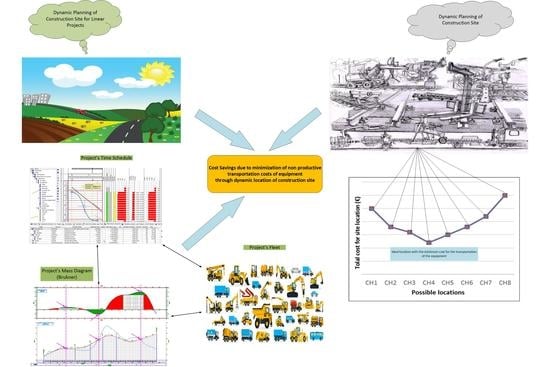

Dynamic Planning of Construction Site for Linear Projects

Abstract

:1. Introduction

2. Literature Review

2.1. Scientometric Analysis

2.2. Literature Review on Dynamic Construction Site Facilities Relocation

3. Dynamic Optimization Module

3.1. Decision Variables for Site Location

- Free locations for site layouts (including regulatory factors such as the use of land, archeology, biodiversity, etc.) [36].

- Electricity, water, and sewage supply systems.

- Ground morphology suitability [31].

- Environmental conditions of the area [33].

- Ground slope. Slopes that are more than 17% are considered unsuitable because of the high grade of resistance in the movement of the equipment that means higher transportation cost and waste of time [32].

3.2. Cost Parameters/Factors

- Transport costs of workers and machinery to the working area. The cost-effectiveness of this variable becomes higher for long linear projects.

- Cost of truck and tank operator due to travel to and forth the construction site (transportation of soil, inert, asphalt, water, refueling of project machinery, etc.).

- Fuel costs of trucks and tanks due to transport to and from the construction site.

- Duration of transportation for work. If the duration of transportation from the construction site to the workplace is long, then the production rate drops [38].

- Slope effectiveness. For steep slopes above 10% but below 17%, a modulation of the ground would be necessary.

- The influence of the morphology and the quality of the ground on the total cost (loose sand, clay, sludge, etc.). In case the ground is not suitable to host heavy facilities, soil reinforcement should be applied.

- Accessibility of construction site by trucks hauling material deliveries, fire trucks, ambulances [39].

- Accessibility from the construction site to the working area. In case there is no access, temporary site roads should be constructed.

- A minimum profit. This is an amount set by the contractor for which he would proceed with a relocation (for the purposes of this study, this marginal profit was taken equal to zero).

- Distance from neighboring infrastructure (negative rating scale) (<100 m, 100 m–1 km, >1 km).

3.3. Presentation of the Optimization Equation/Objective

- i: chainage of the controlled “ideal” location (m);

- x: the chainages of the worksites in which the project is divided (m);

- tp: the time period, for which the quantities are taken into the calculation;

- Transportationx,tp: the total number of necessary transportations from the construction site (i) to the work site (x) for the machinery (trucks, excavator, concrete mixer) to execute a task, within the examined time period. This factor is the result of the quantities (m3) for every task divided with the capacity (m3) of the trucks;

- fuel consumption: the fuel consumption of each machine(lt/km);

- machinery speed: the speed of the machine (km/h);

- fuel cost the cost of the necessary fuel that is used for the function of the machines, to execute the demanded tasks in the examined time period ( €/lt);

- hourly wage: the average wage that the workers are paid per hour of work ( €/h);

- GRcosti: the cost that is necessary in case that ground reinforcement is demanded ( €);

- Sli: the cost that is necessary in case that slope leveling is demanded ( €);

- RCi: the cost for the construction of the road service network ( €);

3.4. Description of the Optimization Algorithm

4. Performance Evaluation of the Model

4.1. General Description of Case Studies

4.2. Analysis and Results of Case Study 1

- 2 excavator (with a bucket capacity of 2.40 m3)

- 2 loaders (with a bucket capacity of 3.50 m3)

