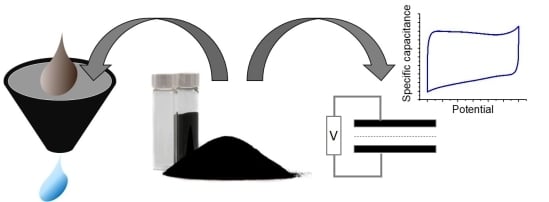

Plasma-Derived Graphene-Based Materials for Water Purification and Energy Storage

Abstract

:1. Introduction

2. Materials and Experimental Methods

3. Results and Discussion

3.1. Morphological, Structural and Porosity Studies

3.2. Dispersion and Wettability Studies

3.3. Filtration Studies

3.4. Electrochemical Studies

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef]

- Geim, A.K.; Novoselov, K.S. The rise of graphene. In Nanoscience and Technology; Macmillan Publishers Ltd.: London, UK, 2009; pp. 11–19. [Google Scholar]

- Goh, P.S.; Ismail, A.F. Graphene-based nanomaterial: The state-of-the-art material for cutting edge desalination technology. Desalination 2015, 356, 115–128. [Google Scholar] [CrossRef]

- Kostoglou, N.; Tarat, A.; Walters, I.; Ryzhkov, V.; Tampaxis, C.; Charalambopoulou, G.; Steriotis, T.; Mitterer, C.; Rebholz, C. Few-layer graphene-like flakes derived by plasma treatment: A potential material for hydrogen adsorption and storage. Microporous Mesoporous Mater. 2016, 225, 482–487. [Google Scholar] [CrossRef]

- Kostoglou, N.; Tzitzios, V.; Kontos, A.G.; Giannakopoulos, K.; Tampaxis, C.; Papavasiliou, A.; Charalambopoulou, G.; Steriotis, T.; Li, Y.; Liao, K.; et al. Synthesis of nanoporous graphene oxide adsorbents by freeze-drying or microwave radiation: Characterization and hydrogen storage properties. Int. J. Hydrogen Energy 2015, 40, 6844–6852. [Google Scholar] [CrossRef]

- Russo, P.; Hu, A.; Compagnini, G. Synthesis, Properties and Potential Applications of Porous Graphene: A Review. Nano-Micro Lett. 2013, 5, 260–273. [Google Scholar] [CrossRef] [Green Version]

- Yi, M.; Shen, Z. A review on mechanical exfoliation for the scalable production of graphene. J. Mater. Chem. A 2015, 3, 11700–11715. [Google Scholar] [CrossRef]

- Tetlow, H.; Posthuma de Boer, J.; Ford, I.J.; Vvedensky, D.D.; Coraux, J.; Kantorovich, L. Growth of epitaxial graphene: Theory and experiment. Phys. Rep. 2014, 542, 195–295. [Google Scholar] [CrossRef] [Green Version]

- Pei, S.; Cheng, H.-M. The reduction of graphene oxide. Carbon N. Y. 2012, 50, 3210–3228. [Google Scholar] [CrossRef]

- Yang, S.; Lohe, M.R.; Müllen, K.; Feng, X. New-Generation Graphene from Electrochemical Approaches: Production and Applications. Adv. Mater. 2016, 28, 6213–6221. [Google Scholar] [CrossRef] [PubMed]

- Zhao, G.; Shao, D.; Chen, C.; Wang, X. Synthesis of few-layered graphene by H2O2 plasma etching of graphite. Appl. Phys. Lett. 2011, 98, 183114. [Google Scholar] [CrossRef]

- McEvoy, N.; Nolan, H.; Ashok Kumar, N.; Hallam, T.; Duesberg, G.S. Functionalisation of graphene surfaces with downstream plasma treatments. Carbon N. Y. 2013, 54, 283–290. [Google Scholar] [CrossRef] [Green Version]

