Design for Additive Manufacturing: Recent Innovations and Future Directions

Abstract

:1. Introduction

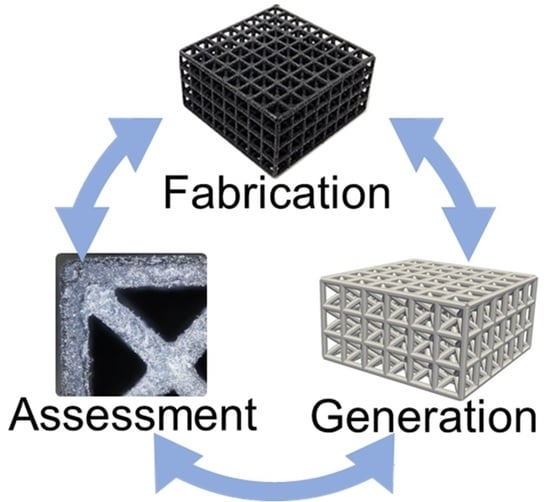

2. Fabrication

2.1. Materials

2.2. Processes

2.3. Constraints

3. Generation

3.1. Conceptualization

3.2. Configuration

3.3. Optimization

4. Assessment

4.1. Validation

4.2. Testing

4.3. Modeling

5. Applications

5.1. Aerospace

5.2. Automotive

5.3. Construction

5.4. Food

5.5. Medical

5.6. Robotics

5.7. Applications Summary

6. Outlook

6.1. Innovation Services

6.2. Bio-Inspired Design

6.3. Robotic Fabrication

6.4. Machine Learning

7. Conclusions

- Fabrication: There are diverse materials and printing processes currently available, with research innovations leading to new material capabilities such as strong superalloys, biocompatibility, and magnetofunctional materials. Many of these materials are limited by suitable printing processes and fabrication constraints. Future work could consider expanding the available AM design space by improving printing time and accuracy across scales as new printable materials emerge.

- Generation: Due to the complex AM design space, it is challenging to configure optimal designs tailored for specific applications. Human designers are necessary to generate innovative solutions but have difficulty overcoming biases and barriers, while computational design requires a well-defined search space that limits innovation. Future work could consider intelligent computational methods that work with, or mimic, humans while incorporating mechanisms to reduce biases during searches.

- Assessment: There is often a mismatch between the ideal digital design and the as-fabricated design that can affect dimensional accuracy and mechanical performance, especially near the resolution limits of a printing process in which innovation occurs. Future work is necessary to better characterize how different printing processes affect design accuracy and mechanics, in addition to understanding the complex failure mechanics of AM parts based on their topological configurations.

- Applications: AM innovations are prevalent across numerous application areas that benefit from the diversity of materials and processes available, especially regarding polymers and metal printing. Soft material printing, such as that for food and tissue engineering, are emerging areas with a need for applying well-established DfAM principles to characterize new design opportunities. Across all domains, there is a need for advancing DfAM to more efficiently tailor and optimize designs to fully leverage AM’s capabilities for customization.

- Outlook: Emerging areas in DfAM include considerations of on-demand printing services and using the broad capabilities of DfAM to enable new functionality via bio-inspiration. Robotic printing processes are enabling large-scale design and more efficient printing, while machine learning capabilities provide promise for automated design tailoring and integration across DfAM phases. Further advances in these fields provide great opportunities for researchers to impact AM and drive new innovations.

Funding

Data Availability Statement

Conflicts of Interest

References

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. Manuf. Technol. 2016, 65, 737–760. [Google Scholar] [CrossRef] [Green Version]

- Candi, M.; Beltagui, A. Effective use of 3D printing in the innovation process. Technovation 2019, 80, 63–73. [Google Scholar] [CrossRef]

- Lindwall, A.; Dordlofva, C.; Öhrwall Rönnbäck, A.; Törlind, P. Innovation in a box: Exploring creativity in design for additive manufacturing in a regulated industry. J. Eng. Des. 2022, 33, 567–586. [Google Scholar] [CrossRef]

- Li, S.; Xin, Y.; Yu, Y.; Wang, Y. Design for additive manufacturing from a force-flow perspective. Mater. Des. 2021, 204, 109664. [Google Scholar] [CrossRef]

- Haleem, A.; Javaid, M. 3D printed medical parts with different materials using additive manufacturing. Clin. Epidemiol. Glob. Health 2020, 8, 215–223. [Google Scholar] [CrossRef] [Green Version]

- Dong, G.; Tang, Y.; Li, D.; Zhao, Y.F. Design and optimization of solid lattice hybrid structures fabricated by additive manufacturing. Addit. Manuf. 2020, 33, 101116. [Google Scholar] [CrossRef]

- Egan, P.F.; Khatri, N.R.; Parab, M.A.; Arefin, A.M. Mechanics of 3D-Printed Polymer Lattices with Varied Design and Processing Strategies. Polymers 2022, 14, 5515. [Google Scholar] [CrossRef]

- Egan, P.F. Special Issue Editorial: Applications of 3D Printing for Polymers. Polymers 2023, 15, 1638. [Google Scholar] [CrossRef]

- Al-Dulimi, Z.; Wallis, M.; Tan, D.K.; Maniruzzaman, M.; Nokhodchi, A. 3D printing technology as innovative solutions for biomedical applications. Drug Discov. Today 2020, 26, 360–383. [Google Scholar] [CrossRef]

- Vaneker, T.; Bernard, A.; Moroni, G.; Gibson, I.; Zhang, Y. Design for additive manufacturing: Framework and methodology. CIRP Ann. 2020, 69, 578–599. [Google Scholar] [CrossRef]

- Sossou, G.; Demoly, F.; Gomes, S.; Montavon, G. An Assembly-Oriented Design Framework for Additive Manufacturing. Designs 2022, 6, 20. [Google Scholar] [CrossRef]

- Egan, P.F.; Bauer, I.; Shea, K.; Ferguson, S.J. Mechanics of Three-Dimensional Printed Lattices for Biomedical Devices. J. Mech. Des. 2019, 141, 031703. [Google Scholar] [CrossRef]

- Khatri, N.; Smith, J.A.; Egan, P.F. Empirical characterization of lattice, spring, and non-assembly mechanisms fabricated with nylon powder printing. In Proceedings of the ASME IDETC Design Automation Conference, St. Louis, MO, USA, 14–17 August 2022. [Google Scholar]

- Pandelidi, C.; Lee, K.P.M.; Kajtaz, M. Effects of polyamide-11 powder refresh ratios in multi-jet fusion: A comparison of new and used powder. Addit. Manuf. 2021, 40, 101933. [Google Scholar] [CrossRef]