- 1 crane truck

- 4 earthmoving trucks

- 4 road trucks

- 2 asphalt trucks

- 2 pavers

- 1 finisher

- 1 water tank

4.3. Analysis and Results of Case Study 2

- 1 excavator (with a bucket capacity of 3.60 m3)

- 4 loaders (with a bucket capacity of 3.50 m3)

- 1 crane truck

- 4 earthmoving trucks

- 10 road trucks

- 6 asphalt trucks

- 3 pavers

- 2 finisher

- 2 water tanks

4.4. Analysis and Results of Case Study 3

- 1 excavator (with a bucket capacity of 2.41 m3)

- 1 loader (with a bucket capacity of 4.30 m3)

- 1 crane truck

- 6 earthmoving trucks

- 4 road trucks

- 4 asphalt trucks

- 1 pavers

- 1 finisher

- 1 water tank

4.5. Analysis and Results of Case Study 4

- 2 excavators (with a bucket capacity of 1.32 m3)

- 2 loaders (with a bucket capacity of 2.45 m3)

- 10 earthmoving trucks

- 8 road trucks

- 5 asphalt trucks

- 8 pavers

- 1 finisher

- 4 water tanks

5. Discussions

6. Concluding Remarks

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Papadaki, I.; Chassiakos, A. Multi-objective construction site layout planning using genetic algorithms. Procedia Eng. 2016, 164, 20–27. [Google Scholar] [CrossRef]

- Elbeltagi, E.; Hosny, A.; Eldosouky, A. Schedule-dependent evolution of site layout planning. Constr. Manag. Econ. 2001, 19, 689–697. [Google Scholar] [CrossRef]

- Ning, X.; Lam, K.C.; Lam, M.C.K. A decision-making system for construction site layout planning. Autom. Constr. 2011, 20, 459–473. [Google Scholar] [CrossRef]

- Heesom, D.; Mahdjoubi, L.; Proverbs, D. A dynamic VR system for visualizing construction space usage. In Construction Research Congress; American Society of Civil Engineers: Reston, VA, USA, 2003. [Google Scholar]

- Chau, K.; Anson, M.; Zhang, J. 4D dynamic construction management and visualization software: 1. Development. Autom. Constr. 2005, 14, 512–524. [Google Scholar] [CrossRef] [Green Version]

- Chavada, R.; Dawood, N.; Kassem, M. Construction Workspace Management: The Development and Application of a Novel nD Planning Approach and Tool. J. Inf. Technol. Constr. 2012, 17, 213–236. [Google Scholar]

- Ma, Z.; Shen, Q.; Zhang, J. Application of 4D for dynamic site layout and management of construction projects. Autom. Constr. 2005, 14, 369–381. [Google Scholar] [CrossRef]

- Li, H.; Love, P.E.D. Genetic search for solving construction site-level unequal-area facility layout problems. Autom. Constr. 2000, 9, 217–226. [Google Scholar] [CrossRef]

- Huang, C.; Wong, C.K. Optimisation of site layout planning for multiple construction stages with safety considerations and requirements. Autom. Constr. 2015, 53, 58–68. [Google Scholar] [CrossRef]

- Chau, K.W. A two-stage dynamic model on allocation of construction facilities with genetic algorithm. Autom. Constr. 2004, 13, 481–490. [Google Scholar] [CrossRef]

- Osman, H.M.; Georgy, M.E.; Ibrahim, M.E. A hybrid CAD-based construction site layout planning system using genetic algorithms. Autom. Constr. 2003, 12, 749–764. [Google Scholar] [CrossRef]

- Alavipour, R.; Arditi, D. Optimizing Financing Cost in Construction Projects with Fixed Project Duration. J. Constr. Eng. Manag. 2018, 144, 04018012. [Google Scholar] [CrossRef]

- Omopariola, E.; Windapo, A.; Edwards, D.; Twala, W. Contractors’ perceptions of the effects of cach flow on construction projects. J. Eng. Des. Technol. 2019. [Google Scholar] [CrossRef]

