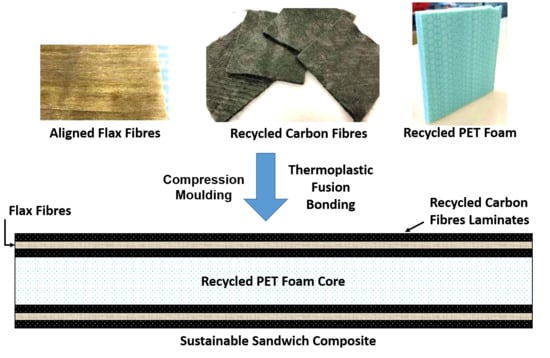

Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Panel Design

2.2. Manufacturing of the Sandwich Panel

2.3. Mechanical Characterization

3. Results and Discussion

3.1. SEM Characterization of Bonding Region

3.2. Three-Point Bending Test Results

3.3. Failure of the Samples

3.4. Recyclable Sandwich Composites for Truck Side Panels: A Case Study

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mishnaevsky, L.; Branner, K.; Petersen, H.N.; Beauson, J.; McGugan, M.; Sørensen, B.F. Materials for wind turbine blades: An overview. Materials 2017, 10, 1285. [Google Scholar] [CrossRef] [Green Version]

- Lakreb, N.; Bezzazi, B.; Pereira, H. Mechanical strength properties of innovative sandwich panels with expanded cork agglomerates. Eur. J. Wood Wood Prod. 2015, 73, 465–473. [Google Scholar] [CrossRef]

- Poullikkas, A. Sustainable options for electric vehicle technologies. Renew. Sustain. Energy Rev. 2015, 41, 1277–1287. [Google Scholar] [CrossRef]

- Mayyas, A.; Omar, M.; Hayajneh, M.; Mayyas, A.R. Vehicle’s lightweight design vs. electrification from life cycle assessment perspective. J. Clean. Prod. 2018, 167, 687–701. [Google Scholar] [CrossRef]

- Yaman, M.; Önal, T. Investigation of dynamic properties of natural material-based sandwich composites: Experimental test and numerical simulation. J. Sandw. Struct. Mater. 2016, 18, 397–414. [Google Scholar] [CrossRef]

- Sargianis, J.J.; Kim, H.I.; Andres, E.; Suhr, J. Sound and vibration damping characteristics in natural material based sandwich composites. Compos. Struct. 2013, 96, 538–544. [Google Scholar] [CrossRef]

- Kandare, E.; Luangtriratana, P.; Kandola, B.K. Fire reaction properties of flax/epoxy laminates and their balsa-core sandwich composites with or without fire protection. Compos. Part B Eng. 2014, 56, 602–610. [Google Scholar] [CrossRef] [Green Version]

- Monti, A.; Mahi, A.E.L.; Jendli, Z.; Guillaumat, L. Quasi-static and fatigue properties of a balsa cored sandwich structure with thermoplastic skins reinforced by flax fibres. J. Sandw. Struct. Mater. 2019, 21, 2358–2381. [Google Scholar] [CrossRef] [Green Version]

- Bach, M.R.; Chalivendra, V.B.; Alves, C.; Depina, E. Mechanical characterization of natural biodegradable sandwich materials. J. Sandw. Struct. Mater. 2017, 19, 482–496. [Google Scholar] [CrossRef]

- Osman, S.; Ahmad, M. Flexural and impact properties of bamboo-aluminum sandwich composites. Adv. Mater. Res. 2013, 608–609, 1728–1731. [Google Scholar] [CrossRef]

- Kabir, M.M.; Wang, H.; Cardona, F.; Aravinthan, T. Effect of chemical treatment on the mechanical and thermal properties of hemp fibre reinforced thermoset sandwich composites. In Incorporating Sustainable Practice in Mechanics of Structures and Materials, Proceedings of the 21st Australian Conference on the Mechanics of Structures and Materials, Melbourne, Australia, 7–10 December 2010; University of Southern Queensland: Toowoomba, Australia, 2011. [Google Scholar]

- Dweib, M.A.; Hu, B.; O’Donnell, A.; Shenton, H.W.; Wool, R.P. All natural composite sandwich beams for structural applications. Compos. Struct. 2004, 63, 147–157. [Google Scholar] [CrossRef]

