1. Introduction

With the incentivized rapid decarbonization of electric power generation industry and aggressive renewable portfolio standards (RPS) in most states, an aggressive integration of distributed energy resources (DERs) largely in the distribution system is expected [

1,

2]. To this regard and additionally owing to the improvements in technology performance, decrease in cost, and growing consumer interest, grid-tied photovoltaic (PV) power generation has been increasing worldwide. The International Energy Agency (IEA) estimates that by 2050, PV power generation will contribute to 16% of the world’s electricity out of which 20% of the total PV capacity will come from residential installations [

3]. Since utility distribution systems are designed for a centralized power generation and are optimized for the unidirectional power flow, the integration of high levels of PV penetration may disrupt system’s normal operating conditions [

4,

5].

In literature, several studies have been conducted to determine the impacts of PV systems on distribution circuit operations [

6,

7,

8,

9,

10,

11]. Multiple operational issues can result from integrating a large percentage of distributed PVs including feeder overvoltage problems, increased voltage variability [

6,

7,

8,

9], thermal limit violations, increased feeder loses [

10], and an increase in number of capacitor switching and regulator tap operations [

11]. The increasing rate of PV integration and the undesirable impacts of PVs on distribution circuit call for determining the largest PV capacity a given distribution circuit can accommodate without violating the circuit’s operational limits. The obtained capacity is referred to as circuit’s PV hosting capacity or PV accommodation limit. The emerging DER integration trend also calls for methods to mitigate PV concerns and facilitate the PV integration.

In literature, several methods have been proposed to determine the feeder’s maximum PV penetration limits [

12,

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23,

24,

25,

26]. These methods are briefly discussed in

Section 1.1. For distribution feeders, voltage problems particularly overvoltage issues are the primary concern and are often the limiting criteria for integrating additional PVs [

24]. The existing methods do not include voltage control devices while evaluating the feeder’s PV integration limits. Since the voltage control of smart inverter is becoming an industry norm; it is imperative to revise hosting capacity study and include voltage control techniques in the analysis framework. Furthermore, along with feeder’s PV hosting capacity, other key parameters affecting feeders with high PV penetrations should be explored.

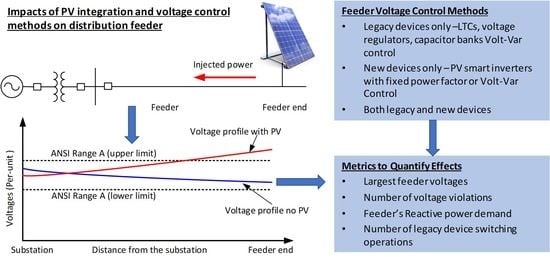

The objective of this paper is to evaluate the impacts of residential PV deployments on feeder and customer voltages while including voltage control methods into the analysis framework. The primary research questions that this article aims at addressing are the following:

What are the impacts of different voltage control modes for both distribution system’s legacy and smart inverters on feeder’s PV hosting capacity, feeder’s primary and secondary voltage violations, and feeder’s reactive power demand?

What are the impacts of smart inverter control with high levels of PV penetration on feeder’s legacy control devices and how some of the undesirable impacts can be mitigated?

To this regard, multiple voltage control methods are implemented. The impacts of PV deployment when voltage control is included are assessed using customer- and system-level metrics. The voltage control methods are compared for their effectiveness in mitigating the impacts of high levels of distributed PV deployment. Furthermore, a simple case study is presented to mitigate high number capacitor tap operations resulting from smart inverter control.

1.1. Literature Review

The undesirable impacts of high percentages of PV integration call for the study to determine the circuit’s PV hosting capacity [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22,

23]. Given a large number of potential PV deployment scenarios, researchers have primarily looked into simulation-based frameworks [

13,

14,

15,

16,

17,

18,

19,

20,

21,

22]. Most of these methods either used a simplified feeder model [

13,

14,

15] or simulated PV systems at only at a few specific locations [

13,

14,

15]. Reference [

16,

17] proposed a stochastic analysis framework to obtain PV integration limits by simulating large numbers of potential PV deployment scenarios by varying residential PV panel locations and sizes. Building upon the framework proposed in [

17], a stochastic analysis approach was proposed [

20] while taking the hourly variations in load demand and PV generation into consideration.

Although the integration of a high percentage of PV may result in multiple operational challenges for the distribution system, feeder overvoltage problem is one of the major concerns. Given the impacts of DERs on feeder voltages, researchers have worked actively on optimizing feeder voltages and reactive power (Volt-VAR optimization) by controlling and coordinating distribution system’s legacy devices (capacitor banks and load tap changers (LTCs)) and new devices (smart inverters) [

27,

28,

29,

30]. The existing algorithms use centralized or distributed control approach to optimize the real-time operation of the feeder, while assuming that an advanced communication system exists to control and coordinate the feeder devices. For example, in [

27] authors propose a non-cooperative game for Volt-VAR optimization (VVO) while achieving an optimal energy consumption. In [

28], a mixed-integer quadratically constrained programming (MIQCP) problem is formulated to optimize VVO by controlling and coordinating capacitor banks, voltage regulators, and load-tap changers for day-ahead operation. References [

29,

30] present a discussion on multiple Volt-VAR control methods for a utility distribution feeder.

