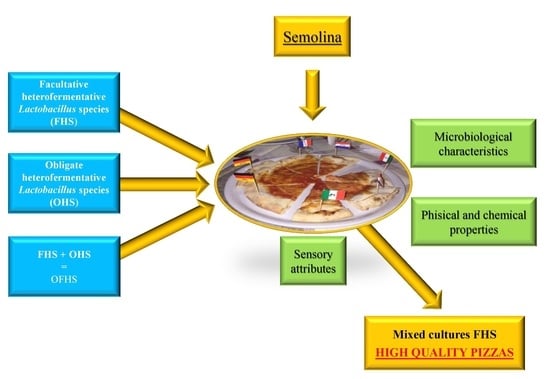

Performances of Different Metabolic Lactobacillus Groups During the Fermentation of Pizza Doughs Processed from Semolina

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials, Starter Strains, and Growth Conditions

2.2. Inoculum Preparation and Sourdough Production

2.3. Chemical Analyses of Sourdoughs

2.4. Microbiological Analysis and Monitoring of the Added Strains

2.5. Pizza Baking and Analysis

2.6. Sensory Analysis

2.7. Statistical Analyses

3. Results and Discussion

3.1. Changes of Chemical Parameters

3.2. Microbial Evolution and Monitoring of the Added Cultures

3.3. Characteristics after Baking

3.4. Evaluation of the Sensory Attributes of Pizzas

3.5. Multivariate Statistical Analysis

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Caporaso, N.; Panariello, V.; Sacchi, R. The “True” Neapolitan pizza: Assessing the influence of extra virgin olive oil on pizza volatile compounds and lipid oxidation. J. Culin. Sci. Food Technol. 2015, 13, 29–48. [Google Scholar] [CrossRef]

- Chavan, R.S.; Chavan, S.R. Sourdough Technology—A Traditional Way for Wholesome Foods: A Review. Compr. Rev. Food Sci. Food Saf. 2011, 10, 170–183. [Google Scholar] [CrossRef]

- Corsetti, A.; Settanni, L. Lactobacilli in sourdough fermentation: A review. Food Res. Int. 2007, 40, 539–558. [Google Scholar] [CrossRef]

- Corsetti, A.; Settanni, L.; Van Sinderen, D.; Felis, G.E.; Dellaglio, F.; Gobbetti, M. Lactobacillus rossii sp. nov. isolated from wheat sourdough. Int. J. Syst. Evol. Microbiol. 2005, 55, 35–40. [Google Scholar] [CrossRef] [PubMed]

- Vera, A.; Rigobello, V.; Demarigny, Y. Comparative study of culture media used for sourdough lactobacilli. Food Microbiol. 2009, 26, 728–733. [Google Scholar] [CrossRef] [PubMed]

- Hammes, W.P.; Vogel, R.F. The genus Lactobacillus. In The Genera of Lactic Acid Bacteria; Wood, B.J.B., Holzapfel, W.H., Eds.; Blackie Academic & Professional: London, UK, 1995; pp. 19–54. [Google Scholar]

- Coppola, S.; Pepe, O.; Masi, P.; Sepe, M. Characterization of leavened doughs for pizza in Naples. Adv. Food Sci. 1996, 18, 160–162. [Google Scholar]

- Coppola, S.; Pepe, O.; Mauriello, G. Effect of leavening microflora on pizza dough properties. J. Appl. Microbiol. 1998, 85, 891–897. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Salovaara, H. Lactic acid bacteria in cereal-based products. In Lactic Acid Bacteria Microbiology and Functional Aspects; Salminen, S., von Wright, A., Eds.; Marcel Dekker: New York, NY, USA, 1988; pp. 115–138. [Google Scholar]

- Corsetti, A.; De Angelis, M.; Dellaglio, F.; Paparella, A.; Fox, P.F.; Settanni, L.; Gobbetti, M. Characterization of sourdough lactic acid bacteria based on genotypic and cell-wall protein analyses. J. Appl. Microbiol. 2003, 94, 641–654. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Axelsson, L. Lactic acid bacteria: Classification and physiology. In Lactic Acid Bacteria Microbiology and Functional Aspects; Salminen, S., von Wright, A., Eds.; Marcel Dekker: New York, NY, USA, 1998; pp. 1–72. [Google Scholar]

