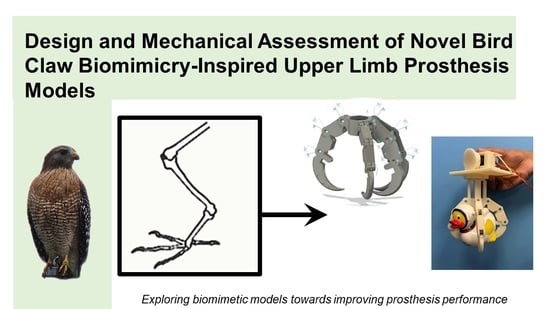

Design and Assessment of Bird-Inspired 3D-Printed Models to Evaluate Grasp Mechanics

Abstract

:1. Introduction

1.1. Motivation

1.2. Background

1.3. Applications

2. Materials and Methods

2.1. Design

2.2. Testing Methods

2.2.1. Qualitative Assessment

2.2.2. Quantitative Assessment

3. Results and Discussion

3.1. Qualitative Grasp Test Results

3.2. Quantitative Grasp Test Results

3.3. Limitations

4. Conclusions

- The cable attachment points and torsion springs placement along the digits allowed for rotation of the most proximal sections of the digits inward followed by the more distal components. This pattern appeared more natural and was advantageous in securely grasping larger objects by wrapping the digits around them rather than pinching them by initiating contact with the fingertips.

- The palm design of the bird-inspired device, with a smaller and more central palm relative to the digits, compared to the human-hand prosthetic improved the ability of both the biomimetic claws to grasp and hold the various objects. This design feature enabled the proximal portions of the digits to have a better opportunity to establish contact with the object to improve the overall grasp.

- The curved talon at the distal end of the digit held benefits in offering support for wider objects. For objects small enough for the digits to wrap around them, the curved talons also acted as an enclosure for the object by converging at the base to reduce the chances of accidentally dropping it. A disadvantage of this feature was the difficulty in securely holding thin objects because of the thin contact point and reduced application of force due to the curved tip angle.

- Although a pinch-type actuation for the five-fingered hand was observed to grasp larger geometries with less security, it demonstrated greater success in holding thin objects as observed in the object interactions with the five-fingered device. The flatter fingertip shape of the human-inspired five-finger hand further contributes to handling thin objects relative to the talon structure of the bird models by increasing surface area at the points of contact.

- In comparing the anisodactyl and zygodactyl configurations, each digit setup had grasp advantages for certain object types. The anisodactyl’s 3 × 1 structure allows a wider grasp for more cylindrical objects. The central front and back digits create the primary grasp, the outer two digits in the front supply greater reach, and the greater angle between the front and back digits allows for the object to not be obstructed by another digit. The more symmetrical 2 × 2 feature of the zygodactyl allows an advantage when grasping smaller, more symmetrical objects as it more evenly supports the object on multiple sides and reduces the space between the digits for the object to potentially slip out.

- Mechanical load testing results indicate that the robustness of the assembly is validated by testing standards traditionally applied for upper-limb prostheses and plastic properties. The maximum recorded load values were 64.3 N, 86.1 N, and 74.1 N for the single digit, anisodactyl claw, and the zygodactyl claw models, respectively. These values exceed the load metrics of 30 N for a single digit and 60 N for a full grasp set for prosthetic testing. The low averages for the full grasp tests across five trials warrant further testing with a mechanized force application procedure to further validate the initial results.

Future Research in Upper-Limb Prostheses

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| AM | Additive manufacturing |

| FDM | Fused deposition modeling |

| ABS | Acrylonitrile butadiene styrene |

| CAD | Computer-aided design |

| FEA | Finite element analysis |

References

- Resnik, L. Development and testing of new upper-limb prosthetic devices: Research designs for usability testing. J. Rehabil. Res. Dev. 2011, 48, 697. [Google Scholar] [CrossRef] [PubMed]

- Biddiss, E.; Chau, T. Upper-limb prosthetics: Critical factors in device abandonment. Am. J. Phys. Med. Rehabil. 2007, 86, 977–987. [Google Scholar] [CrossRef] [PubMed]

- Espinosa, M.; Nathan-Roberts, D. Understanding prosthetic abandonment. Proc. Hum. Factors Ergon. Soc. Annu. Meet. 2019, 63, 1644–1648. [Google Scholar] [CrossRef]

