3.1. Stochastic Process Model

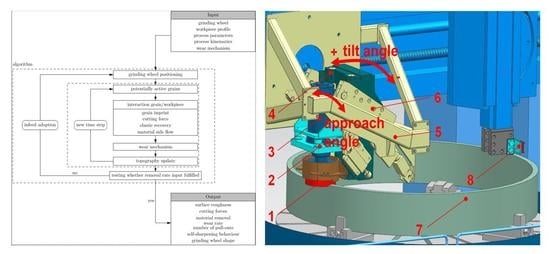

Based on the kinematic simulation presented in [

17,

18,

19] a kinematic model with implemented wear model is developed for resin bonded grinding wheels. The general scheme of the stochastic process simulation with its main steps is shown in

Figure 4.

The main input of the simulation is the grinding wheel geometry. Its generation is presented and follows in six steps: the generation of the basic grain form, the modification of the grain shape, the grain density definition, the extraction of the cutting profile, the positioning of the grain at the grinding wheel surface, and the height distribution of the grain. The grinding wheel macro geometry is defined by a circle formula. For abrasive grains modelled, five basic forms: cuboid, triangular prism, two triangular pyramid, and dodecahedron are defined. These are re-shaper by edge and corner fracture. This shape modification leads to a large amount of different abrasive grains corresponding with the real grinding wheel, where crushed corundum abrasive grains are used. The abrasive grain density is estimated experimentally leading and used as input for the grinding wheel generation. For the abrasive grain height distribution, a triangular distribution delivers the most accurate results, compared with uniform and normal distribution, and it is used in the grinding wheel topography modelling. The resulting modelled grinding wheel topography is then compared with the topography of the grinding wheel used experimentally by Abbott-Firestone curve. A good agreement can be found as shown in

Figure 5. The deviation towards the higher profile ratio is due to the modelled grinding wheel, where only one layer of the abrasive grains is taken into account and the modelling concentrates on the cutting edge space that comes into contact with the material. The deviation in the valleys of the grinding wheel due to the approach of monolayer does not play any role for the process. The workpiece geometry is meshed with nodes in radial and tangential direction. The nodes can be chosen arbitrarily. In the meshed workpiece geometry, the resulting penetration between workpiece and grinding wheel grains is saved as a surface roughness. The result quality is directly dependent on node quantity.

Process parameters that are used in the experiment and listed in the previous section are used also in the simulation. The kinematic description used in the simulation is taken from [

17].

After the definition of all the input parameters from

Figure 4, including the grinding wheel, the kinematic simulation can be performed. Abrasive grains, which cannot be in contact with the workpiece, are deleted and only possible kinematic active grains are used for further calculation. This allows, particularly for small cutting depths, a huge reduction of computational time.

In the simulation an ideal grinding wheel shape is loaded. According to the defined approach angle, the geometry needs to be adapted. The dressed grinding wheel geometry is determined by the contact points of this idealised grinding wheel with the workpiece profile. All of the cutting points between the grinding wheel zero plane at outer and inner wheel diameter and between the workpiece profile need to be found. The approach angle can be gained by contact point height difference at the inner and outer grinding wheel diameter. In

Figure 6, possible contact points are shown for grinding process where the dressing angle

is defined.

The positioning vector of the contact point can be calculated in the workpiece and grinding wheel coordinate system. Transforming both positioning vectors in the global coordinate system and equalising them, an equation for each contact point can be defined. A cutting point on the grinding wheel surface follows according to the equation:

where the

SS subscript indicates that point

P is the cutting point from a grinding wheel point of view.

R0P,SS is the connecting vector between an arbitrary point P at the grinding wheel surface and the origin of the coordinate system indicated in

Figure 6.

R0B is the connecting vector from the origin to the grinding wheel centre,

RBC is the connecting vector from grinding wheel centre to the tilting point,

RCD is the connecting vector from the tilting point to the already tilted centre of the grinding wheel, and

RDP is the connecting vector from the tilted grinding wheel centre to the arbitrary point on the grinding wheel surface P. The nomenclature of the vector is as follows: subscript describes the connection between two points in a coordinate system.

