Developing Pavement Marking Management Systems: A Theoretical Model Framework Based on the Experiences of the US Transportation Agencies

Abstract

:1. Introduction

2. Fundamentals and Core Concepts

- Have enough flexibility for being applied to both existing and future assets.

- Allow the integration of decision-making across asset classes. For example, enable agencies to accommodate pavement marking needs in pavement construction plans.

- Account for new construction, reconstruction, maintenance, and rehabilitation.

- Be feasible and easy to implement for adopting agencies while economically attractive to transportation stakeholders.

- Be policy-driven, which means a systematic and unambiguous body of policy goals and objectives is in place to support decision-making.

- Be performance-based, which means involving measurable parameters that indicate the outcome of the AMS implementation, and the difference made by AMS implementation can be quantified (compared to non-systematic or existing pavement management methods).

- Incorporate customer/user expectation and needs in policymaking and enable collecting feedback from users, staff, operators, and contractors.

- Enable performance monitoring.

- Have clear data quality assurance procedures.

3. Discussions

3.1. Establishing Performance Measures and Targets Specific to Pavement Markings

3.1.1. Identifying Principal Performance Measures

- Connecting policies to objectives. In other words, representing the outcome rather than output.

- Reflecting long-term characteristics of assets and thus can be incorporated in life-cycle analyses and performance models.

- Being sensitive to the source of change, i.e., a variation in the measure can be traced back to its cause.

- Involving a reasonable amount of effort to obtain. The number of parameters should be kept under control to avoid excessive variability in the data and make it too difficult to collect the required data.

- Being easy-to-understand, objective, and quantifiable.

- Applicability in condition/performance prediction models. For this, the parameter or measures should describe the asset condition or performance level, can be predicted by mathematical models, and can be age/time-dependent.

- Being possible to be estimated or predicted by professional judgment.

- Having wide acceptance among professionals.

- Compatibility with existing resources.

- Measurability with reasonable accuracy and precision.

- Reflecting user experience.

- Consistency of interpretation.

- A benefit-to-cost ratio greater than 1.

- Compatibility with standards and specifications.

- Involving reliable data collection practices.

- Representing controllable characteristics of assets.

- Versatility. A measure that applies to more than one asset or serves different purposes would be more desirable than those limited to only one asset or provide only one type of information.

- Glass beads

- ▪

- Material (e.g., glass, PMMA, VisiBeads™, or other)

- ▪

- Amount and dispersion

- ▪

- Embedment depth [percentage of bead diameter]

- ▪

- Refractive index

- ▪

- Size type. Size types I and II are described by AASHTO and larger types III, IV, and V are described by the FHWA, which has given gradations for them. Type I is the smallest and most common bead. Larger beads improve wet-night visibility by standing higher than water level.

- ▪

- Clarity

- ▪

- Roundness

- Binder material

- ▪

- Color. Yellow markings have retroreflectivity equivalent to 70–80% of white markings.

- ▪

- Type/material, that includes waterborne, durable waterborne, thermoplastic, epoxy, polyurea, or tape.

- ▪

- Thickness

- Other factors

- ▪

- Pavement surface roughness

- ▪

- Dirt or other blinding materials

- ▪

- Marking level (recessed, surface, elevated)

- Materials costs.

- Cost of pre-striping pavement preparations such as grooving, removing of existing markings, and cleaning.

- Direct cost of installation operations.

- Costs imposed by special requirements or conditions.

- Administrative costs.

- Organizational costs.

- Costs related to societal effects of pavement markings and striping operations:

- ▪

- Traffic delay costs

- ▪

- Costs of accidents/crashes caused by striping operations

- ▪

- Costs associated with reduced road safety due to degraded or poor marking performance.

- Environmental life cycle assessment of materials that also reflects environmental impacts relative to a material’s effective service life.

- Materials toxicity and any health hazards they may pose to workers and the public during transportation, handling, storage, installation, service, and removal. This includes toxic fume, hazardous chemicals, and particulate matter [2].

- Environmental impacts of installation, maintenance, and removal (eradication) operations [2].

3.1.2. Performance Targets

- Subjective Evaluations, where drivers are asked to evaluate pavement markings while they drive on a given road.

- Objective Evaluations, where drivers are asked to detect pavement markings of varying retroreflectivity levels while driving on a given road.

- Visibility Models, which are methods of using computer software to predict necessary levels of retroreflectivity based on actual data.

- Driver-related factors (each of which often declines with driver’s age):

- ▪

- Visual capabilities

- ▪

- Cognitive processing capabilities

- ▪

- Motor skills

- Roadway-related factors:

- ▪

- Speed of the vehicle

- ▪

- Presence of continuous roadway lighting

- ▪

- Presence of retroreflective raised pavement markers

- ▪

- Color of the marking.