- Tijssen, R.J.; Van Raan, A.F. Mapping Changes in Science and Technology: Bibliometric Co-Occurrence Analysis of the R&D Literature. Eval. Rev. 1994, 18, 98–115. [Google Scholar] [CrossRef]

- Cobo, M.J.; López-Herrera, A.G.; Herrera-Viedma, E.; Herrera, F. Science mapping software tools: Review, analysis, and cooperative study among tools. J. Am. Soc. Inf. Sci. Technol. 2001, 62, 1382–1402. [Google Scholar] [CrossRef]

- van Eck, N.J.; Waltman, L. Software survey: VOSviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [Green Version]

- van Eck, N.J.; Waltman, L. Text Mining and Visualization Using VOSviewer. 2011. Available online: http://www.vosviewer.com (accessed on 31 March 2020).

- van Eck, N.J.; Waltman, L. Visualizing Bibliometric Networks. Meas. Sch. Impact 2014, 285–320. [Google Scholar] [CrossRef]

- Zouein, P.P.; Tommelein, I.D. Dynamic Layout Planning Using a Hybrid Incremental Solution Method. J. Constr. Eng. Manag. 1998, 125, 400–408. [Google Scholar] [CrossRef] [Green Version]

- Said, H.; El-Rayes, K. Optimizing the planning of construction site security for critical infrastructure projects. Autom. Constr. 2010, 19, 221–234. [Google Scholar] [CrossRef]

- Cheng, M.-Y.; Yang, S.-C. GIS-Based Cost Estimates Integrating with Material Layout Planning. J. Constr. Eng. Manag. 2001, 127. [Google Scholar] [CrossRef]

- Elbeltagi, E.; Hegazy, T.; Eldosouky, A. Dynamic Layout of Construction Temporary Facilities Considering Safety. J. Constr. Eng. Manag. 2004, 130, 534–541. [Google Scholar] [CrossRef]

- Xu, J.; Li, Z. Multi-Objective Dynamic Construction Site Layout Planning in Fuzzy Random Environment. Autom. Constr. 2012, 27, 155–169. [Google Scholar] [CrossRef]

- Andayesh, M.; Sadeghpour, F. Dynamic site layout planning through minimization of total potential energy. Autom. Constr. 2013, 31, 92–102. [Google Scholar] [CrossRef]

- Said, H.; El-Rayes, K. Performance of global optimization models for dynamic site layout planning of construction projects. Autom. Constr. 2013, 36, 71–78. [Google Scholar] [CrossRef]

- Tam, C.; Tong, T.; Leung, A.; Chiu, G. Site layout planning using nonstructural fuzzy decision support system. J. Constr. Eng. Manag. 2002, 128, 220–231. [Google Scholar] [CrossRef] [Green Version]

- Li, H.; Love, P. Site-level facilities layout using genetic algorithms. J. Comput. Civ. Eng. 1998, 12, 227–231. [Google Scholar] [CrossRef]

- Yeh, I.-C. Construction-site layout using annealed neural network. J. Comput. Civ. Eng. 1995, 9, 201–208. [Google Scholar] [CrossRef]

- Cheng, J.C.P.; Kumar, S.S. A BIM based construction site layout planning framework considering actual travel paths. In Proceedings of the 31st International Symposium on Automation and Robotics in Construction and Mining, ISARC 2014, Sydney, Australia, 9–11 July 2014; pp. 450–457. [Google Scholar] [CrossRef] [Green Version]

- Al Hawarneh, A.; Bendak, S.; Ghanim, F. Dynamic facilities planning model for large scale construction projects. Autom. Constr. 2019, 98, 72–89. [Google Scholar] [CrossRef]

- Zolfagharian, S.; Irizarry, J. Current Trends in Construction Site Layout Planning. In Proceedings of the Construction Research Congress, Atlanta, GA, USA, 19–21 May 2014; pp. 1723–1732. [Google Scholar]

- Greek Government. Building Regulation of Greece; Article 21; Greek Parliament: Athens, Greece, 1989. [Google Scholar]