- Corona, O.; Alfonzo, A.; Ventimiglia, G.; Nasca, A.; Francesca, N.; Martorana, A.; Settanni, L. Industrial application of selected lactic acid bacteria isolated from local semolinas for typical sourdough bread production. Food Microbiol. 2016, 59, 43–56. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gobbetti, M.; Simonetti, M.S.; Corsetti, A.; Santinelli, F.; Rossi, J.; Damiani, P. Volatile compound and organic acid production by mixed wheat sour dough starters: Influence of fermentation parameters and dynamics during baking. Food Microbiol. 1995, 12, 497–507. [Google Scholar] [CrossRef]

- Alfonzo, A.; Ventimiglia, G.; Corona, O.; Di Gerlando, R.; Gaglio, R.; Francesca, N.; Settanni, L. Diversity and technological potential of lactic acid bacteria of wheat flours. Food Microbiol. 2013, 36, 343–354. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Alfonzo, A.; Miceli, C.; Nasca, A.; Franciosi, E.; Ventimiglia, G.; Di Gerlando, R.; Settanni, L. Monitoring of wheat lactic acid bacteria from the field until the first step of dough fermentation. Food Microbiol. 2017, 62, 256–269. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ventimiglia, G.; Alfonzo, A.; Galluzzo, P.; Corona, O.; Francesca, N.; Caracappa, S.; Settanni, L. Codominance of Lactobacillus plantarum and obligate heterofermentative lactic acid bacteria during sourdough fermentation. Food Microbiol. 2015, 51, 57–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kline, L.; Sugihara, T.F. Microorganisms of the San Francisco sourdough bread process. II. Isolation and characterization of un described bacterial species responsible for the souring activity. Appl. Microbiol. 1971, 21, 459–465. [Google Scholar] [PubMed]

- Settanni, L.; Ventimiglia, G.; Alfonzo, A.; Corona, O.; Miceli, A.; Moschetti, G. An integrated technological approach to the selection of lactic acid bacteria of flour origin for sourdough production. Food Res. Int. 2013, 54, 1569–1578. [Google Scholar] [CrossRef] [Green Version]

- Alfonzo, A.; Urso, V.; Corona, O.; Francesca, N.; Amato, G.; Settanni, L.; Di Miceli, G. Development of a method for the direct fermentation of semolina by selected sourdough lactic acid bacteria. Int. J. Food Microbiol. 2016, 239, 65–78. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Cruciata, M.; Gaglio, R.; Scatassa, M.L.; Sala, G.; Cardamone, C.; Palmeri, M.; Settanni, L. Formation and characterization of early bacterial biofilms on different wood typologies applied in dairy production. Appl. Environ. Microbiol. 2018, 84, e02107–e02117. [Google Scholar] [CrossRef] [PubMed]

- Gaglio, R.; Francesca, N.; Di Gerlando, R.; Mahony, J.; DeMartino, S.; Stucchi, C.; Settanni, L. Enteric bacteria of food ice and their survival in alcoholic beverages and soft drinks. Food Microbiol. 2017, 67, 17–22. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bernklau, I.; Neußer, C.; Moroni, A.V.; Gysler, C.; Spagnolello, A.; Chung, W.; Becker, T. Structural, textural and sensory impact of sodium reduction on long fermented pizza. Food Chem. 2017, 234, 398–407. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, T.; Rasband, W. ImageJ User Guide IJ1.46r. 2012. Available online: https://imagej.nih.gov/ij/docs/guide/user-guide.pdf/ (accessed on 12 December 2017).

- Comendador, F.J.; Cavella, S.; Di Monaco, R.; Dinnella, C.; Moneta, E.; Monteleone, E.; Sinesio, F. Il pane e altri prodotti da forno. In Atlante Sensoriale dei Prodotti Alimentari; Societa Italiana di Scienze Sensoriali, Ed.; Tecniche Nuove: Milano, Italy, 2012; pp. 156–176. [Google Scholar]

- Martins, Z.E.; Erben, M.; Gallardo, A.E.; Silva, R.; Barbosa, I.; Pinho, O.; Ferreira, I.M. Effect of spent yeast fortification on physical parameters, volatiles and sensorial characteristics of home-made bread. Int. J. Food Sci. Technol. 2015, 50, 1855–1863. [Google Scholar] [CrossRef]