- Segil, J.L.; Pulver, B.; Huddle, S.; Weir, R.F.f.; Sliker, L. The point digit II: Mechanical design and testing of a ratcheting prosthetic finger. Mil. Med. 2021, 186, 674–680. [Google Scholar] [CrossRef] [PubMed]

- Wagner, L.V.; Bagley, A.M.; James, M.A. Reasons for prosthetic rejection by children with unilateral congenital transverse forearm total deficiency. JPO J. Prosthetics Orthot. 2007, 19, 51–54. [Google Scholar] [CrossRef]

- Light, C.M.; Chappell, P.H.; Kyberd, P.J.; Ellis, B.S. A critical review of functionality assessment in natural and prosthetic hands. Br. J. Occup. Ther. 1999, 62, 7–12. [Google Scholar] [CrossRef]

- Seankennedy. Biomimicry/Bimimetics: General Principles and Practical Examples. SCQ. 2004. Available online: https://www.scq.ubc.ca/biomimicrybimimetics-general-principles-and-practical-examples/ (accessed on 18 October 2023).

- Volstad, N.L.; Boks, C. On the use of biomimicry as a useful tool for the industrial designer: Biomimicry as a tool for the industrial designer. Sustain. Dev. 2012, 20, 189–199. [Google Scholar] [CrossRef]

- Marshall, A.; Lozeva, S. Questioning the theory and practice of biomimicry. Int. J. Des. Nat. Ecodyn. 2009, 4, 1–10. [Google Scholar] [CrossRef]

- Gosline, J.M.; Guerette, P.A.; Ortlepp, C.S.; Savage, K.N. The mechanical design of spider silks: From fibroin sequence to mechanical function. J. Exp. Biol. 1999, 202, 3295–3303. [Google Scholar] [CrossRef]

- Römer, L.; Scheibel, T. The elaborate structure of spider silk: Structure and function of a natural high performance fiber. Prion 2008, 2, 154–161. [Google Scholar] [CrossRef]

- Vollrath, F. Strength and structure of spiders’ silks. Rev. Mol. Biotechnol. 2000, 74, 67–83. [Google Scholar] [CrossRef] [PubMed]

- Mazzolai, B.; Beccai, L.; Mattoli, V. Plants as model in biomimetics and biorobotics: New perspectives. Front. Bioeng. Biotechnol. 2014, 2, 2. [Google Scholar] [CrossRef] [PubMed]

- Lurie-Luke, E. Product and technology innovation: What can biomimicry inspire? Biotechnol. Adv. 2014, 32, 1494–1505. [Google Scholar] [CrossRef] [PubMed]

- Hapsari, F.N.; Purwaningsih, R.; Azzahra, F.; Sari, D.P. Velcro product design with biomimicry approaches. IOP Conf. Ser. Earth Environ. Sci. 2022, 1111, 012057. [Google Scholar] [CrossRef]

- Clark, J.; Cham, J.; Bailey, S.; Froehlich, E.; Nahata, P.; Full, R.; Cutkosky, M. Biomimetic design and fabrication of a hexapedal running robot. In Proceedings of the 2001 ICRA IEEE International Conference on Robotics and Automation (Cat. No.01CH37164), Seoul, Republic of Korea, 21–26 May 2001; Volume 4, pp. 3643–3649. [Google Scholar] [CrossRef]

- Guetta, O.; Shachaf, D.; Katz, R.; Zarrouk, D. A novel wave-like crawling robot has excellent swimming capabilities. Bioinspir. Biomim. 2023, 18, 026006. [Google Scholar] [CrossRef] [PubMed]

- Dharmdas, A.; Patil, A.Y.; Baig, A.; Hosmani, O.Z.; Mathad, S.N.; Patil, M.B.; Kumar, R.; Kotturshettar, B.B.; Fattah, I.M.R. An experimental and simulation study of the active camber morphing concept on airfoils using bio-inspired structures. Biomimetics 2023, 8, 251. [Google Scholar] [CrossRef] [PubMed]

- Feliu-Talegon, D.; Rafee Nekoo, S.; Suarez, A.; Acosta, J.A.; Ollero, A. Modeling and under-actuated control of stabilization before take-off phase for flapping-wing robots. In Proceedings of the ROBOT2022: Fifth Iberian Robotics Conference, Zaragoza, Spain, 23–25 November 2022; Tardioli, D., Matellán, V., Heredia, G., Silva, M.F., Marques, L., Eds.; Springer: Cham, Switzerland, 2023; pp. 376–388. [Google Scholar] [CrossRef]