- Budgeting plans and available funding.

- Policy goals, statewide priorities, or priorities by route classification.

- Inputs from other organizations/states, public, or relevant authorities at local, state, and national levels.

- Current condition.

- Existing (measured) or projected performance data.

- Discussions with the construction industry.

- Life-cycle cost analyses, tradeoff analyses, and estimates of the marginal value of the additional investment.

- Determine the time span that the target covers. Is it short-term, mid-term, or long-term? Is there an exact time window for it? It is of substantial importance in PMMS that material characteristics are used as the basis of estimation at this step. Performance targets, if tied to age, should be defined differently for durable and regular pavement markings.

- Define the context of the target, i.e., the process or policy items that the target is tied to. For example, is it a part of the budgeting process or a part of a plan to fulfill the enforced financial reporting requirements?

- Based on the target context, choose the performance measures that should be included in the target setting. At this step, only those quantitative measures (not qualitative ones) should be used for which enough baseline and trend data, and prediction tools/methods are available. NCHRP report 551 recommends labeling performance measures as “mature” for which baseline data and targets exist, “emerging” for which baseline data are available but no target has been set, and “developmental” for which neither data nor targets exist yet.

- Investigate driver needs with respect to the selected measures. To this end, inquire input from experts and stakeholders.

- Develop performance targets considering:

- Driver needs—meeting driver needs over the entire service life is all that PMMS is about, and thus, it takes the highest level of priority.

- Financials and policies—typically, funding/resource availability and agency policies govern how conservative the targets are. For example, agencies may opt to take less conservative measures upon facing financial limitations.

- Projected performance—consider predicted scenarios when setting performance targets. In other words, utilize the prediction of what will happen under different scenarios to determine realistic targets.

- Monitor the progress of the agency toward achieving the targets using the performance measures.

3.2. Planning and Scheduling Pavement Marking Operations

- (a)

- Determining when the markings on a certain road or road segment need to be rehabilitated. This can be accomplished through:

- (a-I)

- visual inspection and inquiring input from the agency’s staff.

- (a-II)

- quantitative measurements of selected performance measures, particularly retroreflectivity, in certain cycles. In this stage, comparing results against performance targets is the basis of decision-making.

- (a-III)

- taking advantage of service life predicting models (if applicable). According to Abboud and Bowman [43] predictive pavement marking operation scheduling should account for application cost, service life as a variable of material characteristics and ADT, user cost imposed by crashes during service life traffic disturbance by installation and maintenance operations, and unexpected events affecting schedules.

- (b)

- Zoning the agency’s jurisdiction area based on pavement marking deterioration risk.

- (c)

- Prioritizing projects location-wise by their respective deterioration risk zone.

3.3. Developing Consistent Processes for Acquisition of Goods and Services

- Target drives the budget.

- Budget drives the target.

- Percent of inventory annually: budget is recommended as required to address a given percentage of inventory every year.

- Judgment politics: budget is driven by agency officials’ judgment and political/societal priorities.

- No specific approach: a tiny percentage of participating agencies (<5%) did not use any specific approach for this purpose.

- Percent of the total budget: a certain percent of the total budget is allocated to pavement markings. This approach was found to be the second least popular method, being second only to the no-specific-approach.

- Preferably, merge as many projects as possible under one work plan performed under one contract. The cost-effectiveness of the project is improved with the amount of work involved [3]. In addition, multi-agency contracts are an excellent option to entitle smaller agencies with the benefits of large-quantity pricing, consistent material and installation specifications, and easier contracting or dispute resolution [19].

- Most agencies use a different name for their line items, which are not necessarily the same as those used by contractors. As a result, contractors may provide items that deviate from what the agency has requested [2]. Therefore, it is recommended to include descriptions of essential items in the bid documents.

- A procedure should be in place to monitor the value of contractors’ work, particularly in the absence of time stipulation in contracts. Texas DOT’s study on performance-based pavement marking maintenance contracts (PBPMMC) on two case study projects in San Antonio and Dallas [31,44] showed that under both contracts, the value of work done by the contractors was less than what they were compensated. Agencies may define a dynamic, contractor work monitoring task that keeps track of the number of projects done by contractors under each type of contract during the entire length of the contract. The results can serve two purposes: (1) determining which contract type (see Figure 4) provides the highest efficiency and value, and (2) determine if and when timing stipulations need to be involved in contracts (for example, specifying the number of projects that need to be done in different time periods).

3.4. Developing Consistent Procedures for Material Selection and Application

- (a)

- Type of striping operation: new construction or restriping

- (b)

- Type of marking by function (centerline, edge, crosswalk, etc.) and alignment (longitudinal, transverse, text, or symbol)

- (c)

- Type of pavement or underlying marking: Different pavement types with respect to influence on marking performance are [14]:

- Different variations of Hot mix asphalt (HMA) pavement

- Different variations of Hydraulic cement concrete (HCC)

- Open-graded bituminous pavements (surface treatment, seal-coat, chip seal, Otta seal, and the like).