Unfortunately, the existing PV hosting methods freeze the voltage control devices while calculating the PV hosting capacity [

17,

19,

20,

21]. The rationale for the assumption being legacy voltage control devices such as LTCs and capacitor banks are not fast enough, and, therefore, momentary overvoltage condition will be observed. Additionally, smart inverter control for PV units is also disabled. The primary objective of calculating PV hosting capacity is to inform utility providers about the limits of PV integration capacity for their feeder without necessitating grid upgrades [

22]. Therefore, given the recent advances in voltage control techniques and an increased deployment of PVs with smart inverters, including voltage control in PV hosting analysis is necessary.

One of the relatively recent works [

31] aims at addressing the above problem. The article evaluates the impacts of Volt-VAR control of smart inverters on PV hosting capacity [

31]. However, the authors neither consider other voltage control methods/devices nor evaluate the impacts of voltage control on other system parameters. It should be noted that the voltage control may improve PV hosting capacity but result in undesirable system impacts, including high reactive power demand from substation or an increased number of switching operations. This calls for a more detailed analysis and comparison to the multiple voltage control methods/devices for their pros and cons. The voltage control can be achieved using: (1) feeder’s legacy devices such as LTCs and capacitor banks; and (2) new voltage regulation devices such as smart inverters connected to DERs. In this work, we present a thorough evaluation of different voltage control methods applied to both legacy and new devices. The analysis, therefore, helps to evaluate and compare the voltage control methods and devices for their effectiveness in improving the hosting capacity and for their impacts on distribution system technical constraints.

1.2. Objectives and Assumptions

This paper aims at evaluating the impacts of high percentages of PV integration on distribution system overvoltage conditions while taking voltage control approach into consideration. It should be noted that this paper has a different objective when compared to the literature on feeder voltage control methods [

27,

28,

29,

30]. Our objective is to evaluate the relative benefits of legacy and new voltage control devices by comparing their different control modes. The voltage control methods are compared for their effectiveness in mitigating PV integration challenges, in facilitating the integration of additional PVs, and for their impacts on other system parameters. The analysis framework and assumptions are summarized next.

Voltage Control Framework—The following methods are included in this analysis: (1) controlling only legacy devices—capacitor banks and LTCs; (2) controlling only smart inverters—power factor control and Volt-VAR control; and (3) controlling both legacy devices and smart inverters.

Metrics to Quantify Impacts—The following metrics are used to quantify the impacts of voltage control approach: (1) feeder’s PV hosting capacity for primary bus overvoltage; (2) the number of customers with voltage violations; (3) largest primary and secondary bus voltages; (4) reactive power supplied by the substation; and (5) the number of LTC and capacitor change operations.

Analysis Approach—The presented analysis framework includes both snapshot and time-series power flow studies. The snapshot power flow analysis is conducted at a specific operating point, in this case, at feeder’s minimum load condition. The time-series analysis is simulated for 1-year using 1-year load demand data available in 1-h interval and 1-year PV generation data available in 1-min interval.

1.3. Contributions

This paper extends the existing models for PV hosting capacity study by including feeder voltage control into the analysis framework. Essentially, this paper presents a study on (1) the impacts voltage control in mitigating overvoltage problem and improving feeder’s PV integration limits; (2) other parameters that should be compared to evaluate the effectiveness of a voltage control approach in solving the overvoltage problem; and (3) the impacts of voltage control on other system parameters, including feeder’s reactive power demand and the switching of legacy voltage support devices. Given the push towards changing the standards for DER integration, this paper provides a useful study for assessing the best approaches to solve PV integration challenges.

The distribution circuit selected for this analysis is adapted from EPRI’s 34.5-kV test circuit [

32]. A background on PV hosting capacity problems and voltage control methods are provided in

Section 2. The PV impact analysis and hosting capacity framework along with the data and modeling requirement to conduct the study is detailed in

Section 3 followed by the verification method and results in

Section 4. A detailed discussion of the simulation results is presented in

Section 5, followed by conclusions in

Section 6.

2. Photovoltaic (PV) Hosting Capacity Problem and Voltage Control Framework

A feeder’s PV hosting capacity is defined as the largest PV generation that can be accommodated without violating the circuit’s operational limits. This study is concerned with the overvoltage recorded in the primary wires due to PV integration. PV hosting capacity is equal to the largest PV, for which feeder voltages are within acceptable ANSI voltage limits i.e., <1.05 pu [

24]. In order to capture the stochasticity of the PV deployment resulting from the uncertainties in PV locations and size, we use the Monte Carlo simulation approach [

17]. This section presents a discussion on PV hosting problem and voltage control methods.

