Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes

Abstract

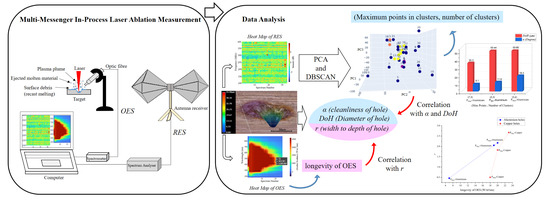

:1. Introduction

2. Materials and Methods

2.1. Experimental Set-Up

2.2. In-Process Spectroscopy System

2.3. Heat Map and PCA Method

2.4. Post-Process Microscopy

2.5. Materials

3. Results and Discussion

3.1. Physical Phenomena of Plasma Plumes

3.2. Correlation/Relationships of RES with Quality and Morphology Characteristics of Ablated Surfaces

3.3. Relation of OES with Morphological Characteristics of the Ablated Surface

4. Conclusions

- Finished Surface Quality: Correlation of ablated surface cleanliness and symmetry of ablated holes with RES data;

- Variation in Ablated Hole Uniformities Changes of the height/depth of hole, and the Diameter of Hole (DoH) using a combination of OES and RES data.

5. Patents

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix B

References

- Purtonen, T.; Kalliosaari, A.; Salminen, A. Monitoring and adaptive control of laser processes. Phys. Procedia 2014, 56, 1218–1231. [Google Scholar] [CrossRef]

- Grasso, M.; Colosimo, B.M. Process defects and in situ monitoring methods in metal powder bed fusion: A review. Meas. Sci. Technol. 2017, 28, 044005. [Google Scholar] [CrossRef]

- Spears, T.G.; Gold, S.A. In-process sensing in selective laser melting (SLM) additive manufacturing. Integr. Mater. Manuf. Innov. 2016, 5, 16–40. [Google Scholar] [CrossRef]

- Everton, S.K.; Hirsch, M.; Stravroulakis, P.; Leach, R.K.; Clare, A.T. Review of in-situ process monitoring and in-situ metrology for metal additive manufacturing. Mater. Des. 2016, 95, 431–445. [Google Scholar] [CrossRef]

- Sharratt, B.M. Non-Destructive Techniques and Technologies for Qualification of Additive Manufactured Parts and Processes; Sharratt Research and Consulting Inc.: Victoria, BC, Canada, 2015. [Google Scholar]

- Bayle, F.; Doubenskaia, M. Selective laser melting process monitoring with high speed infra-red camera and pyrometer. In Fundamentals of Laser Assisted Micro-and Nanotechnologies; International Society for Optics and Photonics: Bellingham, WC, USA, 2008; Volume 6985, p. 698505. [Google Scholar] [CrossRef]

- Dowding, C. Laser ablation. In Advances in Laser Materials Processing; Elsevier: Amsterdam, The Netherlands, 2010; pp. 575–628. [Google Scholar] [CrossRef]

- Lough, C.S.; Escano, L.I.; Qu, M.; Smith, C.C.; Landers, R.G.; Bristow, D.A.; Chen, L.; Kinzel, E.C. In-situ optical emission spectroscopy of selective laser melting. J. Manuf. Process. 2020, 53, 336–341. [Google Scholar] [CrossRef]

- Kelly, S.; McNally, P.J. Remote sensing of a low pressure plasma in the radio near field. Appl. Phys. Express 2017, 10, 096101. [Google Scholar] [CrossRef]

- Ekoi, E.J.; Degli-Alessandrini, G.; Zeeshan Mughal, M.; Vijayaraghavan, R.K.; Obeidi, M.A.; Groarke, R.; Kraev, I.; Krishnamurthy, S.; Brabazon, D. Investigation of the microstructure and phase evolution across multi-material Ni50.83Ti49.17-AISI 316L alloy interface fabricated using laser powder bed fusion (L-PBF). Mater. Des. 2022, 221, 110947. [Google Scholar] [CrossRef]

- McCann, R.; Hughes, C.; Brabazon, D. Laser Powder Bed Fusion of Aluminium Alloy 6061 for Ultra-High Vacuum Applications. Key Eng. Mater. 2022, 926, 242–249. [Google Scholar] [CrossRef]

- Marimuthu, S.; Dunleavey, J.; Liu, Y.; Smith, B.; Kiely, A.; Antar, M. Characteristics of hole formation during laser drilling of SiC reinforced aluminium metal matrix composites. J. Mater. Process. Technol. 2019, 271, 554–567. [Google Scholar] [CrossRef]

- Ancona, A.; Röser, F.; Rademaker, K.; Limpert, J.; Nolte, S.; Tünnermann, A. High speed laser drilling of metals using a high repetition rate, high average power ultrafast fiber CPA system. Opt. Express 2008, 16, 8958–8968. [Google Scholar] [CrossRef] [PubMed]