- Porter, D.A.; Di Prima, M.A.; Badhe, Y.; Parikh, A.R. Nylon lattice design parameter effects on additively manufactured structural performance. J. Mech. Behav. Biomed. Mater. 2022, 125, 104869. [Google Scholar] [CrossRef]

- Nazir, A.; Arshad, A.B.; Lin, S.-C.; Jeng, J.-Y. Mechanical Performance of Lightweight-Designed Honeycomb Structures Fabricated Using Multijet Fusion Additive Manufacturing Technology. 3D Print. Addit. Manuf. 2022, 9, 311–325. [Google Scholar] [CrossRef]

- Arshad, A.B.; Nazir, A.; Jeng, J.-Y. Design and performance evaluation of multi-helical springs fabricated by Multi Jet Fusion additive manufacturing technology. Int. J. Adv. Manuf. Technol. 2022, 118, 195–206. [Google Scholar] [CrossRef]

- Somireddy, M.; Czekanski, A. Anisotropic material behavior of 3D printed composite structures–Material extrusion additive manufacturing. Mater. Des. 2020, 195, 108953. [Google Scholar] [CrossRef]

- Park, S.; Shou, W.; Makatura, L.; Matusik, W.; Fu, K.K. 3D printing of polymer composites: Materials, processes, and applications. Matter 2022, 5, 43–76. [Google Scholar] [CrossRef]

- Dixit, T.; Al-Hajri, E.; Paul, M.C.; Nithiarasu, P.; Kumar, S. High performance, microarchitected, compact heat exchanger enabled by 3D printing. Appl. Therm. Eng. 2022, 210, 118339. [Google Scholar] [CrossRef]

- Cimolai, G.; Dayyani, I.; Qin, Q. Multi-objective shape optimization of large strain 3D helical structures for mechanical metamaterials. Mater. Des. 2022, 215, 110444. [Google Scholar] [CrossRef]

- Bol, E.; Ramulu, M. Dimensional Accuracy of Electron Beam Powder Bed Fusion with Ti-6Al-4V. Designs 2023, 7, 53. [Google Scholar] [CrossRef]

- Einbergs, E.; Spustaka, A.; Vitola, V.; Zolotarjovs, A. By visualizing the deformation with mechanoluminescent particles, additive manufacturing offers a practical alternative to stress and strain simulation. Designs 2023, 7, 54. [Google Scholar] [CrossRef]

- Panwisawas, C.; Tang, Y.T.; Reed, R.C. Metal 3D printing as a disruptive technology for superalloys. Nat. Commun. 2020, 11, 2327. [Google Scholar] [CrossRef] [PubMed]

- Mostafaei, A.; Neelapu, S.H.V.R.; Kisailus, C.; Nath, L.M.; Jacobs, T.D.; Chmielus, M. Characterizing surface finish and fatigue behavior in binder-jet 3D-printed nickel-based superalloy 625. Addit. Manuf. 2018, 24, 200–209. [Google Scholar] [CrossRef] [Green Version]

- Ghoussoub, J.N.; Klupś, P.; Dick-Cleland, W.J.; Rankin, K.E.; Utada, S.; Bagot, P.A.; McCartney, D.G.; Tang, Y.T.; Reed, R.C. A new class of alumina-forming superalloy for 3D printing. Addit. Manuf. 2022, 52, 102608. [Google Scholar] [CrossRef]

- Fortuna, S.; Gurianov, D.; Kalashnikov, K.; Chumaevskii, A.; Mironov, Y.P.; Kolubaev, E. Directional solidification of a nickel-based superalloy product structure fabricated on stainless steel substrate by electron beam additive manufacturing. Met. Mater. Trans. A 2021, 52, 857–870. [Google Scholar] [CrossRef]

- Risangud, N.; Jiraborvornpongsa, N.; Pasee, S.; Kaewkong, P.; Kunkit, N.; Sungkhaphan, P.; Janvikul, W. Poly (ester-co-glycidyl methacrylate) for digital light processing in biomedical applications. J. Appl. Polym. Sci. 2021, 138, 51391. [Google Scholar] [CrossRef]

- Lantean, S.; Barrera, G.; Pirri, C.F.; Tiberto, P.; Sangermano, M.; Roppolo, I.; Rizza, G. 3D printing of magnetoresponsive polymeric materials with tunable mechanical and magnetic properties by digital light processing. Adv. Mater. Technol. 2019, 4, 1900505. [Google Scholar] [CrossRef]

- Egan, P.; Wang, X.; Greutert, H.; Shea, K.; Wuertz-Kozak, K.; Ferguson, S. Mechanical and Biological Characterization of 3D Printed Lattices. 3D Print. Addit. Manuf. 2019, 6, 73–81. [Google Scholar] [CrossRef]

- Steyrer, B.; Neubauer, P.; Liska, R.; Stampfl, J. Visible light photoinitiator for 3D-printing of tough methacrylate resins. Materials 2017, 10, 1445. [Google Scholar] [CrossRef] [Green Version]

- Zhang, C.; Li, X.; Jiang, L.; Tang, D.; Xu, H.; Zhao, P.; Fu, J.; Zhou, Q.; Chen, Y. 3D printing of functional magnetic materials: From design to applications. Adv. Funct. Mater. 2021, 31, 2102777. [Google Scholar] [CrossRef]

- Shao, G.; Ware, H.O.T.; Li, L.; Sun, C. Rapid 3D printing magnetically active microstructures with high solid loading. Adv. Eng. Mater. 2020, 22, 1900911. [Google Scholar] [CrossRef]

- Samykano, M.; Selvamani, S.; Kadirgama, K.; Ngui, W.; Kanagaraj, G.; Sudhakar, K. Mechanical property of FDM printed ABS: Influence of printing parameters. Int. J. Adv. Manuf. Technol. 2019, 102, 2779–2796. [Google Scholar] [CrossRef]

- Sheoran, A.J.; Kumar, H. Fused Deposition modeling process parameters optimization and effect on mechanical properties and part quality: Review and reflection on present research. Mater. Today: Proc. 2020, 21, 1659–1672. [Google Scholar]

- Kam, M.; İpekçi, A.; Şengül, Ö. Investigation of the effect of FDM process parameters on mechanical properties of 3D printed PA12 samples using Taguchi method. J. Thermoplast. Compos. Mater. 2023, 36, 307–325. [Google Scholar] [CrossRef]

- Zaeri, A.; Zgeib, R.; Cao, K.; Zhang, F.; Chang, R.C. Numerical analysis on the effects of microfluidic-based bioprinting parameters on the microfiber geometrical outcomes. Sci. Rep. 2022, 12, 3364. [Google Scholar] [CrossRef]