2.1. Monte Carlo Based Method for PV Hosting Problem

Feeder’s actual PV hosting capacity can be obtained only by simulating all of the possible PV deployment scenarios. Since a large number of PV deployment scenarios are possible by varying the location and size of PV panels, the PV hosting analysis is done using Monte Carlo approach [

17]. Monte Carlo approach is used to simulate a large but finite number of PV deployment scenarios in a systematic way [

20]. This section details a mathematical framework to quantify feeder’s PV hosting capacity. The following terms are defined in order to formulate the PV hosting problem.

Customer Penetration Level ()—Defined as the percentage of customers equipped with PV panels. is obtained by populating customers with PV panels, where .

PV Penetration Level ()—Defined as the total PV generation in kW added to the distribution circuit corresponding to the ith customer penetration level ().

PV Deployment Scenarios ()—A PV deployment scenario characterizes the locations and sizes of individual PV panels at each customer load location for a given customer penetration level. Here, a PV deployment scenario, , represents jth PV deployment scenario corresponding to ith customer penetration level.

The PV hosting problem is defined as follows. For a given distribution circuit, let number of PV deployment scenarios are simulated at each customer penetration level, each representing one Mote Carlo run. Since in this study, Monte Carlo runs/scenarios are simulated at each customer penetration level, the method is termed as k-run Monte Carlo study (k-run MCS). The feeder’s hosting capacity is defined in terms of First- and All-hosting capacity as following:

First-hosting Capacity ()—The First-hosting capacity is equal to the lowest PV penetration for which at least one scenario in a k-run MCS observes an overvoltage condition.

All-hosting capacity ()—The All-hosting capacity is defined as the lowest PV penetration such that all k scenarios (i.e., 100%) in a k-run MCS observe an overvoltage condition.

The First-hosting capacity (

) and All-hosting capacity (

) are obtained by solving (1) and (2).

where,

| S | be the set of discrete customer penetration levels indexed by |

| PVpen | be the set of all PV penetration levels indexed by customer penetration level |

| Set of maximum primary voltages recorded for k PV deployment scenarios simulated at . |

2.2. Voltage Control Framework

With the ongoing emphasis on grid-modernization enabling new control and communication capabilities, a realistic PV impact analysis framework must include voltage control capabilities. Depending upon the level of grid modernization and the type of PV systems deployed, the feeder voltages can be potentially regulated by using legacy voltage control devices and new equipment. Traditionally, distribution systems include voltage regulators, LTCs, and capacitor banks for voltage support. With the advancement in PV technology and ongoing efforts for new DER interconnection standards, PVs with smart inverters are expected to be installed. A smart inverter can provide reactive power support for the feeder by operating in several control modes. These are relatively faster than legacy devices thus potential candidates for mitigating voltage quality problems resulting from PV generation variability. In this paper, the operation of both legacy voltage control devices and new control equipment is included. The control methods evaluated and compared in this paper are detailed in this section and also summarized in

Table 1.

2.2.1. Control 1—Voltage Control with Legacy Control Devices

Distribution circuits are equipped with voltage control devices such as LTCs, voltage regulators, and capacitor banks for voltage support. The existing PV integration studies freeze the operation of legacy devices while calculating feeder’s PV hosting capacity. In this control method, the operation of legacy devices is included while calculating PV hosting capacity. It should be noted that there is a delay in the operation of legacy control devices. Thus, the feeder may record an overvoltage condition for a few minutes until the control device operates. The devices operate based on the local information and the control settings, and thus do not require an external communication interface.

2.2.2. Control 2—Voltage Control with Smart Inverters

The following two voltage regulation methods are implemented for smart inverters: (1) Fixed power factor control; and (2) Volt-VAR control. Note that PV panels can also regulate feeder voltages by controlling their active power generation either by setting up a generation limit or using Volt-Watt control methods. However, active power control methods are likely to be not preferred by PV owners. Therefore, in this study, only the methods based on reactive power control are included.

Fixed Power Factor Control—Usually, the PV panels operate at a unity power factor only generating active power. The smart inverter connecting the PV panel to the grid can be programmed to allow PV panels to operate at a lagging power factor and absorb reactive power to mitigate overvoltage concern. The impacts of power factor control of PV panels on the distribution circuit are evaluated by programming smart inverters to operate at a lagging power factor. Two cases are simulated: (1) at 0.995 lagging power factor; and (2) at 0.98 lagging power factor. This control method can be simply implemented by one-time programming of PV inverters, thus not requiring any critical communication during operation.

Volt-VAR Control—This function allows control on the reactive power output of the PVs according to the voltage at the point of connection of PV system and the available reactive power. In this study, the reactive power generated or absorbed by the smart inverter for Volt-VAR control follows the curve shown in

Figure 1. The available reactive power (

) is calculated using (3). In this control approach, PV inverters operate based on the voltages at their point of common coupling (PCC).

where,

2.2.3. Control 3—Control of both Legacy Control Devices and Smart Inverters

This approach enables control of both legacy control devices and smart inverters. The LTCs, capacitor banks, voltage regulators, and smart inverters operate based on only local information and control settings. The smart inverters either work based on the one-time programming (power factor control) or local PV bus information (Volt-VAR control). Since in this analysis, both legacy devices and smart inverters operate based on their respective local control settings with no coordination, no external communication is required.