- Azmi, M.A.; Abdullah, H.Z.; Idris, M.I. Properties of polyurethane foam/coconut coir fiber as a core material and as a sandwich composites component. IOP Conf. Ser. Mater. Sci. Eng. 2013, 50. [Google Scholar] [CrossRef] [Green Version]

- Hoto, R.; Furundarena, G.; Torres, J.P.; Muñoz, E.; Andrés, J.; García, J.A. Flexural behavior and water absorption of asymmetrical sandwich composites from natural fibers and cork agglomerate core. Mater. Lett. 2014, 127, 48–52. [Google Scholar] [CrossRef]

- Oliveira, P.R.; Bonaccorsi, A.M.S.; Panzera, T.H.; Christoforo, A.L.; Scarpa, F. Sustainable sandwich composite structures made from aluminium sheets and disposed bottle caps. Thin-Walled Struct. 2017, 120, 38–45. [Google Scholar] [CrossRef] [Green Version]

- Balcıoğlu, H.E. Flexural Behaviors of Sandwich Composites Produced Using Recycled and Natural Material. Mugla J. Sci. Technol. 2018, 64–73. [Google Scholar] [CrossRef]

- Petrone, G.; Rao, S.; de Rosa, S.; Mace, B.R.; Franco, F.; Bhattacharyya, D. Behaviour of fibre-reinforced honeycomb core under low velocity impact loading. Compos. Struct. 2013, 100, 356–362. [Google Scholar] [CrossRef] [Green Version]

- Petrone, G.; Rao, S.; de Rosa, S.; Mace, B.R.; Franco, F.; Bhattacharyya, D. Initial experimental investigations on natural fibre reinforced honeycomb core panels. Compos. Part B Eng. 2013, 55, 400–406. [Google Scholar] [CrossRef] [Green Version]

- Petrone, G.; D’Alessandro, V.; Franco, F.; Mace, B.; de Rosa, S. Modal characterisation of recyclable foam sandwich panels. Compos. Struct. 2014, 113, 362–368. [Google Scholar] [CrossRef]

- Maia, B.S.; Tjong, J.; Sain, M. Material characterization of recycled and virgin carbon fibers for transportation composites lightweighting. Mater. Today Sustain. 2019, 5, 100011. [Google Scholar] [CrossRef]

- van de Werken, N.; Reese, M.S.; Taha, M.R.; Tehrani, M. Investigating the effects of fiber surface treatment and alignment on mechanical properties of recycled carbon fiber composites. Compos. Part A Appl. Sci. Manuf. 2019, 119, 38–47. [Google Scholar] [CrossRef]

- Rahimizadeh, A.; Kalman, J.; Fayazbakhsh, K.; Lessard, L. Recycling of fiberglass wind turbine blades into reinforced filaments for use in Additive Manufacturing. Compos. Part B Eng. 2019, 175, 107101. [Google Scholar] [CrossRef]

- Cousins, D.S.; Suzuki, Y.; Murray, R.E.; Samaniuk, J.R.; Stebner, A.P. Recycling glass fiber thermoplastic composites from wind turbine blades. J. Clean. Prod. 2019, 209, 1252–1263. [Google Scholar] [CrossRef]

- Yamamoto, T.; Yabushita, S.; Irisawa, T.; Tanabe, Y. Enhancement of bending strength, thermal stability and recyclability of carbon-fiber-reinforced thermoplastics by using silica colloids. Compos. Sci. Technol. 2019, 181, 107665. [Google Scholar] [CrossRef]

- Shamsuyeva, M.; Hansen, O.; Endres, H.J.; Abu-Jdayil, B. Review on Hybrid Carbon/Flax Composites and Their Properties. Int. J. Polym. Sci. 2019, 2019, 9624670. [Google Scholar] [CrossRef] [Green Version]

- Armacell Launches Recycled Foam Core. Available online: https://www.materialstoday.com/composite-processing/products/armacell-launches-recycled-foam-core-/ (accessed on 21 December 2020).

- Longana, M.L.; Ondra, V.; Yu, H.; Potter, K.D.; Hamerton, I. Reclaimed carbon and flax fibre composites: Manufacturing and mechanical properties. Recycling 2018, 3, 52. [Google Scholar] [CrossRef] [Green Version]

- ASTM International. ASTM D7249/D 7249M—06 Standard Test Method for Facing Properties of Sandwich Constructions by Long Beam Flexure. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM International. ASTM D 7250/D 7250M Standard Practice for Determining Sandwich Beam Flexural and Shear Stiffness. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- ASTM International. ASTM C393/C 393 M—06 Standard Test Method for Core Shear Properties of Sandwich Constructions by Beam. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2009. [Google Scholar]

- Pronk, A.C. Calibration of 4pb tests taking into account shear forces and other equipment factors. Road Mater. Pavement Des. 2009, 10, 373–386. [Google Scholar] [CrossRef]

- Pronk, A.C. Theory of the Four Point Dynamic Bending Test; Ministry of Transport, Public Works and Water Management: The Netherlands, 1996.