- Pant, A.; Lee, A.Y.; Karyappa, R.; Lee, C.P.; An, J.; Hashimoto, M.; Tan, U.X.; Wong, G.; Chua, C.K.; Zhang, Y. 3D food printing of fresh vegetables using food hydrocolloids for dysphagic patients. Food Hydrocoll. 2021, 114, 106546. [Google Scholar] [CrossRef]

- Schwab, A.; Levato, R.; D’Este, M.; Piluso, S.; Eglin, D.; Malda, J. Printability and shape fidelity of bioinks in 3D bioprinting. Chem. Rev. 2020, 120, 11028–11055. [Google Scholar] [CrossRef]

- Pérez, B.; Nykvist, H.; Brøgger, A.F.; Larsen, M.B.; Falkeborg, M.F. Impact of macronutrients printability and 3D-printer parameters on 3D-food printing: A review. Food Chem. 2019, 287, 249–257. [Google Scholar] [CrossRef]

- Korium, M.S.; Roozbahani, H.; Alizadeh, M.; Perepelkina, S.; Handroos, H. Direct metal laser sintering of precious metals for jewelry applications: Process parameter selection and microstructure analysis. IEEE Access 2021, 9, 126530–126540. [Google Scholar] [CrossRef]

- Choi, S.; Kim, J.-W.; Lee, S.; Yoon, W.Y.; Han, Y.; Kim, K.-J.; Rhie, J.-W.; Suh, T.-S.; Lee, K.-D. Mechanical and biocompatibility properties of sintered titanium powder for mimetic 3D-printed bone scaffolds. ACS Omega 2022, 7, 10340–10346. [Google Scholar] [CrossRef] [PubMed]

- Wei, X.; Li, X.; Wen, S.; Zheng, Y.; Tian, Y. Channel design for 3D models with applications in powder-bed additive manufacturing. Rapid Prototyp. J. 2019, 25, 1536–1544. [Google Scholar] [CrossRef]

- Zeng, Z.; Deng, X.; Cui, J.; Jiang, H.; Yan, S.; Peng, B. Improvement on selective laser sintering and post-processing of polystyrene. Polymers 2019, 11, 956. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nazir, A.; Ali, M.; Hsieh, C.-H.; Jeng, J.-Y. Investigation of stiffness and energy absorption of variable dimension helical springs fabricated using multijet fusion technology. Int. J. Adv. Manuf. Technol. 2020, 110, 2591–2602. [Google Scholar] [CrossRef]

- Fu, Y.; Chen, Z.; Xu, G.; Wei, Y.; Lao, C. Preparation and stereolithography 3D printing of ultralight and ultrastrong ZrOC porous ceramics. J. Alloy Compd. 2019, 789, 867–873. [Google Scholar] [CrossRef]

- Shen, M.; Zhao, W.; Xing, B.; Sing, Y.; Gao, S.; Wang, C.; Zhao, Z. Effects of exposure time and printing angle on the curing characteristics and flexural strength of ceramic samples fabricated via digital light processing. Ceram. Int. 2020, 46, 24379–24384. [Google Scholar] [CrossRef]

- Song, P.; Li, M.; Zhang, B.; Gui, X.; Han, Y.; Wang, L.; Zhou, W.; Guo, L.; Zhang, Z.; Li, Z.; et al. DLP fabricating of precision GelMA/HAp porous composite scaffold for bone tissue engineering application. Compos. Part B: Eng. 2022, 244, 110163. [Google Scholar] [CrossRef]

- Huang, J.; Chen, Q.; Jiang, H.; Zou, B.; Li, L.; Liu, J.; Yu, H. A survey of design methods for material extrusion polymer 3D printing. Virtual Phys. Prototyp. 2020, 15, 148–162. [Google Scholar] [CrossRef]

- Enea, S.; Moon, S.K. Guidelines for 3D printed springs using material extrusion. Rapid Prototyp. J. 2021, 28, 409–427. [Google Scholar] [CrossRef]

- Booth, J.W.; Alperovich, J.; Chawla, P.; Ma, J.; Reid, T.N.; Ramani, K. The design for additive manufacturing worksheet. J. Mech. Des. 2017, 139, 100904. [Google Scholar] [CrossRef] [Green Version]

- Wei, X.; Tian, Y.; Joneja, A. A study on revolute joints in 3D-printed non-assembly mechanisms. Rapid Prototyp. J. 2016, 22, 901–933. [Google Scholar] [CrossRef]

- Schaechtl, P.; Hallmann, M.; Schleich, B.; Wartzack, S. Tolerance analysis of additively manufactured non-assembly mechanisms considering joint clearance. Procedia CIRP 2020, 92, 27–32. [Google Scholar] [CrossRef]

- Rupal, B.S.; Anwer, N.; Secanell, M.; Qureshi, A.J. Geometric tolerance characterization of laser powder bed fusion processes based on skin model shapes. Procedia CIRP 2020, 92, 169–174. [Google Scholar] [CrossRef]

- Prabhu, R.; Bracken, J.; Armstrong, C.B.; Jablokow, K.; Simpson, T.W.; Meisel, N.A. Additive creativity: Investigating the use of design for additive manufacturing to encourage creativity in the engineering design industry. Int. J. Des. Creat. Innov. 2020, 8, 198–222. [Google Scholar] [CrossRef]

- Sinha, S.; Chen, H.-E.; Meisel, N.A.; Miller, S.R. Does Designing for Additive Manufacturing Help Us Be More Creative? An Exploration in Engineering Design Education. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Cleveland, OH, USA, 6–9 August 2017; p. V003T04A014. [Google Scholar]

- Friesike, S.; Flath, C.M.; Wirth, M.; Thiesse, F. Creativity and productivity in product design for additive manufacturing: Mechanisms and platform outcomes of remixing. J. Oper. Manag. 2019, 65, 735–752. [Google Scholar] [CrossRef] [Green Version]

- Prabhu, R.; Miller, S.R.; Simpson, T.W.; Meisel, N.A. Teaching design freedom: Understanding the effects of variations in design for additive manufacturing education on students’ creativity. J. Mech. Des. 2020, 142, 094501. [Google Scholar] [CrossRef]

- Blösch-Paidosh, A.; Shea, K. Enhancing Creative Redesign Through Multimodal Design Heuristics for Additive Manufacturing. J. Mech. Des. 2021, 143, 102003. [Google Scholar] [CrossRef]

- Schauer, A.M.; Fillingim, K.B.; Fu, K. Impact of timing in the design process on students’ application of design for additive manufacturing heuristics. J. Mech. Des. 2022, 144, 062301. [Google Scholar] [CrossRef]

- Li, X.; Zhao, J.; He, R.; Tian, Y.; Wei, X. Parametric design of scalable mechanisms for additive manufacturing. J. Mech. Des. 2018, 140, 022302. [Google Scholar] [CrossRef]