- Grupp, M.; Reinermann, N. Copper Welding with High-Brightness Fiber Lasers. Laser Tech. J. 2017, 14, 25–29. [Google Scholar] [CrossRef]

- Vivó-Truyols, G.; Schoenmakers, P.J. Automatic Selection of Optimal Savitzky−Golay Smoothing. Anal. Chem. 2006, 78, 4598–4608. [Google Scholar] [CrossRef] [PubMed]

- Wilkinson, L.; Friendly, M. The history of the cluster heat map. Am. Stat. 2009, 63, 179–184. [Google Scholar] [CrossRef]

- Kellom, M.; Raymond, J. Using dendritic heat maps to simultaneously display genotype divergence with phenotype divergence. PLoS ONE 2016, 11, e0161292. [Google Scholar] [CrossRef] [PubMed]

- Abdi, H.; Williams, L.-J. Principal component Analysis. Wiley Interdiscip. Rev. Comput. Stat. 2010, 2, 433–459. Available online: https://www.google.com/search?q=Abdi+H%2C+Williams+L-J.+2010.+Principal+component+Analysis.Wiley+Interdisciplinary+Reviews%3A+Computational+statistics%2CVol.+2&rlz=1C1GCEB_enIE876IE876&sourceid=chrome&ie=UTF-8 (accessed on 13 April 2022). [CrossRef]

- Green, P.E. Analzing Multivariate Data; Hinsdale Ill; The Dryden Press: New York, NY, USA, 1978. [Google Scholar]

- Brereton, R.G. Chemometrics: Data Analysis for the Laboratory and Chemical Plant; John Wiley & Sons: Hoboken, NJ, USA, 2003. [Google Scholar]

- Massart, D.; Vandeginste, B.M.; Deming, S.N.; Michotte, Y.; Kaufman, L. Chemometrics: A Textbook; Vol. 2 in: Data Handling in Science and Technology; Elsevier, Vrije Universiteit Brussel: Brussels, Belgium, 1988; ISBN 0-444-42660-4. [Google Scholar]

- Dendy, R.O. Plasma Physics: An Introductory Course; Cambridge University Press: Cambridge, UK, 1995. [Google Scholar]

- Bittencourt, J.A. Fundamentals of Plasma Physics; Springer Science & Business Media: New York, NY, USA, 2004. [Google Scholar]

- Rafique, M.S.; Khaleeq-Ur-Rahman, M.; Anwar, M.S.; Ashfaq, F.M.A.; Siraj, K. Angular distribution and forward peaking of laser produced plasma ions. Laser Part. Beams 2005, 23, 131–135. [Google Scholar] [CrossRef]

- Franghiadakis, Y.; Fotakis, C.; Tzanetakis, P. Energy distribution of ions produced by excimer-laser ablation of solid and molten targets. Appl. Phys. A 1999, 68, 391–397. [Google Scholar] [CrossRef]

- Krása, J.; Láska, L.; Rohlena, K.; Pfeifer, M.; Skála, J.; Králiková, B.; Straka, P.; Woryna, E.; Wolowski, J. The effect of laser-produced plasma expansion on the ion population. Appl. Phys. Lett. 1999, 75, 2539–2541. [Google Scholar] [CrossRef]

- Fukushima, K.; Kanke, Y.; Badaye, M.; Morishita, T. Velocity distributions of ions in the ablation plume of a Y1Ba2Cu3Ox target. J. Appl. Phys. 1995, 77, 5406–5410. [Google Scholar] [CrossRef]

- Ester, M.; Kriegel, H.-P.; Sander, J.; Xu, X. A density-based algorithm for discovering clusters in large spatial databases with noise. In Proceedings of the Second International Conference on Knowledge Discovery and Data Mining (KDD-96), Portland, OR, USA, 2–4 August 1996; Volume 96, pp. 226–231. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Samimi, M.; Hosseinlaghab, H.; McCarthy, É.; McNally, P.J. Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes. J. Manuf. Mater. Process. 2022, 6, 106. https://doi.org/10.3390/jmmp6050106

Samimi M, Hosseinlaghab H, McCarthy É, McNally PJ. Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes. Journal of Manufacturing and Materials Processing. 2022; 6(5):106. https://doi.org/10.3390/jmmp6050106

Chicago/Turabian StyleSamimi, Mahdieh, Hassan Hosseinlaghab, Éanna McCarthy, and Patrick J. McNally. 2022. "Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes" Journal of Manufacturing and Materials Processing 6, no. 5: 106. https://doi.org/10.3390/jmmp6050106

APA StyleSamimi, M., Hosseinlaghab, H., McCarthy, É., & McNally, P. J. (2022). Multi-Messenger Radio Frequency and Optical Diagnostics of Pulsed Laser Ablation Processes. Journal of Manufacturing and Materials Processing, 6(5), 106. https://doi.org/10.3390/jmmp6050106