0B and

BC are then transformation matrices defined as:

and

where Ω

A is the approach angle and Ω

K is the tilt angle. The transformation matrix

0B describes the rotation of the local reference system

to the global coordinate system and

BC is responsible for the adjustment of both, the tilt and approach angle.

The interaction between a pre-ground workpiece and a single grain is shown in

Figure 7. From the irregular cross section in cutting speed direction multiple overlaps with the cutting surface of the grain might arise.

For every polygon, the cutting area can be calculated and summed up to a total cutting area for each abrasive grain. This is used then as input for the force calculation. To calculate the force for the whole grinding wheel, information about the force acting points for each grain is necessary. It is assumed that this acting point is in the centre of gravity of the respective cutting area. The radial position

r and height position

h of the centre of gravity are calculated with respect to the grinding wheel referential plane as:

At is the partial polygon area from the intersection between the abrasive grain and the workpiece. The centre of gravity can be then calculated from the partial polygon areas as:

The cutting force can be calculated according to an equation similar to the Kienzle equation as:

where

kc1,1 is the experimentally evaluated specific force and

A represents the abrasive grain area that is engaged with the workpiece and is orthogonal to the cutting direction. The force magnitude delivered by the adapted Kienzle equation needs to be complemented by its direction. From the 3D abrasive grain geometry, as described in [

17], the orthogonal cross-sectional cutting line is derived. In addition to this, the projection of all other grain faces in contact with the workpiece on the orthogonal cutting line is calculated. Each of these projected faces has its normal vector associated with it. This allows the 3D abrasive grain geometry simplification without losing information. Combining these projected normal vectors for one abrasive grain gives a resulting force direction on one abrasive grain:

where

imax is the total number of projected normal faces of one cutting grain,

vi is the volume extracted by the single face

i,

vt is the total volume extracted by the grain in the given time step, and

ni is the normal vector associated with the face

i. This resulting force can be split into the cutting force

Fc, showing in the direction of the cutting speed and the normal force

FN being perpendicular to the cutting force.

The resulting cutting force for the whole grinding wheel is then the sum of all the partial forces acting:

The normal forces are then calculated as:

where the friction coefficient

μ = 0.3 is estimated from the experiment.

As a power controlled spindle is used in the experiment, the proper depth of cut needs to be calculated. As explained above, the nominal current of the grinding spindle electric engine is set and compared with the actually measured current. The measured current is a result of the contact condition between the grinding wheel and the workpiece, and thus of the axial force on the grinding wheel exerted by a pneumatic cylinder. This force needs to be counterbalanced by the sum of the penetration forces of the individual active grains. With increasing force, the amount of active abrasive grains and their penetration depth increases and the current rises. For each height of the grinding wheel, the penetration depth of every single stochastically distributed, oriented, and shaped active grain can be calculated, and thus the forces can be derived from the single grain force model. Iteration is then performed until the sum of the individual grain forces equals the externally applied axial force, pneumatic, and dead weight force, on the spindle. The resulting experimentally measured vertical force is used in the simulation as the nominal value. An estimate of the number of active abrasive grains is known, and thus the force can be distributed among them. The initial grinding wheel position is defined as one where the highest abrasive grain touches the workpiece surface. The simulation is performed with a stepwise increase of the depth of the cut by the amount of one percent of an average abrasive grain diameter, as schematically shown in

Figure 8. If the sum of all vertical forces of the individual abrasive grains in contact with the workpiece is equal to the nominal, experimental, force value, then the simulation continues at this depth of cut. As the propagated wear of the abrasive grain can lead to an unbalance between the nominal and the real vertical force, the depth of cut needs to be adjusted iteratively. In case an abrasive grain is completely worn and is out of contact, the resulting forces are lowered and the depth of cut needs to be increased again. The worn abrasive grain is in contact again and, additionally, new abrasive grains are potentially cutting. The stepwise increase or decrease of the depth of cut is done until the balance between the nominal and simulated force is found again. When the equilibrium between the simulated and experimental forces is reached, the calculation of the workpiece surface roughness can start.