3. Analysis Tools and Proposed Methodology

This section presents a discussion on the analysis tools required for the study, selected test circuit, and the proposed methodology. We implement the PV analysis framework using OpenDSS [

33] and MATLAB. The analysis is conducted using a test circuit adapted from 34.5-kV EPRI test feeder [

32] available open source for distribution system analysis.

3.1. Analysis Tools

The proposed framework requires a detailed distribution feeder model and an interface to simulate and analyze multiple case studies. A detailed feeder model starting from the substation down to individual customer locations is simulated in OpenDSS [

33]. The representative models for customer loads are also developed using the substation load data and customer load characteristics. The PV units are modeled using the equipment model for PV systems that are available in OpenDSS. MATLAB is used to simulate multiple PV deployment scenarios. The PV impact and voltage control studies are simulated by interfacing MATLAB with OpenDSS.

3.1.1. Distribution Circuit Simulator—OpenDSS

OpenDSS is a comprehensive electrical system simulation tool for electric utility distribution system supporting all frequency domain analyses. It supports the quasi-static unbalanced three-phase power flow analysis for radial and looped networks while including user-defined control algorithms for shunt capacitors, voltage regulators, LTCs, and smart-inverters. The simulator also facilitates DER integration analysis and provides pre-defined models of DERs and their control blocks. OpenDSS can be implemented as both a stand-alone executable program and an in-process Component Object Model (COM) server DLL that is designed to be driven by a variety of existing software platforms. In this study, OpenDSS is executed using MATLAB program.

3.1.2. Photovoltaic System Model

An in-built model for PV systems is available in OpenDSS. The model is capable of simulation studies in time steps greater than or equal to 1 s. The PV system is modeled as a power delivery object producing power according to some generation function. A simplified block diagram of the PV system model with inverter control is illustrated in

Figure 2. The active power, P, is a function of the irradiance, temperature, and rated power at the mpp at a selected temperature and at an irradiance of 1.0 kW/m

2. The reactive power for PV system is specified separately from the active power either as fixed kVAR values, or as a fixed power factor value. Additionally, the inverter control is capable of simulating Volt-Var, Volt-Watt, dynamic reactive current, and user-defined control modes.

3.1.3. Required Circuit Data

A detailed feeder model including circuit data, load data, and DER data is required to conduct a realistic distribution system analysis.

Circuit data—Includes the one-line diagram of the feeder, substation model, distribution line characteristics including impedance, ampacity, voltage levels, and connections, and details regarding distribution transformers and capacitor banks.

Load data—Includes the hourly load demand data measured at the substation for one year or more as well as the characteristics of individual customer loads distributed across the feeder.

DER data—Includes details of the existing DER/PV integration. The necessary data include PV panels’ location, size, and generation profiles. High-resolution PV generation data for one year or for a few representative days should be provided.

3.2. Selected Distribution Circuit—Test Circuit

The analysis is conducted using 34.5-kV EPRI test feeder [

32]. The substation transformer supplying the selected feeder has a nominal MVA rating of 45 MVA. The substation transformer is supplying for two feeders, one of which is represented as an equivalent load connected to the substation with a rated load demand of 23.5 MVA. The detailed distribution circuit model is available for the other feeder (Feeder 1), with the one-line diagram shown in

Figure 3 plotted using toolbox provided by Reference [

34]. The PV integration analysis is simulated for Feeder 1. For the selected distribution circuit, the 1-year customer load profile data is available at 1-h resolution. This circuit has three capacitor banks of ratings 0.9 MVAR (capacitor 1), 1.2 MVAR (capacitor 2), and 1.2 MVAR (capacitor 3). Capacitor banks 1 and 2 are operating in kVAR control mode, while capacitor 3 is always online. The substation transformer is equipped with an LTC.

For the given feeder, a power flow analysis is conducted for 1 year. The peak load demand recorded at the substation for the year is equal to 52.15 MVA (Feeder 1 + Feeder 2). For snapshot power flow analysis, a minimum load condition for the feeder is identified. In this study, the minimum load is assumed to be 20% of the feeder’s peak load demand and is equal to 10.43 MVA. For the time-series analysis, 1-year load demand data at an hourly resolution and 1-year PV profile data at 1-min resolution is utilized [

35]. The PV profile in 1-min resolution for 1-day, shown in

Figure 4. The same profile is replicated for each day of the year to obtain the 1-year PV profile.