- (d)

- Condition of pavement: Condition at the time of marking installation affects the bond between the marking and the surface and influences the marking durability performance [28]. Surface characteristics of pavement that affecting marking performance include [14] roughness, heat sensitivity, porosity, distress (such as cracks, spalling, scaling, etc.), and cleanness.

- (e)

- Remaining pavement service life

- (f)

- Traffic characteristics: this primarily involves traffic volume -Average Daily Traffic (ADT)-. Nevertheless, the type of vehicles and average speed may also be considered if they are not included in the route characteristics.

- (g)

- Environmental conditions and/or geographic zone—see Section 3.1 for information about factors that must be considered regarding environmental conditions and geographic location.

- (h)

- Marking level: whether it is recessed or surface-applied and its intended thickness.

- (i)

- Route characteristics:

- Road classification—this can be expressed as the road hierarchy or the number of lanes.

- Traffic speed class.

- Area class—whether it is rural, urban, or interstate.

3.5. Establishing Inspection Guidelines

- Variations caused by data collection practice and schedule:

- ▪

- Timing of data collection (frequency and season)

- ▪

- Inconsistent measurement practices

- ▪

- Variations in speed while collecting data, both for the mobile retroreflectometer and the water truck (if used for washing)

- ▪

- Different environmental conditions on data collection trips

- ▪

- Lack of guidelines for equipment usage under various environmental conditions.

- Equipment-related variations:

- ▪

- Low accuracy and inherent variability of mobile retroreflectometer

- ▪

- Device miscalibration

- ▪

- Change in the geometry of the mobile retroreflectometer when going around horizontal curves.

- Variations originated from marking characteristics:

- ▪

- Changes in application methods by different striping crews that causes inherent variation in marking characteristics

- ▪

- Dust and dirt buildup on the road combined with the cleaning effects of rain.

- Developing standards for marking application equipment and practices

- Developing standard protocols for marking condition assessment and performance evaluation equipment and practices. This includes specifying sampling frequency and sample size or—at least—the method for determining sample size. For example, the Iowa DOT’s protocol for a handheld retroreflectivity measurement device has specified the sampling frequency, measurement locations, number of readings at each site, and measurement instructions for different types of markings (in terms of function, e.g., dash lines, centerlines, crosswalks, edge lines, etc.) [3].

- Providing guidelines for equipment and material usage according to environmental conditions.

- Installation log (see Section 3.7.3 for more information)

- In-installation inspection record (more discussion can be found in [14])

- Post-installation quality control inspection record

- Complete record of post-installation condition assessments.

3.6. Managing Durable Pavement Markings

- Durable marking installation is adequately tracked and recorded into the database.

- Unplanned/premature repainting over durable markings is avoided.

- The performance of durable markings is monitored.

- Durable marking maintenance operations are efficiently planned.

- The application of durable pavement markings is promoted.

3.7. Data Management and Analysis

3.7.1. Developing a Comprehensive Data Management Platform

- Asset inventory containing type, number, condition, and location of assets.

- Database of time-stamped condition and performance levels of inventory assets.

- Condition and performance prediction models. Using performance models, the agency should be able to:

- Predict performance levels based on different installation and operation scenarios, which, at minimum, encompass material types, installation methods, pavement type, winter maintenance operations, environmental conditions, and traffic characteristics.

- Translate the modeling results into costs and investments in order to use them as decision-making tools.

- Determine future asset deployment, procurement, or maintenance needs for operation and investment planning.

- Performance targets and repair thresholds.

- Cost estimation models capable of estimating the benefit-to-cost ratio of given repair/investment scenarios.

- Consistent and effective data quality management procedures.

3.7.2. PMMS Database and Data Integration

- Pavement marking inventory—a database (e.g., a relational database) containing all pavement marking attributes required for implementing PMMS. If the inventory is developed according to suggestions of this guideline, it contains all required data items. Otherwise, it should be assured that the PMMS database includes—at least—the pavement marking performance prediction models.

- Road network attributes—non-spatial road data such as traffic volume, location, speed limit, pavement type, number of lanes, and hierarchical level. This can be established by linking the database to the agency’s road characteristics inventory (RCI).

- Spatial model of the road network—typically a GIS database containing all necessary topological and geometric features of the road, as seen in Figure 6. The location-referenced data in the PMMS database can be projected on road network’s spatial model.

- Available funds, costs, and budgeting information.

- Climatic information related to winter maintenance operations—typically consisting of precipitation data such as average monthly and annual snowfall and normal snowfall (30-year average). The dynamic, GPS-based record of winter maintenance operations is an additional dataset that can be used to monitor damage likelihood in different locations.