- Al Khalil, M.; Belkebir, H.; Lebaal, N.; Demoly, F.; Roth, S. A Biomimetic Design Method for 3D-Printed Lightweight Structures Using L-Systems and Parametric Optimization. Appl. Sci. 2022, 12, 5530. [Google Scholar] [CrossRef]

- Li, C.; Lei, H.; Zhang, Z.; Zhang, X.; Zhou, H.; Wang, P.; Fang, D. Architecture design of periodic truss-lattice cellsfor additive manufacturing. Addit. Manuf. 2020, 34, 101172. [Google Scholar]

- Lei, H.-Y.; Li, J.-R.; Xu, Z.-J.; Wang, Q.-H. Parametric design of Voronoi-based lattice porous structures. Mater. Des. 2020, 191, 108607. [Google Scholar] [CrossRef]

- Fantini, M.; Curto, M.; De Crescenzio, F. A method to design biomimetic scaffolds for bone tissue engineering based on Voronoi lattices. Virtual Phys. Prototyp. 2016, 11, 77–90. [Google Scholar] [CrossRef]

- Hindy, A.; Farahmand, F.; Pourdanesh, F.; Torshabi, M.; Al Janabi, A.H.; Rasoulianboroujeni, M.; Tayebi, L.; Tabatabaei, F.S. Synthesis and characterization of 3D-printed functionally graded porous titanium alloy. J. Mater. Sci. 2020, 55, 9082–9094. [Google Scholar] [CrossRef]

- Letov, N.; Zhao, Y.F. Beam-based lattice topology transition with function representation. J. Mech. Des. 2023, 145, 011704. [Google Scholar] [CrossRef]

- Mukhopadhyay, T.; Naskar, S.; Adhikari, S. Anisotropy tailoring in geometrically isotropic multi-material lattices. Extrem. Mech. Lett. 2020, 40, 100934. [Google Scholar] [CrossRef]

- Liu, W.; Song, H.; Huang, C. Maximizing mechanical properties and minimizing support material of PolyJet fabricated 3D lattice structures. Addit. Manuf. 2020, 35, 101257. [Google Scholar] [CrossRef]

- Liu, Y.; Zhuo, S.; Xiao, Y.; Zheng, G.; Dong, G.; Zhao, Y.F. Rapid modeling and design optimization of multi-topology lattice structure based on unit-cell library. J. Mech. Des. 2020, 142, 091705. [Google Scholar] [CrossRef]

- Wang, Z.; Srinivasa, A.; Reddy, J.; Dubrowski, A. Topology Optimization of Lightweight Structures With Application to Bone Scaffolds and 3D Printed Shoes for Diabetics. J. Appl. Mech. 2022, 89, 041009. [Google Scholar] [CrossRef]

- Wang, C.; Qian, X. Simultaneous optimization of build orientation and topology for additive manufacturing. Addit. Manuf. 2020, 34, 101246. [Google Scholar] [CrossRef]

- Kazemi, H.; Norato, J.A. Topology optimization of lattices with anisotropic struts. Struct. Multidiscip. Optim. 2021, 63, 1653–1668. [Google Scholar] [CrossRef]

- Ravari, M.K.; Kadkhodaei, M.; Badrossamay, M.; Rezaei, R. Numerical investigation on mechanical properties of cellular lattice structures fabricated by fused deposition modeling. Int. J. Mech. Sci. 2014, 88, 154–161. [Google Scholar] [CrossRef]

- Okarma, K.; Fastowicz, J.; Lech, P.; Lukin, V. Quality Assessment of 3D Printed Surfaces Using Combined Metrics Based on Mutual Structural Similarity Approach Correlated with Subjective Aesthetic Evaluation. Appl. Sci. 2020, 10, 6248. [Google Scholar] [CrossRef]

- Nar, K.; Majewski, C.; Lewis, R. A comprehensive characterisation of Laser Sintered Polyamide-12 surfaces. Polym. Test. 2022, 106, 107450. [Google Scholar] [CrossRef]

- Ribeiro, A.; Blokzijl, M.M.; Levato, R.; Visser, C.W.; Castilho, M.; Hennink, W.E.; Vermonden, T.; Malda, J. Assessing bioink shape fidelity to aid material development in 3D bioprinting. Biofabrication 2017, 10, 014102. [Google Scholar] [CrossRef] [PubMed]

- Montgomery, S.M.; Demoly, F.; Zhou, K.; Qi, H.J. Pixel-Level Grayscale Manipulation to Improve Accuracy in Digital Light Processing 3D Printing. Adv. Funct. Mater. 2023, 33, 2213252. [Google Scholar] [CrossRef]

- Woodward, I.R.; Fromen, C.A. Scalable, process-oriented beam lattices: Generation, characterization, and compensation for open cellular structures. Addit. Manuf. 2021, 48, 102386. [Google Scholar] [CrossRef]

- Arabnejad, S.; Johnston, R.B.; Pura, J.A.; Singh, B.; Tanzer, M.; Pasini, D. High-strength porous biomaterials for bone replacement: A strategy to assess the interplay between cell morphology, mechanical properties, bone ingrowth and manufacturing constraints. Acta Biomater. 2016, 30, 345–356. [Google Scholar] [CrossRef] [Green Version]

- Alghamdi, A.; Maconachie, T.; Downing, D.; Brandt, M.; Qian, M.; Leary, M. Effect of additive manufactured lattice defects on mechanical properties: An automated method for the enhancement of lattice geometry. Int. J. Adv. Manuf. Technol. 2020, 108, 957–971. [Google Scholar] [CrossRef]

- Wang, Z.; Liu, P.; Ji, Y.; Mahadevan, S.; Horstemeyer, M.F.; Hu, Z.; Chen, L.; Chen, L.-Q. Uncertainty quantification in metallic additive manufacturing through physics-informed data-driven modeling. JOM 2019, 71, 2625–2634. [Google Scholar] [CrossRef]

- Moniruzzaman, M.; O’Neal, C.; Bhuiyan, A.; Egan, P.F. Design and Mechanical Testing of 3D Printed Hierarchical Lattices Using Biocompatible Stereolithography. Designs 2020, 4, 22. [Google Scholar] [CrossRef]

- Kulkarni, N.N.; Ekwaro-Osire, S.; Egan, P.F. Fabrication, Mechanics, and Reliability Analysis for Three-Dimensional Printed Lattice Designs. ASCE-ASME J. Risk Uncertain Eng. Syst. Part B Mech. Eng. 2021, 8, 011107. [Google Scholar] [CrossRef]

- Khatri, N.R.; Egan, P.F. Energy Absorption of 3D Printed ABS and TPU Multimaterial Honeycomb Structures. 3D Print. Addit. Manuf. 2023. [Google Scholar] [CrossRef]