3.3. PV Hosting and PV Impact Analysis Methodology

This section presents a summary of the stochastic analysis framework used for determining the impacts of PV systems on the distribution circuit. The approach includes simulating multiple PV deployment scenarios, quantifying the impacts using snapshot and time-series analysis, and evaluating customer and system-level impact metrics.

3.3.1. Simulate PV Deployment Scenarios

The PV deployment scenarios are simulated using Monte Carlo approach by associating a uniform random variation to PV locations [

17] and by identifying realistic PV system size using [

35]. At each customer penetration level (

), we simulate 100 unique PV deployment scenarios (

). The method to systematically simulate

jth PV deployment scenario, where

is as follows. First, a 2% of distribution customers (

) are integrated with PVs. The customer penetration level is incremented in a step of 2% until it reached 100% and additional PVs are deployed. This constitutes one PV deployment scenario. The above process is repeated 100 times to obtain 100 PV deployment scenarios. Note that the above process results in a total of 5000 PV deployment cases, with 100 unique deployments corresponding to each customer penetration level. Please refer to [

17,

20] for the details regarding simulations.

3.3.2. Quantify PV Impacts on System Voltage

The impacts of PV integration are evaluated using snapshot and time-series power flow analysis.

Snapshot Power Flow Analysis—For each PV deployment scenario, a three-phase unbalanced load flow analysis is simulated at the feeder’s minimum load condition. The voltage control methods are implemented and load flow analysis is simulated again for each PV deployment scenario. The snapshot power flow analysis helps in identifying the impacts of increasing PV penetrations on feeder’s primary and secondary voltages and feeder’s reactive power demand.

Time-series Analysis—For each voltage control approach, the time-series analysis for 1-year is simulated using 1-min quasi-static power flow simulations. A time-series analysis is conducted after implementing different voltage control methods. A PV deployment scenario resulting in overvoltage condition when voltage control methods are not employed is selected for the analysis. Using the time-series analysis, the number of LTC tap changes and capacitor bank switching operations are recorded. The time-series analysis helps in understanding impacts of PV integration and voltage control on feeder’s legacy devices.

3.3.3. Calculate PV Hosting Capacity and Quantify Voltage Control Impacts

Based on the load flow analysis, the feeder’s PV integration limits corresponding to the First-hosting and All-hosting capacities are calculated. Along with feeder’s PV hosting capacity, the following additional parameters are measured to compare the different voltage control methods.

Impacts on Secondary Customer Voltages—The largest feeder voltage and the number of customers observing overvoltage are also recorded to compare the impacts of voltage control.

Impacts on Reactive Power Supplied by the Substation—For each voltage control approach, the reactive power supplied by the substation is recorded and compared.

Impacts on Voltage Control Equipment—Yearly load flow analysis for the base case and for each voltage control case are simulated and the total number of capacitor switching and LTC tap changes are recorded and compared.

4. Results

This section summarizes the results of PV impact analysis and voltage control method for the selected distribution feeder.

4.1. Snapshot Power Flow Analysis

The snapshot power flow analysis evaluates the impact of PV integration by simulating a three-phase unbalanced load flow at a feeder’s minimum load condition equal to 10.43 MVA (20% of peak load). Depending upon the voltage control methods discussed in

Section 2, eight separate case studies are simulated. In order to simplify the discussion, a summary of each case and the corresponding control approach is detailed in

Table 2.

4.1.1. No Voltage Control (Case 1)

In this case, PV panels are operating at a unity power factor, and the capacitor and LTC controls are frozen. The PV penetration is increased to 100% amounting to a total of 24 MW. The PV hosting capacity and the number of primary and secondary buses observing an overvoltage condition are shown in

Figure 5. The selected distribution circuit can accommodate a 9.3 MW of PV capacity without implementing any voltage control method. The All-hosting capacity turns out to be 11.4 MW. As can be seen from

Figure 5b, 1455, and 3990 secondary customers observe overvoltage at First- and All-hosting capacity, respectively. Furthermore, as the PV penetration increases, the number of voltage violation increase sharply with almost all customers recording a voltage violation at 80% penetration.

4.1.2. Control Mode 1—Enabling Load Tap Changer (LTC) and Capacitor Control (Case 2)

For this case study, the control of legacy devices i.e., LTCs and capacitor banks is enabled while conducting the PV impact and hosting capacity study. Since legacy devices take some time to respond; a voltage violation is expected for a short duration until the control activates. The results are shown in

Figure 6. With legacy control enabled, the feeder records very few cases (5 cases out of 5000) of overvoltage in the primary wire. A tap change operation is recorded at PV penetration equal to 4 and 16 MW. The secondary customers record multiple cases of voltage violations.

When compared to Case 1, at the First- and All-hosting capacity limit of Case 1 (9.3 and 11.4 MW PV penetration), in this case, 38 and 104 secondary customers report an overvoltage condition, respectively. The largest number of secondary bus voltage violations for this case is 780, which is significantly less than the number of bus voltage violations recorded for Case 1. In Case 1, approximately all 7200 secondary customers record an overvoltage at 100% penetration.