- Road maintenance and repair data—customarily, the non-spatial data integrated under the maintenance management system (MMS).

3.7.3. Pavement Marking Asset Inventory

- Date

- Road identification and location

- Line types

- Start and stop time of the operation

- Unpredicted incidents (machinery malfunctions, abnormal performance, crew injury, accidents, etc.)

- Conversations

- Commercial information of the materials used (manufacturer, trade name, product code, etc.)

- Quantity of materials used

- Inspection record (As given in pre-installation/installation inspections” and the above table)

- Bead loading [during paint installation] (lbs of bead per gallon of paint) and Glass bead application rate

- Wet thickness [immediately after paint installation]

- Application speed of the truck that sprays the paint

- Lane closure or traffic control information (related to motorists delay and the associated costs of road closure)

3.7.4. Location Referencing

3.7.5. Pavement Marking Service Life Prediction

3.7.6. Developing IT Tools to Facilitate Different PMMS Activities

3.7.7. Integrating PMMS Database with Other AM Systems

- Optimizing the format of striping logs—which are typically automatically collected from DOT trucks [17]—for incorporation into the databases or the tools that perform data integration.

- Using a GPS-based location referencing system integrated with the GIS database as discussed in Section 3.7.4.

4. Summary of Results

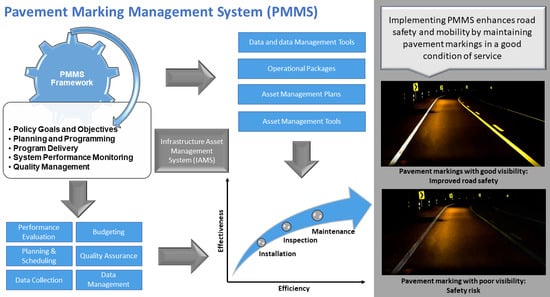

- A general PMMS framework consists of five main building blocks to address (1) policy goals and objectives, (2) planning and programming, (3) program delivery, (4) system performance monitoring, and (5) quality management system, which oversees all the other four blocks. Each block consists of multiple elements that consist of asset management plans, processes, operations, data items, policies, standards, contracts, tools, and databases.

- In addition to the existing cross-asset performance measures, such as the percentage of assets in good condition of service, this paper recommends five asset-specific performance measures for PMMS application: presence, retroreflectivity, durability, cost, and environmental impact. Retroreflectivity is an essential performance measure all PMMSs should consider. Any composite performance measures are better to be derivatives or combinations of these measures.

- This paper acknowledges that the most immediate way of establishing performance targets for pavement markings is defining retroreflectivity thresholds. In the USA, retroreflectivity limits set by FHWA in Section 3A.03 of the MUTCD are the specifications to follow. However, it is recommended to continue research on the driver’s need for visual information, including retroreflectivity.

- The PMMS framework encompasses data-driven strategies for project selection, budgeting, acquisition of goods and services, and contracting.

- A critical function of PMMS to regulate contracts is defining the mechanism to oversee the acceptability of acquired products or services; this involves quality control and quality assurance processes and the specifications associated with them.

- Developing a pavement marking application matrix is the recommended approach to selecting materials.

- Inspection activities begin before the pavement marking installation and continue through the marking’s service life. The intervals of condition assessment inspections shall be shortened toward the end of the service life.

- A PMMS should contain appropriate measures to ensure that durable marking installations are adequately tracked, performance models are modified to address durable markings, and rehabilitation/restriping of durable markings are carefully scheduled.

- The data management component of PMMS must ensure that the data possess (1) positional accuracy, (2) attribute accuracy, (3) data lineage, (4) completeness, (5) consistency, and (6) appropriate data format. Once desirable data quality is achieved, the key activity is to select a suitable data structure or model for storing, processing, visualizing, and sharing the data.

- The inventorying approach that best suits PMMS applications involves using a centralized asset inventory merged with the condition database. Minimum items covered by asset inventory are asset identification, location referencing, material description, site description, and asset quality.

- A useful strategy to enable data integration and facilitate asset positioning is establishing a GPS-based location referencing system integrated with the GIS database.

- Performance prediction in PMMS is equivalent to predicting retroreflectivity over time. To this end, marking deterioration curves are developed considering appropriate variables. This paper recommends giving a higher weight to winter maintenance operations in the performance prediction models.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Markow, M.J. Current asset management practices applied to pavement markings. Transp. Res. Rec. 2008, 78–86. [Google Scholar] [CrossRef]

- Carlson, P.; Park, E.-S.; Pike, A.; Porter, R.J.; Miles, J.; Boulanger, B.; Smadi, O.; Hawkins, N.; Chalmers, S.; Darmiento, F.; et al. Pavement Marking Demonstration Projects: State of Alaska and State of Tennessee; No. FHWA-HRT-12-048; United States Federal Highway Administration, Office of Safety Research and Development: McLean, VA, USA, 2013.