- Varol, H.A.; Dalley, S.A.; Wiste, T.E.; Goldfarb, M. Biomimicry and the design of multigrasp transradial prostheses. In The Human Hand as an Inspiration for Robot Hand Development; Springer Tracts in Advanced Robotics; Balasubramanian, R., Santos, V.J., Eds.; Springer International Publishing: Cham, Switzerland, 2014; pp. 431–451. [Google Scholar] [CrossRef]

- Li, S.; Bai, H.; Shepherd, R.F.; Zhao, H. Bio-inspired design and additive manufacturing of soft materials, machines, robots, and haptic interfaces. Angew. Chem. Int. Ed. 2019, 58, 11182–11204. [Google Scholar] [CrossRef]

- Wang, B.; Yu, T. Numerical investigation of novel 3D-SPA for gripping analysis in multi-environment. Int. J. Mech. Sci. 2023, 240, 107916. [Google Scholar] [CrossRef]

- Perera, A.S.; Coppens, M.O. Re-designing materials for biomedical applications: From biomimicry to nature-inspired chemical engineering. Philos. Trans. R. Soc. A Math. Phys. Eng. Sci. 2019, 377, 20180268. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, J.; Liu, X.; Zhang, Q.; Cong, Q.; Chen, T.; Liu, C. Advanced bionic attachment equipment inspired by the attachment performance of aquatic organisms: A review. Biomimetics 2023, 8, 85. [Google Scholar] [CrossRef]

- Rao, R. Biomimicry in architecture. Int. J. Adv. Res. Civil Struct. Environ. Infrastruct. Eng. Dev. 2014, 1, 101–107. [Google Scholar]

- Zhu, Y.; He, X.; Zhang, P.; Guo, G.; Zhang, X. Perching and grasping mechanism inspired by a bird’s claw. Machines 2022, 10, 656. [Google Scholar] [CrossRef]

- Roderick, W.R.; Chin, D.D.; Cutkosky, M.R.; Lentink, D. Birds land reliably on complex surfaces by adapting their foot-surface interactions upon contact. eLife 2019, 8, e46415. [Google Scholar] [CrossRef] [PubMed]

- Csermely, D.; Rossi, O. Bird claws and bird of prey talons: Where is the difference? Ital. J. Zool. 2006, 73, 43–53. [Google Scholar] [CrossRef]

- Leblanc, K.; Pintore, R.; Galvão, A.; Heitz, E.; Provini, P. Foot adaptation to climbing in ovenbirds and woodcreepers (Furnariida). J. Anat. 2023, 242, 607–626. [Google Scholar] [CrossRef] [PubMed]

- Roderick, W.R.T.; Cutkosky, M.R.; Lentink, D. Bird-inspired dynamic grasping and perching in arboreal environments. Sci. Robot. 2021, 6, eabj7562. [Google Scholar] [CrossRef] [PubMed]

- Nabi, F.G.; Sundaraj, K.; Vijean, V.; Shafiq, M.; Planiappan, R.; Talib, I.; Rehman, H.U. A novel design of robotic hand based on bird claw model. J. Phys. Conf. Ser. 2021, 1997, 012034. [Google Scholar] [CrossRef]

- Nadan, P.M.; Anthony, T.M.; Michael, D.M.; Pflueger, J.B.; Sethi, M.S.; Shimazu, K.N.; Tieu, M.; Lee, C.L. A bird-inspired perching landing gear system. J. Mech. Robot. 2019, 11, 061002. [Google Scholar] [CrossRef]

- Manero, A.; Smith, P.; Sparkman, J.; Dombrowski, M.; Courbin, D.; Kester, A.; Womack, I.; Chi, A. Implementation of 3D printing technology in the field of prosthetics: Past, present, and future. Int. J. Environ. Res. Public Health 2019, 16, 1641. [Google Scholar] [CrossRef]

- Manero, A.; Sparkman, J.; Dombrowski, M.; Smith, P.; Senthil, P.; Smith, S.; Rivera, V.; Chi, A. Evolving 3D-Printing Strategies for Structural and Cosmetic Components in Upper Limb Prosthesis. Prosthesis 2023, 5, 167–181. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B. Introduction and basic principles. In Additive Manufacturing Technologies: 3D Printing, Rapid Prototyping, and Direct Digital Manufacturing; Gibson, I., Rosen, D., Stucker, B., Eds.; Springer: New York, NY, USA, 2015; pp. 1–18. [Google Scholar] [CrossRef]