- Lagro, J. Site Analysis: A Contextual Approach to Sustainable Land Planning and Site Design, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2007. [Google Scholar]

- Peurifoy, R.; Schexnayder, C.; Shapira, A.; Schimitt, R. Contruction Planning, Equipment, and Methods, 8th ed.; McGraw Hill International Edition: New York, NY, USA, 2001. [Google Scholar]

- Petroutsatou, K.; Marinelli, M. Construction Equipment, Operational Analysis and Economics of Civil Engineering Projects, 2nd ed.; KRITIKI SA: Athens, Greece, 2018. [Google Scholar]

- Razavialavi, S.; Abourizk, S.; Alanjari, P. Estimating the Size of Temporary Facilities in Construction Site Layout Planning Using Simulation. In Proceedings of the Construction Research Congress, Atlanta, GA, USA, 19–21 May 2014; pp. 70–79. [Google Scholar]

- Lee, K.H.A. Optimization of Construction Site Layout Planning by Generic Algorithm. Doctoral Dissertation, City University of Hong Kong, Hong Kong, August 2013. [Google Scholar]

- Sanad, H.; Ammar, M.; Ibrahim, M. Optimal Construction Site Layout Considering Safety and Environmental Aspects. J. Constr. Eng. Manag. 2008, 134, 536–544. [Google Scholar] [CrossRef]

- Marinelli, M.; Lambropoulos, S.; Petroutsatou, K. Earthmoving trucks condition level prediction using neural networks. J. Qual. Maint. Eng. 2014, 20, 182–192. [Google Scholar] [CrossRef]

| Cluster 1 | Cluster 2 | Cluster 3 |

|---|---|---|

| Construction Site Layout | Construction project | Construction |

| Algorithm | Dynamic site layout planning | BIM |

| Genetic Algorithm | Effectiveness | Cost |

| Location | Model | |

| Safety | Time | |

| Space | ||

| Temporary Facility |

| Quantities (m3) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Chainage | Embankment | Excavations | Drain Age | Plant Land | Sub Base | Base | Asphalt | Concrete | Rebars | Drain Pipes (kgr) |

| 18 + 450 | 1847.4 | 20,561.54 | 308.22 | 2409.6 | 120 | 230 | 10,230 | 44 | 0 | 504,000 |

| Number of Transportation Trucks | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Chainage | Earthmoving Trucks | Drain Age | Subbase | Base | Asphalt | Concrete | Rebars | Drainpipes | Tanks |

| 18 + 450 | 480 | 46 | 18 | 34 | 620 | 30 | 0 | 48 | 76 |

| Scenario X | Location | Cost |

|---|---|---|

| 1st + 2nd + … + N | A | A € |

| (Ν + 1) + … + Last | B | B € |

| Relocation cost | R € | |

| Total scenario cost | (A + B+R+ user’s target) = Χ € | |

| Profit | (TC(i) − X) = Υ € |

| Scenarios | Period | Ideal Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|

| Base Scenario without Relocation | 1st to 6th | 1 + 550 | 142,044.10 € | 142,044.10 € | 37,536.73 € | |

| Ideal = 2 + 650 | 104,507.36 € | 104,507.36 € | ||||

| 3 + 550 | 122,580.05 € | 122,580.05 € | 18,072.68 € | |||

| 1 | 1st to 3rd | Ideal = 3 + 050 | 39,127.72 € | 24,500.00 € | 147,232.24 € | 42,724.87 € |

| 4th to 6th | Ideal = 2 + 050 | 83,604.51 € | ||||

| 2 | 1st to 4th | Ideal = 3 + 050 | 95,602.17 € | 24,500.00 € | 168,100.25 € | 63,592.88 € |

| 5th to 6th | Ideal = 2 + 050 | 47,998.08 € | ||||

| 3 | 1st to 2nd | Ideal = 4 + 250 | 4555.69 € | 49,000.00 € | 158,327.29 € | 53,819.92 € |

