCNTs (ii) COOH-MWCNTs | Flow Electrochemical degradation Adsorption | Ibuprofen | Near 100% removal of target with 2 V bias Higher adsorption performance by COOH-MWCNT membrane, due to increased surface area and hydrophilic chemistry | [161] | |

| PVB fiber + oxidized MWCNTs | Flow Ultrafiltration | BSA Humic acid | Improved filtration performance by MWCNT embedded fibers | [162] | |

| Porous alumina + CNTs | Flow Adsorption | Humic acid | High initial water flux capacity Strong adsorption of humic acid, led to decline in flux | [145] | |

| MWCNT network supported on PTFE membrane | Flow Electrochemical degradation Adsorption | Tetracycline | High degradation and removal efficiency of MWCNT electrochemical filter Performance was negatively effected by the presence of natural organic matter | [148] | |

| Electrospun fiber | Carbon nanofiber of polyacrylonitrile + MWCNTs | Flow Adsorption | Atrazine, sulfmethoxazole | Comparable adsorption capacity to AC, faster adsorption kinetics | [163] |

| Target Class | Specific Compound(s) | Graphene Material Properties | Adsorption Capacity (mg/g) | Ref. |

|---|---|---|---|---|

| Heavy metals | (i) Cu (ii) Pb (iii) Cd | Sulfydryal modified GO/chitosan composite | (i) 425 (ii) 447 (iii) 177 | [110] |

| (i) Cu (ii) Mn | Surfactant modified graphene | (i) 369.16 (ii) 223.67 | [195] | |

| Pb | GO and manganese oxide NPs | 553 | [196] | |

| (i) Ni (ii) Pb (iii) Zn | Cross-linked GO on porous ceramic support | >95% rejection | [197] | |

| (i) As(III) (ii) As(V) | Fe3O4/non-oxidative graphene/CNT composite | (i) 9.11 (ii) 5.21 | [160] | |

| (i) Cu(II) (ii) Pb(II) | GO/chitosan hydrogel | (i) 70 (ii) 90 | [187] | |

| Pb(II) | Magnetic chitosan/GO composite, imprinted with Pb(II) | 79 | [188] | |

| (i) Pb(II) (ii) Cd(II) | Polydopamine/GO hydrogel | (i) 336.32 (ii) 145.48 | [189] | |

| Dyes | (i) MB (ii) Rhodamine B | GO hydrogel | (i) 7.85 (ii) 29.44 | [198] |

| (i) MB (ii) Eosin Y | GO/chitosan hydrogel | >300 | [187] | |

| (i) Rhodamine B (ii) p-nitrophenol | Polydopamine/GO hydrogel | (i) 207.06 (ii) 260.38 | [189] | |

| MB | Graphene/CNT aerogel | 81.97 | [190] | |

| Pharmaceuticals | Ibuprofen | Ethylene diamine modified GO | 95.2 | [199] |

| DOM | Humic acid | TiO2 nanowire/Fe2O3 nanoparticle/GO composite | >98% rejection | [185] |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sweetman, M.J.; May, S.; Mebberson, N.; Pendleton, P.; Vasilev, K.; Plush, S.E.; Hayball, J.D. Activated Carbon, Carbon Nanotubes and Graphene: Materials and Composites for Advanced Water Purification. C 2017, 3, 18. https://doi.org/10.3390/c3020018

Sweetman MJ, May S, Mebberson N, Pendleton P, Vasilev K, Plush SE, Hayball JD. Activated Carbon, Carbon Nanotubes and Graphene: Materials and Composites for Advanced Water Purification. C. 2017; 3(2):18. https://doi.org/10.3390/c3020018

Chicago/Turabian StyleSweetman, Martin J., Steve May, Nick Mebberson, Phillip Pendleton, Krasimir Vasilev, Sally E. Plush, and John D. Hayball. 2017. "Activated Carbon, Carbon Nanotubes and Graphene: Materials and Composites for Advanced Water Purification" C 3, no. 2: 18. https://doi.org/10.3390/c3020018

APA StyleSweetman, M. J., May, S., Mebberson, N., Pendleton, P., Vasilev, K., Plush, S. E., & Hayball, J. D. (2017). Activated Carbon, Carbon Nanotubes and Graphene: Materials and Composites for Advanced Water Purification. C, 3(2), 18. https://doi.org/10.3390/c3020018