- Hegab, H.M.; Zou, L. Graphene oxide-assisted membranes: Fabrication and potential applications in desalination and water purification. J. Memb. Sci. 2015, 484, 95–106. [Google Scholar] [CrossRef]

- Cohen-Tanugi, D.; Grossman, J.C. Water Desalination across Nanoporous Graphene. Nano Lett. 2012, 12, 3602–3608. [Google Scholar] [CrossRef]

- Liu, C.; Yu, Z.; Neff, D.; Zhamu, A.; Jang, B.Z. Graphene-Based Supercapacitor with an Ultrahigh Energy Density. Nano Lett. 2010, 10, 4863–4868. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Z.; Huang, Y.; Ma, Y.; Wang, C.; Chen, M.; Chen, Y. Supercapacitor Devices Based on Graphene Materials. J. Phys. Chem. C 2009, 113, 13103–13107. [Google Scholar] [CrossRef]

- Han, Y.; Xu, Z.; Gao, C. Ultrathin Graphene Nanofiltration Membrane for Water Purification. Adv. Funct. Mater. 2013, 23, 3693–3700. [Google Scholar] [CrossRef]

- Max, L.; Beguin, F.; Frackowiak, E. Supercapacitors: Materials, Systems and Applications; John Wiley & Sons: Hoboken, NJ, USA, 2013. [Google Scholar]

- Suss, M.E.; Porada, S.; Sun, X.; Biesheuvel, P.M.; Yoon, J.; Presser, V. Water desalination via capacitive deionization: What is it and what can we expect from it? Energy Environ. Sci. 2015, 8, 2296–2319. [Google Scholar] [CrossRef]

- Lin, Z.; Goikolea, E.; Balducci, A.; Naoi, K.; Taberna, P.L.; Salanne, M.; Yushin, G.; Simon, P. Materials for supercapacitors: When Li-ion battery power is not enough. Mater. Today 2018, 21, 419–436. [Google Scholar] [CrossRef]

- Van der Bruggen, B.; Vandecasteele, C. Distillation vs. membrane filtration: Overview of process evolutions in seawater desalination. Desalination 2002, 143, 207–218. [Google Scholar] [CrossRef]

- Greenlee, L.F.; Lawler, D.F.; Freeman, B.D.; Marrot, B.; Moulin, P. Reverse osmosis desalination: Water sources, technology, and today’s challenges. Water Res. 2009, 43, 2317–2348. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.P.; Arnot, T.C.; Mattia, D. A review of reverse osmosis membrane materials for desalination—Development to date and future potential. J. Memb. Sci. 2011, 370, 1–22. [Google Scholar] [CrossRef] [Green Version]

- Mattia, D.; Lee, K.P.; Calabrò, F. Water permeation in carbon nanotube membranes. Curr. Opin. Chem. Eng. 2014, 4, 32–37. [Google Scholar] [CrossRef] [Green Version]

- Mattia, D.; Leese, H.; Calabrò, F. Electro-osmotic flow enhancement in carbon nanotube membranes. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2016, 374, 20150268. [Google Scholar] [CrossRef] [PubMed]

- Calabrò, F. Modeling the effects of material chemistry on water flow enhancement in nanotube membranes. MRS Bull. 2017, 42, 289–293. [Google Scholar] [CrossRef]

- Rivera-Utrilla, J.; Sánchez-Polo, M.; Gómez-Serrano, V.; Álvarez, P.M.; Alvim-Ferraz, M.C.M.; Dias, J.M. Activated carbon modifications to enhance its water treatment applications. An overview. J. Hazard. Mater. 2011, 187, 1–23. [Google Scholar] [CrossRef]

- Béguin, F.; Presser, V.; Balducci, A.; Frackowiak, E. Supercapacitors: Carbons and Electrolytes for Advanced Supercapacitors (Adv. Mater. 14/2014). Adv. Mater. 2014, 26, 2283. [Google Scholar] [CrossRef]

- How Many Drinks | FAQ | Coca-Cola GB, (n.d.). Available online: https://www.coca-cola.co.uk/faq/how-many-cans-of-coca-cola-are-sold-worldwide-in-a-day (accessed on 12 December 2018).