- Mazur, M.; Leary, M.; Sun, S.; Vcelka, M.; Shidid, D.; Brandt, M. Deformation and failure behaviour of Ti-6Al-4V lattice structures manufactured by selective laser melting (SLM). Int. J. Adv. Manuf. Technol. 2016, 84, 1391–1411. [Google Scholar] [CrossRef]

- Altamimi, S.; Lee, D.-W.; Barsoum, I.; Rowshan, R.; Jasiuk, I.M.; Abu Al-Rub, R.K. On Stiffness, Strength, Anisotropy, and Buckling of 30 Strut-Based Lattices with Cubic Crystal Structures. Adv. Eng. Mater. 2022, 24, 2101379. [Google Scholar] [CrossRef]

- Leary, M.; Mazur, M.; Williams, H.; Yang, E.; Alghamdi, A.; Lozanovski, B.; Zhang, X.; Shidid, D.; Farahbod-Sternahl, L.; Witt, G.; et al. Inconel 625 lattice structures manufactured by selective laser melting (SLM): Mechanical properties, deformation and failure modes. Mater. Des. 2018, 157, 179–199. [Google Scholar] [CrossRef]

- Chua, C.; Sing, S.L.; Chua, C. Characterisation of in-situ alloyed titanium-tantalum lattice structures by laser powder bed fusion using finite element analysis. Virtual Phys. Prototyp. 2023, 18, e2138463. [Google Scholar] [CrossRef]

- Abdulhadi, H.S.; Fadeel, A.; Alwattar, T.A.; Mian, A. Developing scaling laws to predict compressive mechanical properties and determine geometrical parameters of modified BCC lattice structures. Eng. Rep. 2023, 5, e12566. [Google Scholar] [CrossRef]

- Alghamdi, A.; Downing, D.; Tino, R.; Almalki, A.; Maconachie, T.; Lozanovski, B.; Brandt, M.; Qian, M.; Leary, M. Buckling phenomena in AM lattice strut elements: A design tool applied to Ti-6Al-4V LB-PBF. Mater. Des. 2021, 208, 109892. [Google Scholar] [CrossRef]

- Liu, Y.; Yang, H.; Zhao, Y.F.; Zheng, G. A heterogeneous lattice structure modeling technique supported by multiquadric radial basis function networks. J. Comput. Des. Eng. 2022, 9, 68–81. [Google Scholar] [CrossRef]

- Wang, R.; Wu, Z. Recent advancement in finite element analysis of spinal interbody cages: A review. Front. Bioeng. Biotechnol. 2023, 11, 1041973. [Google Scholar] [CrossRef] [PubMed]

- Arefin, A.M.; Lahowetz, M.; Egan, P.F. Simulated tissue growth in tetragonal lattices with mechanical stiffness tuned for bone tissue engineering. Comput. Biol. Med. 2021, 138, 104913. [Google Scholar] [CrossRef]

- Zagidullin, R.; Zezin, N.; Rodionov, N. Improving the quality of FDM 3D printing of UAV and aircraft parts and assemblies by parametric software changes. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1027, p. 012031. [Google Scholar]

- Schmitt, M.; Mehta, R.M.; Kim, I.Y. Additive manufacturing infill optimization for automotive 3D-printed ABS components. Rapid Prototyp. J. 2020, 26, 89–99. [Google Scholar] [CrossRef]

- Gardner, L.; Kyvelou, P.; Herbert, G.; Buchanan, C. Testing and initial verification of the world’s first metal 3D printed bridge. J. Constr. Steel Res. 2020, 172, 106233. [Google Scholar] [CrossRef]

- Scheele, S.C.; Hartmann, C.; Siegrist, M.; Binks, M.; Egan, P.F. Consumer Assessment of 3D Printed Food Shape, Taste, and Fidelity using Chocolate and Marzipan Materials. 3D Print. Addit. Manuf. 2021, 9, 473–782. [Google Scholar] [CrossRef]

- Lee, H.; Jang, Y.; Choe, J.K.; Lee, S.; Song, H.; Lee, J.P.; Lone, N.; Kim, J. 3D-printed programmable tensegrity for soft robotics. Sci. Robot. 2020, 5, eaay9024. [Google Scholar] [CrossRef]

- Skawiński, I.; Goetzendorf-Grabowski, T. FDM 3D printing method utility assessment in small RC aircraft design. Aircr. Eng. Aerosp. Technol. 2019, 91, 865–872. [Google Scholar] [CrossRef]

- Nicholson, G.; Roberts, C. University of Sheffield/AMRC, FDM-Printed Fixed Wing UAV. Available online: https://www.amrc.co.uk/case-studies/fdm-printed-fixed-wing-uav (accessed on 19 May 2023).

- Ravindrababu, S.; Govdeli, Y.; Wong, Z.W.; Kayacan, E. Evaluation of the influence of build and print orientations of unmanned aerial vehicle parts fabricated using fused deposition modeling process. J. Manuf. Process. 2018, 34, 659–666. [Google Scholar] [CrossRef]

- Wang, Y.-C.; Chen, T.; Yeh, Y.-L. Advanced 3D printing technologies for the aircraft industry: A fuzzy systematic approach for assessing the critical factors. Int. J. Adv. Manuf. Technol. 2019, 105, 4059–4069. [Google Scholar] [CrossRef]

- Blachowicz, T.; Pająk, K.; Recha, P.; Ehrmann, A. 3D printing for microsatellites-material requirements and recent developments. AIMS Mater. Sci. 2020, 7, 926–938. [Google Scholar] [CrossRef]

- Li, H.; Meng, H.; Lan, M.; Zhou, J.; Xu, M.; Zhao, X.; Xiang, B. Development of a novel material and casting method for in situ construction on Mars. Powder Technol. 2021, 390, 219–229. [Google Scholar] [CrossRef]

- Korniejenko, K.; Pławecka, K.; Kozub, B. An Overview for Modern Energy-Efficient Solutions for Lunar and Martian Habitats Made Based on Geopolymers Composites and 3D Printing Technology. Energies 2022, 15, 9322. [Google Scholar] [CrossRef]

- Mohanavel, V.; Ali, K.A.; Ranganathan, K.; Jeffrey, J.A.; Ravikumar, M.; Rajkumar, S. The roles and applications of additive manufacturing in the aerospace and automobile sector. Mater. Today Proc. 2021, 47, 405–409. [Google Scholar] [CrossRef]

- Szalai, S.; Herold, B.; Kurhan, D.; Németh, A.; Sysyn, M.; Fischer, S. Optimization of 3D printed rapid prototype deep drawing tools for automotive and railway sheet material testing. Infrastructures 2023, 8, 43. [Google Scholar] [CrossRef]