- Hawkins, N.R.; Smadi, O.G.; Hans, Z.N. Planning, Developing, and Implementing the Iowa Pavement Marking Management System (IPMMS): Phases I and II; Center for Transportation Research and Education, Iowa State University: Ames, IA, USA, 2006. [Google Scholar]

- Rasdorf, W.; Hummer, J.E.; Harris, E.A.; Sitzabee, W.E. IT Issues for the Management of High-Quantity, Low-Cost Assets. J. Comput. Civ. Eng. 2009, 23, 91–99. [Google Scholar] [CrossRef]

- Akofio-Sowah, M.A.; Boadi, R.; Amekudz, A.; Meyer, M. Managing ancillary transportation assets: The state of the practice. J. Infrastruct. Syst. 2014, 20, 1–8. [Google Scholar] [CrossRef]

- Markow, M.J. NCHRP Synthesis 371-Managing Selected Transportation Assets: Signals, Lighting, Signs, Pavement Markings, Culverts, and Sidewalks; National Academies of Sciences, Engineering, and Medicine: Washington, DC, USA, 2007. [Google Scholar] [CrossRef]

- Choubane, B.; Sevearance, J.; Holzschuher, C.; Fletcher, J.; Wang, C.(R.). Development and Implementation of a Pavement Marking Management System in Florida. Transp. Res. Rec. 2018, 2672, 209–219. [Google Scholar] [CrossRef]

- Choubane, B. Leveraging Technology to Develop and Implement a Pavement Marking Management System in Florida; Number 317; Transportation Research Board of the National Academies of Science Engineering and Medicine: Washington, DC, USA, 2018; pp. 48–50. [Google Scholar]

- Hawkins, N.; Smadi, O.; Knickerbocker, S.; Pike, A.; Carlson, P. Evaluating All-Weather Pavement Markings in Illinois: Volume 1; Research Report No. FHWA-ICT-15-018; United States Federal Highway Administration: Ames, IA, USA, 2015.

- Federal Highway Administration. National Standards for Traffic Control Devices; the Manual on Uniform Traffic Control Devices for Streets and Highways; United States Federal Highway Administration: Washington, DC, USA, 2009.

- Migletz, J.; Fish, J.K.; Graham, J.L. Roadway Delineation Practices Handbook; No. FHWA-SA-93-001; United States Federal Highway Administration: Washington, DC, USA, 1994.

- Grant, A.R.; Bloomfield, J.R. Guidelines for the Use of Raised Pavement Markers; United States Federal Highway Administration, Office of Safety Research and Development: McLean, VA, USA, 1998.

- Turner, S.M.; Carlson, P.J. Pedestrian Crossing Guidelines for Texas; No. FHWA/TX-01/2136-2; Texas Department of Transportation: Austin, TX, USA, 2000.

- Lopez, C.A. Pavement Marking Handbook; Texas Department of Transportation: Austin, TX, USA, 2004.

- Chacon, M.A. Sign Guidelines and Applications Manual; Texas Department of Transportation: Austin, TX, USA, 2020.

- Zhang, Y. Pavement Marking Management System Database; 0-5548-P1; Texas Transportation Institute, The Texas A&M University System: College Station, TX, USA, 1999. [Google Scholar]

- Smadi, O. Putting Research into Practice: Pavement Marking Management Tool; Minnesota Department of Transportation: St. Paul, MN, USA, 2013.

- Hawkins, N.; Smadi, O. Developing and Implementing Enhanced Pavement Marking Management Tools: Phase I—Mapping Tool; Minnesota Department of Transportation: St. Paul, MN, USA, 2008.

- Hawkins, N.; Smadi, O. Local Agency Pavement Marking Plan; No. IHRB Project TR-55; Iowa Highway Research Board: Ames, IA, USA, 2010.

- Hawkins, N.; Smadi, O.; Hans, Z.; Maze, T.H. Integrated approach to pavement marking management. Transp. Res. Rec. 2006, 99–107. [Google Scholar] [CrossRef]

- Pavement Marking Manual; Wyoming Department of Transportation: Cheyenne, WY, USA, 2012. Available online: http://www.dot.state.wy.us/files/live/sites/wydot/files/shared/Traffic%20data/Pavement%20Marking%20Manual.pdf (accessed on 10 November 2020).

- Guideline for the Installation of Crosswalk Markings and Pedestrian Signing at Marked and Unmarked Crossings; Vermont Agency of Transportation: Montpelier, VT, USA, 2004. Available online: https://casetext.com/regulation/vermont-administrative-code/agency-14-agency-of-transportation/subagency-010-transportation-board/chapter-018-guideline-for-the-installation-of-crosswalk-markings-and-pedestrian-signs-at-marked-and-unmarked-crossings (accessed on 10 November 2020).