- Klikocka, H.; Tatarczak, A. The use of cluster analysis to evaluate yield and yield components of spring barley in a two-variable field experiment. Int. J. Agric. Stat. Sci. 2015, 11, 35–42. [Google Scholar]

- Dillon, W.R.; Goldstein, M. Multivariate Analysis. Methods and Applications; John Wiley and Sons: New York, NY, USA, 1984. [Google Scholar]

- Mazzei, P.; Francesca, N.; Moschetti, G.; Piccolo, A. NMR spectroscopy evaluation of direct relationship between soils and molecular composition of red wines from Aglianico grapes. Anal. Chim. Acta 2010, 673, 167–172. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jolliffe, I.T. Principal Component Analysis; Springer: New York, NY, USA, 1986. [Google Scholar]

- Yi, L.; Dong, N.; Liu, S.; Yi, Z.; Zhang, Y. Chemical features of Pericarpium Citri Reticulatae and Pericarpium Citri Reticulatae Viride revealed by GC–MS metabolomics analysis. Food Chem. 2015, 186, 192–199. [Google Scholar] [CrossRef] [PubMed]

- Spicher, G. Baked goods. In Biotechnology; Rehm, H.J., Reed, G., Eds.; Verlag Chemie: Weinheim, Germany, 1983; pp. 1–80. [Google Scholar]

- Minervini, F.; Di Cagno, R.; Lattanzi, A.; De Angelis, M.; Antonielli, L.; Cardinali, G.; Gobbetti, M. Lactic acid bacterium and yeast microbiotas of 19 sourdoughs used for traditional/typical Italian breads: Interactions between ingredients and microbial species diversity. Appl. Environ. Microbiol. 2012, 78, 1251–1264. [Google Scholar] [CrossRef] [PubMed]

- Gänzle, M.G.; Ehmann, M.; Hammes, W.P. Modeling of growth of Lactobacillus sanfranciscensis and Candida milleri in response to process parameters of sourdough fermentation. Appl. Environ. Microbiol. 1998, 64, 2616–2623. [Google Scholar] [PubMed]

- Ottogalli, G.; Galli, A.; Foschino, R. Italian bakery products obtained with sourdough: Characterization of the typical microflora. Adv. Food Sci. 1996, 18, 131–144. [Google Scholar]

- Lhomme, E.; Orain, S.; Courcoux, P.; Onno, B.; Dousset, X. The predominance of Lactobacillus sanfranciscensis in French organic sourdoughs and its impact on related bread characteristics. Int. J. Food Microbiol. 2015, 213, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Valmorri, S.; Settanni, L.; Suzzi, G.; Gardini, F.; Vernocchi, P.; Corsetti, A. Application of a novel polyphasic approach to study the lactobacilli composition of sourdoughs from the Abruzzo region (central Italy). Lett. Appl. Microbiol. 2006, 43, 343–349. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Messens, W.; De Vuyst, L. Inhibitory substances produced by Lactobacilli isolated from sourdoughs—A review. Int. J. Food Microbiol. 2002, 72, 31–43. [Google Scholar] [CrossRef]

- De Vuyst, L.; Neysens, P. The sourdough microflora: Biodiversity and metabolic interactions. Trends Food Sci. Technol. 2005, 16, 43–56. [Google Scholar] [CrossRef]

- Birch, A.N.; Petersen, M.A.; Hansen, Å.S. Review: Aroma of wheat bread crumb. Cereal Chem. J. 2013, 91, 105–114. [Google Scholar] [CrossRef]

- Purlis, E.; Salvadori, V.O. Modelling the browning of bread during baking. Food Res. Int. 2009, 42, 865–870. [Google Scholar] [CrossRef]

- Hansen, A.; Schieberle, P. Generation of aroma compounds during sourdough fermentation: Applied and fundamental aspects. Trends Food Sci. Technol. 2005, 16, 85–94. [Google Scholar] [CrossRef]

- Salim-ur-Rehman Paterson, A.; Piggott, J.R. Flavour in sourdough breads: A review. Trends Food Sci. Technol. 2006, 17, 557–566. [Google Scholar] [CrossRef]