- Nascimento, D.L.d.M.; Nepomuceno, R.M.; Caiado, R.G.G.; Maqueira, J.M.; Moyano-Fuentes, J.; Garza-Reyes, J.A. A sustainable circular 3D printing model for recycling metal scrap in the automotive industry. J. Manuf. Technol. Manag. 2022, 33, 876–892. [Google Scholar] [CrossRef]

- Komara, A.I.; Budiwantoro, B.; Setiawan, R. Cellular Structure Design and Manufacturability for Electric Vehicle: A Review. Int. J. Sustain. Transp. Technol. 2022, 5, 70–79. [Google Scholar] [CrossRef]

- Aslan, B.; Yıldız, A.R. Optimum design of automobile components using lattice structures for additive manufacturing. Mater. Test. 2020, 62, 633–639. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Ji, G.; Ding, T.; Xiao, J.; Du, S.; Li, J.; Duan, Z. A 3D printed ready-mixed concrete power distribution substation: Materials and construction technology. Materials 2019, 12, 1540. [Google Scholar] [CrossRef] [Green Version]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction–CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Salet, T.A.; Ahmed, Z.Y.; Bos, F.P.; Laagland, H.L. Design of a 3D printed concrete bridge by testing. Virtual Phys. Prototyp. 2018, 13, 222–236. [Google Scholar] [CrossRef] [Green Version]

- Vantyghem, G.; De Corte, W.; Shakour, E.; Amir, O. 3D printing of a post-tensioned concrete girder designed by topology optimization. Autom. Constr. 2020, 112, 103084. [Google Scholar] [CrossRef]

- Kanyilmaz, A.; Demir, A.G.; Chierici, M.; Berto, F.; Gardner, L.; Kandukuri, S.Y.; Kassabian, P.; Kinoshita, T.; Laurenti, A.; Paoletti, I.; et al. Role of metal 3D printing to increase quality and resource-efficiency in the construction sector. Addit. Manuf. 2022, 50, 102541. [Google Scholar] [CrossRef]

- Alhumayani, H.; Gomaa, M.; Soebarto, V.; Jabi, W. Environmental assessment of large-scale 3D printing in construction: A comparative study between cob and concrete. J. Clean. Prod. 2020, 270, 122463. [Google Scholar] [CrossRef]

- Mahmoud, R.; Nguyen, Q.; Christopher, G.; Egan, P.F. 3D printed food design and fabrication approach for manufacturability, rheology, and nutrition trade-offs. In Proceedings of the ASME IDETC Design Automation Conference, Virtual Conference, 17–19 August 2021. [Google Scholar]

- Scheele, S.C.; Binks, M.; Christopher, G.; Maleky, F.; Egan, P.F. Printability, texture, and sensory trade-offs for 3D printed potato with added proteins and lipids. J. Food Eng. 2023, 351, 111517. [Google Scholar] [CrossRef]

- Derossi, A.; Paolillo, M.; Verboven, P.; Nicolai, B.; Severini, C. Extending 3D food printing application: Apple tissue microstructure as a digital model to create innovative cereal-based snacks. J. Food Eng. 2022, 316, 110845. [Google Scholar] [CrossRef]

- Yang, G.; Tao, Y.; Wang, P.; Xu, X.; Zhu, X. Optimizing 3D printing of chicken meat by response surface methodology and genetic algorithm: Feasibility study of 3D printed chicken product. Lwt 2022, 154, 112693. [Google Scholar] [CrossRef]

- Lin, Y.-J.; Punpongsanon, P.; Wen, X.; Iwai, D.; Sato, K.; Obrist, M.; Mueller, S. FoodFab: Creating food perception illusions using food 3D printing. In Proceedings of the 2020 CHI Conference on Human Factors in Computing Systems, Honolulu, HI, USA, 25–30 April 2020; 2021; pp. 1–13. [Google Scholar]

- Motoki, K.; Park, J.; Spence, C.; Velasco, C. Contextual acceptance of novel and unfamiliar foods: Insects, cultured meat, plant-based meat alternatives, and 3D printed foods. Food Qual. Prefer. 2022, 96, 104368. [Google Scholar] [CrossRef]

- Alkhatib, F.; Mahdi, E.; Cabibihan, J.-J. Design and analysis of flexible joints for a robust 3D printed prosthetic hand. In Proceedings of the 2019 IEEE 16th International Conference on Rehabilitation Robotics (ICORR), Toronto, ON, Canada, 24–28 June 2019; pp. 784–789. [Google Scholar]

- Ahrendt, D.; Karam, A.R. Development of a computer-aided engineering–supported process for the manufacturing of customized orthopaedic devices by three-dimensional printing onto textile surfaces. J. Eng. Fibers Fabr. 2020, 15, 1558925020917627. [Google Scholar] [CrossRef]

- Keukenkamp, R.; van Netten, J.J.; Busch-Westbroek, T.E.; Nollet, F.; Bus, S.A. Users’ needs and expectations and the design of a new custom-made indoor footwear solution for people with diabetes at risk of foot ulceration. Disabil. Rehabil. 2022, 44, 8493–8500. [Google Scholar] [CrossRef]

- Alaña, M.; Lopez-Arancibia, A.; Ghouse, S.; Rodriguez-Florez, N.; de Galarreta, S.R. Additively manufactured lattice structures with controlled transverse isotropy for orthopedic porous implants. Comput. Biol. Med. 2022, 150, 105761. [Google Scholar] [CrossRef]

- Egan, P.; Ferguson, S.; Shea, K. Design of hierarchical 3D printed scaffolds considering mechanical and biological factors for bone tissue engineering. J. Mech. Des. 2017, 139, 061401. [Google Scholar] [CrossRef]

- Egan, P.F.; Shea, K.A.; Ferguson, S.J. Simulated tissue growth for 3D printed scaffolds. Biomech. Model. Mechanobiol. 2018, 17, 1481–1495. [Google Scholar] [CrossRef]

- Cendrero, A.M.; Martínez, F.F.; Requejo, W.G.S.; Lantada, A.D. Open-source library of tissue engineering scaffolds. Mater. Des. 2022, 223, 111154. [Google Scholar] [CrossRef]

- Van Belleghem, S.; Mahadik, B.; Snodderly, K.; Mote, Z.; Jiang, B.; Yu, J.R.; McLoughlin, S.; He, X.; Nam, A.J.; Fisher, J.P. Dual Extrusion Patterning Drives Tissue Development Aesthetics and Shape Retention in 3D Printed Nipple-Areola Constructs. Adv. Healthc. Mater. 2021, 10, 2101249. [Google Scholar] [CrossRef]