- Uddin, W.; Hudson, W.R.; Haas, R.C. Public Infrastructure Asset Management, 2nd ed.; McGraw-Hill Education: New York, NY, USA, 2013. [Google Scholar]

- Gordon, M.; Smith, G.J.; Thompson, P.D.; Park, H.A.; Harrison, F.; Elston, B. AASHTO Transportation Asset Management Guide—A Focus on Implementation; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2013. [Google Scholar]

- NCHRP Report 632: An Asset-Management Framework for the Interstate Highway System; The National Academies Press: Washington, DC, USA, 2009; Available online: https://www.nap.edu/catalog/14233/an-asset-management-framework-for-the-interstate-highway-system (accessed on 10 November 2020). [CrossRef]

- Vanier, D.J. Advanced Asset Management: Tools and Techniques; Innovations in Urban Infrastructure Seminar; American Public Works Association (APWA): Kansas City, MO, USA, 2000; pp. 39–56. [Google Scholar]

- NCHRP 551: Performance Measures and Targets for Transportation Asset Management; The National Academies Press: Washington, DC, USA, 2006. Available online: https://www.trb.org/publications/nchrp/nchrp_rpt_551.pdf (accessed on 10 November 2020).

- Morse, K.; Armstrong, K. Pavement Marking Selection, Installation and Inspection Manual; Illinois Department of Transportation Bureau of Materials and Physical Research Bureau of Operations: Springfield, IL, USA, 2015. Available online: https://idot.illinois.gov/Assets/uploads/files/Doing-Business/Manuals-Guides-&-Handbooks/Highways/Operations/Pavement%20Marking%20Selection,%20Installation%20and%20Inspection%20Manual.pdf (accessed on 10 November 2020).

- Transportation Research Circular E-C098: Maintenance Management; Transportation Research Board of the National Academies of Science Engineering and Medicine: Washington, DC, USA, 2006. Available online: http://onlinepubs.trb.org/onlinepubs/circulars/ec098.pdf (accessed on 10 November 2020).

- Martin, P.; Perrin, J.; Jitprasithsiri, S.; Hansen, B. A Comparative Analysis of the Alternative Pavement Marking Materials for the State of Utah; Salt Lake City, UT, USA, 1990. Available online: http://www.trafficlab.utah.edu/research/projects/current/acrobat/UDOTfin.pdf (accessed on 10 November 2020).

- Pike, A.; Songchitruksa, P.; Geedipally, S.; Kang, D.; Damnjanovic, I. Evaluating the Effectiveness of Performance Based Pavement Marking Maintenance Contracts; Texas, Report No. FHWA/TX-14/0-6705-1; Texas Department of Transportation: Austin, TX, USA, 2014.

- Parker, N.A.; Meja, M.S.J. Evaluation of Performance of Permanent Pavement Markings. Transp. Res. Rec. 2003, 123–132. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, X.; Lin, H.; Gui, R.; Cao, M.; He, L. Automatic road-marking detection and measurement from laser-scanning 3D profile data. Autom. Constr. 2019, 108. [Google Scholar] [CrossRef]

- Alyami, Z.; Tighe, S.L. A methodology for integrating asset valuation in transportation asset management. In Proceedings of the 11th International Transportation Specialty Conference at the Canadian Society of Civil Engineers CSCE, London, ON, Canada, 1–4 June 2016. [Google Scholar]

- Pike, A.M.; Bommanayakanahalli, B. Development of a Pavement Marking Life Cycle Cost Tool. Transp. Res. Rec. 2018, 2672, 148–157. [Google Scholar] [CrossRef] [Green Version]

- Lundkvist, S.-O.; Johansen, T.C. Road Marking Management System; The Swedish National Road and Transport Research Institute (VTI): Linköping, Sweden, 2009.

- National Volatile Organic Compound Emission Standards for Architectural Coatings–Background for Promulgated Standards; United States Environmental Protection Agency (US EPA): Chicago, IL, USA, 1998. Available online: https://www.federalregister.gov/documents/2008/03/24/E8-5589/national-volatile-organic-compound-emission-standards-for-aerosol-coatings (accessed on 10 November 2020).

- Rasdorf, W.J.; Hummer, J.E.; Zhang, G.; Sitzabee, W.E. Pavement Marking Performance Analysis; North Carolina Department of Transportation: Raleigh, NC, USA, 2009.