- Imielińska, K.; Guillaumat, L.; Wojtyra, R.; Castaings, M. Effects of manufacturing and face/core bonding on impact damage in glass/polyester-PVC foam core sandwich panels. Compos. Part B Eng. 2008, 39, 1034–1041. [Google Scholar] [CrossRef]

- Kim, C.G.; Hong, C.S. Buckling of unbalanced anisotropic sandwich plates with finite bonding stiffness. AIAA J. 1988, 26, 982–988. [Google Scholar] [CrossRef]

- Singh, J.I.P.; Singh, S.; Dhawan, V. Effect of Curing Temperature on Mechanical Properties of Natural Fiber Reinforced Polymer Composites. J. Nat. Fibers 2018, 15, 687–696. [Google Scholar] [CrossRef]

- Bourmaud, A.; Baley, C. Effects of thermo mechanical processing on the mechanical properties of biocomposite flax fibers evaluated by nanoindentation. Polym. Degrad. Stab. 2010, 95, 1488–1494. [Google Scholar] [CrossRef]

- Corvaglia, P.; Passaro, A.; Manni, O.; Barone, L.; Maffezzoli, A. Recycling of PP-based sandwich panels with continuous fiber composite skins. J. Thermoplast. Compos. Mater. 2006, 19, 731–745. [Google Scholar] [CrossRef]

- Poulakis, J.G.; Varelidis, P.C.; Papaspyrides, C.D. Recycling of Polypropylene-Based Composites. Wiley 1997, 16, 313–322. [Google Scholar] [CrossRef]

| Type of Material | E1 (GPa) | E2 (GPa) | G12 (GPa) | G13 (GPa) | G23 (GPa) | μ12 | Density (kg/m3) |

|---|---|---|---|---|---|---|---|

| RCF skin | 14.96 | 1.49 | 0.52 | 5.72 | 0.50 | 0.4 | 1034 |

| Hybrid skin | 21.84 | 1.70 | 0.6 | 8.07 | 0.61 | 0.41 | 1085 |

| PET foam | 2.5 | 2.5 | 0.018 | 0.018 | 0.018 | 0.43 | 1380 |

| Sample Properties | Density (kg/m3) | Flexural Strength (MPa) | Flexural Rigidity * (Nm2) | Predicted Flexural Rigidity (Nm2) | Sandwich Bending Modulus (GPa) |

|---|---|---|---|---|---|

| Sample 1 (RCF) | 562 | 76.7 (±2.7) | 73.2 (±3.1) | 66.4 | 2.21 (±0.11) |

| Sample 2 (mix) | 551 | 41.9 (±2.1) | 96.2 (±4.8) | 119 | 1.15 (±0.06) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, Q.; Chen, G.; Kumar, A.; Mills, A.; Jani, K.; Rajamohan, V.; Venugopal, B.; Rahatekar, S. Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core. J. Compos. Sci. 2021, 5, 2. https://doi.org/10.3390/jcs5010002

Jiang Q, Chen G, Kumar A, Mills A, Jani K, Rajamohan V, Venugopal B, Rahatekar S. Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core. Journal of Composites Science. 2021; 5(1):2. https://doi.org/10.3390/jcs5010002

Chicago/Turabian StyleJiang, Qihong, Guiyong Chen, Abhideep Kumar, Andrew Mills, Krutarth Jani, Vasudevan Rajamohan, Barathan Venugopal, and Sameer Rahatekar. 2021. "Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core" Journal of Composites Science 5, no. 1: 2. https://doi.org/10.3390/jcs5010002

APA StyleJiang, Q., Chen, G., Kumar, A., Mills, A., Jani, K., Rajamohan, V., Venugopal, B., & Rahatekar, S. (2021). Sustainable Sandwich Composites Manufactured from Recycled Carbon Fibers, Flax Fibers/PP Skins, and Recycled PET Core. Journal of Composites Science, 5(1), 2. https://doi.org/10.3390/jcs5010002