- Molard, R.; Nago, M.C.; Drapron, R. Influence of breadmaking method on French bread flavour. Baker’s Dig. 1979, 53, 34–38. [Google Scholar]

- Pico, J.; Bernal, J.; Gómez, M. Wheat bread aroma compounds in crumb and crust: A review. Food Res. Int. 2015, 75, 200–215. [Google Scholar] [CrossRef] [PubMed]

- Mildner-Szkudlarz, S.; Zawirska-Wojtasiak, R.; Szwengiel, A.; Pacyński, M. Use of grape by-product as a source of dietary fibre and phenolic compounds in sourdough mixed rye bread. Int. J. Food Sci. Technol. 2011, 46, 1485–1493. [Google Scholar] [CrossRef]

- Glicerina, V.; Balestra, F.; Capozzi, F.; Dalla Rosa, M.; Romani, S. Influence of the addition of soy product and wheat fiber on rheological, textural, and other quality characteristics of pizza. J. Texture Stud. 2017. [Google Scholar] [CrossRef] [PubMed]

- Dziedzic, K.; Szwengiel, A.; Górecka, D.; Rudzińska, M.; Korczak, J.; Walkowiak, J. The effect of processing on the phytosterol content in buckwheat groats and by-products. J. Cereal Sci. 2016, 69, 25–31. [Google Scholar] [CrossRef]

| Pizza Doughs | Lactic Acid (mg/g) | Acetic Acid (mg/g) | Fermentation Quotient |

|---|---|---|---|

| CTR T0 | 0.48 ± 0.08 b | 0.13 ± 0.02 d | 2.46 |

| CTR T8 | 3.22 ± 0.18 a | 0.52 ± 0.07 bc | 4.13 |

| OHS T0 | 0.81 ± 0.21 b | 0.20 ± 0.06 cd | 2.70 |

| OHS T8 | 3.38 ± 0.31 a | 0.85 ± 0.27 ab | 2.65 |

| FHS T0 | 0.91 ± 0.28 b | 0.07 ± 0.02 d | 8.67 |

| FHS T8 | 3.91 ± 0.38 a | 0.16 ± 0.05 d | 16.29 |

| OFHS T0 | 0.97 ± 0.18 b | 0.16 ± 0.05 d | 4.04 |

| OFHS T8 | 3.96 ± 0.45 a | 0.89 ± 0.17 a | 2.97 |

| Statistical significance | *** | *** | n.d. |

| Trial | Weight Loss (g) | Color | White Area % | Average Area of White Cells (mm2) | Shape Descriptors | ||||

|---|---|---|---|---|---|---|---|---|---|

| L* | a* | b* | Circularity | Roundness | Solidity | ||||

| CTR | 3.23 ± 0.13 b | 40.64 ± 0.84 b | 4.36 ± 0.26 a | 17.27 ± 0.33 b | 33.63 ± 0.31 ab | 1.65 ± 0.05 a | 0.82 ± 0.03 a | 0.74 ± 0.05 a | 0.86 ± 0.04 a |

| OHS | 4.51 ± 0.17 ab | 67.76 ± 1.78 a | −0.52 ± 0.05 b | 21.42 ± 0.35 a | 32.73 ± 0.38 b | 1.24 ± 0.03 ab | 0.86 ± 0.03 a | 0.74 ± 0.06 a | 0.91 ± 0.02 a |

| FHS | 6.57 ± 0.17 a | 64.56 ± 1.76 a | −0.54 ± 0.03 b | 18.63 ± 0.26 b | 37.35 ± 0.32 a | 0.95 ± 0.02 b | 0.84 ± 0.06 a | 0.72 ± 0.05 a | 0.89 ± 0.04 a |

| OFHS | 5.67 ± 0.14 ab | 62.12 ± 1.62 a | 3.80 ± 0.04 a | 23.46 ± 0.42 a | 34.41 ± 0.39 ab | 0.57 ± 0.01 c | 0.90 ± 0.02 a | 0.79 ± 0.08 a | 0.92 ± 0.03 a |