- Boyjoo, Y.; Cheng, Y.; Zhong, H.; Tian, H.; Pan, J.; Pareek, V.K.; Jiang, S.P.; Lamonier, J.-F.; Jaroniec, M.; Liu, J. From waste Coca Cola® to activated carbons with impressive capabilities for CO2 adsorption and supercapacitors. Carbon N. Y. 2017, 116, 490–499. [Google Scholar] [CrossRef]

- Myers, D.V.; Howell, J.C. Characterization and specifications of caramel colours: An overview. Food Chem. Toxicol. 1992, 30, 359–363. [Google Scholar] [CrossRef]

- Walters, I.; Walters, D.I.; Walters, D. Walters, Particles Comprising Stacked Graphene Layers, US 2017/0174520 A1. 2015. Available online: https://patents.google.com/patent/US20170174520A1/en (accessed on 12 December 2018).

- Hammersley, A.P. FIT2D: A multi-purpose data reduction, analysis and visualization program. J. Appl. Crystallogr. 2016, 49, 646–652. [Google Scholar] [CrossRef]

- Pedersen, J.S. IUCr A flux- and background-optimized version of the NanoSTAR small-angle X-ray scattering camera for solution scattering. J. Appl. Crystallogr. 2004, 37, 369–380. [Google Scholar] [CrossRef]

- International Organization for Standardization. Determination of the Specific Surface Area of Solids by Gas Adsorption: BET Method; International Organization for Standardization: Geneva, Switzerland, 2010. [Google Scholar]

- Neimark, A.V.; Lin, Y.; Ravikovitch, P.I.; Thommes, M. Quenched solid density functional theory and pore size analysis of micro-mesoporous carbons. Carbon N. Y. 2009, 47, 1617–1628. [Google Scholar] [CrossRef]

- Weingarth, D.; Zeiger, M.; Jäckel, N.; Aslan, M.; Feng, G.; Presser, V. Graphitization as a Universal Tool to Tailor the Potential-Dependent Capacitance of Carbon Supercapacitors. Adv. Energy Mater. 2014, 4, 1400316. [Google Scholar] [CrossRef]

- Lee, J.; Jäckel, N.; Kim, D.; Widmaier, M.; Sathyamoorthi, S.; Srimuk, P.; Kim, C.; Fleischmann, S.; Zeiger, M.; Presser, V. Porous carbon as a quasi-reference electrode in aqueous electrolytes. Electrochim. Acta 2016, 222, 1800–1805. [Google Scholar] [CrossRef]

- Glatter, O.; Kratky, O. Small-Angle X-ray Scattering; Academic Press: New York, NY, USA, 1982; ISBN 978-0122862809. [Google Scholar]

- Ismail, I.M.K.; Pfeifer, P. Fractal Analysis and Surface Roughness of Nonporous Carbon Fibers and Carbon Blacks. Langmuir 1994, 10, 1532–1538. [Google Scholar] [CrossRef]

- Ruland, W. Small-angle scattering of two-phase systems: Determination and significance of systematic deviations from Porod’s law. J. Appl. Crystallogr. 1971, 4, 70–73. [Google Scholar] [CrossRef]

- Smarsly, B.; Antonietti, M.; Wolff, T. Evaluation of the small-angle x-ray scattering of carbons using parametrization methods. J. Chem. Phys. 2002, 116, 2618–2627. [Google Scholar] [CrossRef]

- Wang, S.; Ábrahám, D.; Vallejos-Burgos, F.; László, K.; Geissler, E.; Takeuchi, K.; Endo, M.; Kaneko, K. Distorted Graphene Sheet Structure-Derived Latent Nanoporosity. Langmuir 2016, 32, 5617–5622. [Google Scholar] [CrossRef] [PubMed]