- Andrady, A.L. Pavement Marking Materials: Assessing Environment-Friendly Performance; NCHRP Report 392; National Academy Press: Washington, DC, USA, 1997. [Google Scholar]

- Schnell, T.; Zwahlen, H.T. Computer-Based Modeling to Determine the Visibility and Minimum Retroreflectivity of Pavement Markings. Transp. Res. Rec. 2000, 47–60. [Google Scholar] [CrossRef]

- Saetern, L.T. Commercial Pavement Marking Management Systems; California Department of Transportation (Caltrans): Sacramento, CA, USA, 2016.

- Loetterle, F.E.; Beck, R.A.; Carlson, J. Public perception of pavement-marking brightness. Transp. Res. Rec. J. Transp. Res. Board. 2000, 1715, 51–59. [Google Scholar] [CrossRef]

- Abboud, N.; Bowman, B.L. Cost-and longevity-based scheduling of paint and thermoplastic striping. Transp. Res. Rec. 2002, 55–64. [Google Scholar] [CrossRef]

- Damnjanovic, I.; Pike, A.; Martinez, E. Analysis of Performance-Based Pavement Markings and Markers Contracts: Case Study from San Antonio. J. Manag. Eng. 2018, 34, 1–10. [Google Scholar] [CrossRef]

- Thomas, G.B.; Schloz, C. Durable, Cost-Effective Pavement Markings. Phase I: Synthesis of Current Research; Ames, IA, USA, 2001. Available online: http://publications.iowa.gov/13585/1/pavemark.pdf (accessed on 10 November 2020).

- Rich, M.J.; Maki, R.E.; Morena, J. Development of a pavement marking management system: Measurement of glass sphere loading in retroreflective pavement paints. Transp. Res. Rec. 2002, 49–54. [Google Scholar] [CrossRef]

- Sitzabee, W.E.; Rasdorf, W.; Hummer, J.E.; Devine, H.A. Data Integration of Pavement Markings: A Case in Transportation Asset Management. J. Comput. Civ. Eng. 2009, 23, 288–298. [Google Scholar] [CrossRef]

- Rasdorf, W.; Cai, H.; Tilley, C.; Brun, S.; Karimi, H.; Robson, F. Transportation distance measurement data quality. J. Comput. Civ. Eng. 2003, 17, 75–87. [Google Scholar] [CrossRef]

- Cunningham, C.M.; Findley, D.J.; Hovey, K.; Foley, P.B.; Smith, J.; Fowler, T.; Chang, J.; Arnold, J.; Hummer, J.E. Improved asset management and inventory development through sample analysis and vendor-client communication. J. Infrastruct. Syst. 2016, 22, 1–16. [Google Scholar] [CrossRef]

- Longley, P.A.; Goodchild, M.F.; Maguire, D.J.; Rhind, D.W. Geographic Information Science and Systems, 4th ed.; Wiley: London, UK, 2015. [Google Scholar]

- Zhang, Y. User’s Guide: Pavement Marking Management System Database; Texas Transportation Institute, The Texas A&M University System: College Station, TX, USA, 2011. [Google Scholar]

- Sasidharan, L.; Karwa, V.; Donnell, E.T. Use of pavement marking degradation models to develop a pavement marking management system. Public Work. Manag. Policy 2009, 14, 148–173. [Google Scholar] [CrossRef]

- Bektas, B.A.; Gkritza, K.; Smadi, O. Pavement Marking Retroreflectivity and Crash Frequency: Segmentation, line type, and imputation effects. J. Transp. Eng. 2016, 142, 04016030. [Google Scholar] [CrossRef]

- Ozelim, L.; Turochy, R.E. Modeling retroreflectivity performance of thermoplastic pavement markings in Alabama. J. Transp. Eng. 2014, 140, 1–6. [Google Scholar] [CrossRef]

- Karwa, V.; Donnell, E.T. Predicting pavement marking retroreflectivity using artificial neural networks: Exploratory analysis. J. Transp. Eng. 2010, 137, 91–103. [Google Scholar] [CrossRef]

- Migletz, J.; Graham, J.L.; Harwood, D.W.; Bauer, K.M. Service life of durable pavement markings. Transp. Res. Rec. J. Transp. Res. Board. 2002, 1749, 13–21. [Google Scholar] [CrossRef]

- Kopf, J. Reflectivity of Pavement Markings: Analysis of Retroreflectivity Degradation Curves; No. WA-RD 592.1; Washington State Department of Transportation: Olympia, WA, USA, 2004.