| 3rd to 4th | Ideal = 2 + 950 | 56,773.51 € | ||||

| 5th to 6th | Ideal = 2 + 050 | 47,998.08 € |

| Scenarios | Period | Ideal Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|

| Base scenario without relocation | 1st to 6th | 11 + 650 | 1.469,784.12 € | 1,469,784.12 € | 340,308.53 € | |

| 11 + 850 | 1,436,149.95 € | 1,436,149.95 € | 306,674.36 € | |||

| 14 + 050 | 1,166,642.71 € | 1,166,642.71 € | 37,167.12 € | |||

| Ideal = 14 + 850 | 1,129,475.59 € | 1,129,475.59 € | ||||

| 19 + 450 | 1,363,944.17 € | 1,363,944.17 € | 234,468.58 € | |||

| 1 | 1st to 4th | Ideal = 14 + 650 | 835,489.50 € | 33,500.00 € | 1,031,715.90 € | 97,759.69 € |

| 5th to 6th | Ideal = 19 + 450 | 162,726.40 € | ||||

| 2 | 1st to 3rd | Ideal = 14 + 050 | 538,520.79 € | 33,500.00 € | 1,077,709.39 € | 51,766.20 € |

| 4th to 6th | Ideal = 19 + 450 | 505,688.60 € | ||||

| 3 | 1st to 2nd | Ideal = 14 + 850 | 227,522.67 € | 67,000.00 € | 1,089,889.16 € | 39,586.43 € |

| 3rd | Ideal = 11850 | 289,677.88 € | ||||

| 4th to 6th | Ideal = 19450 | 505,688.60 € | ||||

| 4 | 1st | Ideal = 14850 | 103,764.33 € | 67,000.00 € | 1,060,204.67 € | 69,270.93 € |

| 2nd to 4th | Ideal = 14250 | 726,713.93 € | ||||

| 5th to 6th | Ideal =1 9450 | 162,726.40 € | ||||

| 5 | 1st to 2nd | Ideal = 14850 | 227,522.67 € | 67,000.00 € | 1,057,209.26 € | 72,266.33 € |

| 3rd to 4th | Ideal = 14050 | 599,960.19 € | ||||

| 5th to 6th | Ideal = 19450 | 162,726.40 € |

| Scenario | Relocation | Chainage | Ideal Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 8550–15,550 | Ideal = 11,850 | 258,293.48 € | 33,500.00 € | 596,593.71 € | 532,881.89 € |

| 15,650–23,350 | Ideal = 19,450 | 304,800.23 € | |||||

| 2 | 2 | 8550–15,550 (Earthworks and technical works) | Ideal = 11,850 | 157,274.60 € | 67,000.00 € | 864,536.16 € | 264,939.43 € |

| 15,650–23,350 (Earthworks and technical works) | Ideal = 19,450 | 177,154.92 € | |||||

| 8550–23,550 (Asphalt paving) | Ideal = 14,850 | 463,106.64 € |

| Scenarios | Period | Ideal Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|

| Base scenario (without relocation) | 1st to 8th | 2250 | 5,763,803.74 € | € | 5,763,803.74 € | 2,899,958.93 € |

| 11,850 | 4,619,248.26 € | € | 4,619,248.26 € | 1,755,403.45 € | ||

| Ideal = 14,050 | 2,857,596.34 € | € | 2,857,596.34 € | € | ||

| 19,450 | 4,191,612.89 € | € | 4,191,612.89 € | 1,334,016.54 € | ||

| 1 | 1st to 4th | Ideal = 14,350 | 1,706,998.63 € | 35,000.00 € | 2,769,518.63 € | 94,326.17 € |

| 5th to 8th | Ideal = 11,350 | 1,027,520 € | ||||

| 2 | 1st to 5th | Ideal = 14,350 | 2,203,460.65 € | 35,000.00 € | 2,741,003.30 € | 122,841.51 € |