- Thommes, M.; Kaneko, K.; Neimark, A.V.; Olivier, J.P.; Rodriguez-Reinoso, F.; Rouquerol, J.; Sing, K.S.W. Physisorption of gases, with special reference to the evaluation of surface area and pore size distribution (IUPAC Technical Report). Pure Appl. Chem. 2015, 87, 1051–1069. [Google Scholar] [CrossRef] [Green Version]

- Tzitzios, V.; Kostoglou, N.; Giannouri, M.; Basina, G.; Tampaxis, C.; Charalambopoulou, G.; Steriotis, T.; Polychronopoulou, K.; Doumanidis, C.; Mitterer, C.; et al. Solvothermal synthesis, nanostructural characterization and gas cryo-adsorption studies in a metal–organic framework (IRMOF-1) material. Int. J. Hydrogen Energy 2017, 42. [Google Scholar] [CrossRef]

- Wang, G.; Shen, X.; Wang, B.; Yao, J.; Park, J. Synthesis and characterisation of hydrophilic and organophilic graphene nanosheets. Carbon N. Y. 2009, 47, 1359–1364. [Google Scholar] [CrossRef]

- Förch, R.; Schönherr, H.; Schonherr, H.; Jenkins, A.T. Surface Design: Applications in Bioscience and Nanotechnology; Wiley-VCH: Weinheim, Germany, 2009; ISBN 3527407898. [Google Scholar]

- Reddy, A.; Norris, D.F.; Momeni, S.S.; Waldo, B.; Ruby, J.D. The pH of beverages in the United States. J. Am. Dent. Assoc. 2016, 147, 255–263. [Google Scholar] [CrossRef]

- Prehal, C.; Koczwara, C.; Jäckel, N.; Schreiber, A.; Burian, M.; Amenitsch, H.; Hartmann, M.A.; Presser, V.; Paris, O. Quantification of ion confinement and desolvation in nanoporous carbon supercapacitors with modelling and in situ X-ray scattering. Nat. Energy 2017, 2, 16215. [Google Scholar] [CrossRef]

- Jäckel, N.; Simon, P.; Gogotsi, Y.; Presser, V. Increase in Capacitance by Subnanometer Pores in Carbon. ACS Energy Lett. 2016, 1, 1262–1265. [Google Scholar] [CrossRef] [Green Version]

- Cericola, D.; Spahr, M.E. Impedance Spectroscopic Studies of the Porous Structure of Electrodes containing Graphite Materials with Different Particle Size and Shape. Electrochim. Acta 2016, 191, 558–566. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Natter, N.; Kostoglou, N.; Koczwara, C.; Tampaxis, C.; Steriotis, T.; Gupta, R.; Paris, O.; Rebholz, C.; Mitterer, C. Plasma-Derived Graphene-Based Materials for Water Purification and Energy Storage. C 2019, 5, 16. https://doi.org/10.3390/c5020016

Natter N, Kostoglou N, Koczwara C, Tampaxis C, Steriotis T, Gupta R, Paris O, Rebholz C, Mitterer C. Plasma-Derived Graphene-Based Materials for Water Purification and Energy Storage. C. 2019; 5(2):16. https://doi.org/10.3390/c5020016

Chicago/Turabian StyleNatter, Nikolas, Nikolaos Kostoglou, Christian Koczwara, Christos Tampaxis, Theodore Steriotis, Ram Gupta, Oskar Paris, Claus Rebholz, and Christian Mitterer. 2019. "Plasma-Derived Graphene-Based Materials for Water Purification and Energy Storage" C 5, no. 2: 16. https://doi.org/10.3390/c5020016

APA StyleNatter, N., Kostoglou, N., Koczwara, C., Tampaxis, C., Steriotis, T., Gupta, R., Paris, O., Rebholz, C., & Mitterer, C. (2019). Plasma-Derived Graphene-Based Materials for Water Purification and Energy Storage. C, 5(2), 16. https://doi.org/10.3390/c5020016