4.1.3. Control Mode 2—Smart Inverter Control (Cases 3,4,5)

This control mode enables smart inverter control of PV panels. The control of legacy devices is disabled. The smart inverters are programmed for constant power factor (PF) control and Volt-VAR control. For constant power factor control, two cases are simulated with all of the inverters set to operate at (1) (Case 3) a lagging power factor of 0.995 and (2) (Case 4) at a lagging power factor of 0.98. The Volt-VAR control (Case 5) is based on the curve shown in

Figure 1.

For both constant power factor and Volt-VAR control modes, the feeder can accommodate a larger PV capacity. The First-hosting is increased to 17.1 and 24 MW (100% customer penetration) when smart inverters are operating a lagging power factor of 0.995 and 0.98, respectively (see

Figure 7a,b). In Volt-VAR control mode, the feeder can accommodate 100% of PV capacity without violating the limits for primary overvoltage criteria (see

Figure 7c). Furthermore, the number of secondary customers observing an overvoltage condition decreases for each PV deployment scenario (

Figure 7d–f). For Case 3, with smart inverters operating art PF = −0.995, at 100% penetration, a total of 1000 secondary customers record an overvoltage (see

Figure 7d). When the power factor is decreased to 0.98 lagging, the numbed of secondary customers with overvoltage violations further decreased to less than 20 at the customer penetration level

= 100% (see

Figure 7e). The Volt-VAR control mode is most effective in regulating both primary and secondary feeder voltages. In Volt-VAR control mode, the largest secondary voltage decreases significantly with fewer than eight secondary customers observing any overvoltage at customer penetration level (see

Figure 7f).

The PV inverters operating in power factor and Volt-VAR control modes will absorb reactive power to correct an overvoltage condition. The three control methods are compared for their reactive power requirement from the substation in

Figure 8. The comparison is made at two penetration levels: 40% (corresponding to the feeder’s PV hosting capacity without any control) and at 100%. The reactive power provided by the substation increases for each control mode as customer penetration (

) is increased from 40% to 100%. Also, reactive power drawn from the substation increases when power factor is decreased to 0.98. The Volt-VAR method requires the largest reactive power demand from the substation explaining its effectiveness in regulating secondary voltages. At 100% PV penetration, at PF = −0.995, the reactive power drawn is 1.3 MVAR which increases to 3.8 MVAR at PF = −0.98 and to 6.8 MVAR for Volt-Var control.

4.1.4. Control Mode 3—Enable Both Legacy Devices and Smart Inverter Control (Cases 6, 7 and 8)

In this control mode, both legacy devices and smart inverter controls are enabled. Three cases are simulated by enabling the control of legacy devices with (1) (Case 6) smart inverters operating at lagging PF = 0.995; (2) (Case 7) smart inverters operating at lagging PF = 0.98; and (3) (Case 8) smart inverters operating in Volt-VAR control.

It is observed that LTC control with power factor control results in a better regulation of both primary and secondary feeder voltages. When compared to Cases 3–5, enabling LTC control increases the PV accommodation limit for all of the control modes of smart inverters. With LTC control, when smart inverter is operating at a lagging PF = 0.995, the feeder is able to accommodate 100% of the customer with PV (see

Figure 9a) compared to 17.1 MW (

Figure 7a) when LTC control is disabled. An LTC tap change is observed at PV generation that is equal to 5 MW. Same as without enabling LTC control, the feeder can accommodate 100% of customers with PV when the smart inverters are operating at 0.98 lagging power factor, as shown in

Figure 9b. The number of secondary voltage violations and the magnitude of the largest secondary voltages also decrease significantly when compared to the case when LTC control is disabled.

Figure 9d shows that for Case 6 with 0.995 lagging pf, only a total of 62 secondary customers record overvoltage at 100% customer penetration level as compared to 1000 customers in Case 3 (see

Figure 7d). On reducing the pf to 0.98 lagging and with LTC control enabled, the number of secondary buses recording an overvoltage further decrease to less than 10 cases (see

Figure 9e). Furthermore, as shown in

Figure 9c,f, on enabling LTC control with smart inverter control operating in Volt-VAR mode, the feeder does not report any primary or secondary bus voltage violations for any of the PV deployment scenarios and can accommodate 100% of PV penetration.

4.2. Time-Series Analysis

The objective of time-series analysis is to (1) evaluate the impacts of different smart-inverter control modes on the number of LTC tap changes and capacitor bank switching operations; and (2) to present a simple approach to reduce the unnecessary switching of legacy devices. The time-series analysis is conducted for one of the PV deployment scenarios with customer penetration () = 40% that corresponds to the hosting capacity obtained for the feeder without enabling any voltage control. For yearly analysis, the customer load profile in 1-h resolution and PV generation profile in 1-min resolution is used. A comparison of different control modes for their impacts on LTC tap changes and capacitor bank switching is presented. Next, a simple control approach is detailed to reduce the number of switching operations of legacy devices.