- Gul, J.Z.; Sajid, M.; Rehman, M.M.; Siddiqui, G.U.; Shah, I.; Kim, K.-H.; Lee, J.-W.; Choi, K.H. 3D printing for soft robotics–a review. Sci. Technol. Adv. Mater. 2018, 19, 243–262. [Google Scholar] [CrossRef] [Green Version]

- Takishima, Y.; Yoshida, K.; Khosla, A.; Kawakami, M.; Furukawa, H. Fully 3D-printed hydrogel actuator for jellyfish soft robots. ECS J. Solid State Sci. Technol. 2021, 10, 037002. [Google Scholar] [CrossRef]

- Ntagios, M.; Nassar, H.; Pullanchiyodan, A.; Navaraj, W.T.; Dahiya, R. Robotic hands with intrinsic tactile sensing via 3D printed soft pressure sensors. Adv. Intell. Syst. 2020, 2, 1900080. [Google Scholar] [CrossRef] [Green Version]

- Desai, J.P.; Sheng, J.; Cheng, S.S.; Wang, X.; Deaton, N.J.; Rahman, N. Toward patient-specific 3D-printed robotic systems for surgical interventions. IEEE Trans. Med. Robot. Bionics 2019, 1, 77–87. [Google Scholar] [CrossRef]

- Joyee, E.B.; Pan, Y. Additive manufacturing of multi-material soft robot for on-demand drug delivery applications. J. Manuf. Process. 2020, 56, 1178–1184. [Google Scholar] [CrossRef]

- Kantaros, A.; Diegel, O.; Piromalis, D.; Tsaramirsis, G.; Khadidos, A.O.; Khadidos, A.O.; Khan, F.Q.; Jan, S. 3D printing: Making an innovative technology widely accessible through makerspaces and outsourced services. Mater. Today Proc. 2022, 49, 2712–2723. [Google Scholar] [CrossRef]

- Tran, P.; Ngo, T.D.; Ghazlan, A.; Hui, D. Bimaterial 3D printing and numerical analysis of bio-inspired composite structures under in-plane and transverse loadings. Compos. Part B Eng. 2017, 108, 210–223. [Google Scholar] [CrossRef]

- Zhang, X.; Li, M.; Lim, J.H.; Weng, Y.; Tay, Y.W.D.; Pham, H.; Pham, Q.-C. Large-scale 3D printing by a team of mobile robots. Autom. Constr. 2018, 95, 98–106. [Google Scholar] [CrossRef]

- Lee, S.; Zhang, Z.; Gu, G.X. Deep Learning Accelerated Design of Mechanically Efficient Architected Materials. ACS Appl. Mater. Interfaces 2023, 15, 22543–22552. [Google Scholar] [CrossRef]

- Beltagui, A.; Sesis, A.; Stylos, N. A bricolage perspective on democratising innovation: The case of 3D printing in makerspaces. Technol. Forecast. Soc. Chang. 2021, 163, 120453. [Google Scholar] [CrossRef]

- Kim, N.P.; Kim, J.; Han, M.S. The convergence of three-dimensional printing and nail-art technology. J. Cosmet. Med. 2019, 3, 94–101. [Google Scholar] [CrossRef] [Green Version]

- Rouf, S.; Raina, A.; Haq, M.I.U.; Naveed, N.; Jeganmohan, S.; Kichloo, A.F. 3D printed parts and mechanical properties: Influencing parameters, sustainability aspects, global market scenario, challenges and applications. Adv. Ind. Eng. Polym. Res. 2022, 5, 143–158. [Google Scholar] [CrossRef]

- Beltagui, A.; Kunz, N.; Gold, S. The role of 3D printing and open design on adoption of socially sustainable supply chain innovation. Int. J. Prod. Econ. 2020, 221, 107462. [Google Scholar] [CrossRef]

- Butt, J. Exploring the interrelationship between additive manufacturing and Industry 4.0. Designs 2020, 4, 13. [Google Scholar] [CrossRef]

- Ashima, R.; Haleem, A.; Bahl, S.; Javaid, M.; Mahla, S.K.; Singh, S. Automation and manufacturing of smart materials in Additive Manufacturing technologies using Internet of Things towards the adoption of Industry 4.0. Mater. Today: Proc. 2021, 45, 5081–5088. [Google Scholar] [CrossRef]

- Nicoloso, L.G.D.V.; Pelz, J.; Barrack, H.; Kuester, F. Towards 3D printing of a monocoque transtibial prosthesis using a bio-inspired design workflow. Rapid Prototyp. J. 2021, 27, 67–80. [Google Scholar] [CrossRef]

- Jaradat, M.; Soliman, E.; Taha, M.R. 3D-printed bio-inspired mechanically interlocked viscoelastic dampers for energy dissipation. Mater. Des. 2023, 228, 111826. [Google Scholar] [CrossRef]

- Verma, S.; Kumar, A.; Lin, S.-C.; Jeng, J.-Y. A bio-inspired design strategy for easy powder removal in powder-bed based additive manufactured lattice structure. Virtual Phys. Prototyp. 2022, 17, 468–488. [Google Scholar] [CrossRef]

- Mehboob, H.; Tarlochan, F.; Mehboob, A.; Chang, S.-H.; Ramesh, S.; Harun, W.S.W.; Kadirgama, K. A novel design, analysis and 3D printing of Ti-6Al-4V alloy bio-inspired porous femoral stem. J. Mater. Sci. Mater. Med. 2020, 31, 78. [Google Scholar] [CrossRef] [PubMed]

- Song, K.; Li, D.; Zhang, C.; Liu, T.; Tang, Y.; Xie, Y.M.; Liao, W. Bio-inspired hierarchical honeycomb metastructures with superior mechanical properties. Compos. Struct. 2023, 304, 116452. [Google Scholar] [CrossRef]

- Hamzehei, R.; Zolfagharian, A.; Dariushi, S.; Bodaghi, M. 3D-printed bio-inspired zero Poisson’s ratio graded metamaterials with high energy absorption performance. Smart Mater. Struct. 2022, 31, 035001. [Google Scholar] [CrossRef]

- Namvar, N.; Moloukzadeh, I.; Zolfagharian, A.; Demoly, F.; Bodaghi, M. Bio-inspired design, modeling, and 3D printing of lattice-based scale model scooter decks. Int. J. Adv. Manuf. Technol. 2023, 126, 2887–2903. [Google Scholar] [CrossRef]

- Soltani, A.; Noroozi, R.; Bodaghi, M.; Zolfagharian, A.; Hedayati, R. 3D printing on-water sports boards with bio-inspired core designs. Polymers 2020, 12, 250. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- De Marzi, A.; Vibrante, M.; Bottin, M.; Franchin, G. Development of robot assisted hybrid additive manufacturing technology for the freeform fabrication of lattice structures. Addit. Manuf. 2023, 66, 103456. [Google Scholar] [CrossRef]