- Barri, K.; Jahangiri, B.; Davami, O.; Buttlar, W.G.; Alavi, A.H. Smartphone-based molecular sensing for advanced characterization of asphalt concrete materials. Measurement 2020, 151, 107212. [Google Scholar] [CrossRef]

- NCHRP Report 545: Analytical Tools for Asset Management; The National Academies Press: Washington, DC, USA, 2005; Available online: https://www.nap.edu/catalog/13851/analytical-tools-for-asset-management (accessed on 10 November 2020). [CrossRef]

| Road Category | Speed Limit (mph) | ||

| ≤30 | 35–50 | ≥50 | |

| Minimum Retroreflectivity Measured acc. to Standard (mcd/m2/lux) | |||

| Two-lane roads with centerline markings only | N/A | 100 | 250 |

| All other roads | N/A | 50 | 100 |

| Scope | Task | Controlling Ellement (in the PMMS) | Data Items or Factors | ||

|---|---|---|---|---|---|

| General | Approving the materials | Standards and specs | Physical and chemical properties | ||

| Performance targets | Performance measures | ||||

| Policy goals | Performance measures | ||||

| Project | Selecting the materials and application methods |

| Remaining service life of pavement | ||

| Environmental conditions | |||||

| Type of operation |

| ||||

| Type of marking |

| ||||

| Traffic characteristics |

| ||||

| Route characteristics |

| ||||

| Underlying surface | Pavement or pre-existing marking:

| ||||

| Pre-Installation | Environment and Road Conditions | Logistics and Operations |

|

| |

| In-Installation | Quality Assurance (Procedure Monitoring) | Quality Control of Markings |

|

| |

| Post-Installation | Inspection Immediately After Installation: Quality Control | Periodic Inspection During Service Life: Condition Assessment |

|

|

| # | Inventory Component | Data Items | Typical Data Type |

|---|---|---|---|

| 1 | Asset ID | Type of Marking 1, Project Name, Operator/Contractor Name | Text 2 |

| Installation Date and Time | Number (Date/Time) | ||

| 2 | Location Referencing | Road ID, Coordinates in the Location Referencing System (GPS/LRS) | Number |

| District, County, Route, MileSpot | Text/Number | ||

| 3 | Material Description | Product Commercial Name, Manufacturer Name, Material Type 1, Installation Method 1 | Text |

| Product ID, Manufacturer ID | Number/Text | ||

| Technical Datasheets and SDSs | Text/Link or File Attachment | ||

| 4 | Site Description | Installation Length, Location Reference of Installation Start–End Points, Traffic Volume (ADT), Speed Limit, Pavement Age, Truck Percentage | Number |

| Road ID, Surface Type 1, Surface Condition | Text | ||

| 5 | Quality | Current condition and performance level categorized as per performance measures and targets, Qualitative Measures | Text and/or Link to Inspections Database 3 |

| Quantitative Measures | Number/Link to Database | ||

| Condition Indicator | Text/Number | ||

| 6 | Performance Measures | Defined or Selected Performance Measures | Text |

| 7 | Performance Targets | Defined or Adopted Performance Targets corresponding to Each Performance Measure | Text and Number |

| 8 | Minimum Standards | Controlling Standards | Text/File Attachments/Links |

| Minimum Acceptable Condition as per Qualitative Measures | Text | ||

| Minimum Standard Values for Quantitative Performance Measures | Number | ||

| 9 | Projected Performance | Life Cycle Prediction | Number/Image/Link to IT Tool or Database |

| Projected rehabilitation or replacement schedule | Number (Date/Time) | ||

| 10 | Marking Application Records | Installation and/or Rehabilitation Operation Logs 1 | Text/Link or File Attachment |

| 11 | Winter Maintenance Exposure | Annual Record of Winter Maintenance Operations the Asset Has Been Exposed to Since Installation | Text/Number/Link to Database |

| Winter Maintenance Exposure Severity Category | Text | ||

| 12 | Decision Actions | N/A 1 | Text |

| 13 | Descriptions | N/A 1 | Text |

| 14 | Multimedia | N/A 1 | Image/Video |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sassani, A.; Smadi, O.; Hawkins, N. Developing Pavement Marking Management Systems: A Theoretical Model Framework Based on the Experiences of the US Transportation Agencies. Infrastructures 2021, 6, 18. https://doi.org/10.3390/infrastructures6020018

Sassani A, Smadi O, Hawkins N. Developing Pavement Marking Management Systems: A Theoretical Model Framework Based on the Experiences of the US Transportation Agencies. Infrastructures. 2021; 6(2):18. https://doi.org/10.3390/infrastructures6020018

Chicago/Turabian StyleSassani, Alireza, Omar Smadi, and Neal Hawkins. 2021. "Developing Pavement Marking Management Systems: A Theoretical Model Framework Based on the Experiences of the US Transportation Agencies" Infrastructures 6, no. 2: 18. https://doi.org/10.3390/infrastructures6020018

APA StyleSassani, A., Smadi, O., & Hawkins, N. (2021). Developing Pavement Marking Management Systems: A Theoretical Model Framework Based on the Experiences of the US Transportation Agencies. Infrastructures, 6(2), 18. https://doi.org/10.3390/infrastructures6020018