4.2.1. Control Mode 2—With Only LTC and Capacitor Control

In this case, each PV inverter is operating at PF = 1 i.e., neither generating nor absorbing the reactive power. The LTC and capacitor control is enabled. Capacitor banks 1 and 2 are operating in kVAR control mode, while Capacitor bank 3 is a fixed capacitor and always enabled. The positions for LTC taps and capacitor status are shown for 1 year in

Figure 10. In the 1-year simulation, a total of 265 LTC tap operations are recorded. Capacitor 1 switches 174 times over the year while Capacitor 2 observes 16 switching operations.

4.2.2. Control Mode 3—With Legacy and Smart Inverter Constant Power Factor Control

In this case, the PV inverters are controlled using constant power factor mode and are programmed to absorb reactive power. Two cases are simulated, with all of the PV inverters operating at (1) a lagging PF of 0.995 and (2) a lagging power factor of 0.98. The legacy devices operate based on their local control settings. The yearly load flow analysis is simulated, and the number of LTC tap changes and capacitor switching operations are recorded.

When PV inverters operating at a lagging PF of 0.995, a total of 244 tap operations are recorded over the year. Capacitor 1 switches 231 times while Capacitor 2 records a total of 16 switching operations. The tap operations decrease in this case, however, the capacitor banks switch more often with power factor control. On operating PV inverters at 0.98 lagging power factor, both the number of tap operations and capacitor bank switching increase. With 0.98 lagging power factor, in 1-year a total of 274 tap changes are recorded. Capacitor 1 switches 897 times while Capacitor 2 switches 72 times over the year. The number LTC tap changes and capacitor switching operations increase when PV inverters are operating at a lower power factor.

4.2.3. Control Mode 3—With LTC and Smart Inverter Volt-VAR Control

Each PV inverter, in this case, is operating in Volt-VAR control mode that is actively regulating customer voltages. The LTC taps and capacitor bank switching recorded for 1-year are shown in

Figure 11. In this case, the number of LTC tap changes and capacitor switching operations increase significantly. A total of 556 tap changes is recorded over a 1-year period. Capacitor 1 records a total of 708 switching operations, while Capacitor 2 switches for 727 times over the year. Capacitor 3, being fixed capacitor is always on. A Volt-VAR control approach may significantly affect the operation of legacy devices.

4.2.4. Coordinated LTC and Smart Inverter Volt-VAR Control with Modified Control Settings

Based on the previous three cases, we observe that on implementing reactive power control methods for PVs, the number of regulator tap operations and capacitor bank switching increases significantly. This will lead to an increased operating cost and unnecessary aging of the equipment. To reduce the impact of Volt-VAR operation on legacy control devices, we implement modified control settings for the capacitor banks. Capacitor banks 2 and 3, previously operating in kVAR control mode are reconfigured to operate in voltage control mode. Recall that the Volt-VAR control mode supplies the required reactive power demand while regulating the feeder voltages. The capacitor banks, therefore, undergo unnecessary operations while compensating for time-varying reactive power demand/generation resulting from fast Volt-VAR control. This unnecessary switching operation is avoided when capacitor banks are reconfigured to work in voltage control mode.

During the 1-year simulation duration, with the modified control, Capacitor banks 1 and 2 are not required operate. In the beginning of the simulation, capacitor banks 1 and 2 are switched off and are not enabled for entire 1-year duration. This is expected as the smart inverters operating in Volt-VAR control mode are providing the required reactive power support to the grid, thus not requiring any capacitor operation. Capacitor 3 being a fixed capacitor bank remains enabled for the entire 1-year duration. The total number of regulator tap operations with the modified capacitor bank controls reduces to 468 tap changes from 556 tap operations as recorded in the

Section 4.2.3. With the new capacitor control mode, no violations in feeder voltage are recorded either for primary feeders or for secondary service wires.

This study demonstrates that a coordinated operation of legacy devices and new devices can be enabled by using simple control mode change. A more complex coordination approach can also be developed that may require communication and direct the control of legacy and new devices. However, proposing such control scheme is not within the scope of this paper.

5. Discussion

A discussion on several voltage control methods and their impacts on feeder’s PV hosting capacity and on other feeder characteristics is detailed in this section.

Table 3 presents a detailed comparison of the eight case studies.

5.1. PV Hosting Capacity for Primary Feeder Overvoltage Concern

Feeder’s PV hosting capacity increases on implementing voltage control methods. For the selected feeder, 100% of customers could be integrated with PV by simply including existing LTC control in the analysis. Smart inverter control is also effective in increasing the feeder’s PV hosting capacity. When smart inverters are operating either at 0.98 lagging power factor or in Volt-VAR control mode, the feeder can integrate 100% of customers with PV without resulting in any overvoltage condition in the primary feeders. With 0.995 lagging power factor control, PV integration limit increases to 17.1 MW for First-hosting and 24 MW (100%) for All-hosting capacity. Thus, enabling voltage control could be an effective way of mitigating primary overvoltage concerns due to the large percentages of residential PV generation.