| Statistical significance | * | ** | *** | ** | ** | *** | N.S. | N.S. | N.S. |

| Attributes | Trials | SEM | Statistical Significance | ||||

|---|---|---|---|---|---|---|---|

| Control | OHS | FHS | OFHS | Judges | Pizzas | ||

| Crust color | 2.68 b | 3.59 a | 2.93 b | 2.51 b | 0.22 | ** | ** |

| Presence of bubbles | 5.21 ab | 4.27 c | 5.59 a | 4.58 bc | 0.29 | ** | ** |

| Uniformity of bubbles | 3.56 a | 3.03 b | 3.74 a | 3.83 a | 0.16 | ** | * |

| Odor intensity | 3.24 a | 3.25 a | 2.69 b | 3.42 a | 0.14 | ** | ** |

| Yeast odor | 1.36 b | 1.61 a | 1.61 a | 1.46 ab | 0.07 | * | ** |

| Unpleasant odor | 1.25 a | 1.29 a | 1.19 ab | 1.10 b | 0.03 | * | * |

| Resistance to tearing | 3.05 b | 3.63 a | 3.01 b | 3.76 a | 0.16 | ** | ** |

| Crispness | 3.25 b | 4.69 a | 3.58 b | 3.50 b | 0.31 | *** | * |

| Chewiness | 3.69 b | 4.58 a | 4.40 a | 4.61 a | 0.20 | ** | ** |

| Taste of crust: | |||||||

| Sweet | 3.01 b | 2.90 b | 3.41 a | 2.71 b | 0.14 | ** | ** |

| Salty | 2.25 b | 2.53 a | 2.03 b | 2.18 b | 0.11 | ** | * |

| Acid | 1.79 ab | 1.87 a | 1.72 bc | 1.64 c | 0.06 | * | * |

| Bitter | 1.52 b | 1.82 a | 1.77 a | 1.57 b | 0.06 | * | * |

| Taste persistency | 5.20 a | 3.86 b | 3.73 b | 3.60 b | 0.34 | *** | *** |

| Aroma intensity | 4.02 a | 3.32 b | 3.34 b | 3.20 b | 0.11 | ** | ** |

| Yeast aroma | 1.52 b | 2.17 a | 1.76 ab | 2.15 a | 0.13 | ** | ** |

| Taste of center: | |||||||

| Sweet | 3.07 b | 3.15 ab | 3.33 a | 2.97 b | 0.07 | * | * |

| Salty | 2.68 ab | 2.59 bc | 2.77 a | 2.51 c | 0.08 | ** | * |

| Acid | 3.15 a | 2.48 bc | 3.02 ab | 2.64 c | 0.15 | ** | * |

| Bitter | 1.65 c | 1.89 bc | 2.24 a | 1.99 ab | 0.11 | ** | * |

| Taste persistency | 3.96 a | 3.71 b | 3.98 a | 3.91 a | 0.05 | * | * |

| Overall assessment | 4.32 a | 3.85 bc | 4.22 ab | 3.73 c | 0.13 | ** | ** |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gaglio, R.; Alfonzo, A.; Polizzotto, N.; Corona, O.; Francesca, N.; Russo, G.; Moschetti, G.; Settanni, L. Performances of Different Metabolic Lactobacillus Groups During the Fermentation of Pizza Doughs Processed from Semolina. Fermentation 2018, 4, 61. https://doi.org/10.3390/fermentation4030061

Gaglio R, Alfonzo A, Polizzotto N, Corona O, Francesca N, Russo G, Moschetti G, Settanni L. Performances of Different Metabolic Lactobacillus Groups During the Fermentation of Pizza Doughs Processed from Semolina. Fermentation. 2018; 4(3):61. https://doi.org/10.3390/fermentation4030061

Chicago/Turabian StyleGaglio, Raimondo, Antonio Alfonzo, Noemi Polizzotto, Onofrio Corona, Nicola Francesca, Giuseppe Russo, Giancarlo Moschetti, and Luca Settanni. 2018. "Performances of Different Metabolic Lactobacillus Groups During the Fermentation of Pizza Doughs Processed from Semolina" Fermentation 4, no. 3: 61. https://doi.org/10.3390/fermentation4030061

APA StyleGaglio, R., Alfonzo, A., Polizzotto, N., Corona, O., Francesca, N., Russo, G., Moschetti, G., & Settanni, L. (2018). Performances of Different Metabolic Lactobacillus Groups During the Fermentation of Pizza Doughs Processed from Semolina. Fermentation, 4(3), 61. https://doi.org/10.3390/fermentation4030061