- Dudek, P. FDM 3D printing technology in manufacturing composite elements. Arch. Metall. Mater. 2013, 58, 1415–1418. [Google Scholar] [CrossRef]

- Backus, S.B.; Sustaita, D.; Odhner, L.U.; Dollar, A.M. Mechanical analysis of avian feet: Multiarticular muscles in grasping and perching. R. Soc. Open Sci. 2015, 2, 140350. [Google Scholar] [CrossRef] [PubMed]

- Mio, R.; Sanchez, M.; Valverde, Q.; Lara, J.; Rumiche, F. Mechanical testing methods for body-powered upper-limb prostheses: A case study. Adv. Sci. Technol. Eng. Syst. J. 2019, 4, 61–68. [Google Scholar] [CrossRef]

- Smit, G.; Plettenburg, D.H.; van der Helm, F.C.T. The lightweight delft cylinder hand: First multi-articulating hand that meets the basic user requirements. IEEE Trans. Neural Syst. Rehabil. Eng. 2015, 23, 431–440. [Google Scholar] [CrossRef] [PubMed]

- Joyce, T.; Unsworth, A. A test procedure for artificial finger joints. Proc. Inst. Mech. Eng. Part H J. Eng. Med. 2002, 216, 105–110. [Google Scholar] [CrossRef] [PubMed]

- ISO 178:2019; Plastics—Determination of Flexural Properties. International Organization for Standardization: Geneva, Switzerland, 2019.

- ASTM D790-17; Standard Test Methods for Flexural Properties of Unreinforced and Reinforced Plastics and Electrical Insulating Materials. American Society for Testing and Materials: Geneva, Switzerland, 2019.

- ISO 22523:2006; External Limb Prostheses and External Orthoses—Requirements and Test Methods. International Organization for Standardization: Geneva, Switzerland, 2006.

- Kashef, S.R.; Amini, S.; Akbarzadeh, A. Robotic hand: A review on linkage-driven finger mechanisms of prosthetic hands and evaluation of the performance criteria. Mech. Mach. Theory 2020, 145, 103677. [Google Scholar] [CrossRef]

- Kargov, A.; Pylatiuk, C.; Martin, J.; Schulz, S.; Döderlein, L. A comparison of the grip force distribution in natural hands and in prosthetic hands. Disabil. Rehabil. 2004, 26, 705–711. [Google Scholar] [CrossRef]

| Test Type | Source [38,41,42,43] | Minimum Expected Load | Average Measured Load | Maximum Measured Load |

|---|---|---|---|---|

| Single-Digit Extension | Mio et al. (2019) ISO 178, ASTM 790 | 30 N | 61.0 N ± 2.2 N | 64.3 N |

| Anisodactyl Claw Grip | Mio et al. (2019) ISO 22523 | 60 N | 76.8 N ± 9.0 N | 86.1 N |

| Zygodactyl Claw Grip | Mio et al. (2019) ISO 22523 | 60 N | 58.0 N ± 10.2 N | 74.1 N |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Senthil, P.; Vishanagra, O.; Sparkman, J.; Smith, P.; Manero, A. Design and Assessment of Bird-Inspired 3D-Printed Models to Evaluate Grasp Mechanics. Biomimetics 2024, 9, 195. https://doi.org/10.3390/biomimetics9040195

Senthil P, Vishanagra O, Sparkman J, Smith P, Manero A. Design and Assessment of Bird-Inspired 3D-Printed Models to Evaluate Grasp Mechanics. Biomimetics. 2024; 9(4):195. https://doi.org/10.3390/biomimetics9040195

Chicago/Turabian StyleSenthil, Pavan, Om Vishanagra, John Sparkman, Peter Smith, and Albert Manero. 2024. "Design and Assessment of Bird-Inspired 3D-Printed Models to Evaluate Grasp Mechanics" Biomimetics 9, no. 4: 195. https://doi.org/10.3390/biomimetics9040195

APA StyleSenthil, P., Vishanagra, O., Sparkman, J., Smith, P., & Manero, A. (2024). Design and Assessment of Bird-Inspired 3D-Printed Models to Evaluate Grasp Mechanics. Biomimetics, 9(4), 195. https://doi.org/10.3390/biomimetics9040195