The workpiece material side flow and the workpiece spring back are modelled to determine the ground profile. Based on Li [

20], the side burr is modelled as a triangular ridge accompanying the scratch. It is described by its base

b and height

h. Li [

20] claims that the side flow is not significantly affected by the abrasive grain rake angle and that the triangle base

b is three times its height

h which gives for

h:

where

vg is the grain velocity in m/s and

Acut the area of the cutting profile being engaged with the workpiece in m

2.

The material spring back model is based on a publication by Shaw and DeSalvo [

21] about hardness measurements. They claim that the material actively reacting on the imposed pressure on the surface is maximum ten times the penetration of the indenter. The elastic material displacement can be calculated as:

where Δ

l is the elastic material displacement,

F is the normal force acting on the workpiece surface,

E is the elastic modulus,

l is the material depth responding to the abrasive grain penetration, and

A is the workpiece area responding to the applied pressure. The force from experiment is in the range from 1200 to 1400 N. This force is then divided between all of the active abrasive grains and an average force is attributed to a single active grain. The length l is attributed to the workpiece material amount, which answers to the pressure applied.

3.2. Wear Modelling

The main wear mechanism identified as responsible for the geometry change of the grinding wheel is a fracture of the abrasives. This is a result of an initial abrasive grain flattening causing force increase until fracture.

Grain fracture is observed experimentally, after reaching steady state, and is mainly in a vertical direction—the direction of the normal force. The vertical component comes from the high normal pressure due to the spindle weight and the power control. The horizontal component is resulting from the cutting process and thus the spindle torque.

The main parameters influencing the grinding wheel wear are the cutting force, the cutting speed, and the contact temperature. With increasing active time of the abrasive grain, the wear is propagating until a critical load is reached. This behaviour can be expressed as:

where

dW/dt is the wear rate in mm/s,

K is the wear factor,

B is a constant coming from the Arrhenius equation, where activating energy and universal gas constant are considered,

Fc is the cutting force,

vc is the cutting speed for the abrasive grain, and

Tgrind is the contact temperature between the abrasive grain and the workpiece. Evaluation of the wear factor

K is based on an experimental macroscopic wear evaluation.

The cutting area

Acut in Equation (8) changes with the wear progress

W(t) and can be calculated as:

where

h0 is the initial abrasive grain height and

b is the abrasive grain width assumed to be constant during the whole cutting process as shown in

Figure 9.

The cutting force also depends on the cutting edge condition, which by wear becomes duller. This leads to cutting force increase and can be considered by the introduction of a cutting edge dulling factor

M. The force can be then calculated as:

With the cutting area being calculated according to Equation (15), the cutting force can be calculated as:

Substituting Equation (17) into Equation (14) leads to:

The whole term in front of the bracket is a constant in time and is renamed by

H leading to:

This differential equation only for the wear and can be analytically solved to:

where

c1 is a constant. As

W(0) = 0 leads to:

and thus to the solution:

The contact temperature between the abrasive grain and the workpiece defining

H, given by comparison between Equations (18) and (19) is calculated according to [

22] as:

where

Rw is the energy partition coefficient,

qf is the heat flux, α is the workpiece thermal diffusivity,

kT is the thermal conductivity of the workpiece,

vw is the workpiece feed rate, and

l is the half length of the band source.

A criterion needs to be established for the grain failure. Stresses acting on the abrasive grain are estimated and compared to the critical stress value. The stress in the cutting direction can be estimated as:

The stress in the normal direction can be calculated as:

where

FN is the normal force and

is the cross section of the abrasive grain projected in normal direction. The normal force can be calculated from Equation (11).

Additionally, a shear stress can be calculated as:

where

Fc is the cutting force and

b the width of abrasive grain.

For the calculation of the equivalent stress, the Rankine criterion is used:

Plotting this resulting stress

qualitatively for different wear factors

K and with

M = 1 as simplifying assumption, different progressions can be observed as shown in

Figure 10.

From

Figure 10 and together with the knowledge of the experimentally evaluated average time for an abrasive grain failure and the calculated resulting stress, the wear factor can be evaluated. Wear factor

K = 508 × 10

−4 1/N is estimated as shown in

Figure 11.

With the wear factor K, the propagation of wear with time can be calculated according to Equation (22).