5.2. Impacts on Secondary Customer Voltages

Along with primary feeder voltages, both legacy device control and smart inverter control helps in regulating secondary customer voltages. Overall, smart inverter control is more effective in regulating secondary customer voltages. The largest secondary voltages and the number of secondary bus voltage violations decrease on enabling voltage control. After decreasing the inverter’s power factor to 0.98 from 0.995, lower secondary bus voltages and a lesser number of voltage violations are recorded. Volt-VAR control of smart inverter results in the best regulation for secondary bus voltages with the least number of overvoltage cases. For the selected feeder, Volt-VAR control along with LTC control enables 100% PV integration without resulting in any cases of primary or secondary voltage violations.

5.3. Reactive Power Supplied by the Substation

The LTC control does not increase the reactive power demand. However, the smart inverter control of PV comes at the cost of increasing reactive power demand from the substation. As smart inverter operates at lower lagging power factor, the reactive power demand increases. The Volt-VAR control results in the largest increase in reactive power requirement from the substation. This analysis implies that ensuring enough reactive power support from the upstream transmission system is of paramount importance when operating smart inverters in reactive power control modes.

5.4. Number of LTC Tap and Capacitor Switching Operations

The number of LTC and capacitor tap operations increase on implementing smart inverter controls. A significant increase in switching operation is observed when PV inverters are operating in Volt-VAR control mode. The increased number of tap operations may deteriorate the LTC taps and capacitor banks, incurring an increased maintenance and replacement cost. Note that in this framework, both legacy devices and PV inverters are operating using local control settings and local information. Coordinating the control among several devices could be a potential approach to avoid unnecessary switching operations. This, however, will require implementing additional communication interface between the substation, capacitor banks, LTCs, and PV inverters.

Based on the above observations, each voltage control approach has its own pros and cons. A legacy control is easy to implement, requires no additional investments, and does not increase reactive power demand. However, because of delayed-response, it may result in overvoltage for a few minutes. Thus, legacy control may be suitable for the feeders where short-term primary voltage violations are acceptable. Smart inverter control is instantaneous, thus not resulting in any lag in operation. Furthermore, smart inverter control helps in better regulation of both primary and secondary voltages, however, at the cost of additional reactive power demand. Therefore, utilities with strict requirements for both primary and secondary voltage violations may adopt smart inverter control. The choice between constant power factor and Volt-VAR control will depend upon the requirement for secondary voltage regulation and the available reactive power support. If the requirements for secondary voltages limits are strict, then utilities may implement Volt-VAR control. A constant power factor control can be used otherwise. Finally, a coordinated control may be implemented to decrease the number of switching operations of legacy devices. Implementing a coordinated control becomes imperative with PVs operating in advanced voltage control modes.

6. Conclusions

The increasing rate of customer-scale PV deployment coupled with grid modernization efforts, calls for revising the framework for evaluating PV impacts on feeder voltages. With the increased communication and control capabilities, the PV integration analysis framework should incorporate the impacts of voltage control on feeder’s PV hosting capacity. This paper evaluates several voltage control methods, including both the control of feeder’s legacy voltage control devices and smart inverters. A detailed comparison is made by simulating eight cases studies by (1) only controlling legacy devices; (2) only controlling smart inverters; and (3) controlling both legacy devices and smart inverters. For the given test feeder, a large number of PV deployment scenarios are simulated by varying PV locations, size, and customer penetration level. The voltage control methods are implemented, and their effectiveness in mitigating PV impacts is quantified using multiple customer- and system-level metrics based on both snapshot and time-series analysis.

It is observed that controlling either legacy devices or smart inverters increase feeder’s PV hosting capacity. The feeder can accommodate 100% PV penetration for all of the voltage control cases except for Case 3 (smart inverter only at PF = −0.995), as compared to 40% with no voltage control. For Case 3, hosting capacity increases from 9.3 to 17.1 MW. Legacy control, although mitigates the primary feeder voltage problems, is not as effective in regulating the secondary feeder voltages. Smart inverter control results in a better regulation of secondary customer voltages. Furthermore, due to the time-delayed response of legacy control, a voltage violation may be observed for a small time-interval until the control activates. The smart inverter control is instantaneous. However, it comes at the cost of increased reactive power demand and an increased number of switching operations requiring feeder upgrades and additional maintenance cost. The reactive power demand is lower for power factor control (1.3 MVAR for PF = −0.995 and 3.8 MVAR for PF = −0.98) but much higher for Volt-VAR control (6.8 MVAR). The total number of capacitor and LTC operations over 1-year period increases from 455 operations (without smart inverter control) to 491 at PF = −0.995, 1243 at PF = −0.98, and 1991 for Volt-VAR mode. Therefore, a suitable smart inverter control should be identified depending upon the additional factors. In order to avoid unnecessary switching operations, a coordinated control approach instead of local control method can be sought.