| 3 | 6th to 8th | Ideal = 11,350 | 502,542.65 € | 35,000.00 € | 2,776,349.12 € | 85,234.69 € |

| 1st to 5th | Ideal = 14,350 | 2,203,460.65 € | ||||

| 6th to 7th | Ideal = 11,350 | 408.105,39 € | ||||

| 8th | Ideal = 9250 | 94.783,08 € |

| Scenarios | Relocation | Chainage | Ideal Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|---|

| 1 | 1 | 00 + 000–12 + 250 | Ideal = 4 + 650 | 753,963.36 € | 35,000.00 € | 1,526,975 € | 1,336,869.8 € |

| 12 + 350–24 + 450 | Ideal = 16 + 350 | 738,011.55 € | |||||

| 2 | 1 | 00 + 000–24 + 450(Earthworks and technical works) | Ideal = 14 + 350 | 2,230,291 € | 35,000.00 € | 2,860,788 € | 3057.16 € |

| 00 + 000–24 + 450 (Asphalt paving) | Ideal = 11 + 350 | 595,496.63 € | |||||

| 3 | 2 | 00 + 000–11 + 250 (Earthworks and technical works) | Ideal = 4 + 650 | 525,132.36 € | 70,000.00 € | 1,815,405 € | 1,048,440 € |

| 11 + 350–24 + 450 (Earthworks and technical works) | Ideal = 16 + 350 | 624,775.49 € | |||||

| 00 + 000–24 + 450 (Asphalt paving) | Ideal = 11 + 350 | 595,496.63 € |

| Scenarios | Period | Ideal Location | Operating Cost | Relocation | Total Cost | Profit/Loss |

|---|---|---|---|---|---|---|

| base scenario without relocation | 1st to 5th | Ideal = 29 + 100 | 1,730,958.54 € | € | 1,730,958.54 € | |

| 1 | 1st | Ideal = 31 + 600 | 514,192.94 € | 20,500 € | 1,714,344.73 € | 16,613.80 € |

| 2nd to 5th | Ideal = 27 + 500 | 1,179,651.79 € | ||||

| 2 | 1st to 2nd | Ideal = 32 + 200 | 1,160,901.17 € | 20,500 € | 1,544,556.05 € | 186,402.49 € |

| 3rd to 5th | Ideal = 24 + 900 | 363,154.88 € | ||||

| 3 | 1st to 3rd | Ideal = 30 + 200 | 1,576,311.55 € | 20,500 € | 1,645,045.46 € | 85,913.08 € |

| 4th to 5th | Ideal = 22 + 600 | 48,233.92 € |

| Chainage | Site Location | Operating Cost | Relocation Cost | Total Cost | Profit/Loss |

|---|---|---|---|---|---|

| 17 + 700–33 + 100 | 25 + 300 | 603,613.73 € | 20,500.00 € | 1,673,897.37 € | 57,061.17 € |

| 33 + 200–48 + 500 | 44 + 500 | 1,049,783.64 € |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petroutsatou, K.; Apostolidis, N.; Zarkada, A.; Ntokou, A. Dynamic Planning of Construction Site for Linear Projects. Infrastructures 2021, 6, 21. https://doi.org/10.3390/infrastructures6020021

Petroutsatou K, Apostolidis N, Zarkada A, Ntokou A. Dynamic Planning of Construction Site for Linear Projects. Infrastructures. 2021; 6(2):21. https://doi.org/10.3390/infrastructures6020021

Chicago/Turabian StylePetroutsatou, Kleopatra, Nikolaos Apostolidis, Athanasia Zarkada, and Aneta Ntokou. 2021. "Dynamic Planning of Construction Site for Linear Projects" Infrastructures 6, no. 2: 21. https://doi.org/10.3390/infrastructures6020021

APA StylePetroutsatou, K., Apostolidis, N., Zarkada, A., & Ntokou, A. (2021). Dynamic Planning of Construction Site for Linear Projects. Infrastructures, 6(2), 21. https://doi.org/10.3390/infrastructures6020021