- Feucht, T.; Lange, J.; Erven, M.; Costanzi, C.B.; Knaack, U.; Waldschmitt, B. Additive manufacturing by means of parametric robot programming. Constr. Robot. 2020, 4, 31–48. [Google Scholar] [CrossRef]

- Bhatt, P.M.; Kulkarni, A.; Malhan, R.K.; Gupta, S.K. Optimizing part placement for improving accuracy of robot-based additive manufacturing. In Proceedings of the 2021 IEEE International Conference on Robotics and Automation (ICRA), Xi’an, China, 30 May–5 June 2021; IEEE: Piscataway, NJ, USA; pp. 859–865. [Google Scholar]

- Tiryaki, M.E.; Zhang, X.; Pham, Q.-C. Printing-while-moving: A new paradigm for large-scale robotic 3D Printing. In Proceedings of the 2019 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Macau, China, 3–8 November 2019; pp. 2286–2291. [Google Scholar]

- Shen, H.; Pan, L.; Qian, J. Research on large-scale additive manufacturing based on multi-robot collaboration technology. Addit. Manuf. 2019, 30, 100906. [Google Scholar] [CrossRef]

- Dörfler, K.; Dielemans, G.; Lachmayer, L.; Recker, T.; Raatz, A.; Lowke, D.; Gerke, M. Additive Manufacturing using mobile robots: Opportunities and challenges for building construction. Cem. Concr. Res. 2022, 158, 106772. [Google Scholar] [CrossRef]

- Babu, S.S.; Mourad, A.-H.I.; Harib, K.H.; Vijayavenkataraman, S. Recent developments in the application of machine-learning towards accelerated predictive multiscale design and additive manufacturing. Virtual Phys. Prototyp. 2023, 18, e2141653. [Google Scholar] [CrossRef]

- Jiang, J.; Xiong, Y.; Zhang, Z.; Rosen, D.W. Machine learning integrated design for additive manufacturing. J. Intell. Manuf. 2022, 33, 1073–1086. [Google Scholar] [CrossRef]

- Yadav, D.; Chhabra, D.; Garg, R.K.; Ahlawat, A.; Phogat, A. Optimization of FDM 3D printing process parameters for multi-material using artificial neural network. Mater. Today Proc. 2020, 21, 1583–1591. [Google Scholar] [CrossRef]

- Khan, M.F.; Alam, A.; Siddiqui, M.A.; Alam, M.S.; Rafat, Y.; Salik, N.; Al-Saidan, I. Real-time defect detection in 3D printing using machine learning. Mater. Today Proc. 2021, 42, 521–528. [Google Scholar] [CrossRef]

- Yu, Z.; Thakolkaran, P.; Shea, K.; Stanković, T. Artificial neural network supported design of a lattice-based artificial spinal disc for restoring patient-specific anisotropic behaviors. Comput. Biol. Med. 2023, 152, 106475. [Google Scholar] [CrossRef]

- Goh, G.D.; Sing, S.L.; Lim, Y.F.; Thong, J.L.J.; Peh, Z.K.; Mogali, S.R.; Yeong, W.Y. Machine learning for 3D printed multi-materials tissue-mimicking anatomical models. Mater. Des. 2021, 211, 110125. [Google Scholar] [CrossRef]

- Ong, J.J.; Castro, B.M.; Gaisford, S.; Cabalar, P.; Basit, A.W.; Pérez, G.; Goyanes, A. Accelerating 3D printing of pharmaceutical products using machine learning. Int. J. Pharm. X 2022, 4, 100120. [Google Scholar] [CrossRef]

| Area | Applications | Materials | Processes | References |

|---|---|---|---|---|

| Aerospace | Aircraft, UAVs, air ducts, wings, turbocharger blades, spare parts, prototyping, and rapid tooling | PLA, ABS, PET, nylon, carbon fiber, steel, titanium, and custom resins | FDM, SLS, DMLS, and SLA | [95,100,101,102,103] |

| Aerospace | Microsatellites, heat shields, magnetic shields, and spacecrafts | PEEK, PEKK, PEI, polyamide, carbon fiber, AlSi10Mg, and molybdenum | FDM, SLM, and DMLS | [104] |

| Aerospace | Lunar and Martian habitats | Sulfur, magnetite aggregate, silica sand, regolith, and geopolymer composites | Extrusion, powder jetting/fusion, and vat polymerization | [105,106] |

| Automotive | Steering wheel, suspension arm, interior elements, drawing tools, and replacement parts | PLA, ABS, metal powders, and composites | FDM and metal powder printing | [96,107,108,109,110,111] |

| Construction | Bridges, walls, houses, girders, joints, and stiffeners | Concrete, cob, polymer-foam, glass fibers, geopolymers, and metals | Large-scale extrusion, robotic printing, and wire and arc | [97,112,113,114,115,116,117,118] |

| Food | Health treatment, weight loss, consumer appeal, and sustainable food production | Cereals, fruits, vegetables, chocolate, marzipan, meats, dairy, gels, and insects | Extrusion and powder binding | [98,119,120,121,122,123,124] |

| Medical | Prosthetics, medical devices, footwear, implants, orthopedics, and prototyping | PLA, TPU, PETG, carbon fiber, nylon, and stainless steel | FDM, SLA, and PBF | [13,125,126,128] |

| Medical | Tissue scaffolds and interbody spinal cages | PLA, PCL, PEEK, TCP, methacrylates, titanium, biomaterials, and living cells | Extrusion, SLA, DLP, and SLS | [129,130,131,132] |

| Robotics | Soft robotics and actuators | ABS, silicone, polyurethane, hydrogels, nylon, varied elastomers, smart composites | FDM, SLA, inkjet, SLS, Multi-material processes, light-scanning gel printer | [99,133,134,137] |

| Robotics | Surgical robots and robotic prosthetics | PLA, ABS, PVA, TPU, methacrylates, polymer resins, multi-material, and metal paste | FDM, SLS, SLA, inkjet, and multijet | [135,136] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Egan, P.F. Design for Additive Manufacturing: Recent Innovations and Future Directions. Designs 2023, 7, 83. https://doi.org/10.3390/designs7040083

Egan PF. Design for Additive Manufacturing: Recent Innovations and Future Directions. Designs. 2023; 7(4):83. https://doi.org/10.3390/designs7040083

Chicago/Turabian StyleEgan, Paul F. 2023. "Design for Additive Manufacturing: Recent Innovations and Future Directions" Designs 7, no. 4: 83. https://doi.org/10.3390/designs7040083

APA StyleEgan, P. F. (2023). Design for Additive Manufacturing: Recent Innovations and Future Directions. Designs, 7(4), 83. https://doi.org/10.3390/designs7040083