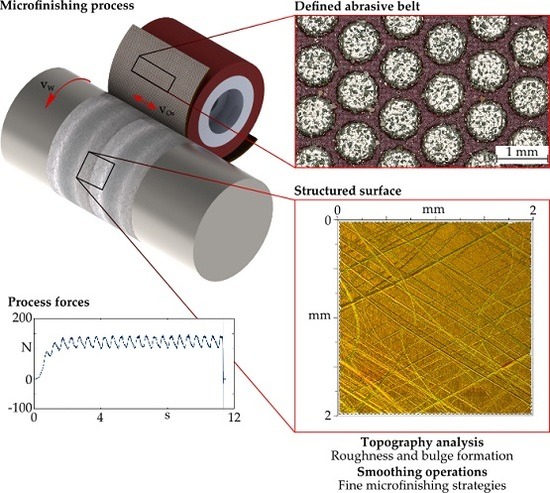

Structuring Surfaces by Microfinishing Using Defined Abrasive Belts

Abstract

:1. Introduction

2. Materials and Methods

3. Results

3.1. Tool Modelling and Simulation

3.2. Force Analysis Regarding Cutting Speed

3.3. Microfinishing Process Sequence—Structuring and Smoothing

3.3.1. Initial Surface

3.3.2. Subsequent Microfinishing Operation—30 µm Film

3.3.3. Subsequent Microfinishing Operation—9 µm Film

4. Discussion

4.1. Tool Model and Geometrical-Kinematic Simulation

4.2. Cutting Speed Influences on the Process Forces

4.3. Subsequent Microfinishing—Surface Smoothing

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| Abbreviation | Meaning | Unit |

| A | Amplitude | mm |

| Al2O3 | Aluminium oxide | - |

| d | diameter | mm |

| dk | Grain size | µm |

| Fn | Normal force | N |

| Ft | Tangential Force | N |

| fOs | Oscillation frequency | Hz |

| HRC | Rockwell hardness | - |

| lc | Contact length between tool and workpiece | mm |

| lOs | Width of oscillation | mm |

| n | Rotational speed | min−1 |

| rf | Ratio fOs/n | - |

| Rk | Core roughness depth | µm |

| Rpk | Reduced peak height | µm |

| Rvk | Reduced valley depth | µm |

| Rz | Maximum profile height | µm |

| SEM | Scanning electron microscope | - |

| t | Process time | s |

| tc | Cutting time | s |

| vfb | Belt feed speed | mm/min |

References

- Tillmann, W.; Leif, H.; Stangier, D.; Laemmerhirt, I.-A.; Biermann, D.; Kersting, P.; Krebs, E. Wear behavior of bio-inspired and technologically structured HVOF sprayed NiCrBSiFe coatings. Abbr. Coat. Technol. 2015, 280, 16–26. [Google Scholar] [CrossRef]

- Bruzzone, A.A.G.; Costa, H.L.; Lonardo, P.M.; Lucca, D.A. Advances in engineered surfaces for functional performance. CIRP Ann. 2008, 57, 750–769. [Google Scholar] [CrossRef]

- Mang, T.; Bobzin, K.; Bartels, T. Industrial Tribology, 1st ed.; Wiley: Aachen, Germany, 2011; pp. 1–21, 113–136. ISBN 978-3-527-320578. [Google Scholar]

- Paffrath, K.-U. Untersuchungen zum Kraftgeregelten Langhubhonen auf Multifunktionalen Bearbeitungszentren. Ph.D. Thesis, Technical University Dortmund, Dortmund, Germany, 2011. [Google Scholar]

- Hashimoto, F.; Yamaguchi, H.; Krajnik, P.; Wegener, K.; Chaudhari, R.; Hoffmeister, H.-W.; Kuster, F. Abrasive fine-finishing technology. CIRP Ann. 2016, 65, 597–620. [Google Scholar] [CrossRef]

- Goeke, S. Oberflächenstrukturierung tribologisch beanspruchter Funktionsflächen durch Microfinishen. Ph.D. Thesis, Technical University Dortmund, Dortmund, Germany, 2016. [Google Scholar]

- Goeke, S.; Biermann, D.; Stickel, D.; Stemmer, P.; Fischer, A.; Geenen, K.; Huth, S.; Theisen, W. Enhancing the Surface Integrity of Tribologically Stressed Contacting Surfaces by an Adjusted Surface Topography. Proced. CIRP 2014, 13, 214–218. [Google Scholar] [CrossRef]

- Schibisch, D.M.; Friedrich, U. Superfinish-Technologie, 3rd ed.; Verlag Moderne Industrie: Landsberg, Germany, 2011; pp. 1–70. ISBN 978-3-86236-016-1. [Google Scholar]

- Biermann, D.; Abrahams, H.; Goeke, S. Optimization of guide pads for the BTA deep hole drilling of high alloyed steels by microfinishing. Prod. Eng. 2014, 8, 33–40. [Google Scholar] [CrossRef]

- Serpin, K.; Mezghani, S.; El Mansori, M. Wear study of structured coated belts in advanced abrasive belt finishing. Surf. Coat. Technol. 2015, 284, 365–376. [Google Scholar] [CrossRef]

- Khellouki, A.; Rech, J.; Zahouani, H. Micro-scale investigation on belt finishing cutting mechanisms by scratch tests. Wear 2013, 308, 17–28. [Google Scholar] [CrossRef]

- Martin, K.; Yegenoglu, K. HSG-Technologie, 1st ed.; Firma Guehring Automation GmbH: Stetten a.k.M.-Frohnstetten, Germany, 1992; pp. 14–39. [Google Scholar]

- Tilger, M.; Siebrecht, T.; Biermann, D. Fundamental Investigations of Honing Processes Related to the Material Removal Mechanisms. In Proceedings of the 7. WGP-Jahreskongress, Aachen, Germany, 5–6 October 2017; pp. 121–128, ISBN 978-3-86359-555-5. [Google Scholar]

- Zum Gahr, K.-H. Wear by hard particles. Tribol. Int. 1998, 31, 587–596. [Google Scholar] [CrossRef]

- Martin, K. Der Werkstoffabtragvorgang beim Feinbearbeitungsverfahren Honen. Maschinenmarkt 1976, 60, 1074–1078. [Google Scholar]

- Serpin, K.; Mezghani, S.; El Mansori, M. Multiscale assessment of structured coated abrasive grits in belt finishing process. Wear 2015, 332–333, 780–787. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tilger, M.; Kipp, M.; Schumann, S.; Dereli, T.T.; Biermann, D. Structuring Surfaces by Microfinishing Using Defined Abrasive Belts. Inventions 2017, 2, 33. https://doi.org/10.3390/inventions2040033

Tilger M, Kipp M, Schumann S, Dereli TT, Biermann D. Structuring Surfaces by Microfinishing Using Defined Abrasive Belts. Inventions. 2017; 2(4):33. https://doi.org/10.3390/inventions2040033

Chicago/Turabian StyleTilger, Meik, Monika Kipp, Sebastian Schumann, Tountzer Tsagkir Dereli, and Dirk Biermann. 2017. "Structuring Surfaces by Microfinishing Using Defined Abrasive Belts" Inventions 2, no. 4: 33. https://doi.org/10.3390/inventions2040033

APA StyleTilger, M., Kipp, M., Schumann, S., Dereli, T. T., & Biermann, D. (2017). Structuring Surfaces by Microfinishing Using Defined Abrasive Belts. Inventions, 2(4), 33. https://doi.org/10.3390/inventions2040033